Custom Octagon Window Frames: 5/8″ MDF

Although these are custom octagon window frames being fabricated at CNCROi.com for a customer, they could be any size and/or shape you want.

For this set of custom octagon window frames, we used 5/8″ MDF (medium density fiberboard) because it’s easy for the customer to nail to their current set-up and paints wonderfully after a quick sanding and wood filler (to cover the nail holes).

Before starting on this project, I wanted to clean-up my CNC spoilboard that’s seen a lot of paint, glue and other fun things that happen when you have a huge 5 ft x 10 ft table in the middle of the shop.

You can see how “messy” the spoilboard is in the top photo and how wonderfully it cleans with just one pass in the image below… that’s why I enjoy using my CNC router for finishing projects, no matter what I do on it, it always cleans-up great!

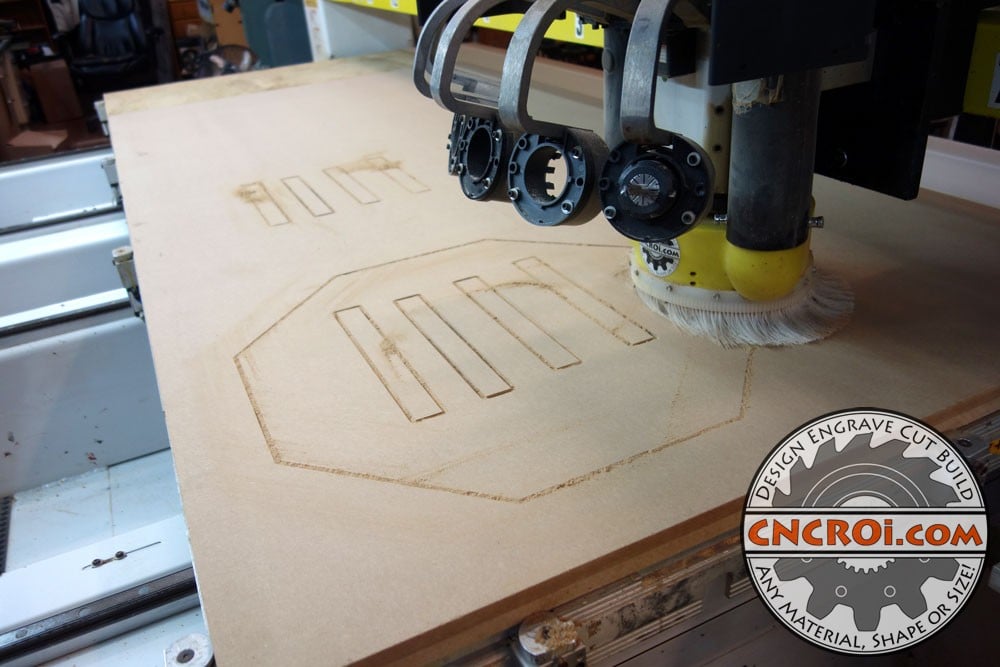

After the Thermwood CNC router is finished removing 0.01″ from the surface of the spoilboard, it’s time to begin manufacturing the two custom octagon window frames.

Of course, if you wanted something a lot more ornmental, CNCROi.com can make it using our laser using details that just aren’t possible using a router.

For this project, I’m actually using two bits, the first is the inner octagon being cut out using a 1/4″ downcut bit, this makes sure I have a clean surface and as tight a “bend” in the inner corner as possible.

The router can’t cut square inner coners, unlike our laser, so a smaller bit will give the illussion of this but first, I cut-out a few rectangles that will be used to ship this out as, the less something weighs, the less it costs to shop, but at the same time, I want something solid to send out so it doesn’t get broken.

I had a few thoughts to accomplish all these goals, at first, it was these sticks but that didn’t work well, so I just used one inner octagon along with bubblewrap, that worked wonderfully to protect these custom octagon window frames.

I’ve also made large window coverings at CNCROi.com, these were two I made for fun as a proof of concept at the shop.

You’ll notice there are no screws used to hold down the sheet of 4 ft x 8 ft MDF, that’s because the vacuum system is sucking it down flat onto the newly cleaned spoilboard.

But you have to keep in mind, as I remove material from the sheet, I am cutting all the way through, I will lose a bit of vacuum as there is no longer a solid seal where the router has done it’s carving, but this is minimal relative to the entire surface area shown, so nothing moved a inch.

When cutting out these custom octagon window frames, it’s important that nothing moves, because if it does, immediately these frames will be out of spec, and would need to be re-cut at CNCROi.com.

Having a dead-flat spoilboard that’s clean also helps to make sure the vacuum seal is good and the router is cutting everything at exactly 90 degrees, thus, there are no kerf angles involved for these custom octagon window frames, though they could be added if the aesthetics required.

You’ll notice all the inside parts are now cut, it’s time to switch to a larger diameter bit in order to more quickly cut the rest of this out.

CNCROi.com can also make polycarbonate and windows as well for various uses, from industrial to agricultural.

A larger diameter bit can go faster as it’s more rigid, it’s still a downcut, and spins just a little bit faster.

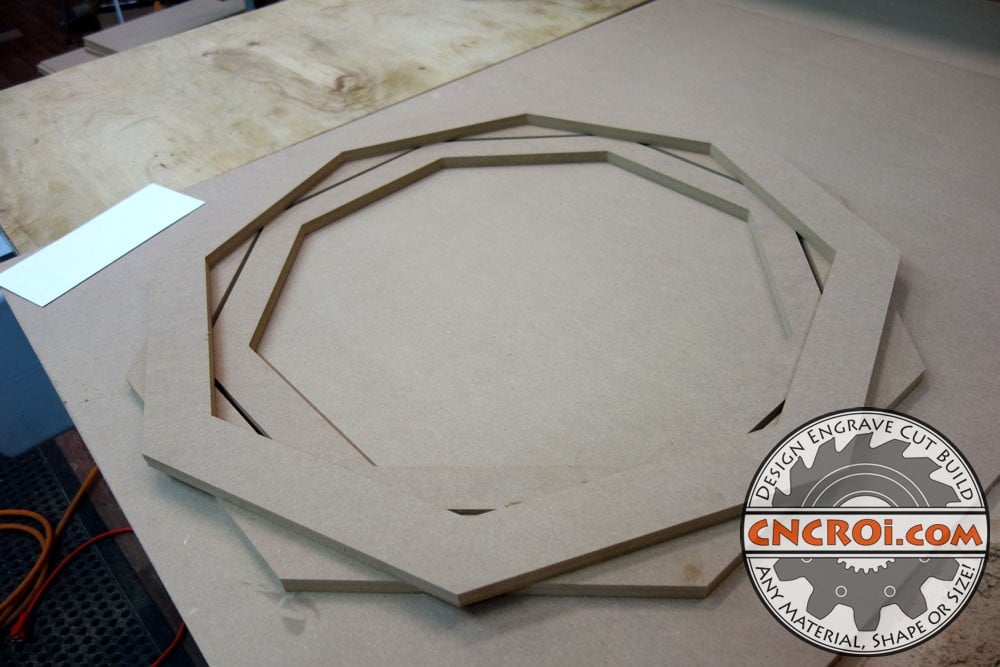

I used a 3/8″ compression bit for cutting out these two custom octagon window frames without having to resort to tabs, because the vacuum table has no problem holding these in place.

A compression bit is both an upcut at the bottom of it and a downcut in the top part of the machined bit, so this means you get a clean surface on both the top and bottom of the custom octagon window frames, though I still give them a light sanding along all the edges.

CNCROi.com isn’t limited to just window frames, we can fabricate the doors as well!

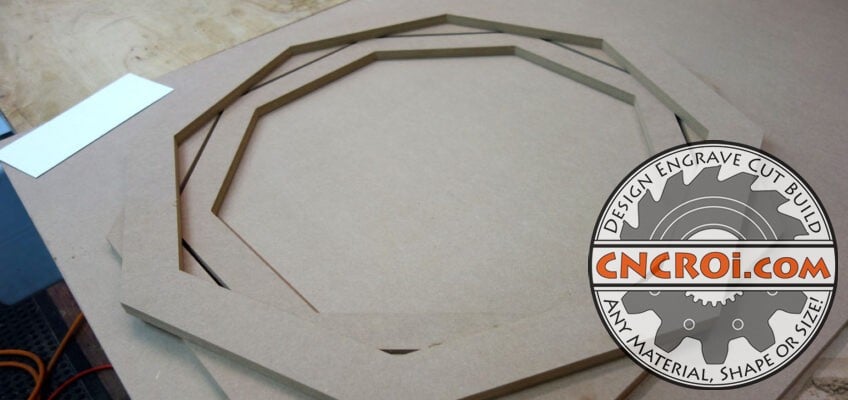

The two custom octagon window frames cut out seamlessly, at the same time, I made a few boards from the scrap left-over, these come in handy for a few projects I need to get done in the shop over the holidays so I have a bit more storage room.

You can tell my dust system is getting a bit full, the suction isn’t as good as I’d like, it was cleaned-out after this custom octagon window frames production.

I’ve flown through a lot of MDF during the course of 2024, next year I’m sure there will be a lot more machining of this material, it’s just so versatile for so many projects.

This pair of custom octagon window frames are now ready to be cleaned-up and shipped to the customer, these are pretty big and the package weighed about 20 pounds for both of them.

Need custom frames? Contact CNCROi.com right now!