Custom Thick UV Printing Jig

This is a custom thick UV printing jig, made from laminated MDF in order to achieve the customer’s desired thickness to hold their parts.

Our thinnest UV printing jig are about 1/16″ and this so far, has been our thickest though we can make these up to 9″ and possibly thicker if required using various fabrication techniques at CNCROi.com.

The general process of making custom thick UV printing jig involves first making a prototype, I don’t want to make junk at CNCROi.com so it’s always better for the customer to test things out on a smaller version of their future BIG jig to make sure everything is calibrated correctly.

Making a custom thick UV printing jig is very much a team approach, the customer has the part, we have the technology to make a jig to hold said part, but there are X, Y and Z tolerances that need to be worked-out and as a result, you want to make sure everything works at the correct tolerances before going into full-on production from both shops.

Have something bigger that needs to be assembled for your production to keep it manageable, yep, we make puzzle based jigs as well!

Before even making a prototype of this custom thick UV printing jig at CNCROi.com, we have to make the laminated MDF block which will be machined down into the massive jig once everything dried.

Each layer of this laminated jig is 5/8″ thick and after the initial glue-up, I also added two more layers, one on both sides, of roughly 1/4″ MDF in order to just add a little more thickness to be machined down into the completed jig.

There is A LOT of glue involved with the fabrication of this custom thick UV printing jig, each layer must be fully bonded, as such, I prefer to use to much rather than enough glue, just to make absolutely sure there are no voids in the jig.

If there is a void in the laminated MDF jig, that can most certainly affect many aspects of this custom thick UV printing jig because you may not have a machined flat surface to put your part into, you can have issues with vacuum or mecanical hold down strength and in addition, a void just looks bad and can affect the longevity of the overall jig.

We can make multi-colored jigs as well, using acrylic or more durable materials such as delrin and HDPE.

The overall process of making this MDF block takes about a week, I like to make absolutely sure that ALL the glue is completely cured, and as oxygen is needed for this process to occur, the middle of the block will be the last part of the jig to fully cure.

So, even if the outside edges of the glue-up are completely solid, it doesn’t mean that the inside parts are in the same state, so waiting a week assures this.

The biggest issue with glue not being fully cured is that the overall block isn’t “set” until this happens, there can still be some warping and other dimensional issues after the fact, as such, I may be able to make the custom thick UV printing jig to perfect spec but if the glue is still hardening, it can throw everything out of wack, however minimal, affecting the use of this jig by the CNCROi.com customer.

To give you an idea of context, the block was a little over 3 1/2″ thick when it was first glued-up, by the time I’m done, it loses about a half inch (roughly quarter inch from both sides), those drill holes you see going all the way around, are through the jig at 3″ depth.

With endless jig options, we are your one stop shop for all your UV printer jig needs.

This is why you see me use very long half inch diameter bits to fabricate certain aspects of this custom thick UV printing jig, this isn’t as easy as it sounds, you need a very powerful and rigid CNC router with almost no harmonics to achieve a good cut through that thick a material.

This is why CNCROi.com‘s CNC router uses HSK63 tooling, which holds bits tighter and “straighter” with a lot less harmonics in the bit itself which can cause shifting as it spins at the RPMs we use with our Thermwood CNC router.

You can see the dried glue along all the edges of the custom thick UV printing jig, the aesthetics of this might not be nice but this block is oversized on purpose to account for this so it won’t be part of the finished jig anyways.

Machining MDF is a straight forward process at CNCROi.com, there are lots of bits available and as such, lots of options available when it comes to machining it to suit just about any design parameters you may have.

Whether you want a one-off custom UV printer jig or something that will last years, we can make it!

Of course, there is a lot of dust generated during the fabrication of this custom thick UV printing jig, MDF expands quite a bit during the machining process, unlike chips, so this looks a lot “worse” than it looks as it’s just puffy clouds of MDF.

All this dust building-up on the top of the jig has no affect on the finished product, the big easily pushes it away and the strength and abrasion that MDF has dissapears once it goes into puffy cloud mode.

This dust is very fine and light, so it’s easily vacuumed-up for a quick clean-up before shipping this out to the CNCROi.com customer who will be using this jig for their products.

This custom thick UV printing jig is meant to be vacuumed down by their UV printer and there are additional screw holes all around to affix this to their bed and to make sure that everything is square to their files and bed.

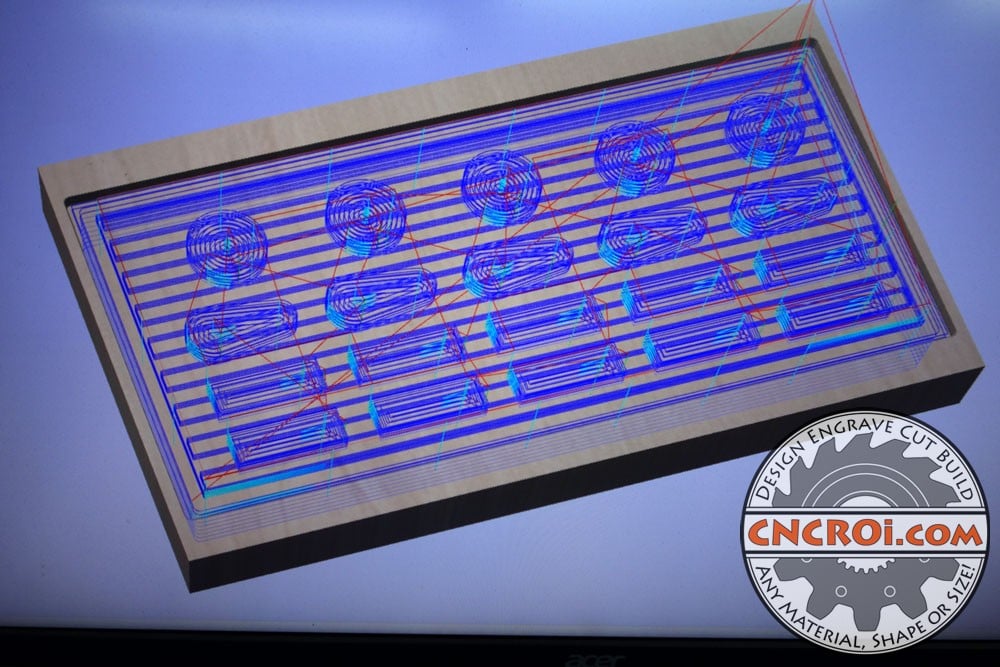

The digital file gives you an idea of the heavier machining that’s required where the customer’s parts fit into this jig.

Need a custom thick UV printing jig? Contact CNCROi.com.