Custom Plywood Display Board Prototyping

CNCROi.com can make custom plywood display board prototyping using pretty much any design profile you have in mind.

https://www.youtube.com/watch?v=-dlr77GQigA/settings

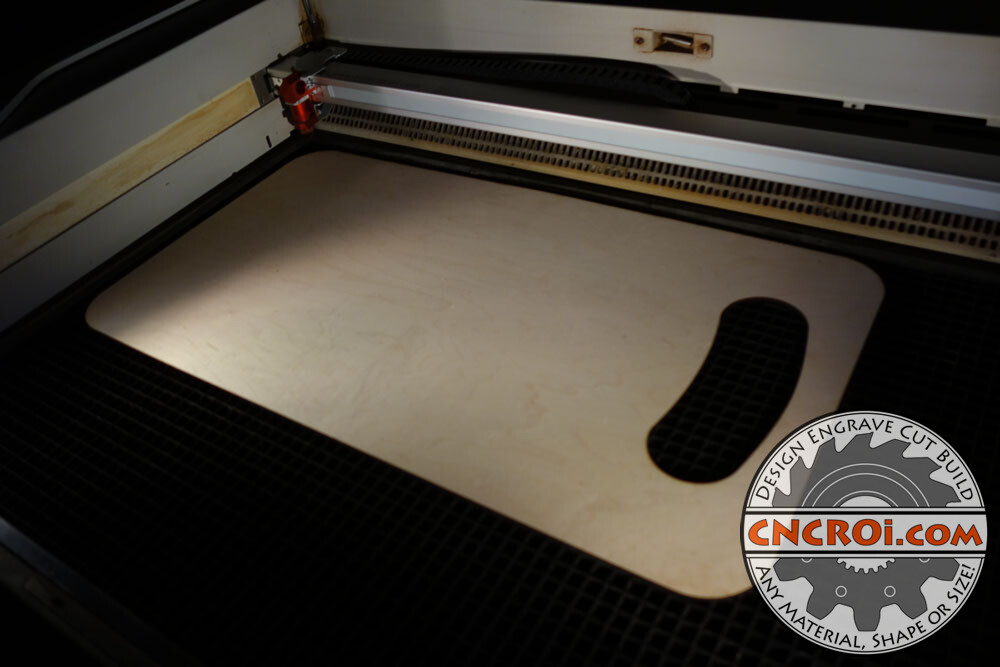

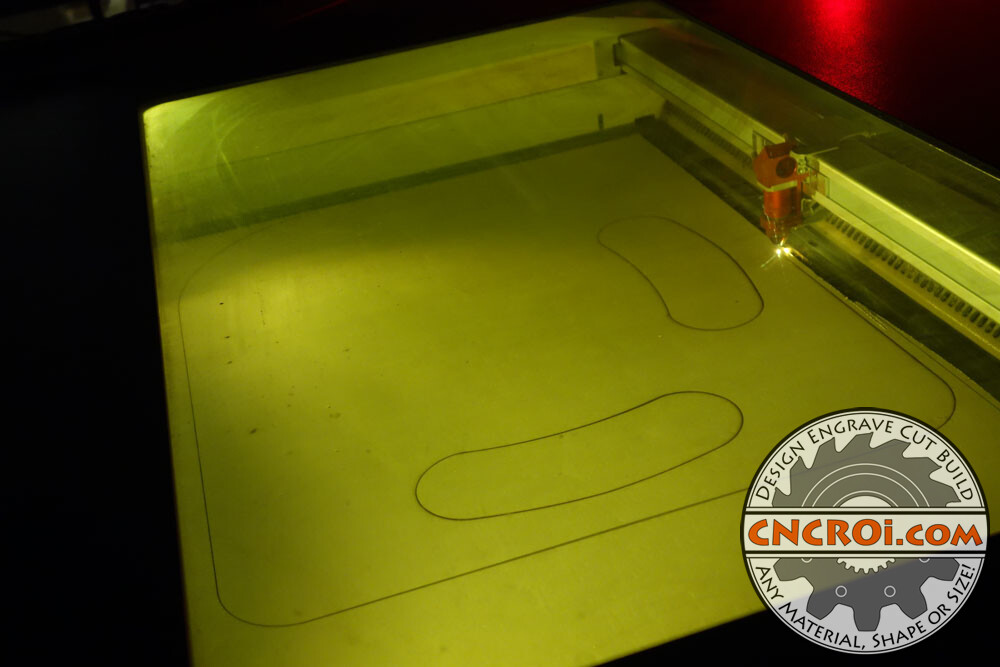

For this project, we made three different types of custom display board prototypes so the client can see which one best suits their needs.

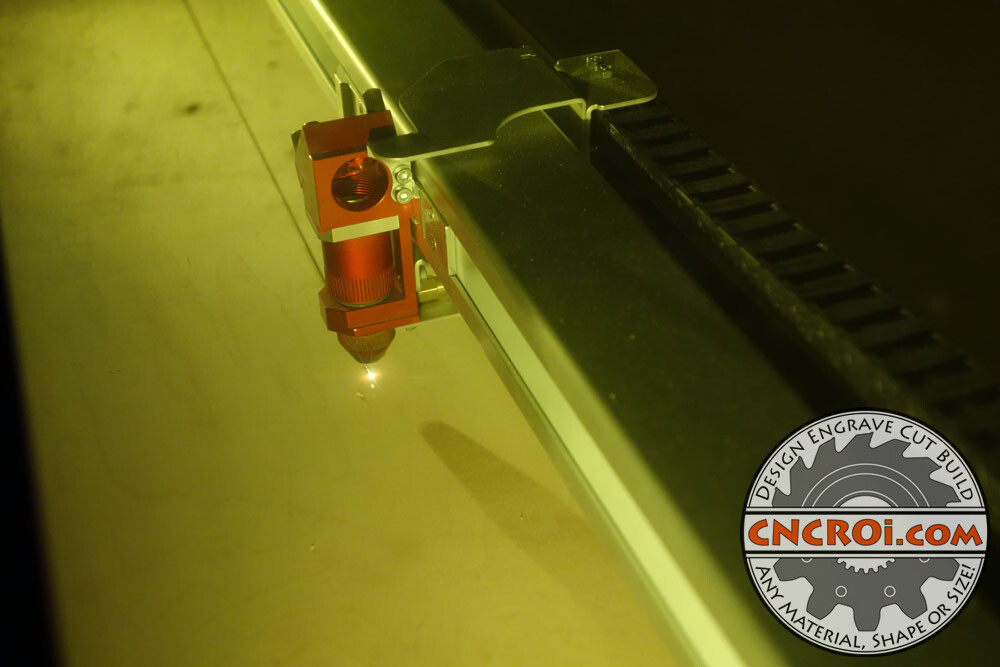

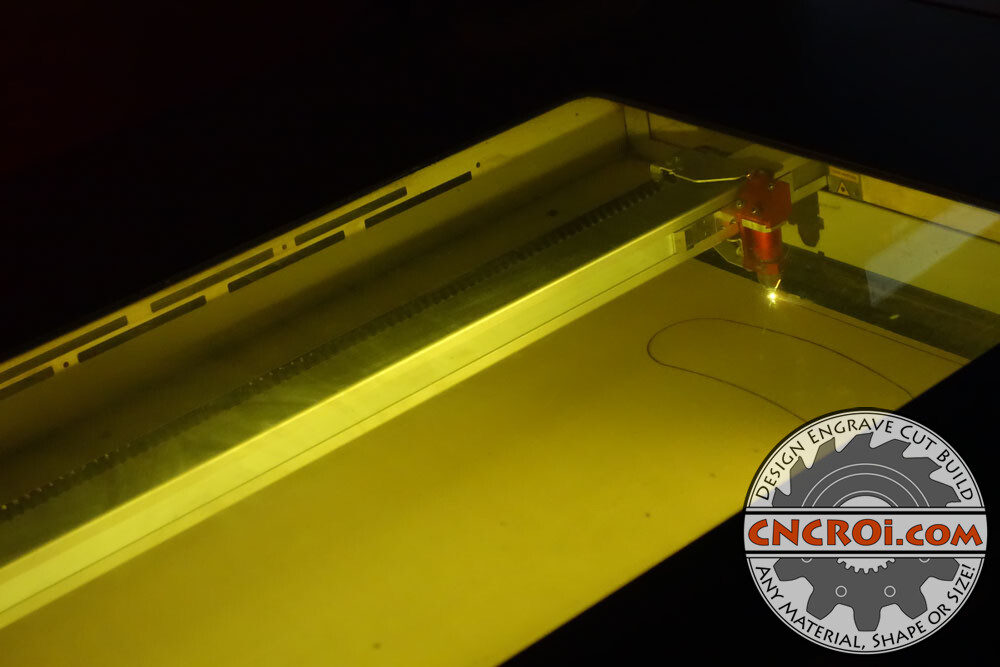

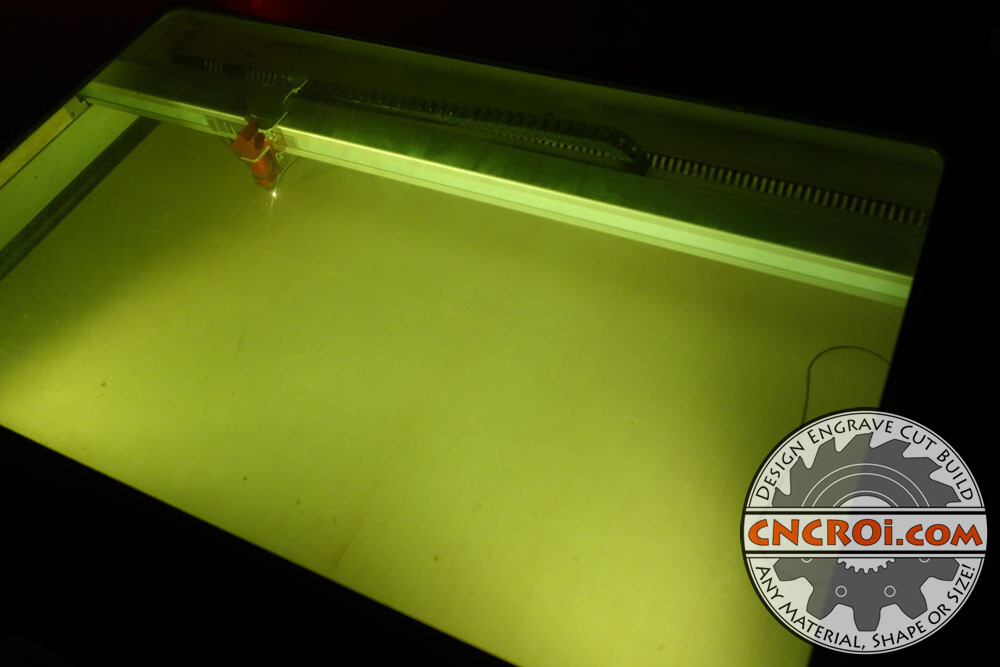

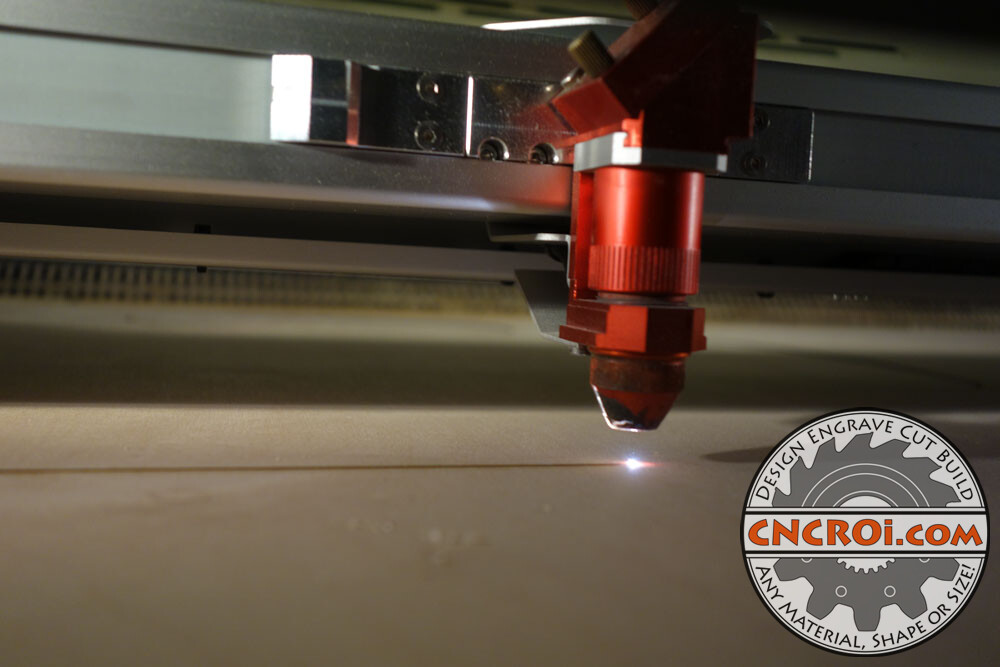

For this specific project, using quarter inch plywood, I could have used the router just as easily as our laser, they both have the same precision and accuracy, but it just worked-out that the laser was free and big enough to do this job so that’s what I used for custom plywood display board prototyping.

Laser has some advantages over router, mainly that I didn’t have to hold down the plywood in order to cut it as the laser is a non-contact method of cutting at CNCROi.com.

Of course, if you want your custom display board to be a whiteboard, that’s no problem for CNCROi.com.

The router on the other hand, needs things held down using vacuum and screws as you have a spinning bit plowing through the material, hence it wants to lift or shift on you during production of custom plywood display board prototyping.

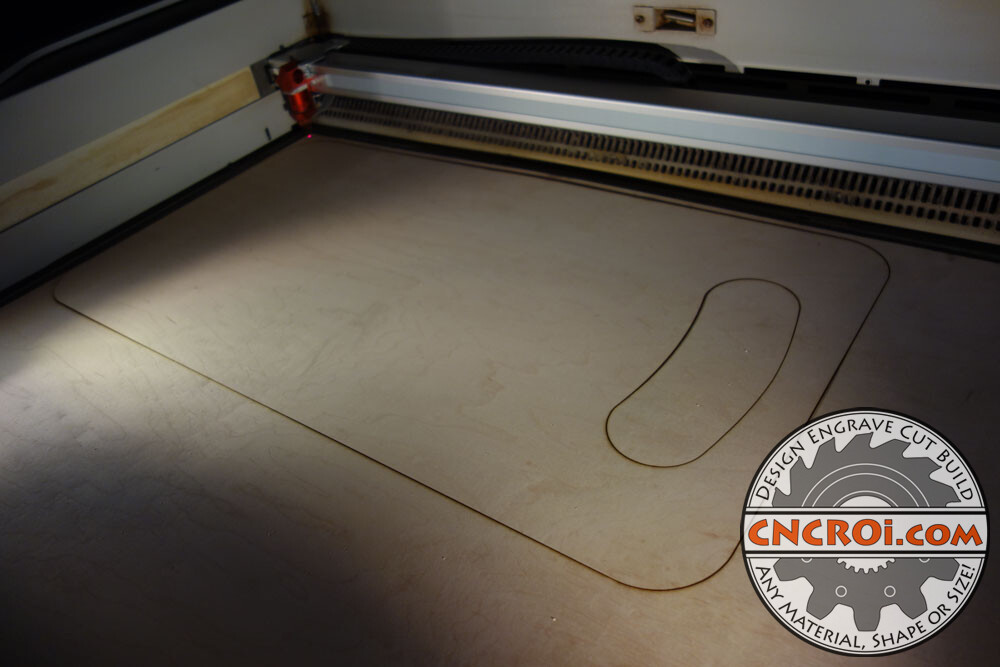

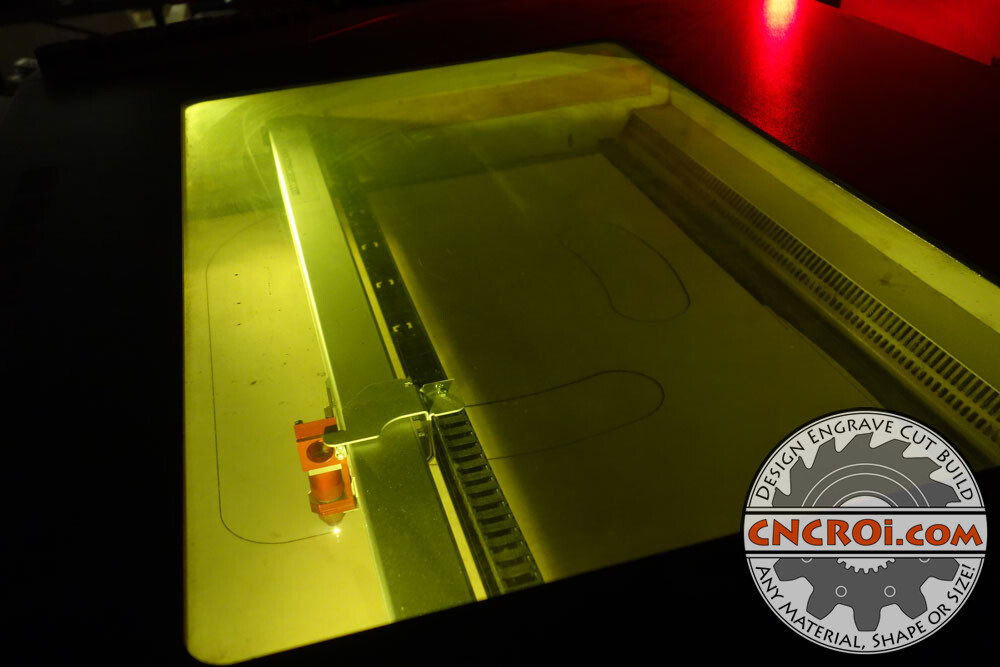

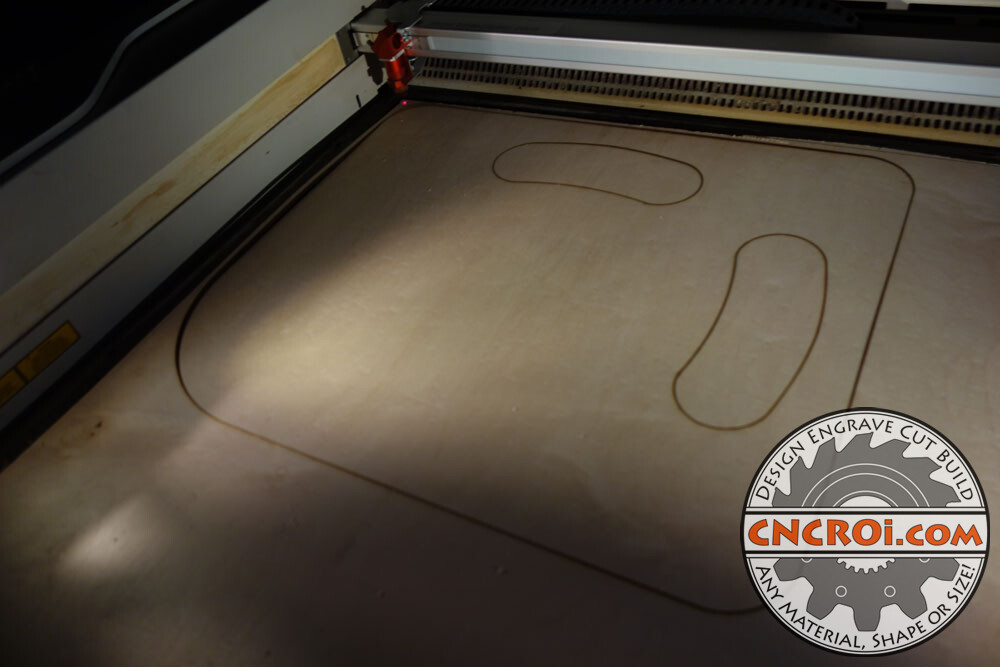

As you can see from the image above, everything is rounded, there are no inner corners that would benefit from laser cutting, as such, either CNCROi.com‘s router or laser could have cut this, and for the actual production where this would be done using quarter inch polycarbonate, we’d certainly use our router to do this custom display board project.

CNCROi.com can make boards however you wish.

Quarter inch polycarbonate is certainly not a material I can cut at CNCROi.com using my laser, it tends to hold-onto heat and bubble and warp quite quickly, issues that just don’t happen with our router as the heat is rejected with the chips.

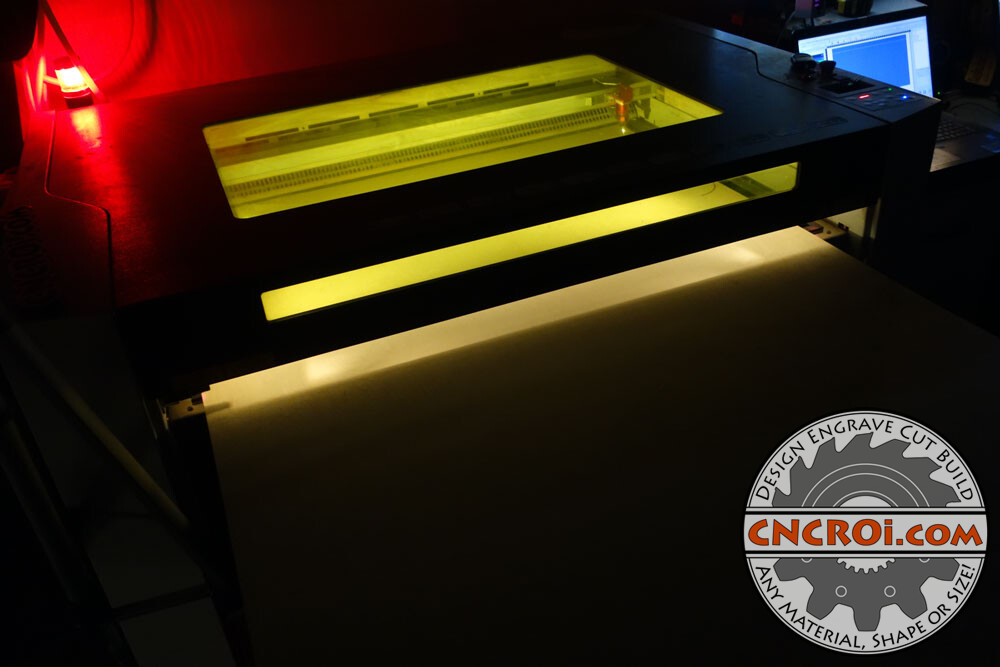

Most of the work at CNCROi.com is done with the lights on, I just turn it off when I do work for the camera because it gets rid of the glare and lighting artifacts that make filming and photography more difficult.

Laser engraving and cutting can be done on just about any material, but not every material is optimal for the laser, just like the router, each has a design and production profile that best suits certain technologies, as such, having many different machines gives CNCROi.com the flexibility to pick the best for the project at hand.

These quarter inch custom plywood display board prototypes cut great at CNCROi.com, I’ve been cutting plywood at this thickness for over 15 years now using various technologies… here’s a blast from the past before CNCROi.com even came into being.

In this case, I used my shopbot desktop, which I still have to this day, as that was the only CNC machine I had way back then.

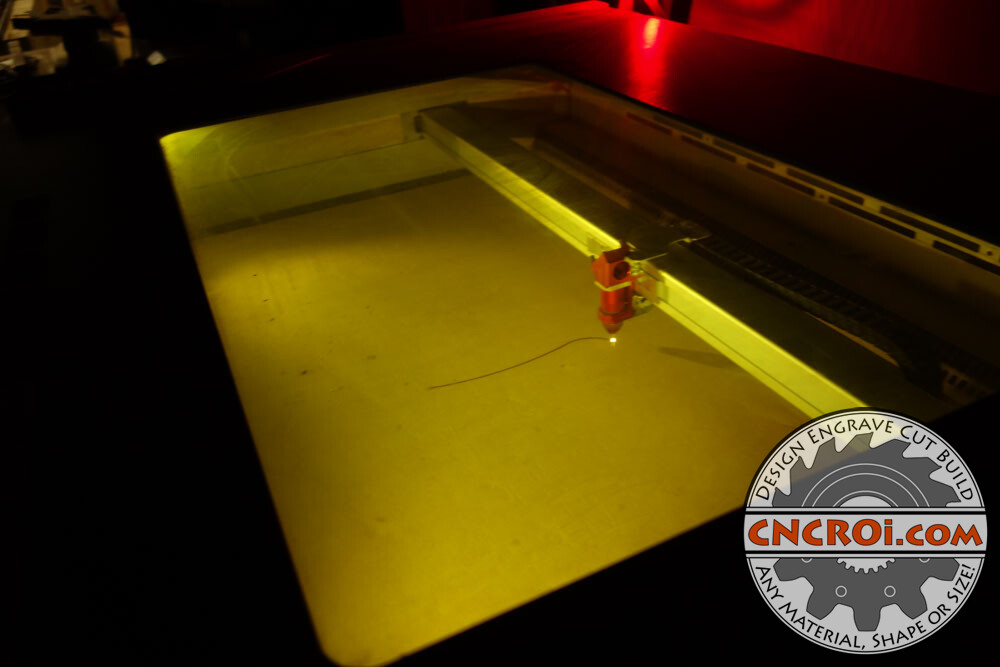

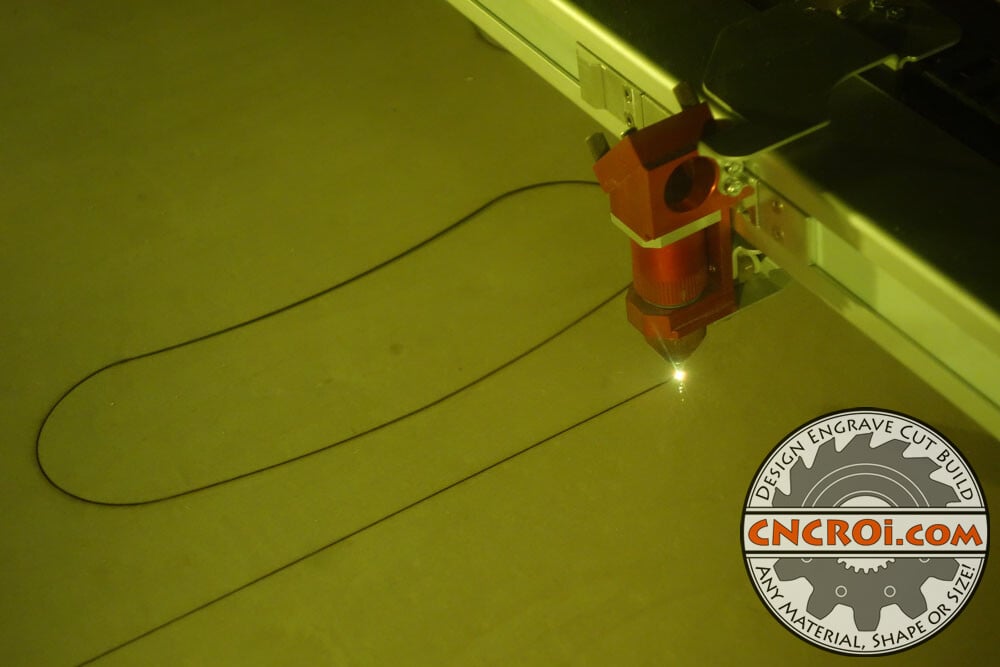

Back to these custom display board prototypes, regardless of the machine that CNCROi.com uses to cut this project, the motion is always nice and smooth, heavy investments into equipment and capability pay huge dividends when it comes to making quality outcomes for our clients.

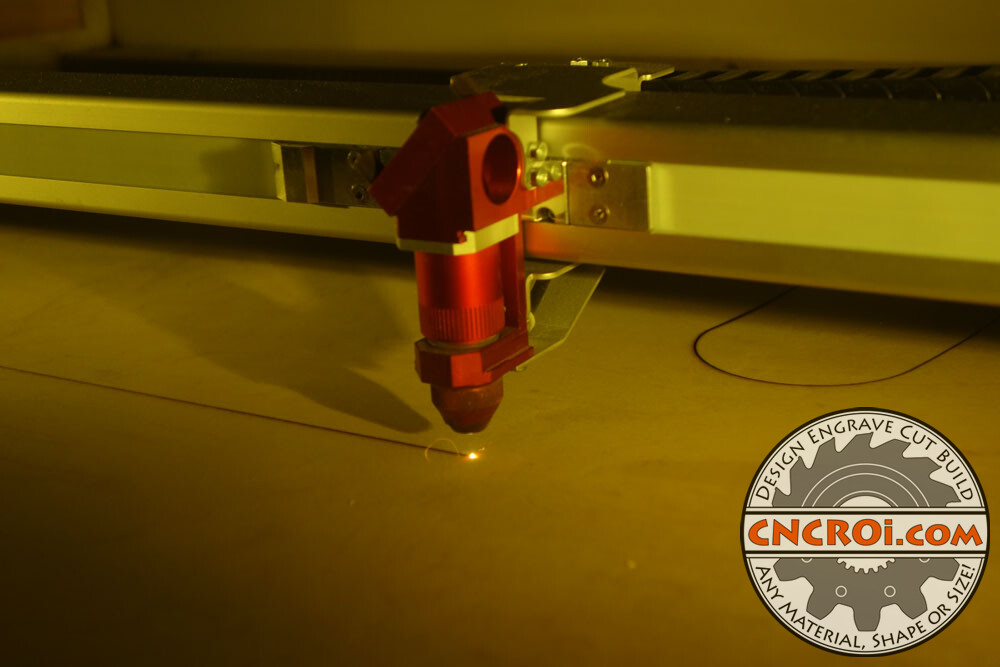

What I really enjoy about laser cutting plywood is just how clean the cut is, it’s hard to describe just how wonderful it is to see the process that I’ve sped-up dramatically in the video for these custom display board prototypes in real life.

When the laser cuts plywood, there is some smoke on the edges and some soot but this is easily removed and masked if this wasn’t needed, as this is a series of prototypes, it doesn’t really matter as long as the shape is made accurately to the customer’s drawing.

The nice thing about having something custom made is that it can suit your own particular needs perfectly.

I cut out the inside of the parts before the outside to make sure everything is cut accurately, although it’s a very small possibility that the parts move either way, as the laser cuts such a small fine line, the possibility of movement is there until everything is totally cut out as there are no vacuum systems or screws holding things down.

As the third of three custom plywood display board prototypes is just about to be finished, you can start to see how smooth the action of our laser is over this material.

You can see the smoke along the edges of the custom plywood display board below, as plywood has a thin veneer on both sides, generally we mask this on both sides if this isn’t wanted as sanding might remove the thin veneer on the wood composite.

Custom display boards can be 3D as well, here’s one I made for my other business TealightBox.com and it has lasted YEARS, still in use to this day.

For an actual production run, CNCROi.com‘s CNC router is a superior fit due to the speed of production compared to the laser and the material that the actual real display board will be made out of, but for prototyping and testing, using this design spec, the laser was more than adequate.

All of these custom display boards came out great, the client can now test them out and see what suits their process the best.

Here’s a picture of the three custom plywood display boards we cut at CNCROi.com, whether we cut one or a thousand, regardless of the technology we’d use, they would all be identical.

There are endless possibilities with CNCROi.com when it comes to the design of your very own display board, any material, size, and design profile works for us.

If you want custom display boards, contact CNCROi.com right now.