Custom Plastic Stencils: Polycarbonate & Mylar

Custom plastic stencils have a wide variety of uses, today we’ll make two polycarbonate stencils for various projects at CNCROi.com.

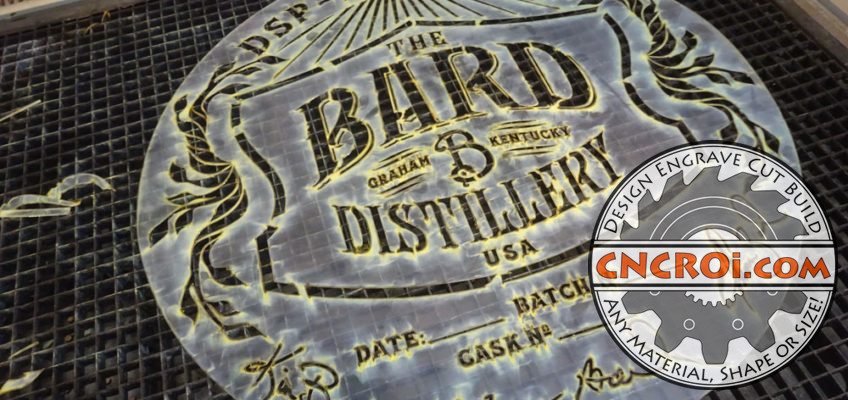

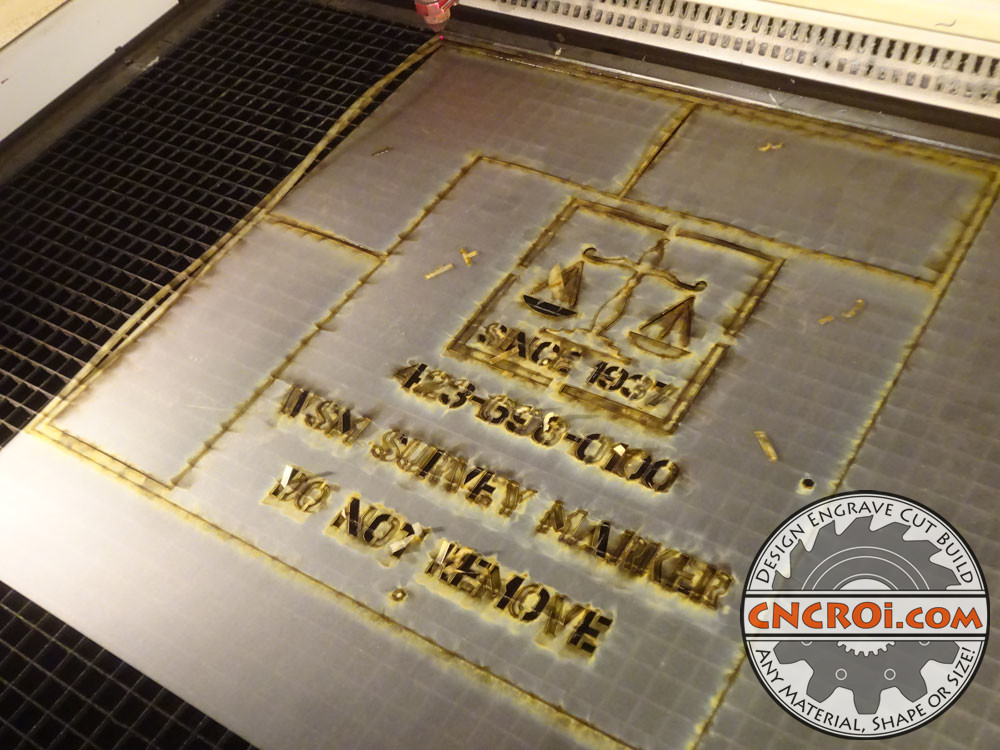

If this stencil design looks familiar, it’s because CNCROi.com make it out of stainless steel a few months back.

https://www.youtube.com/watch?v=mEDJyj24G_8/

Polycarbonate is really my go-to plastic when it comes to making custom plastic stencils, it’s incredibly durable, easy to clean and transparent.

The huge advantage of polycarbonate over any other material, including mylar is the strength, it’s literally bullet proof glass and as a result, it can take a beating and still stay together, but more importantly, you can also roll it up when not in use, unlike acrylic.

There are of course tougher plastics out there but the price point of polycarbonate vs the durability is a sweet spot that so far I haven’t found a better alternative to.

The advantage of stainless steel stencils is the incredible durability and you can either spray paint the pattern or use a propane torch.

https://www.youtube.com/watch?v=fhwwm4DgLSA/

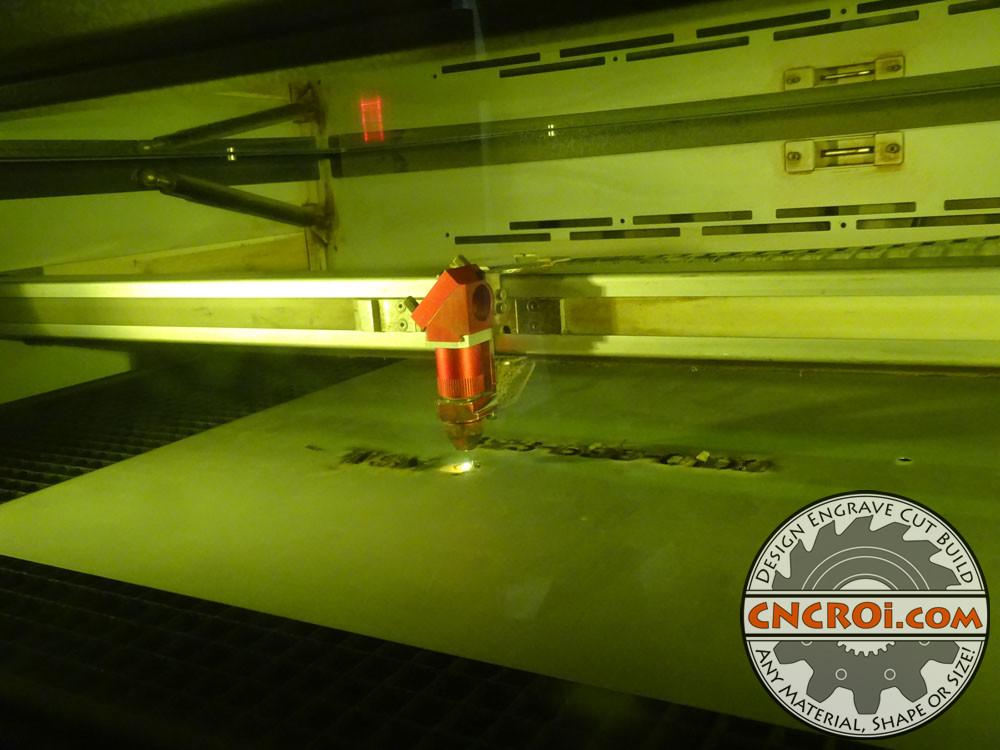

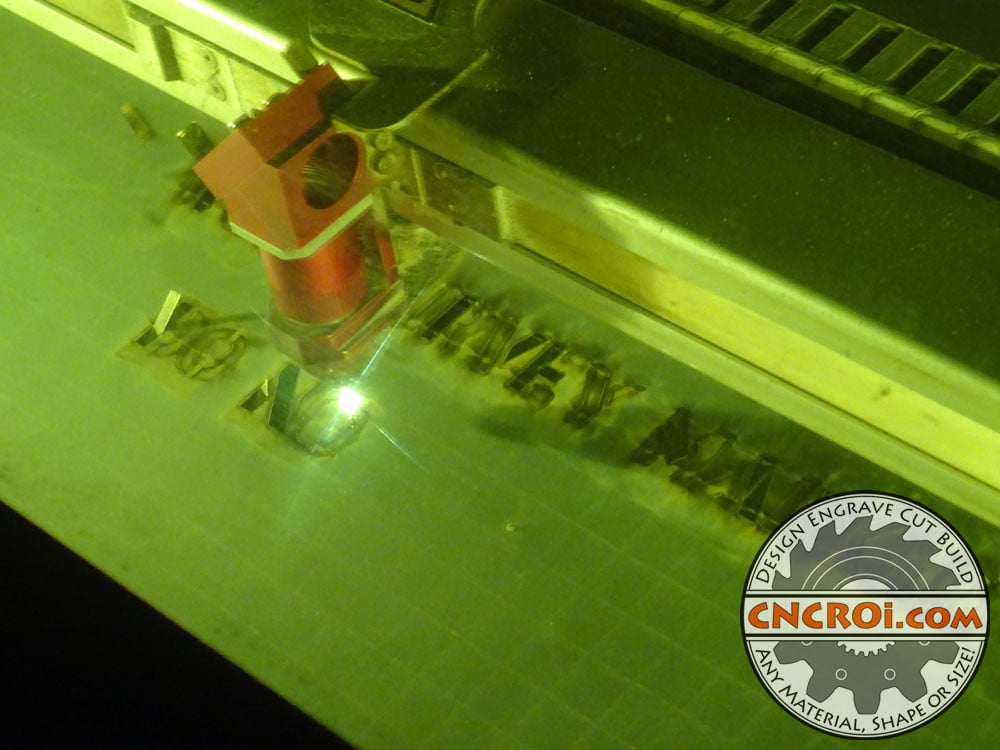

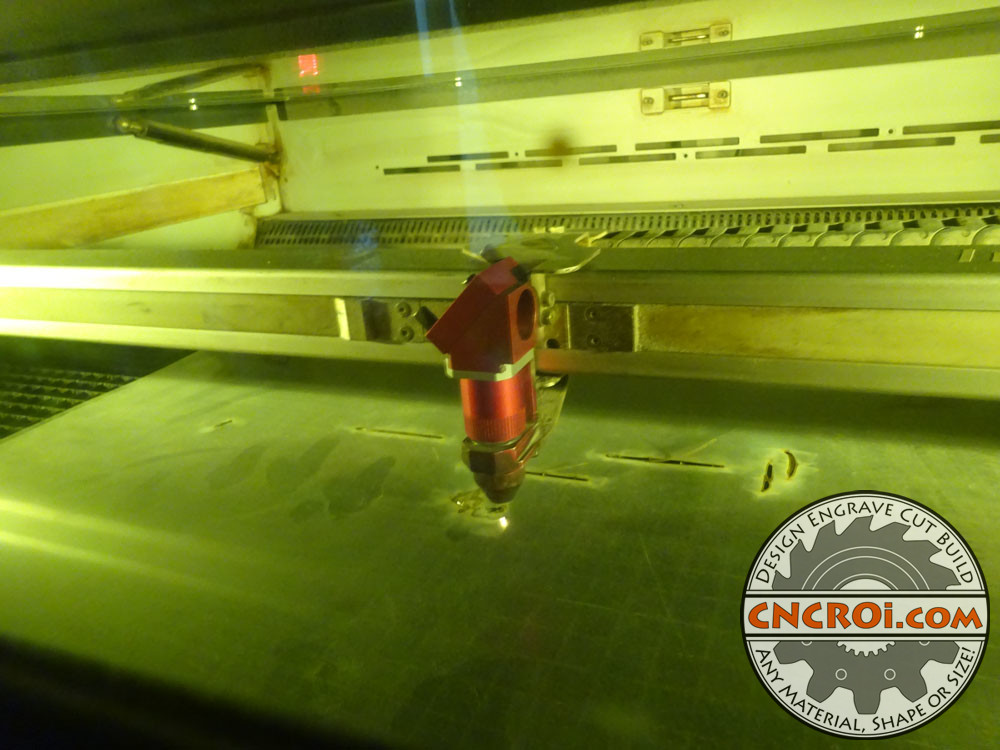

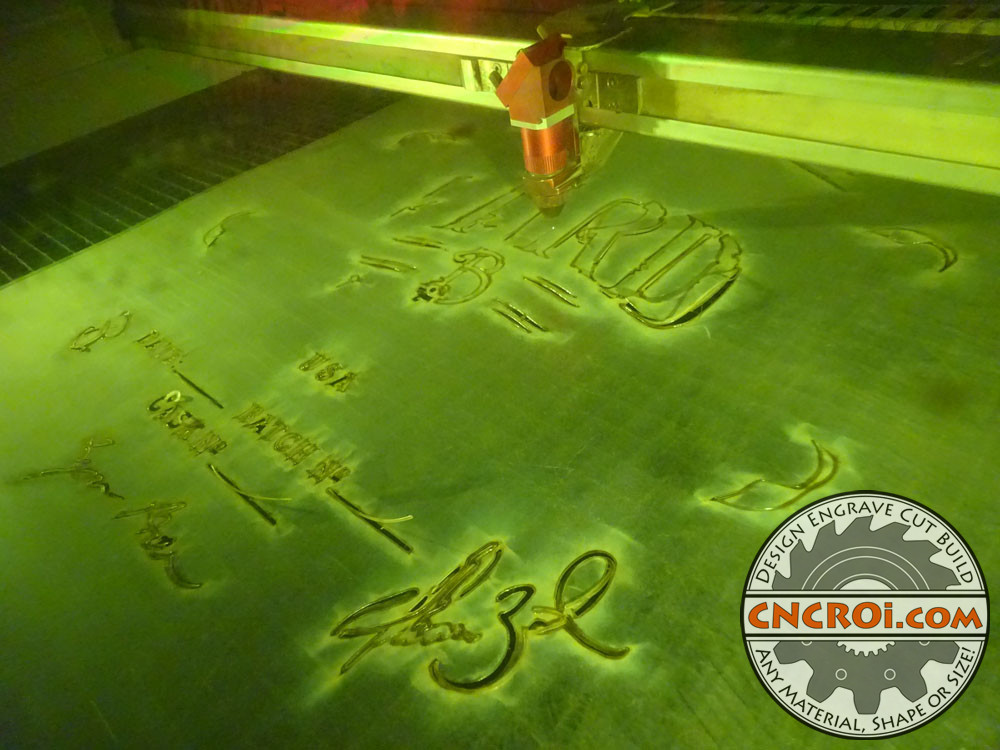

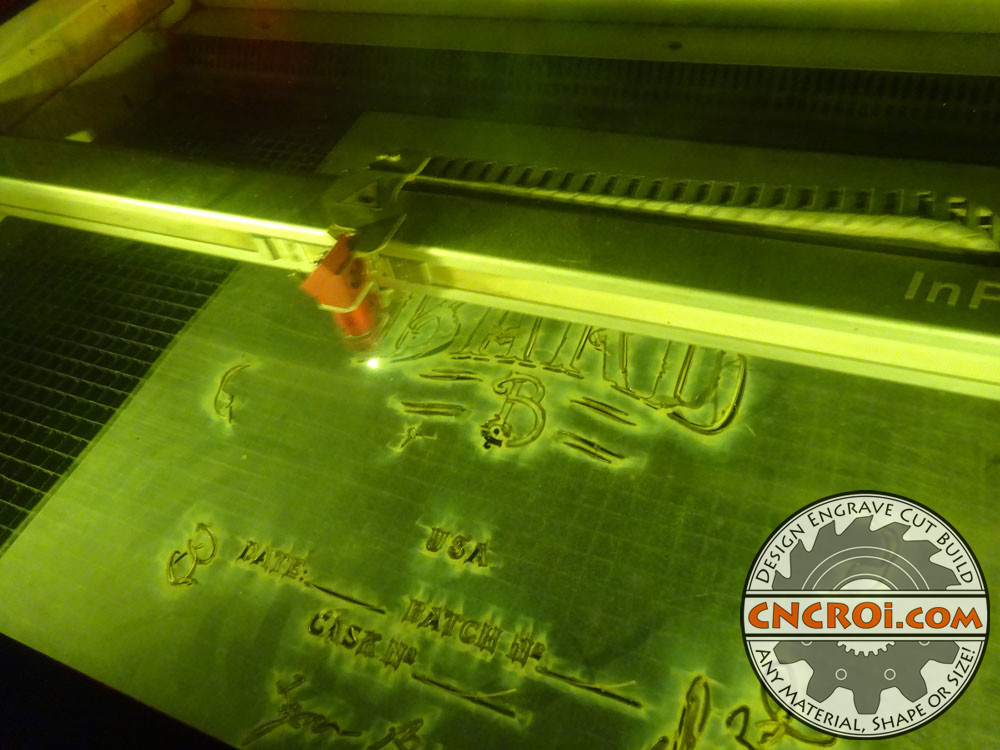

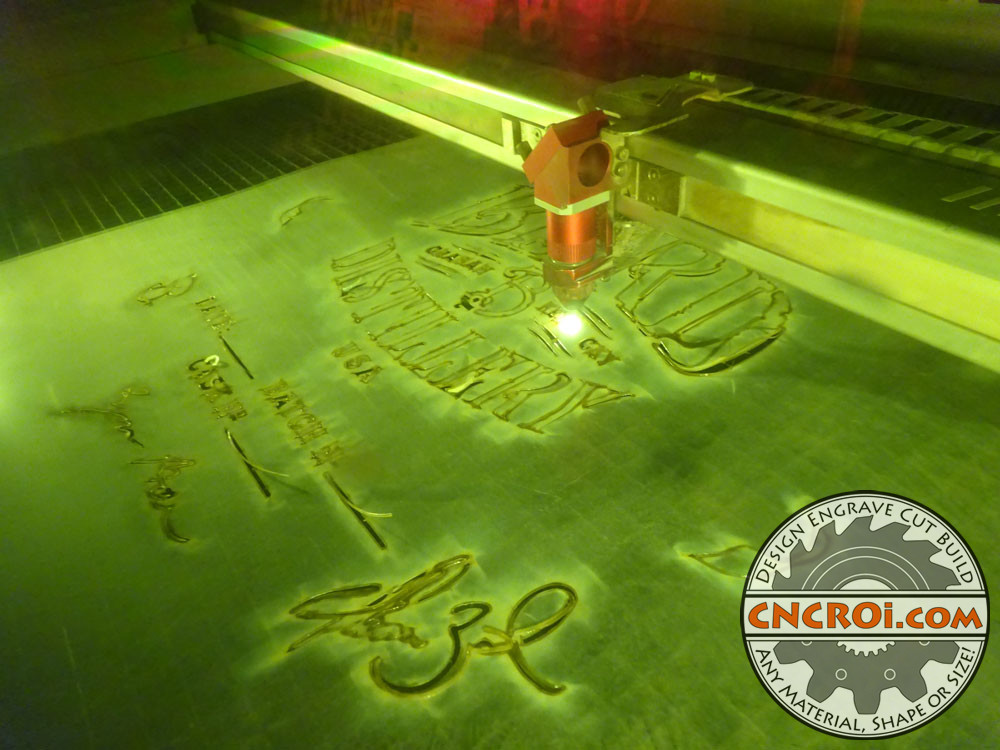

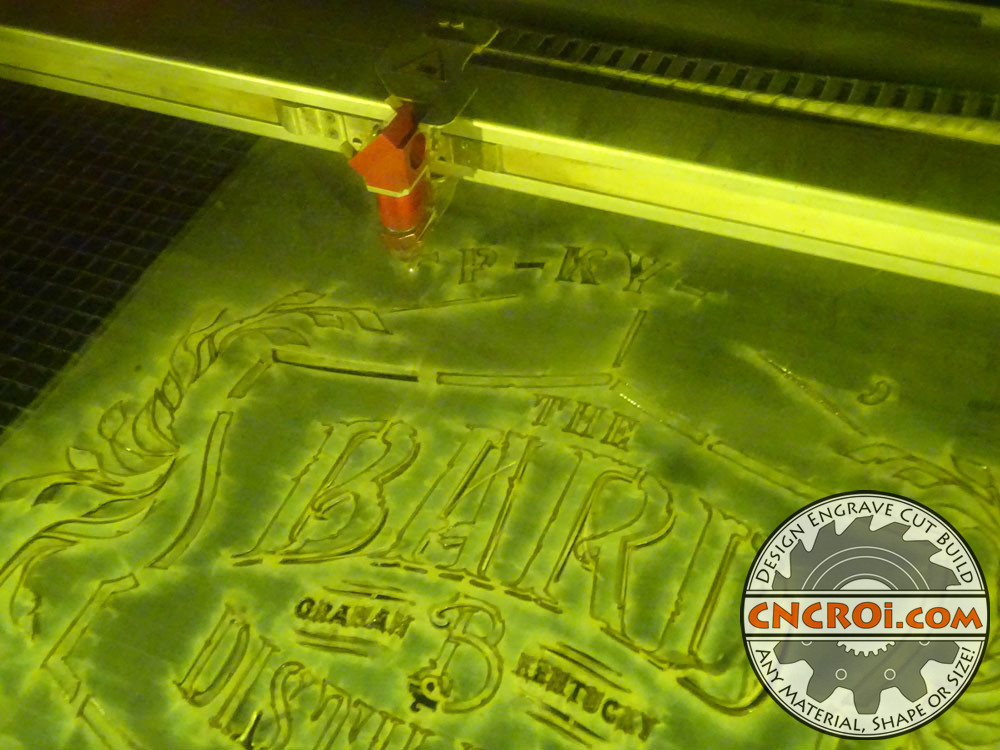

Custom plastic stencils are generally cut at CNCROi.com using our industrial laser, it does quick work of it, can do sharp inner corners and the bridging material is kept to an absolute minimum.

The laser is also a non-contact method of custom plastic stencil creation, meaning there are no forces added to the material during the production process, meaning unlike a router, there is nothing pushing or pulling the material which can possibly warp it.

The customization of polycarbonate regarding design parameters of what can be cut is awesome, unlike acrylic which can get brittle or PETG which can get EXTREMELY brittle when worked with our laser.

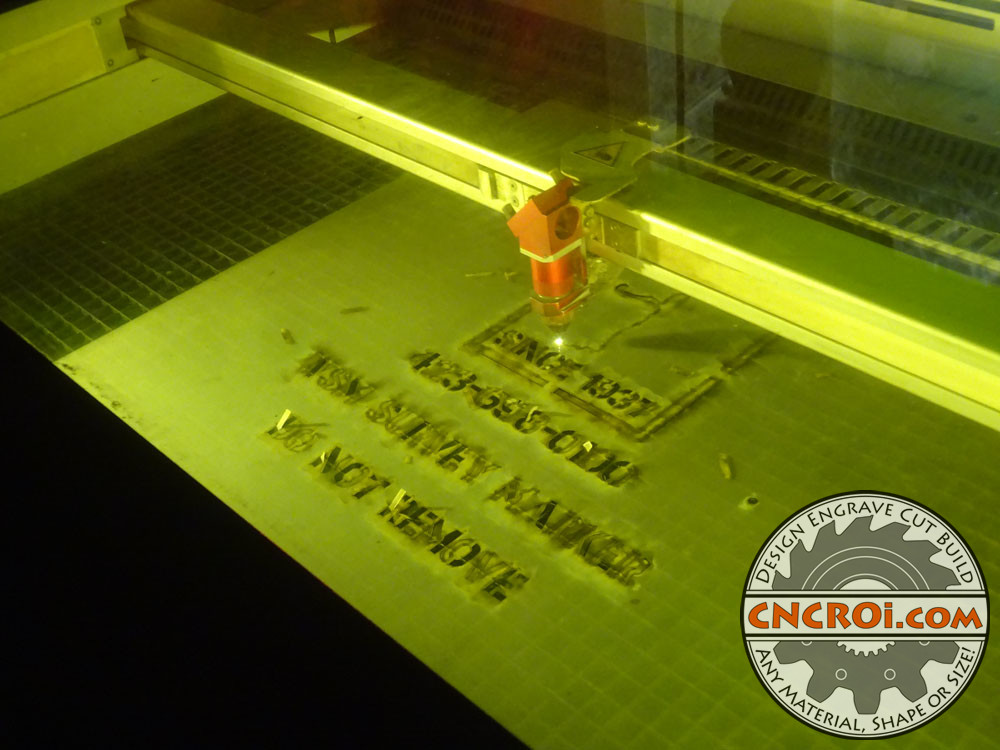

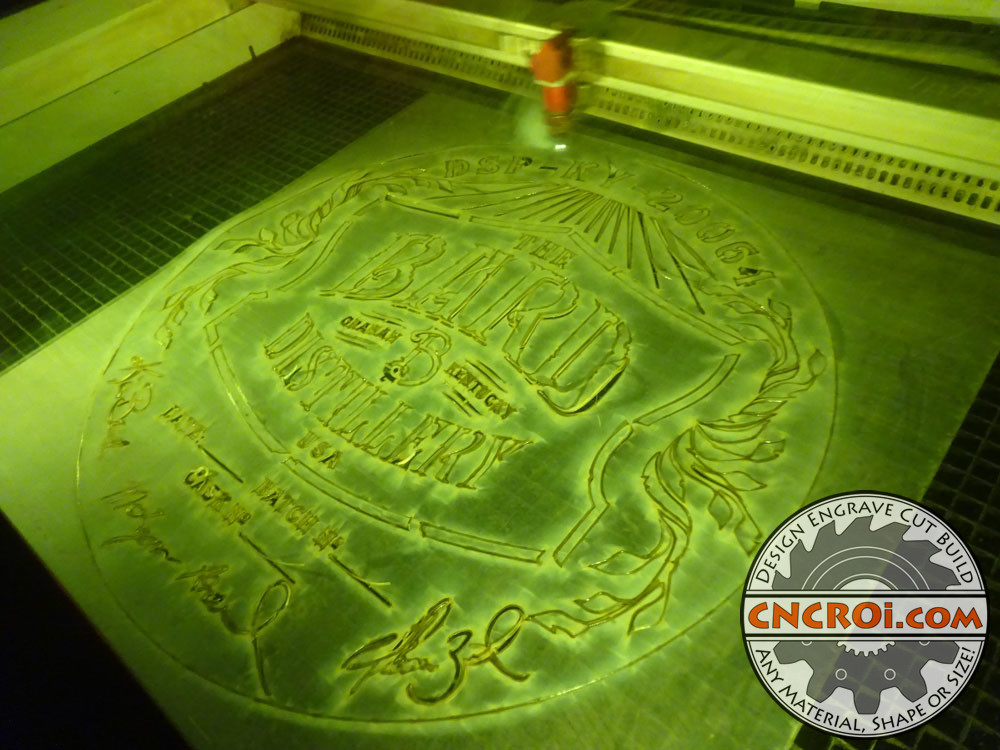

The custom polycarbonate stencil above is ready to go, just the inner parts need to be dropped off and it’s ready for daily use for a very long time, so let’s make an even more complex design to see how the result look like for custom plastic stencils production.

https://www.youtube.com/watch?v=dz27x1cdrt8/

Cardboard is also a good one-time use for stencils, as well as plywood.

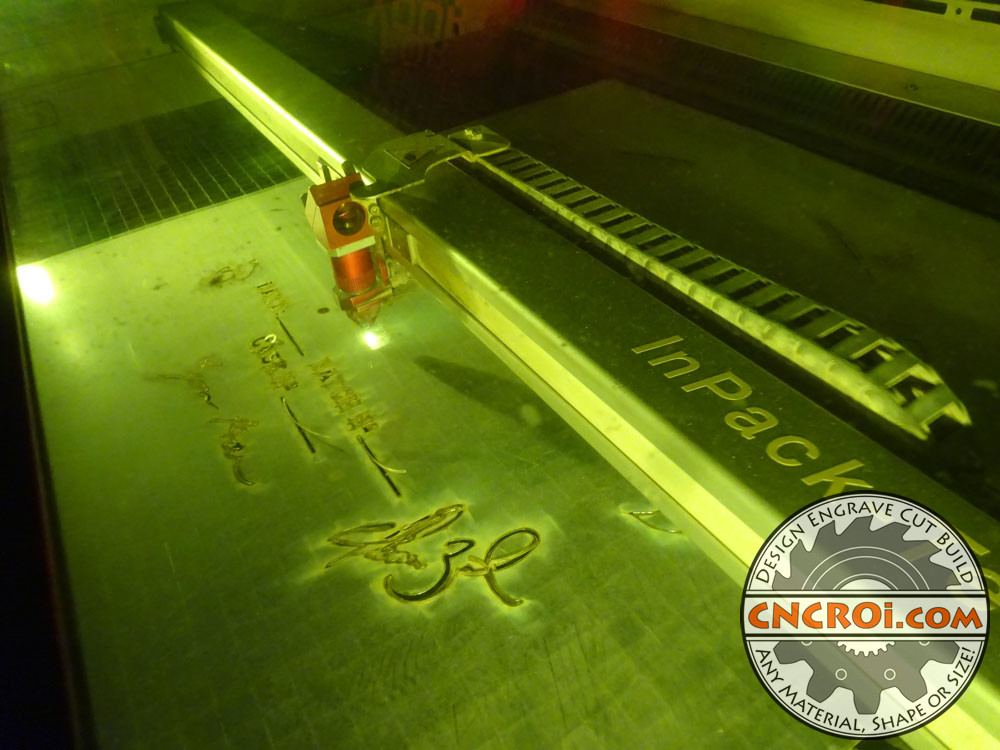

Like the previous stencil, the laser yet again does quick work of the stencil, in this case, I left the protective plastic sheet on both the front and the back of the custom plastic stencils we made in this run.

There are various production methods when it comes to making custom stencils.

https://www.youtube.com/watch?v=yeQeDjIeMtQ/

After spray painting, let the paint dry and then, thanks to the very thin sheet I left on it, the customer can then just remove it after initial use and voila, they have a brand new stencil to work from with minimal cleanup requirements.

When it comes to custom stencil production, CNCROi.com can make them out of any material, but more often than not, it’s either polycarbonate / mylar for spray paint and light use or stainless steel for heavy duty use.

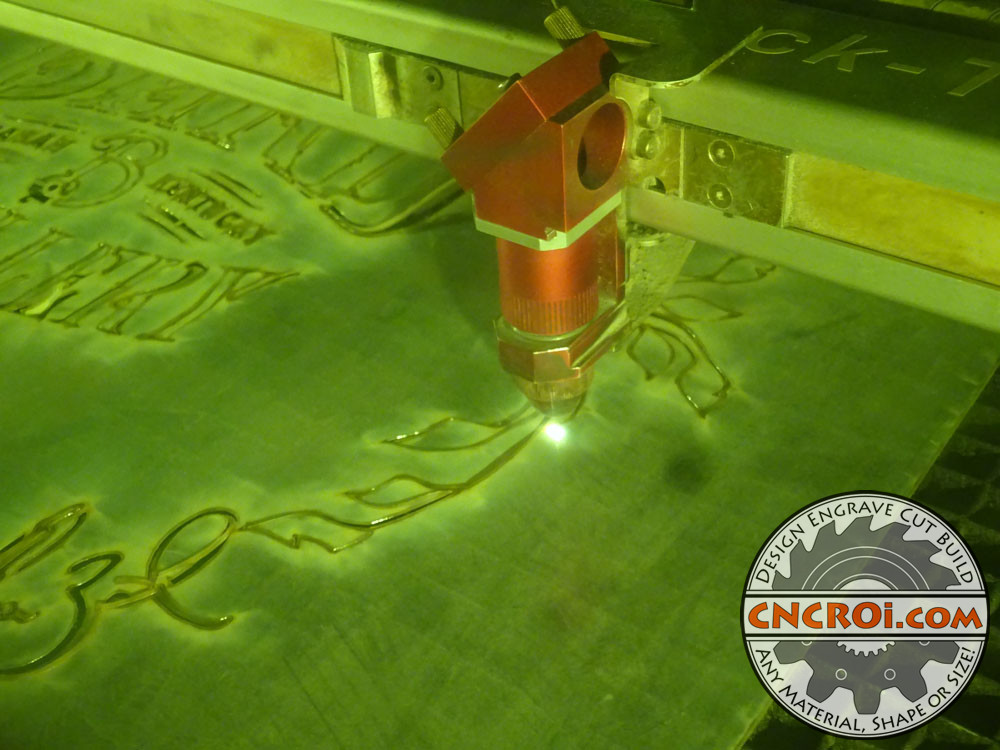

Making custom plastic stencils is fun, but do keep in mind that you must have bridging material to hold inner parts, otherwise when they fall-out, the stencil doesn’t look to nice if number and letters are involved.

The graphics in the custom plastic stencils also need to be vector based, this creates the paths for our industrial laser (or other machines) to cut it out of, just having a colored graphic doesn’t do very much for our production process, it needs to be converted into a line drawing.

If you are wondering what polycarbonate looks like when the protective plastic sheets on the front and back are taken off, check this out.

As you can see, this custom plastic stencil has a lot more fine details involved in it, which is totally fine for our equipment and for this application, a roller with paint will be used rather than fire from a propane torch.

Custom plastic stencils have the same limitations as any other material we can use to make stencils with, you want to keep a certain amount of material untouched so that the overall stencil still has plenty of strength.

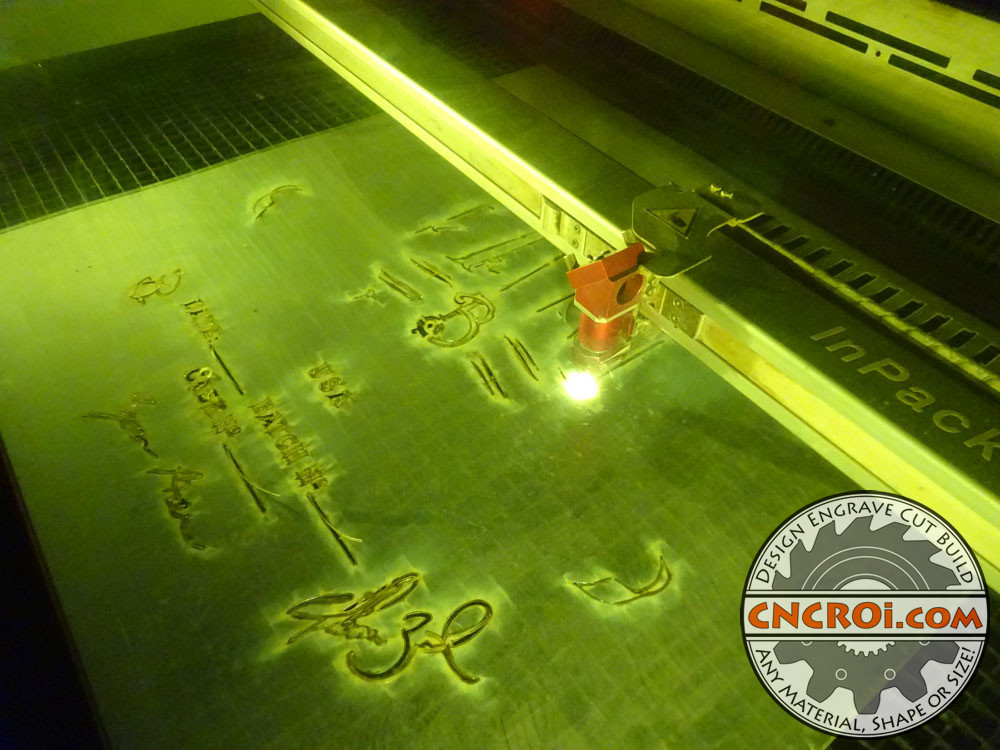

After the custom plastic stencils are produced, it’s time to cut them out from the material they are cut from, all the inner parts look great, sharp and accurately produced at CNCROi.com.

CNCROi.com also makes custom stencils out of regular paper.

https://www.youtube.com/watch?v=-om_S8l0bs8/

Taking a look at this polycarbonate stencil, you may be wondering how the paint will find it’s way through the material…

What you don’t see is that everything in this polycarbonate stencil is cut, it’s just a point of removing the material to reveal the actual stencil.

And below you see the finished stencil, everything looks amazing, the material is polycarbonate and it’s 0.02″ thick.

Need custom plastic stencils? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=ZsfqMnXtoIY/