Custom Polycarbonate Window Fabrication

Custom polycarbonate window fabrication is something CNCROi.com does for both industrial, aerospace and manufacturing customers… as well as some promotional companies and of course, our sister company SandboxRanch.com.

https://vimeo.com/775650334/

Custom polycarbonate window fabrication is a great alternative to acrylic or glass because it’s extra durable, being used for bullet proof glass no less, and as such, for industrial applications, it’s generally employed to keep employees and customers safe from things that can go boom.

When it comes to aerospace, custom polycarbonate window fabrication from CNCROi.com is often employed because unlike glass or acrylic, it will not shatter and unlike those two materials as well, it’s optically clear, so clear in fact, that it’s what people use in shops all around the world for safety glasses!

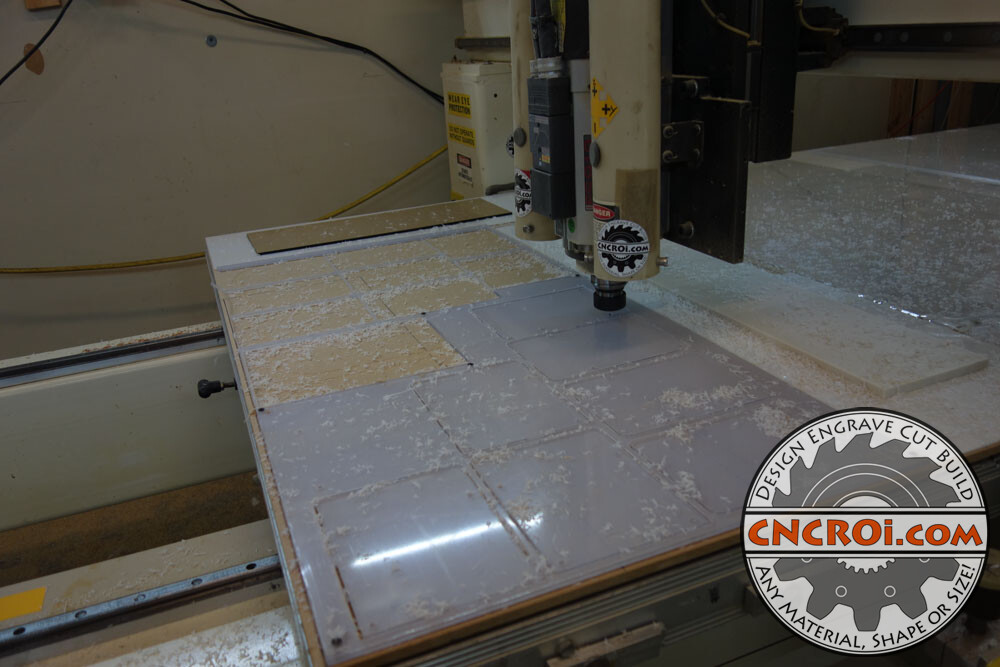

CNCROi.com has both CNC routers for thicker custom polycarbonate window fabrication and a powerful laser for thinner stuff or more intricate requirements, in addition to two fiber laser sources for actually permanently branding it, think QR codes, security or batch number identification.

Holes, chamfers, whatever details you require on your polycarbonate parts, CNCROi.com can produce them!

When it comes to custom polycarbonate window fabrication, we can literally cut and brand just about any spec you have in mind, short of vacuum or thermoforming capabilities, that’s a whole other ball game.

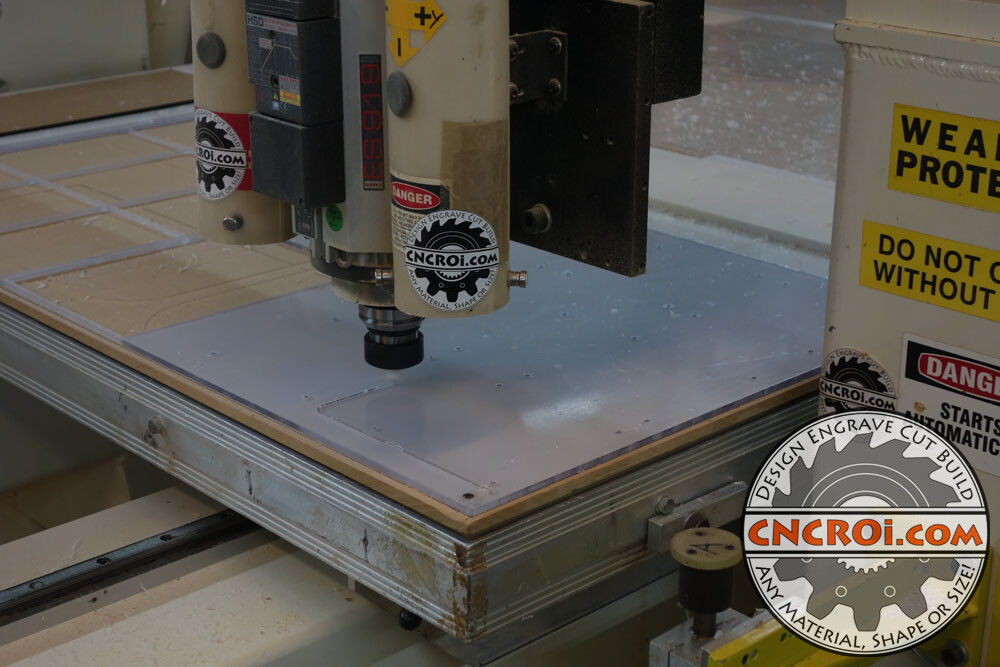

Having a tool changer has really been a game changer for CNCROi.com when it comes to custom polycarbonate window fabrication because it allows for a lot more flexibility when it comes to production methods that are optimal to the task our clients have given us.

Polycarbonate is a lot like stainless steel, it absorbs and holds onto heat, when we laser cut it at CNCROi.com, care must be taken to distribute the cutting process because otherwise, it will warp like an egg on hot pavement and yes, it can also catch fire.

If you are wondering what CNCROi.com’s laser can do with polycarbonate, check this out.

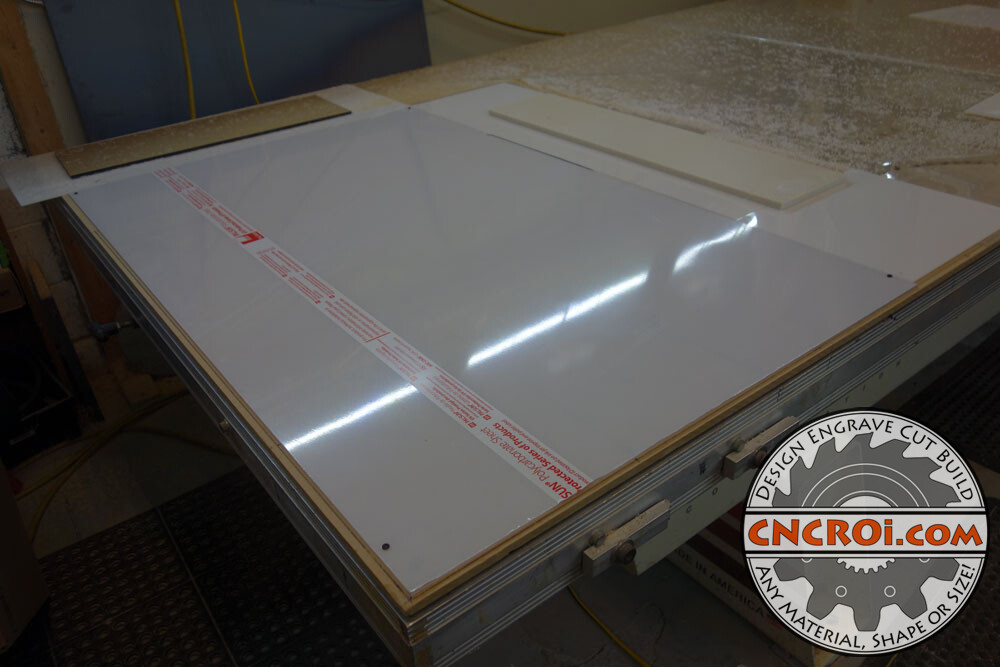

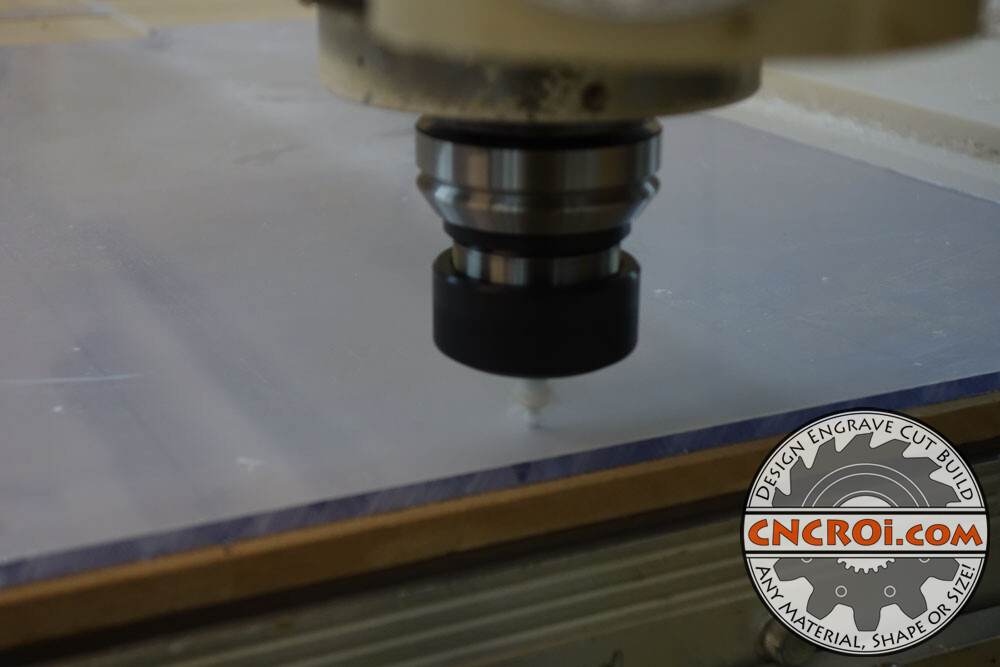

With our router, the challenge is a bit different in that it really does not like being cut, it vibrates, especially the thinner stuff and as such, just causes headaches if not a lot of caution and care is taken during the initial set-up.

You can see throughout the routing process that I’m actually pausing production to add more screws to hold it down as the vacuum quickly goes to junk as soon as you have a material that vibrates.

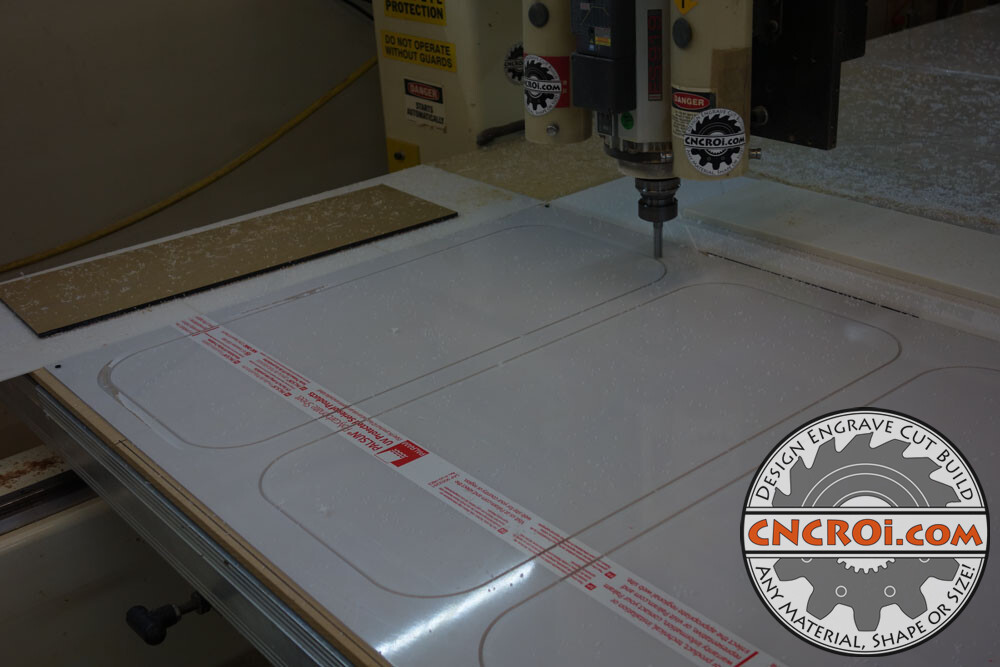

When it comes to what CNCROi.com can produce, there are very few limits, in the case of the pictures you see above and below this paragraph, we are adding a chamfer to the shape before cutting it out, we can also drill holes of various sizes and do other work in the part before cutting it out.

Custom jigs are also a wonderful use of polycarbonate, it’s durable, optically clear (transparent) and very strong against stresses.

One way to greatly reduce vibrations during the cutting process of especially thin polycarbonate is to take your time doing it, instead of trying to cut everything on one pass, do it across many, it reduces stress on the material and hence, less prone to moving around as there is less pressure on the overall piece.

The reason why I didn’t use the laser cut cut the thinner custom polycarbonate window fabrication was due to the chamfer, the at CNCROi.com can cut the chamfer and cut it out in one step while the laser can just cut and I’d have to manually router the edges to create the chamfer.

You’ll notice that there were no tabs applied to the thin polycarbonate windows, that’s because of the chamfer, so the vacuum was going full till to make sure that these did not move during production at CNCROi.com.

Fiber lasers do a wonderful job permanently branding polycarbonate, regardless of the thicknesses involved.

After these thin polycarbonate windows were finished, it was time to switch gears and cut thicker windows using polycarbonate no less.

For this specific project, a very small bit was used for everything as holes were needed to be drilled in them before cutting them out at CNCROi.com, multiple bits could have been used but I’ve used this very small diameter bit for this project before with great success so this journey continued the same way as before.

Especially true and necessary for polycarbonate parts, keeping everything as one solid piece as long as possible necessitates the drilling of all the holes FIRST before going ahead and cutting these smaller yet thicker custom polycarbonate window parts at CNCROi.com.

These will be sanded afterwards against another backing, so although there was some flex in the pieces you see during cutting, it didn’t affect the specs of the final part as lots of give was given to these, unlike the thinner polycarbonate windows that had to be dead-on from the get-go due to the chamfer.

Thin polycarbonate is wonderful for stencils, I use them at CNCROi.com for internal use as well, highly detailed, works great and crazy durable as well.

Since upgrading to my Thermwood CNC router, I’ve been thoroughly impressed by the capabilities it has brought to CNCROi.com, the rigidity of 12 000 pounds is just astounding.

As this round of custom polycarbonate window fabrication finishes-up, it happens that we had two different jobs using this material at different specs at the same time, I hope you gained an appreciation of what we can do for you.

You saw in the video, me, pausing the machine to put more screws into this custom polycarbonate window fabrication sheet, this was because I was quickly losing vacuum power on my table as more and more of this project was being cut out.

Need custom polycarbonate window fabrication? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=DFxPxVDa9GI/settings