Custom Stencil Materials: Polycarbonate, Plywood & Mild Steel

There are a lot of options when it comes to custom stencil materials, let’s review the ones CNCROi.com does the most volume with.

Each material has a + and – associated with them, some can be perfect for one application but horrible for another and as such, let’s review the costs and benefits of three materials we use a lot of in the shop, polycarbonate, plywood and steel.

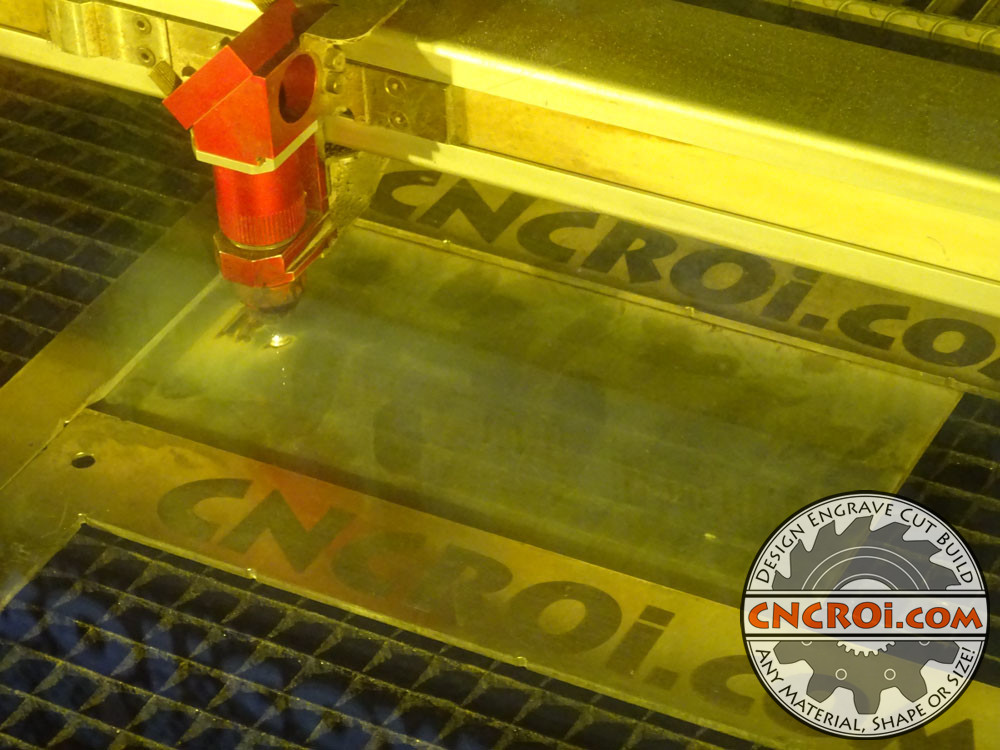

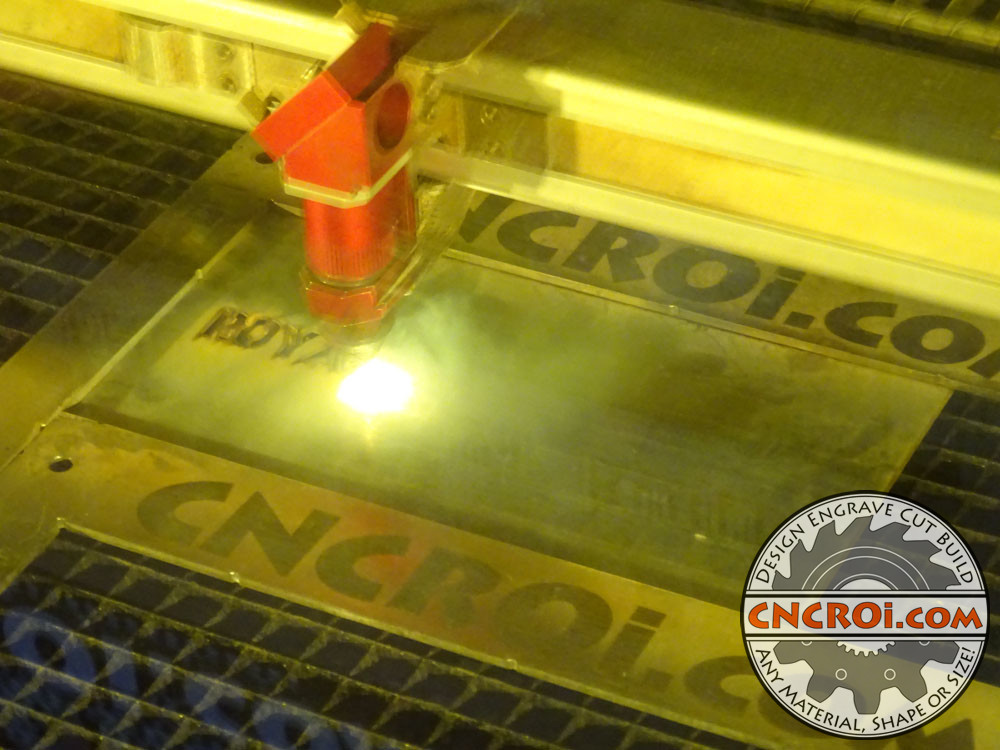

Polycarbonate is a wonderful custom stencil material, it’s incredibly light weight, can be rolled-up for big stencils after use and is optically clear so you can see straight through it without any distortions.

I tend to shy away from paper stencils, they are very cost-effective stencil material wise but production costs are the same as polycarbonate, so might as well go for something you can use multiple times and clean rather than an exclusively one time use.

The reason why it’s generally my go-to material in the shop for both customer projects and my own at CNCROi.com is because you can see through it, positioning is so easy when you can see everything you are working with but it does have some drawbacks.

The biggest drawback of polycarbonate is that it costs a lot of money so if it’s a one time use stencil, something like cardboard or plywood is way better than polycarbonate but if you have something you’ll use annually, or on a regular basis, this should also be your go-to stencil material.

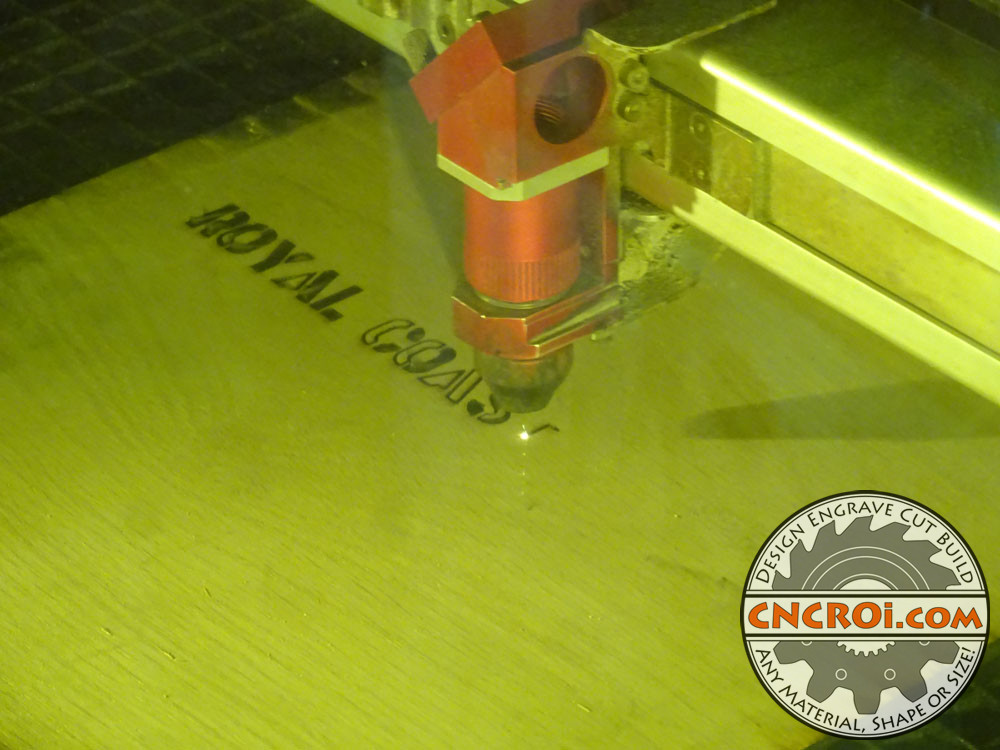

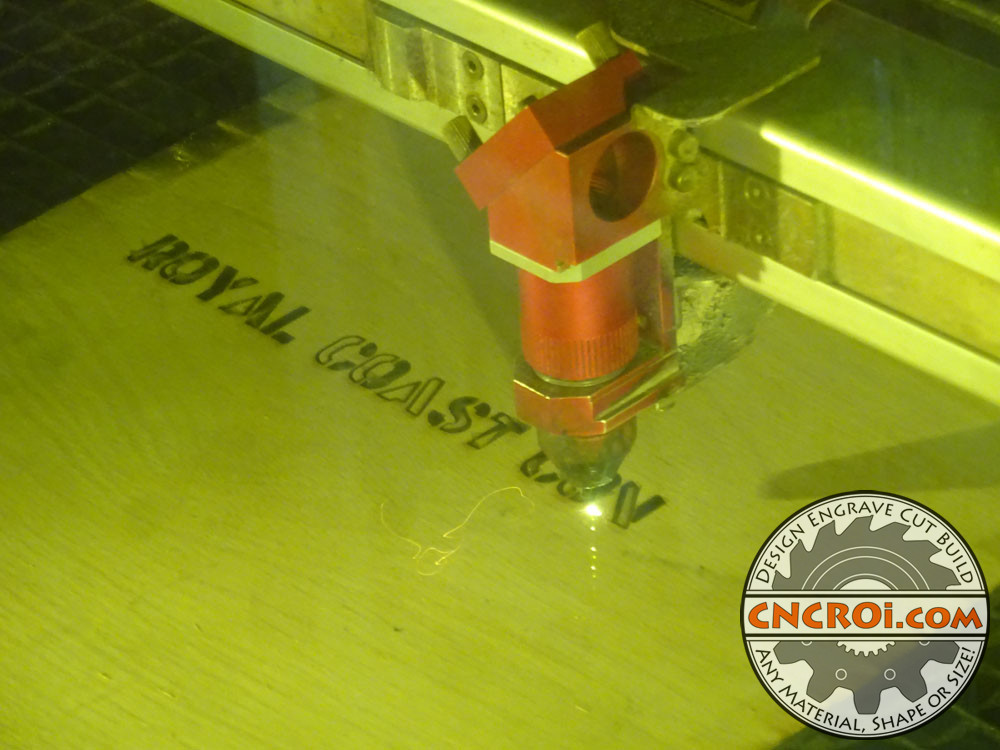

When it comes to plywood vs polycarbonate, each has their costs and benefits, want something rigid without the weight or cost of steel? Plywood wins hands down!

Polycarbonate can be had in half-inch thick down to a fraction of an inch, in the thinner thicknesses, it’s also very flexible so if you have a wall that has lots of curves then this wins big time because you can make it hug it over a stencil material like steel that’s rigid.

Polycarbonate material is also very light weight, it’s easy to affix to a wall using duct tape and shipping again, very light weight so you are paying for volume more than materials when CNCROi.com ships it right to your door.

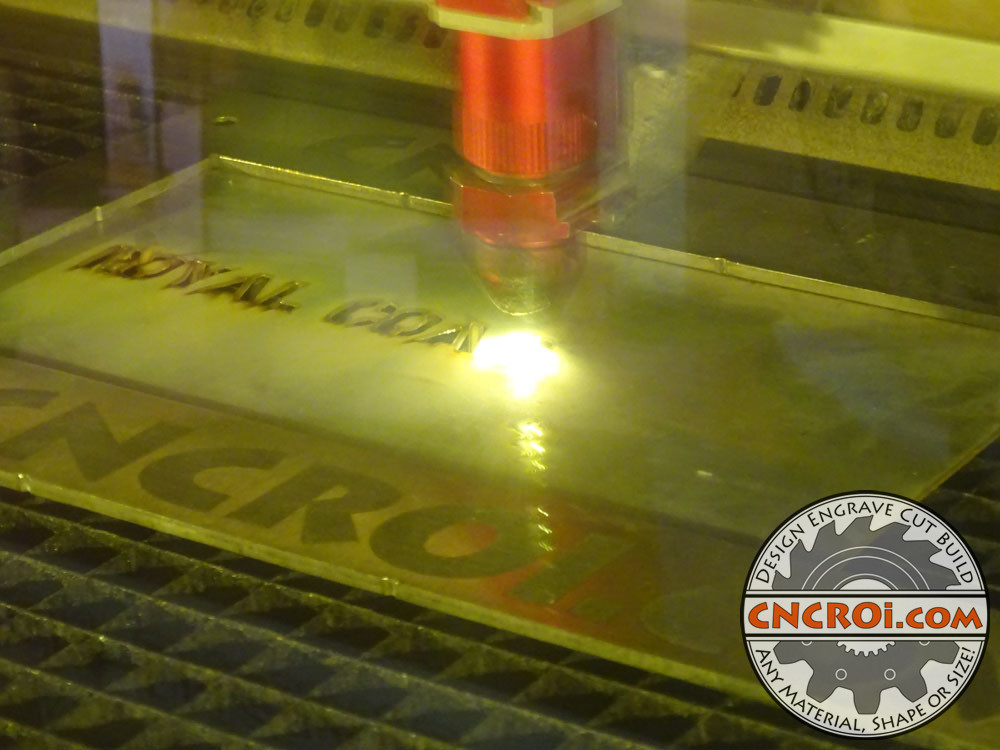

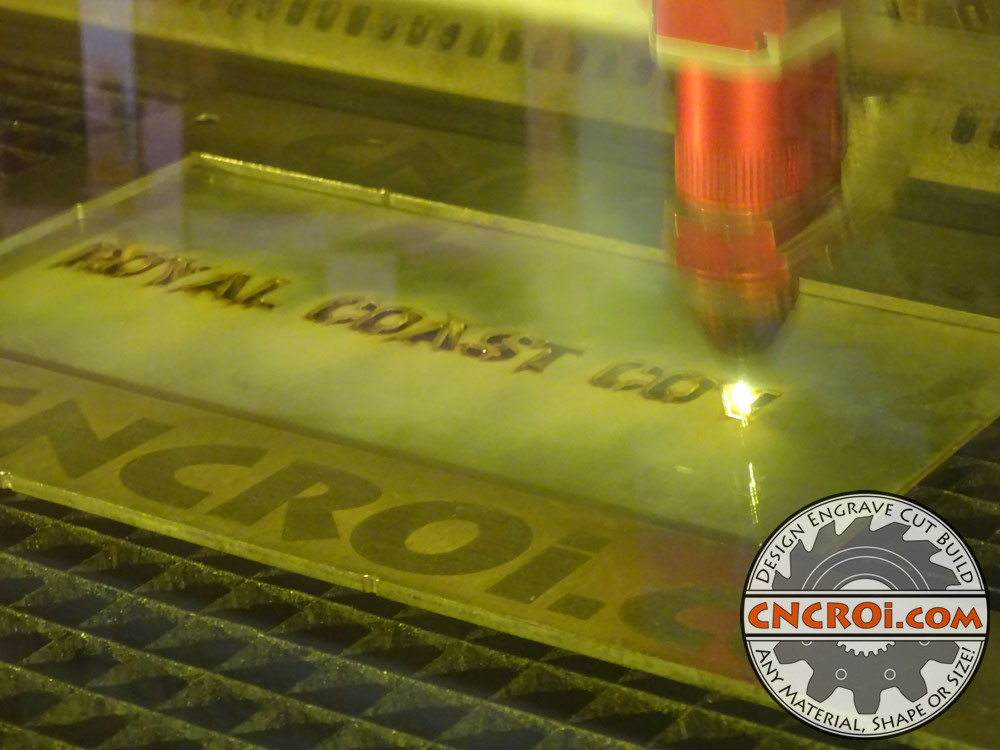

This is a great example of the clarity that polycarbonate gives you when it comes to custom stencil fabrication, quite a contrast from the plywood above that’s rigid and opaque.

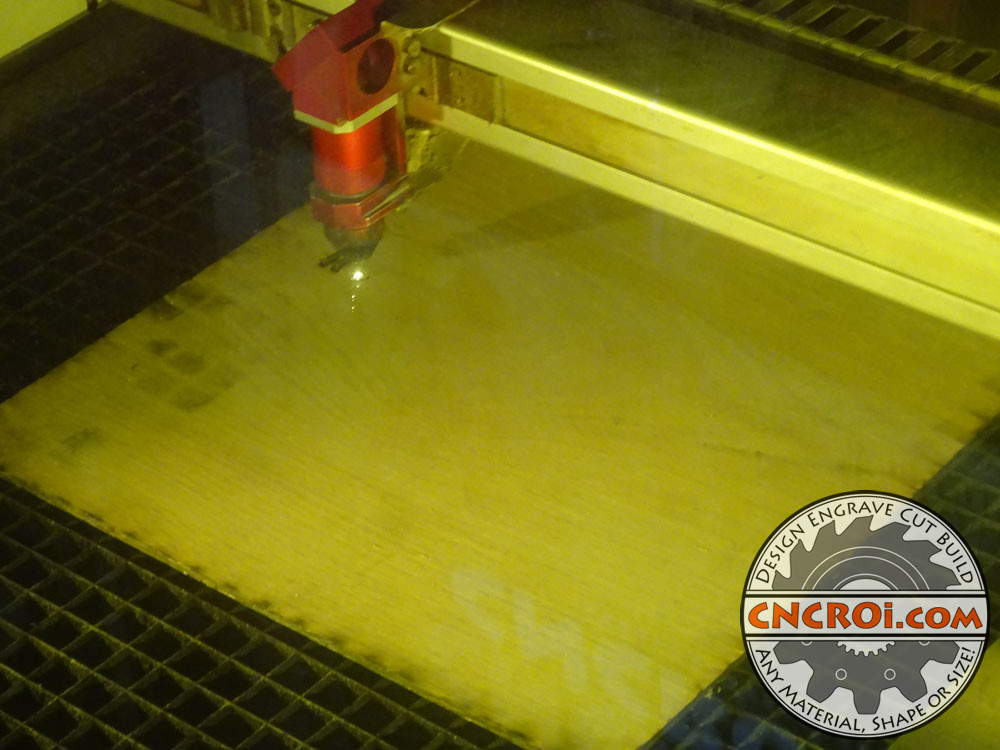

Plywood stencils are a bit of a different animal, they are rigid which isn’t a bad thing, it all depends on your stencil material application, so a hard surface like a sidewalk, this is great because you can just drop it in place, spray away and lift it up and repeat.

Polycarbonate is plastic so you can easily wash it after use, plywood is a bit of an endeavor and so it’s best for volume one-day use as paint slowly builds-up on where CNCROi.com cut the holes out for your stencil.

When it comes to design options like fonts and imagery, there is no difference in tolerances generally speaking between these three or most other materials, same rules apply of leaving enough stencil material to hold the inside parts of p, b and so forth along with room around the stencil to tape or affix it to whatever you are stencilling.

When it comes to font sizing, bigger is always better, same goes with imagery as this is a stencil you plan on having people notice, so make it as big as your budget affords.

Like other projects I take on in the shop, I never get tired of making them, it’s just so much fun working with a huge diversity of materials for applications far and wide, everyday in the shop is different with its own challenges and accomplishments.

Here’s a comparison of plywood and polycarbonate, both wonderful stencil materials to work with both in the shop when CNCROi.com makes them for you and you to use at your end with spray paint.

These two designs are identical cut files, the dirtiness you see around the polycarbonate is on the masking on both sides, it comes right off or better yet, use it, then remove the masking and you got a fresh clean stencil for the next use!

Whether you want custom stencils made out of a super heavy-duty material or something very fragile, CNCROi.com can make it for you and ship it right to your door!

If you are looking for something that can take the heat of a torch to burn your stencil into wood or pallets, mild to stainless steel is the way to go for stencil materials options available to you by CNCROi.com.

The only real difference between mild steel and stainless steel is raw material costs when it comes to custom stencil production, if you don’t care about rust, then it saves you a bit of money as the cut times for the CNC waterjet are about the same regardless of material type and aluminium is a little faster BUT material costs are higher.

The major advantage of doing a custom aluminium stencil is its light weight compared to its steel cousins, but if you don’t care either way, I’d suggest going with stainless steel overall, it costs a little more but esthetics are nicer and no clean-up is required if you don’t use it often in the shop.

Unlike polycarbonate or plywood, steel stencils aren’t combustible, so you can throw your blow torch on it and burn the underlying material without affecting the stencil in a safe and cost-effective manner.

Around the end of the video above you can see me using the dragon stencil I made to burn a piece of press wood with the stencil design, it was great fun!

When it comes to design options, again, regardless of materials, pretty much anything works as long as it’s supported, as it is a stencil after all and parts that aren’t held in place will fall out.

I really love making metal stencils, it’s a dirty and loud process but the results look amazing and the feeling is something substantial in your hands, which is why it’s also a great material for corporate awards and other custom metal projects CNCROi.com takes on.

Need a custom stencil, any size, shape or material? Contact CNCROi.com right now!