Custom Polycarbonate Intricate Parts

Custom polycarbonate intricate parts by CNCROi.com are not just incredibly durable but offer unlimited applications for this bullet proof glass to be used for.

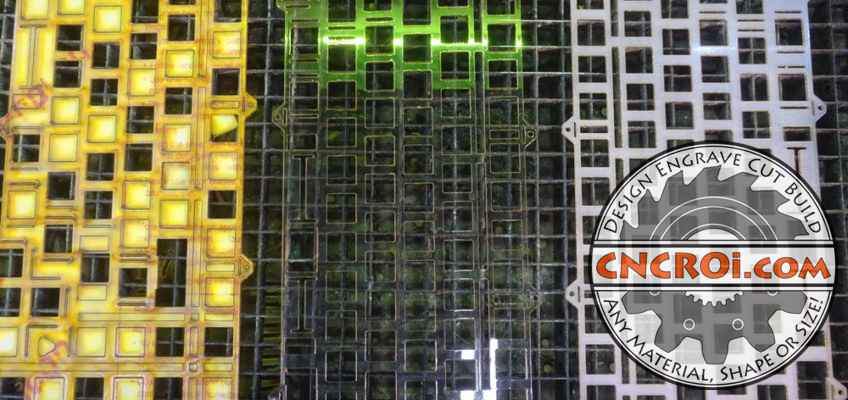

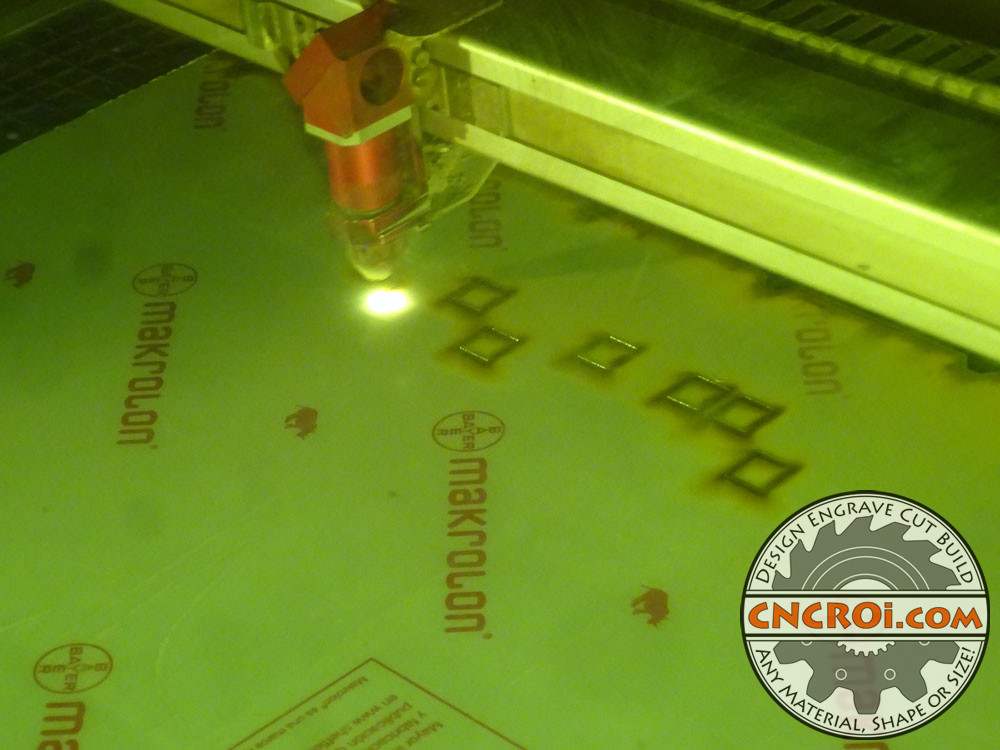

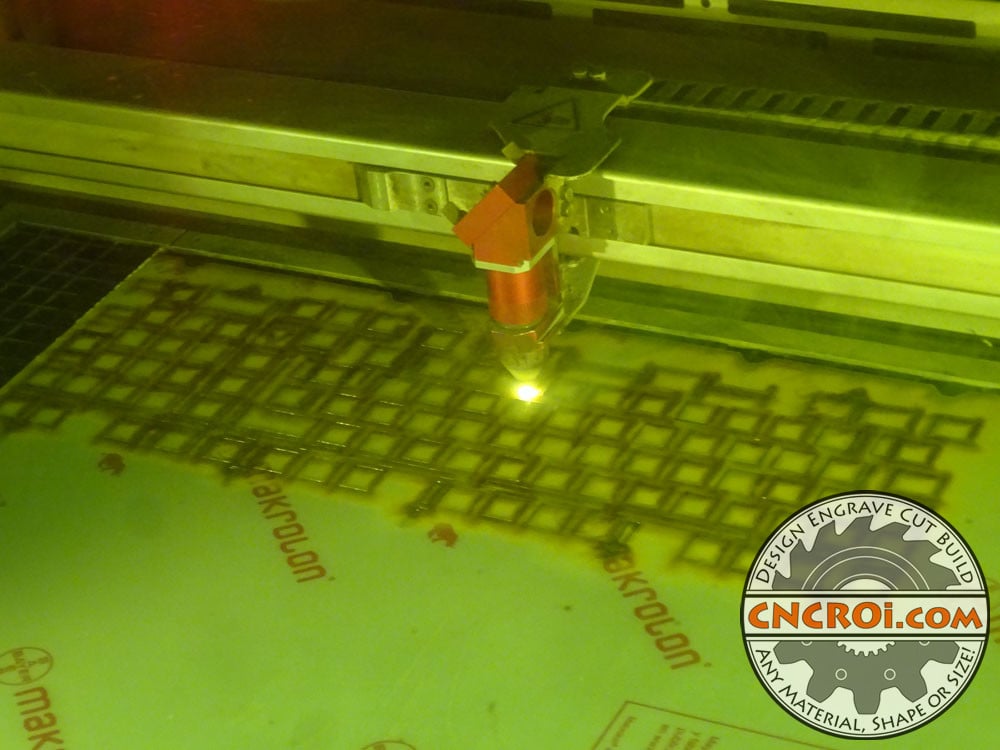

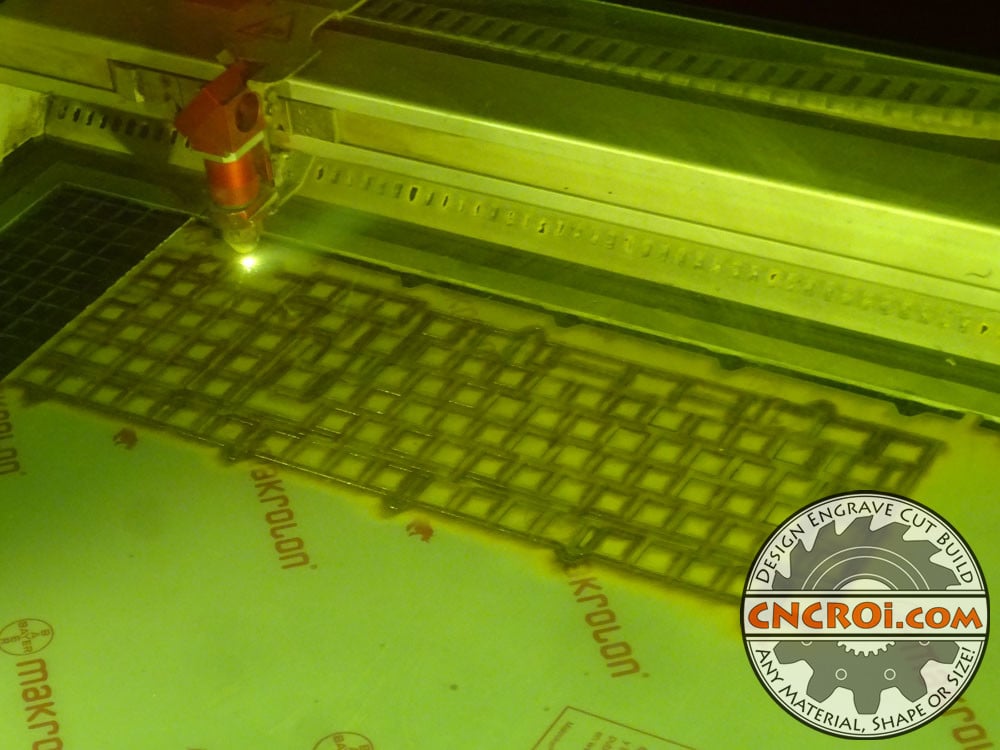

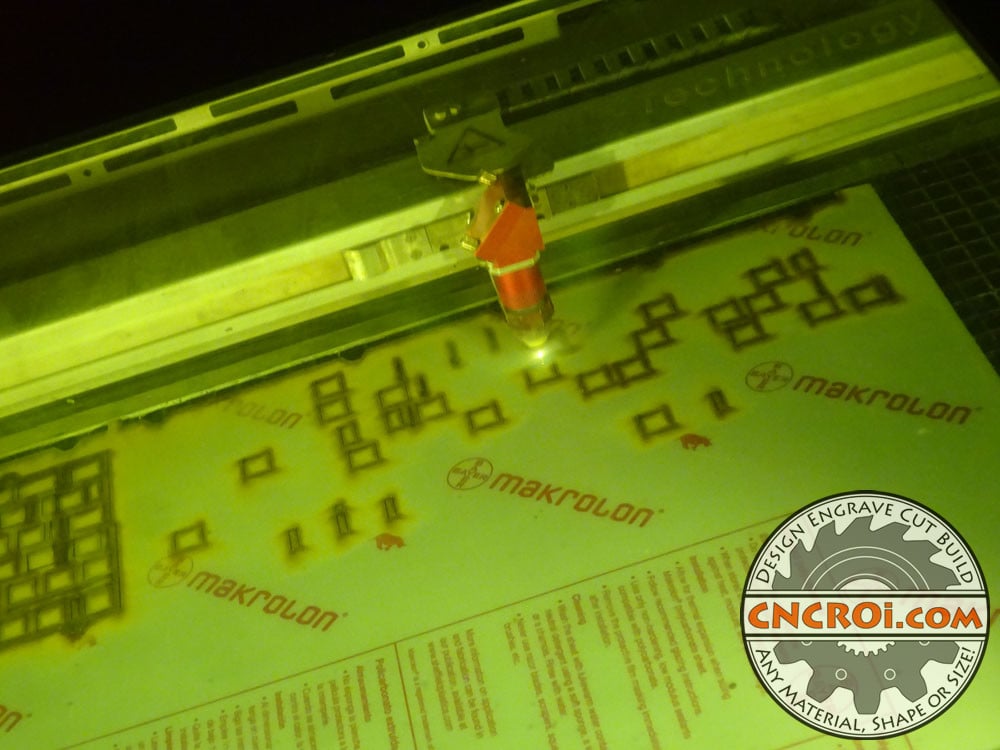

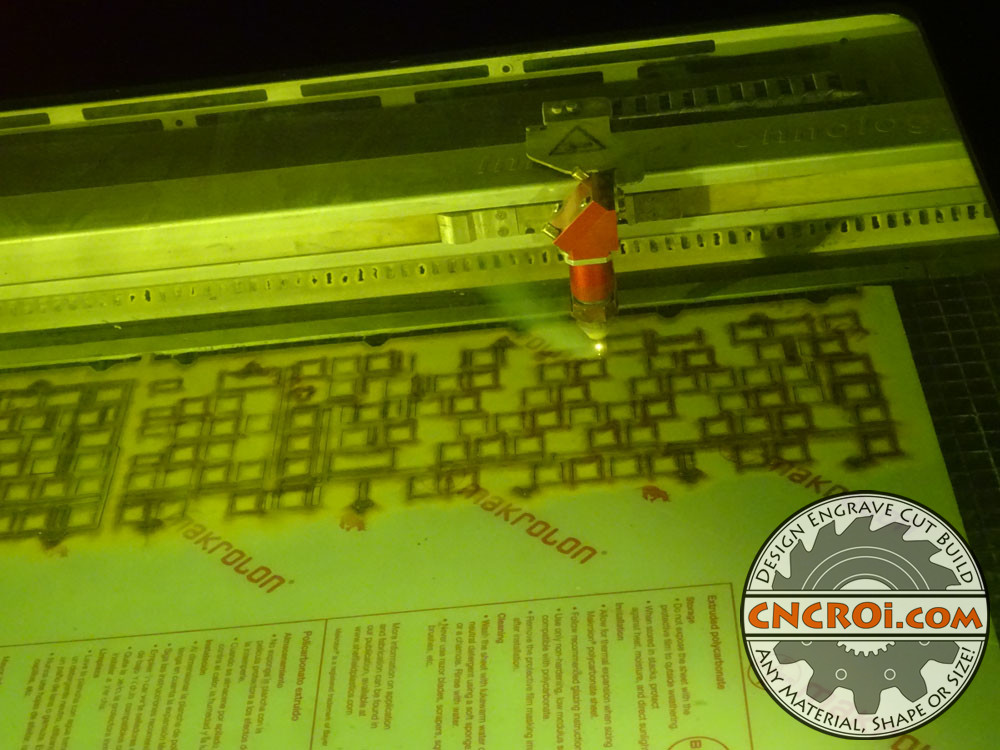

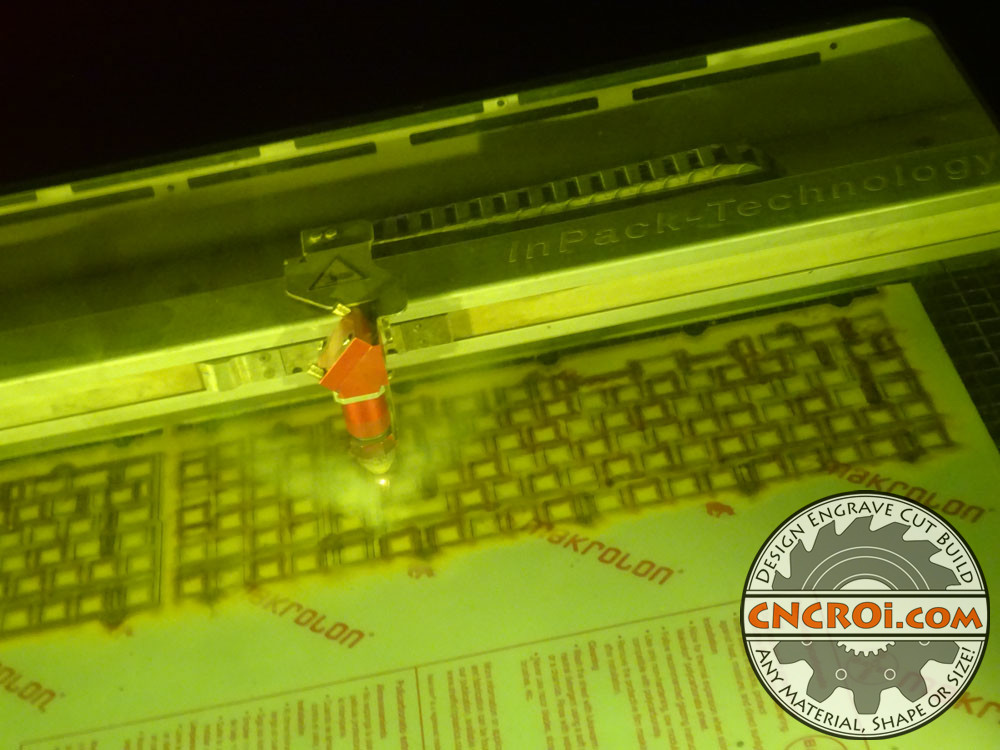

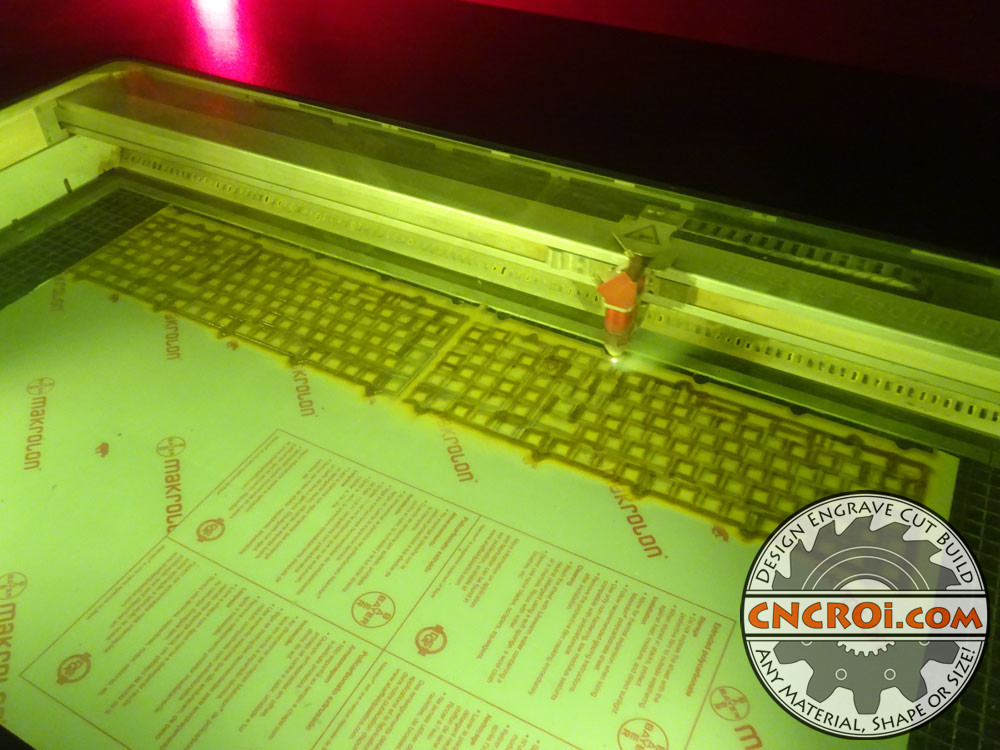

As CNCROi.com produces custom polycarbonate intricate parts on demand, which means that we can make a run of identical or different parts, at varying thicknesses and spec requirements all in one shot using both our CNC routers and CNC lasers.

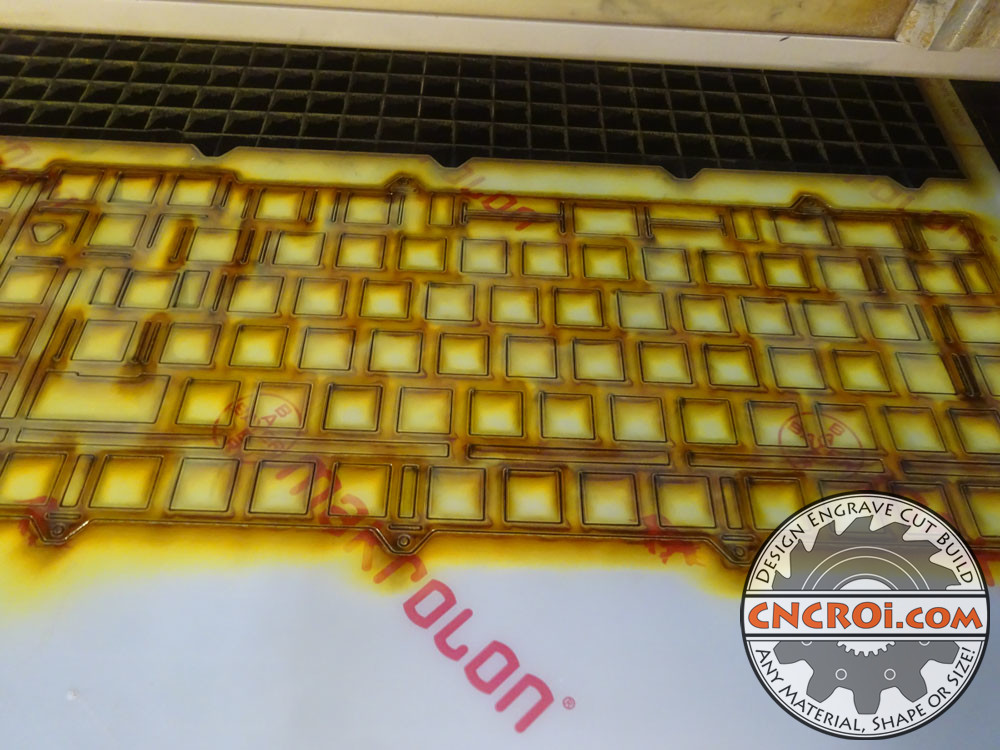

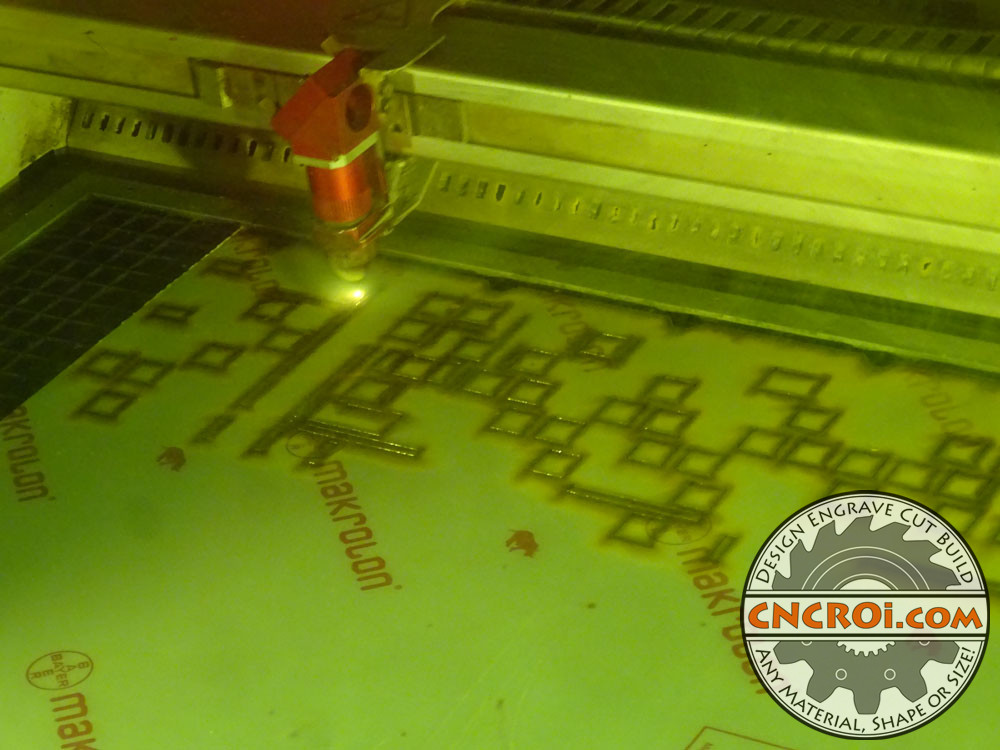

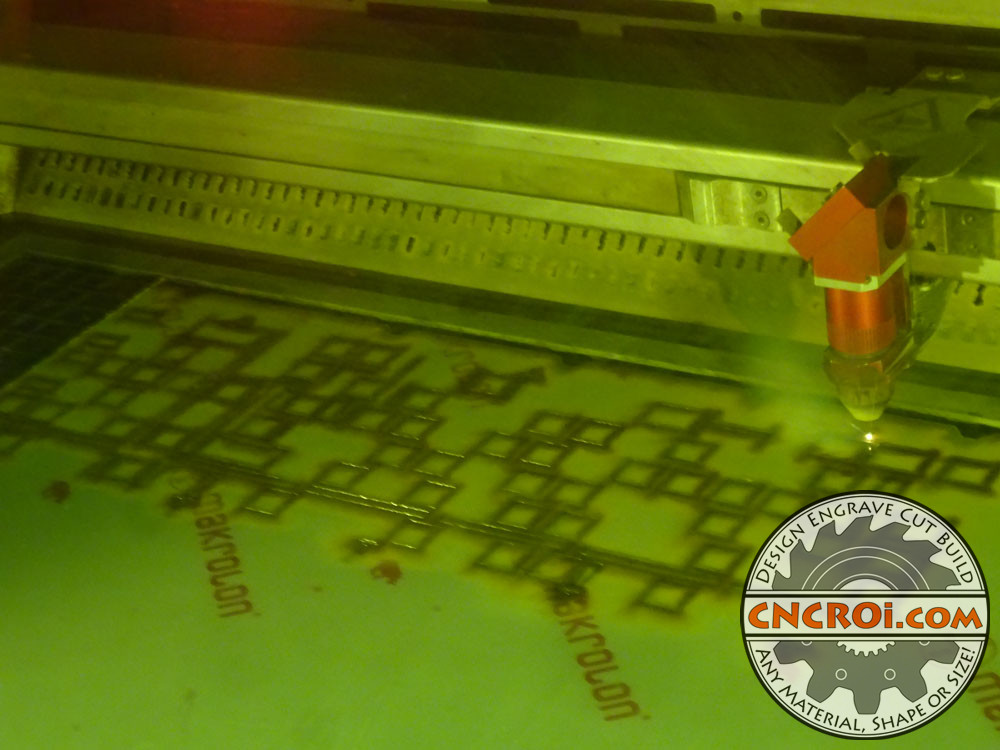

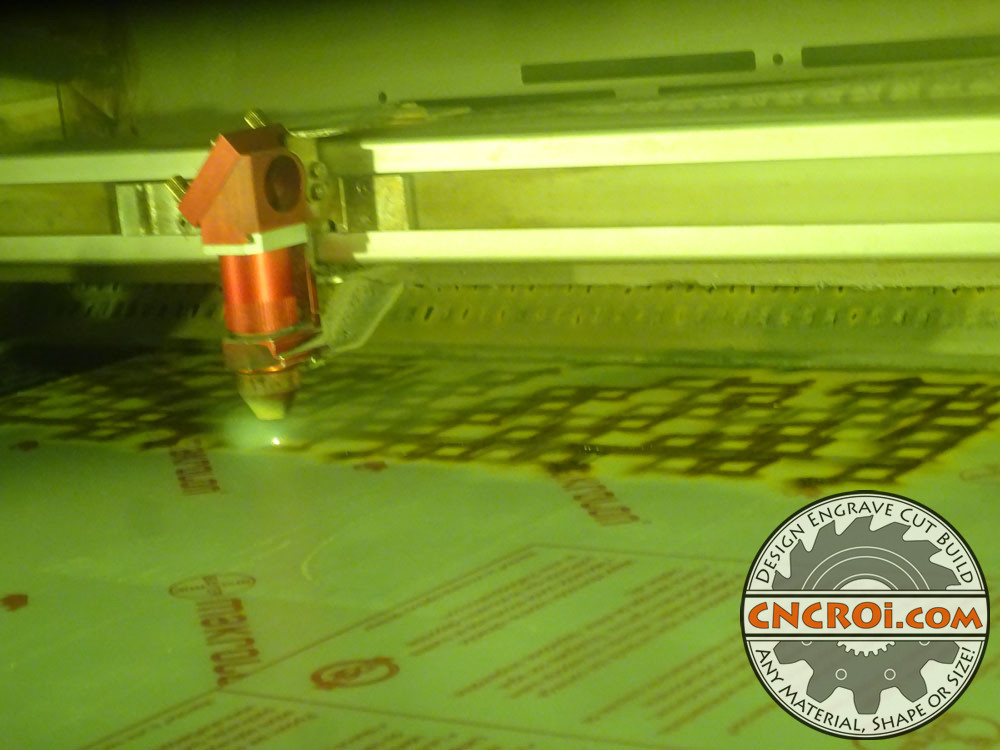

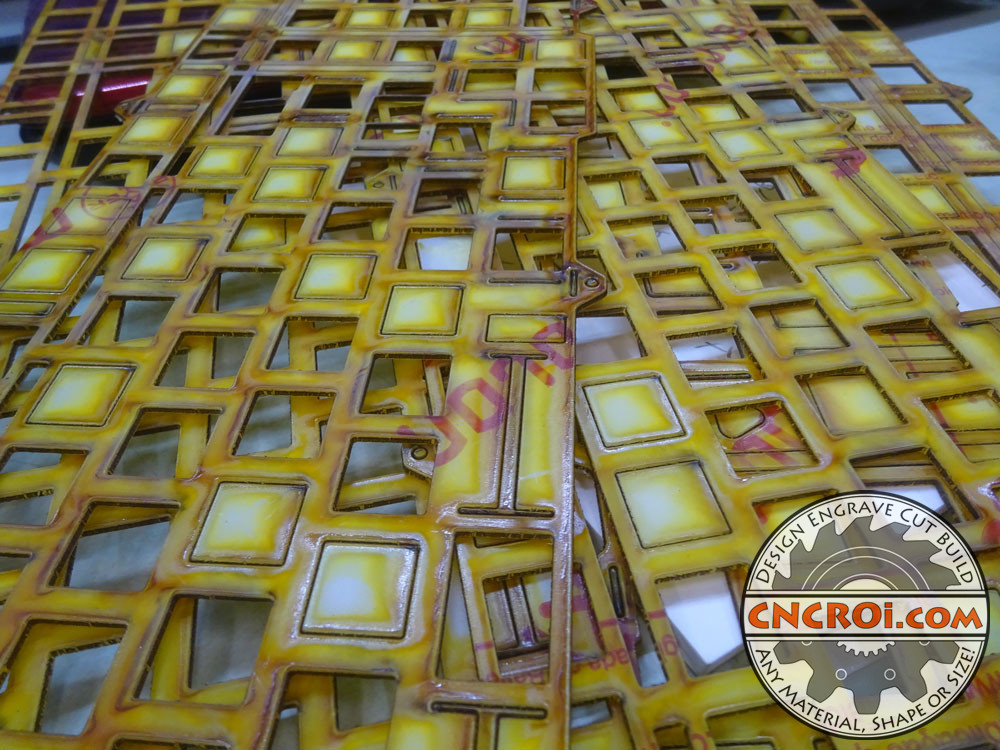

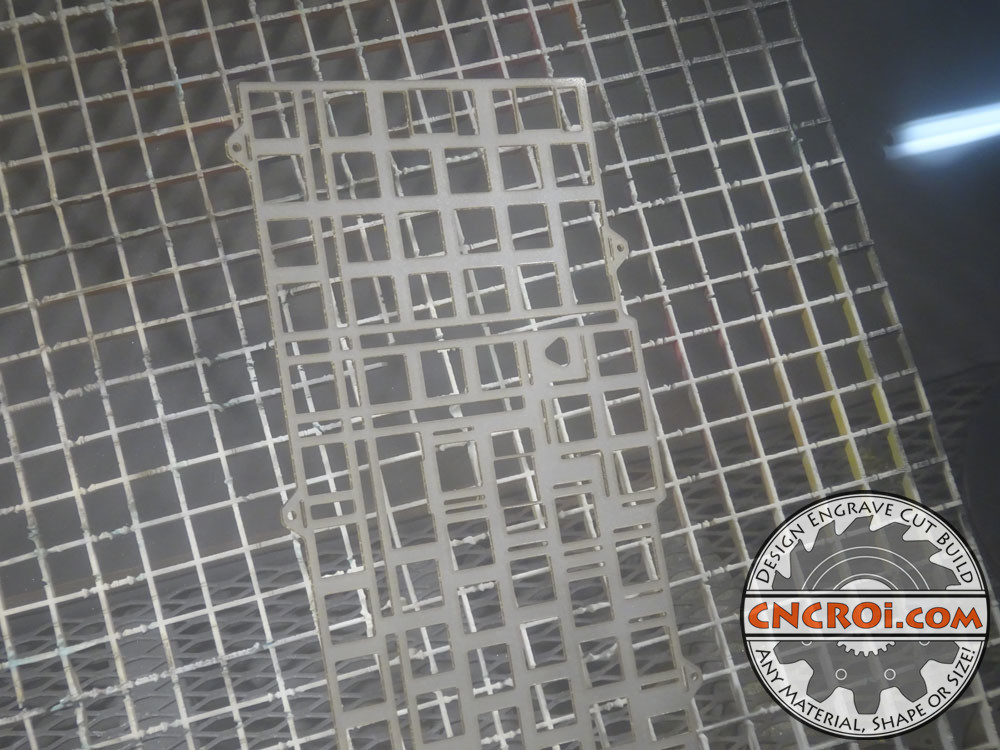

Looking at how ugly these custom polycarbonate intricate parts are right now int he picture above and below, you need to remind yourself that the optically clear polycarbonate is still there, it just has masking on the top and bottom surfaces, THIS COMES OFF.

For this specific job, we cut 0.06″ thick polycarbonate to the customer’s specifications, it didn’t just involve laser cutting it but also sand blasting to give it a nice frosty look while removing some of the burning on the edges.

Some more unique applications for polycarbonate included making custom wedding coasters… not something you see everyday!

The major advantage of polycarbonate when it comes to making parts out of it is that it’s completely clear, so clear, it’s considered an optically clear material… and it’s literally what’s used to make bullet proof glass, meaning it’s incredibly durable and strong.

So applications from protecting people from a dangerous industrial machine to anti-theft devices are wonderful uses for custom polycarbonate intricate parts, and yes, a lot of what CNCROi.com produces with this material ends-up being used for military and robotic applications.

Unlike metal or wood, this clear material can be seen through it, this is a MASSIVE advantage, thus, it’s generally the go-to material for applications such as custom stencils.

Both our CNC routers have cut a ton of polycarbonate over the years we’ve been in business.

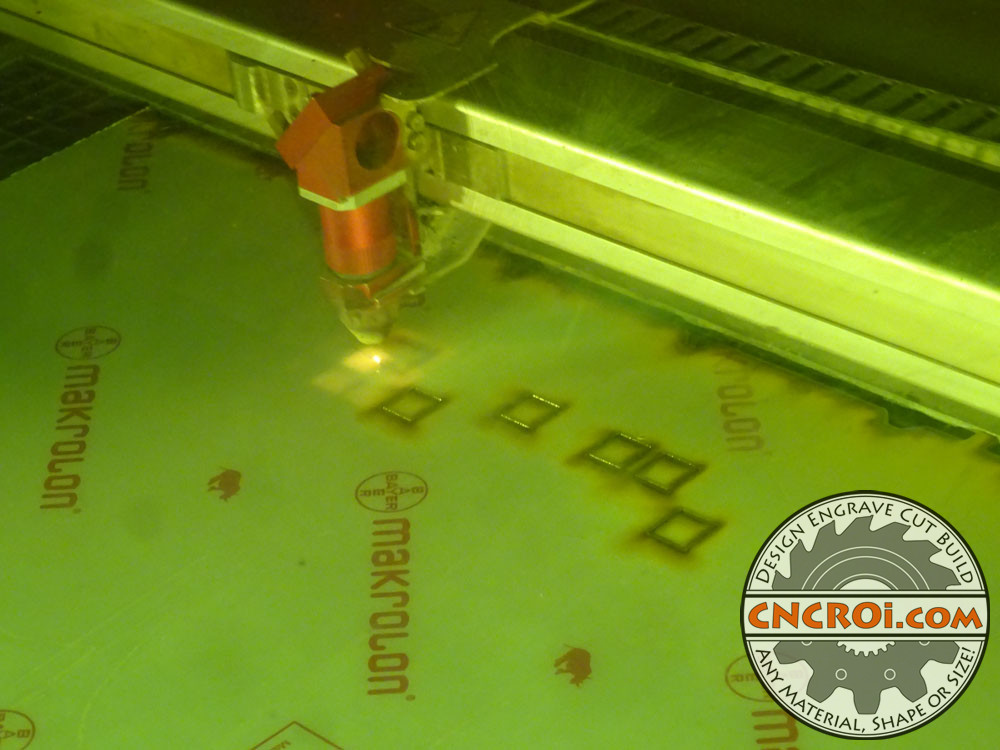

The major advantage cutting custom polycarbonate intricate parts using a laser is that CNCROi.com can cut far smaller details as we aren’t limited by a bit diameter as we’d be using our CNC router.

With thin material up to 0.06″ thick polycarbonate, our laser is generally the best way forward for making custom polycarbonate intricate parts with anything thicker having the CNC router win because this material holds heat and starts to warp from the laser heat.

The one application where CNCROi.com’s CNC router wins all the time is that of making pockets, meaning, we aren’t cutting all the way through the material.

Even highly detailed stencils can be made using polycarbonate, in this case, it’s 0.02″ thick.

On the other hand, the time our laser wins over the router all the time is when it comes to color changing the material, it’s something that can’t be done with a router and the results are permanent without the use of ink or dyes that will fade, crack or peel over time.

CNCROi.com has a powerful extraction system and air feeding system into our CNC laser, as a result, potentially dangerous smoke becomes not so much.

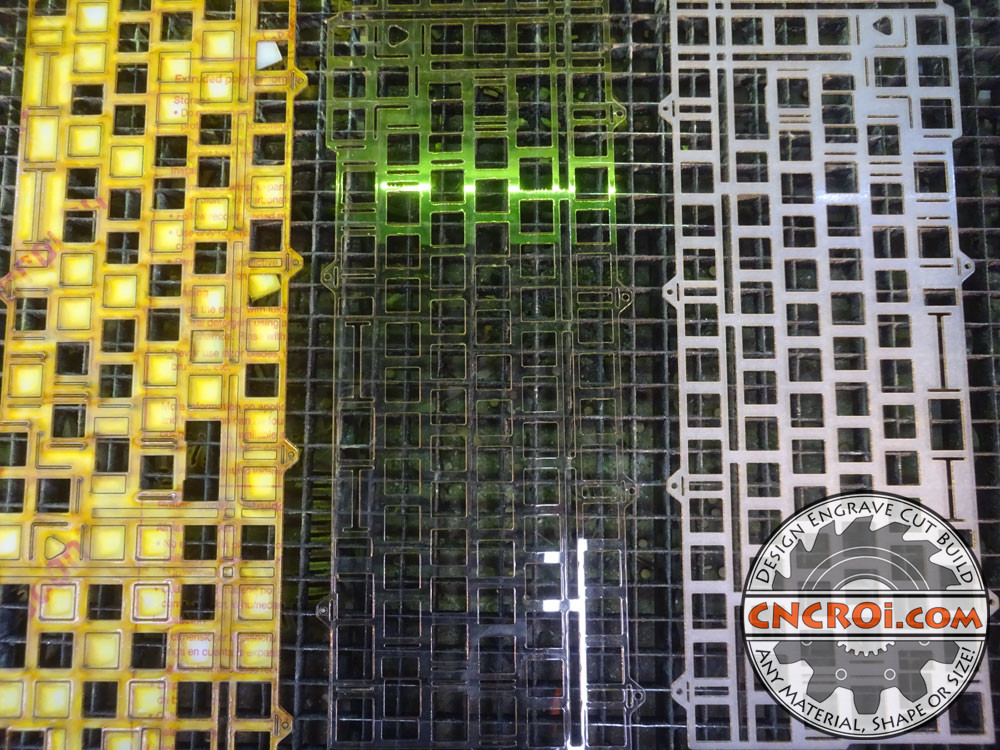

For this specific project, all the custom polycarbonate intricate parts are identical both in the virtual spec and the finished physical part made by CNCROi.com using multiple polycarbonate parts.

As we come to the end of this custom polycarbonate intricate parts production run, you can see that regardless of the first or the 20th, the laser works just as well, the repeatability is incredible and unlike humans, CNCROi.com’s machine will never get tired or bored from all the wonderful jobs we throw at it.

Stencils can be made at any size or shape using any design you can imagine when it comes to making awesome stencils for our customers.

You can see how rough these look right out of the machine, but again, this is all dirty masking, not dirty polycarbonate.

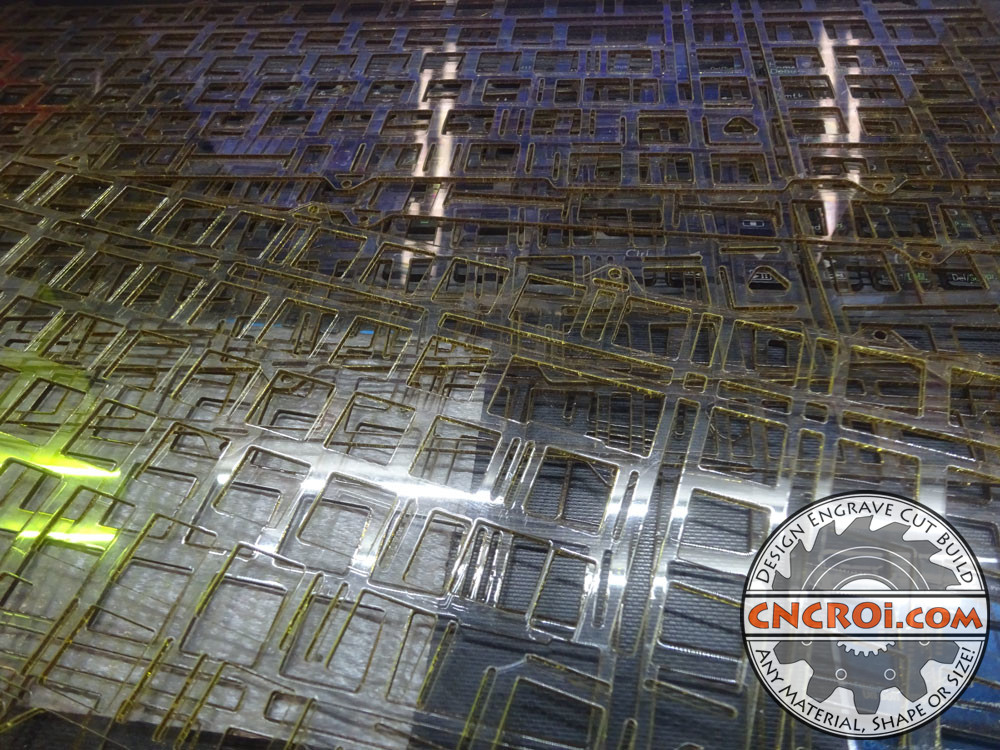

After the masking is removed, you can see how wonderfully clear the polycarbonate remains even after it being laser cut at CNCROi.com.

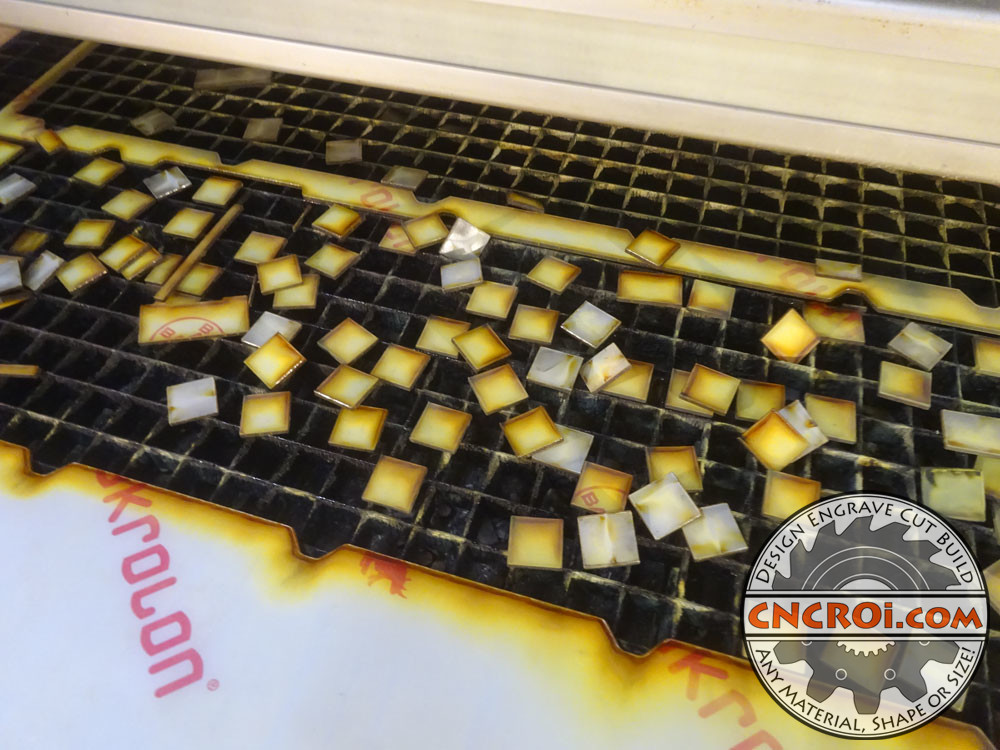

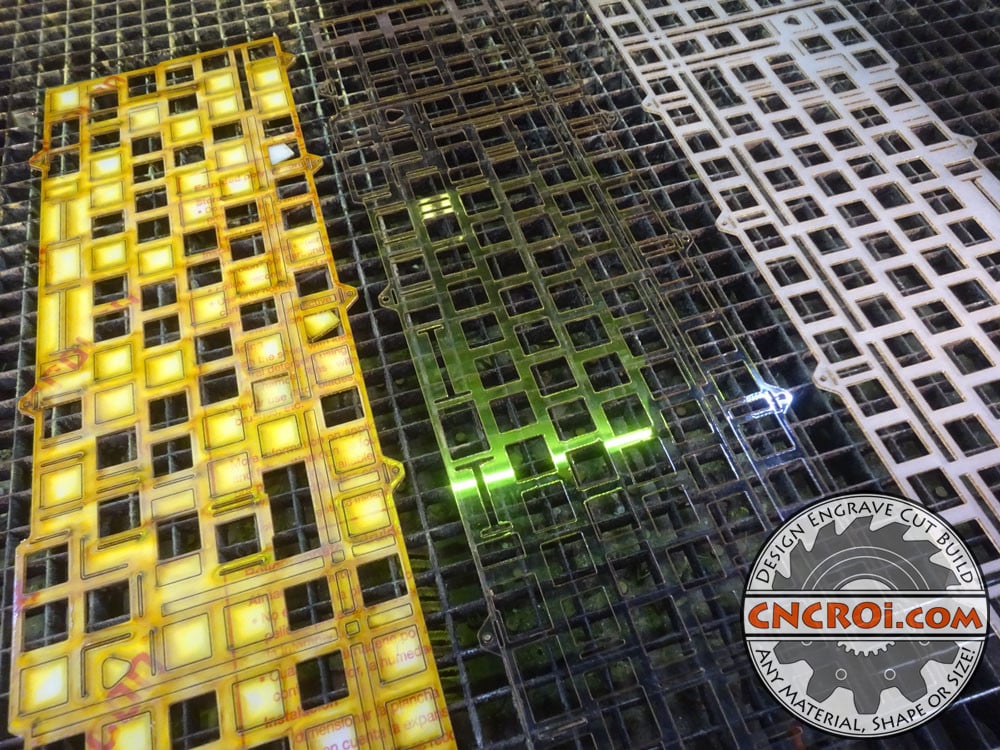

After the laser is done, it’s time to remove the masking on both sides of this polycarbonate so that it can be frosted using our industrial sand blaster.

Sand blasting is great fun, I’ve done a tons of it, even though I don’t showcase it too often here on the blog or in the videos, it does a wonderful job making the polycarbonate with a nice blasted texture to it.

Below you can see the progression of the custom polycarbonate intricate parts, laser to masking removal to sand blasting, I really enjoy sand blasting polycarbonate, it’s a whole new look and yes, CNCROi.com can make a mask to frost only specific areas, same idea like you see with glass.

From another angle, you can see how all the reflectivity and optical characteristics are GONE using the sand blasting on this polycarbonate.

Need custom polycarbonate parts? Contact CNCROi.com right now!