Custom Steel Fire Pit BBQ Grill

When it comes to custom steel fire pit BBQ grill production, CNCROi.com is here to make your dreams a reality!

https://www.youtube.com/watch?v=Ln9EXslzc04/

If this looks familiar, it’s because this is the second prototype, which is now ready for production, of a custom BBQ grill we made a few weeks back for review and testing, here’s a picture of that so you can see it more clearly.

And here’s the video of the first prototype which you see a picture just above this sentence.

https://www.youtube.com/watch?v=nqGlD94761c/

Now onto prototype V2 which is ready for production, using the same 12 ga 304 stainless steel as our first version, but this one has been heavily modified to almost completely reduce the chance of warping and a far stronger overall grill design as well.

Although this custom steel fire pit BBQ grill looks very easy, there has to be a lot of thought put into it to make sure not only is the grill and durable (hence using stainless steel over mild steel) but CNCROi.com also cares about esthetics and most importantly, strong enough to take-on lots of heat and cooling cycles that will happen with anybody using this for their recreational enjoyment.

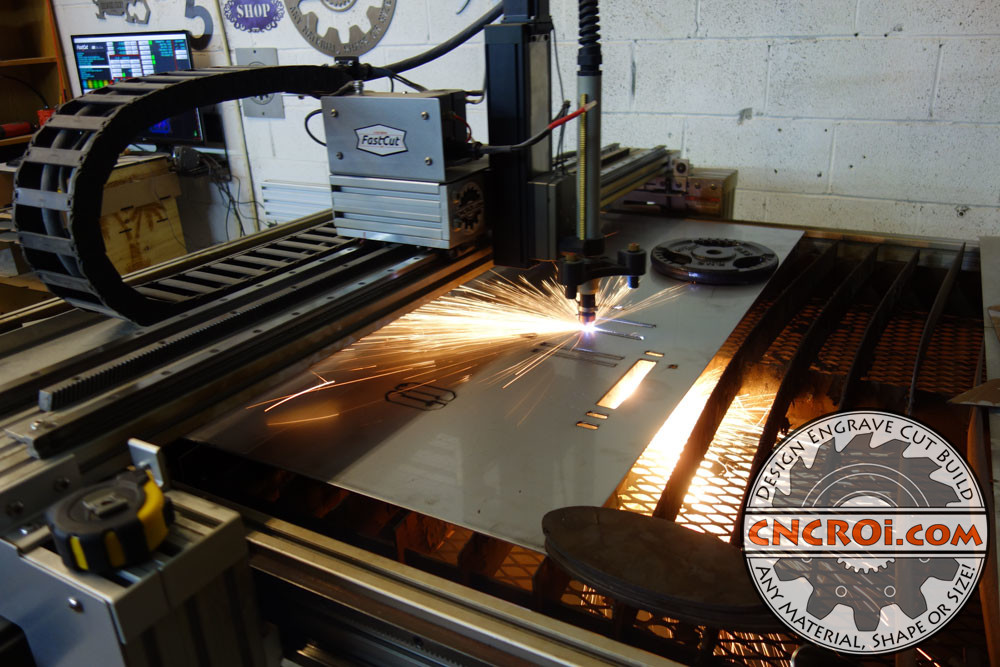

When it comes to plasma cutting, it has really become my tool of choice for this specific type of project, it’s fast, it’s accurate and it makes lots of sparks… a winning combination when it comes to making custom steel fire pit BBQ grills in my book.

Of course, CNCROi.com mixes and matches processes all the time, it’s great having multiple CNC platforms in the shop.

https://www.youtube.com/watch?v=VAasMmiPvy8/

Unlike most of the work we do here at CNCROi.com when it comes to custom metal fabrication, BBQ grills have a special place in my heart because I love having fires and cooking on them in the backyard, being able to share this passion with others is just amazing!

In the photo above, you can see the instant the arc is created by our CNC plasma cutter at CNCROi.com, this will then convert immediately into a massive jet of plasma that will melt the stainless steel as it passes over it.

When it comes to your design options for your very own custom steel fire pit BBQ grill, they are utterly endless, you want it thicker? No problem! You want it bigger or smaller? No problem! You want this to be made using mild steel that you then need to season and clean pretty often, no problem!

When it comes to custom steel fire pit BBQ grill, feel free to go nuts as to what you want and how you want it, regardless, CNCROi.com will cut it, clean it up and ship it right to your door!

We also do a tremendous amount of etching, everything from aluminium to stainless steel.

https://www.youtube.com/watch?v=rWeM9-VUOII/

The advantage of CNCROi.com is that all we do here in the shop is custom, there is nothing typical about our production cycles, one moment we are making custom steel fire pit BBQ grill, the other a live edge wooden table and the next, etching endless widgets for industrial or medical businesses.

By far the biggest change between V1 and V2 of this prototype BBQ grill is the spacing, there are a lot less holes but more importantly, the space between those holes has been increased, this means that there is a lot less heat generated during production into the stainless steel itself and as there is more metal “there”, it’s also far less prone to warp at the same time.

A more subtle change you will only notice if you compare the two videos V1 vs V2 is the cutting order, you’ll notice in the first video of the custom steel fire pit BBQ grill production that the cuts are pretty much happening one next to the other while the second version, they are widely spaced, again, it’s to reduce the chance of heat build-up which leads to warping in one area of the BBQ grill while not in the other.

Even production means even results, and CNCROi.com is really getting into gear optimizing files specifically for the plasma cutter as we get into more complex jobs that require a lot more attention to these small details.

As we work in many different fields at the shop, it’s great being able to offer the same to our woodworking customers who aren’t into metal fabrication but need a little custom metal for their jobs.

https://www.youtube.com/watch?v=IUZfyH1IcYI/

There is no “plasma cutting school” or “CNC school” for that matter, the way I began and continue to learn at CNCROi.com is by buying the machines and more importantly, learning from my mistakes to make things better each and every time… after a while, things get so refined that we can produce what other shops cannot as all we do is custom work for clients across North America, and Europe.

The design of this custom steel fire pit BBQ grill has been modified endless times to try to make something aesthetically pleasing, which is important, durable, hence using stainless steel and hopefully something that can be passed onto future generations… stainless steel is that tough!

How “hot” is plasma cutting? Well, you can feel the heat of the arc during heavy duty cutting and you can’t touch this stainless steel right after production, it needs to be left to cool itself down!

Heat isn’t a bad thing though, you may be wondering, if you know a bit about plasma cutting, why CNCROi.com didn’t get or use a water table to keep the metal cool during production, the reason is simple, it doesn’t cool things down and causes a lot of secondary issues, like a lot of clean-up and a mess in the shop for no real benefit.

Most of our work is industrial marking and tagging, here’s a great example of that, using stainless steel no less.

https://www.youtube.com/watch?v=kpTA718xa5I/

When it comes to plasma cutting metal, an air system shooting air down onto the work and around it is by far the best process for this level of production, of course, there are more advanced plasma cutting systems that do employ water strategically, and those are awesome, but at this point at CNCROi.com, that massive amount of expense, that has to be passed-down to the customer, just isn’t required for this level of work.

It always blows me away just how much heat and power our CNC plasma cutter generates, you can see a solid flame shooting right down and the metal is nothing but an inconvenience to the arc!

As with all our other machines at the shop, we always do the inside parts followed by the outside, to keep everything solidly one piece as long as possible, this custom steel fire pit BBQ grill is no different in that approach.

Of course, I like to have a little fun at the shop too.

https://www.youtube.com/watch?v=fsXTxcW_juQ/

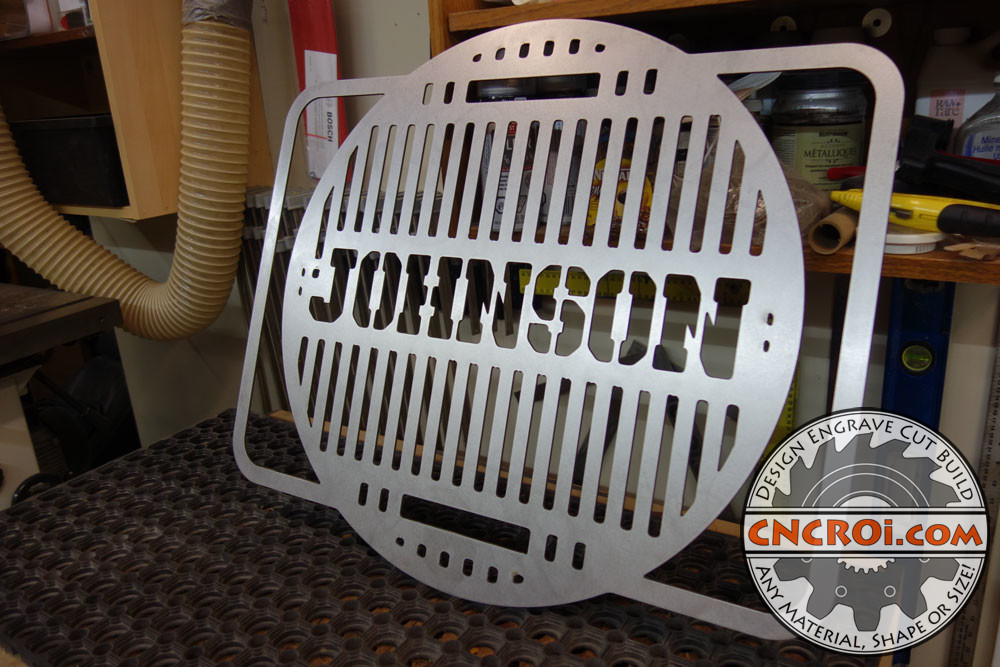

The results produced at CNCROi.com are very clean, the dross is minimal on the underside and you’ll notice that all we do is give the finished custom steel fire pit BBQ grill a light sanding before we ship it out to the customer to enjoy.

When it comes to what CNCROi.com can offer your business or family, it’s absolutely totally custom production, you will not find another grill like this one, unless you are very lucky to receive one… gone are the days of mass produced garbage that has an inferior build quality and horrible durability, we focus on getting is amazing the first time and having it last a very long time.

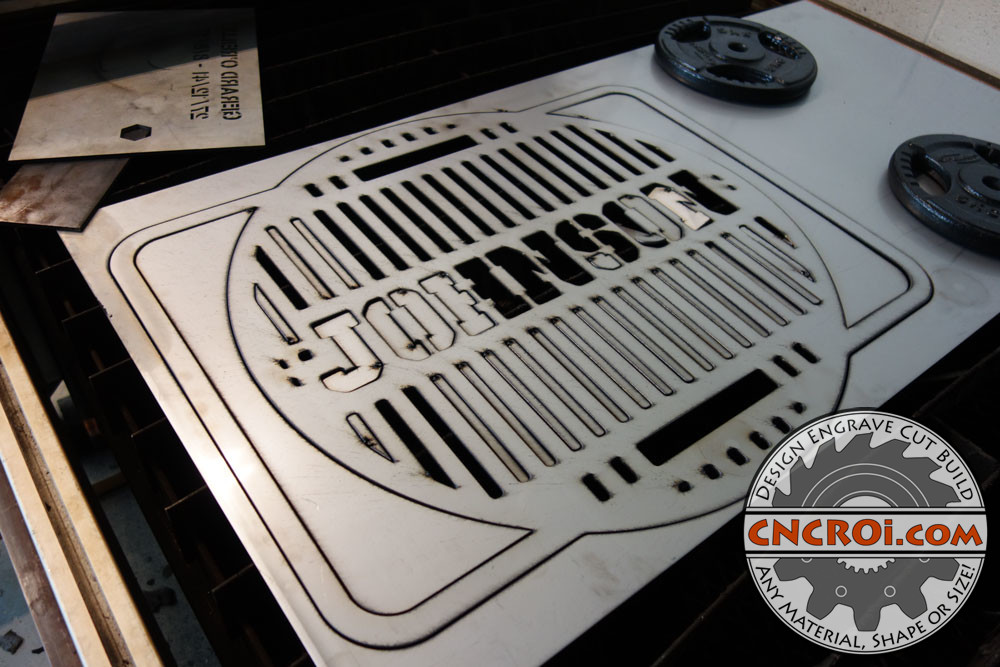

You can now see the cutting out of the custom steel fire pit BBQ grill from the stainless steel, once everything else is taken care of, this is the last step involved with liberating this awesome project to be customer ready!

You can see in the image below just how fantastic this custom steel fire pit BBQ grill is looking.

Anything can be made at CNCROi.com – BBQ grills to Klingon weaponry!

https://www.youtube.com/watch?v=W1eJ0VT8wWM/

Next step is the clean-up, after taking the custom steel fire pit BBQ grill off our plasma cutter, the next step will be to sand it to remove the dross and mill scale on the 304 stainless steel.

And here’s the finished product, looks fantastic, it belongs in a museum, not a fire pit, but that’s how CNCROi.com does production!

Need a custom steel fire pit BBQ grill or a thousand? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=DxHyaObcZjs/