It’s About Customer Service: Cracked Pine Blessing Exit Sign

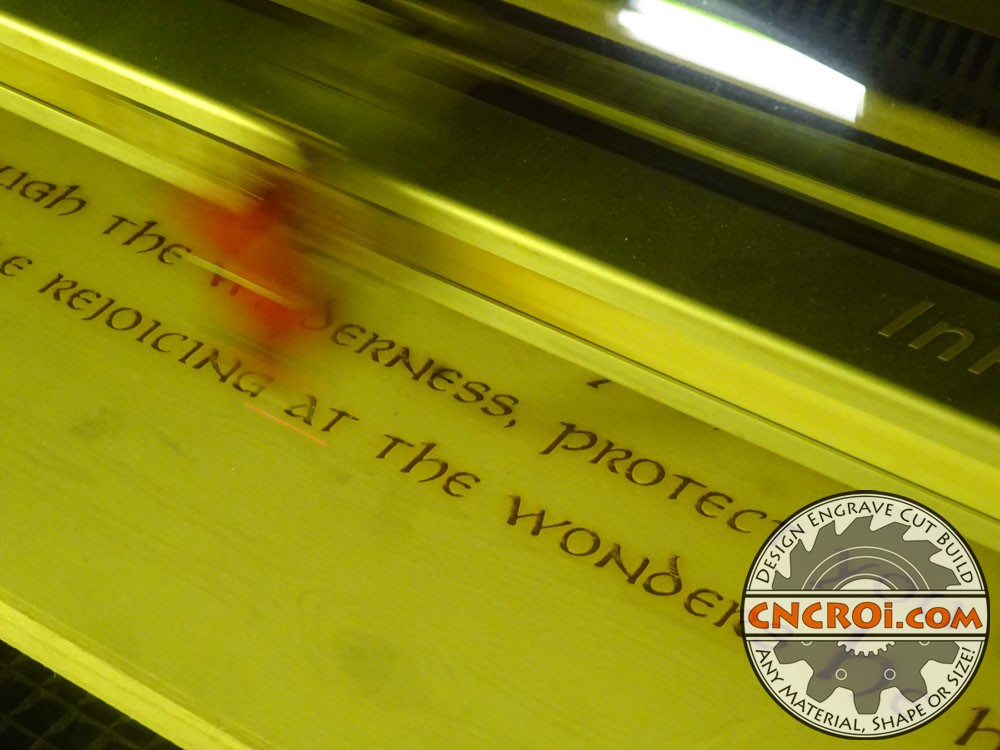

CNCROi.com is all about customer service, from our industry leading flat-rate pricing and general 24 hour turnaround to fixing things when they don’t go to plan and today, we’ll review a project I did last week that tracked in shipment and what we did to fix it ASAP!

To me, running a custom fabrication shop is pretty intuitive, a customer needs something made, so you make it and ship it out.

Most of the time, the entire transaction goes very smoothly, payment through deliverables but sometimes, like this Pine Blessing Exit Sign I made, it got broken during shipment and so, I had the opportunity to do this one-off custom Pine job again.

You may say its odd that a problem becomes an opportunity but that’s the way I see these, it’s easy to be amazing when things are going well but it’s not when things go South so that’s really my only opportunity to prove to my customer that CNCROi.com was and is worth the investment for their custom fabrication job.

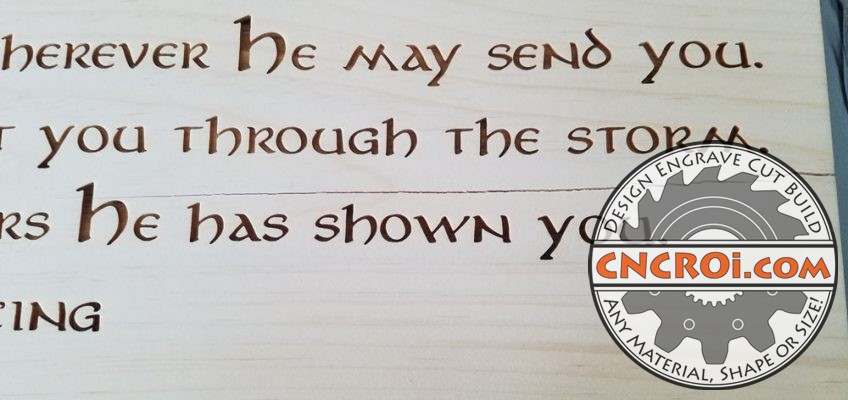

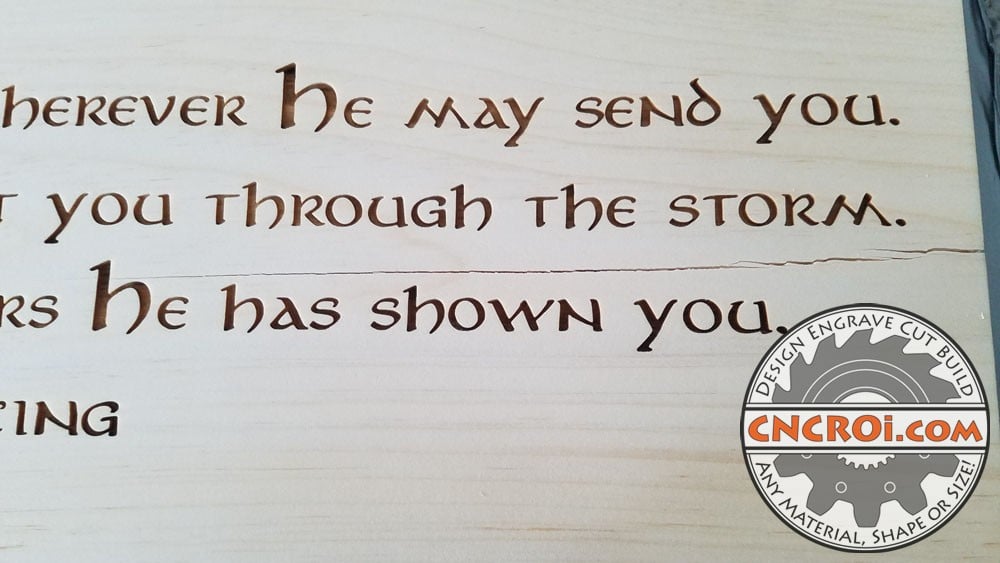

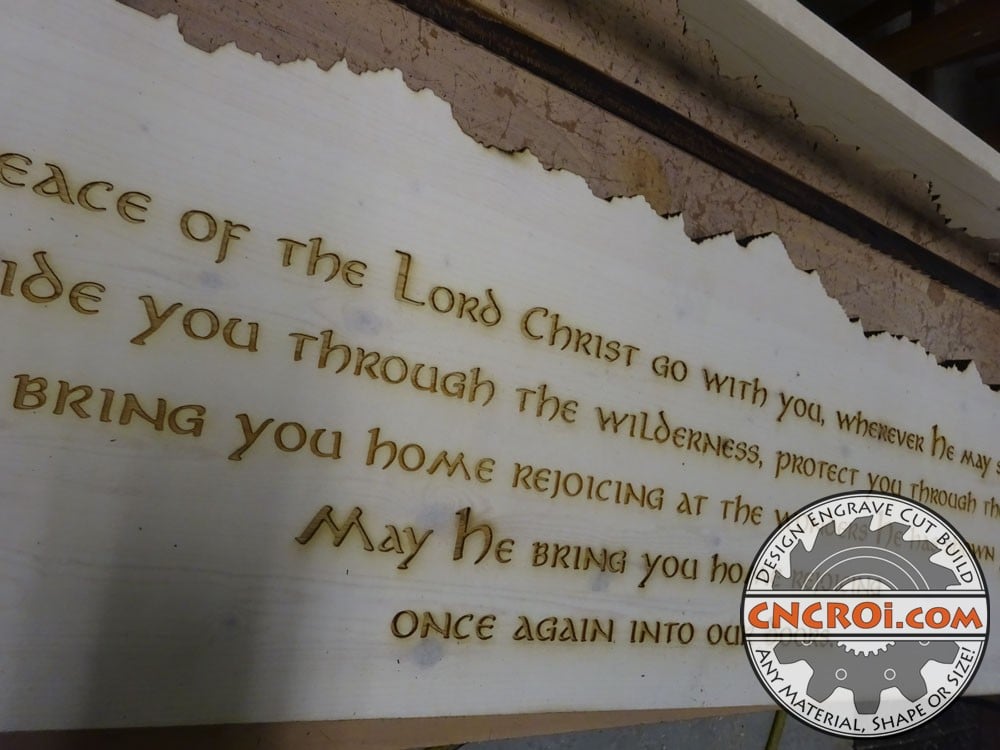

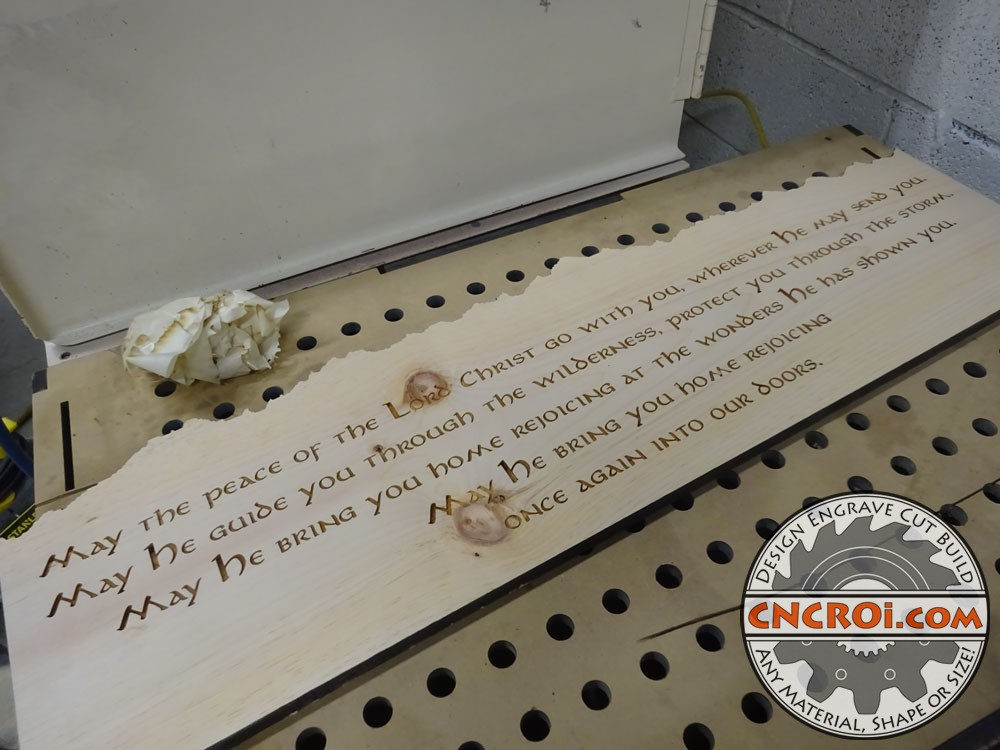

You can clearly see that there is a serious crack going on across this REAL solid pine blessing exit sign, this can happen due to many different factors but at the end of the day, it’s up to ME and my company to fix it, not the customer to screw around with clamps and glue to repair a damaged piece.

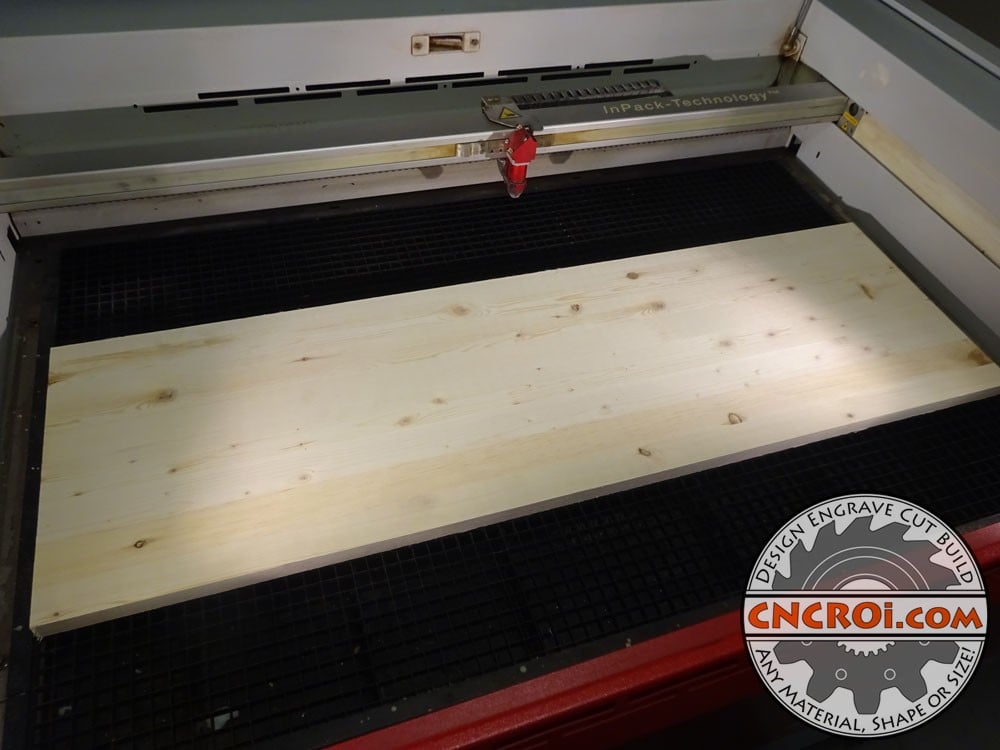

The easiest thing to fix something that’s broken is to honestly just make a new one, shipping the sign back to us, us using glue and clamps to fix the cracked Pine and then shipping it back just delays things when we have our Austrian CNC laser ready to just engrave and cut a fresh 3/4″ board.

Although CNCROi.com is a custom fabrication shop across a host of materials and processes, we generally work off digital files, as such, repeating a job down the line is no problem as we have the file to re-do our work.

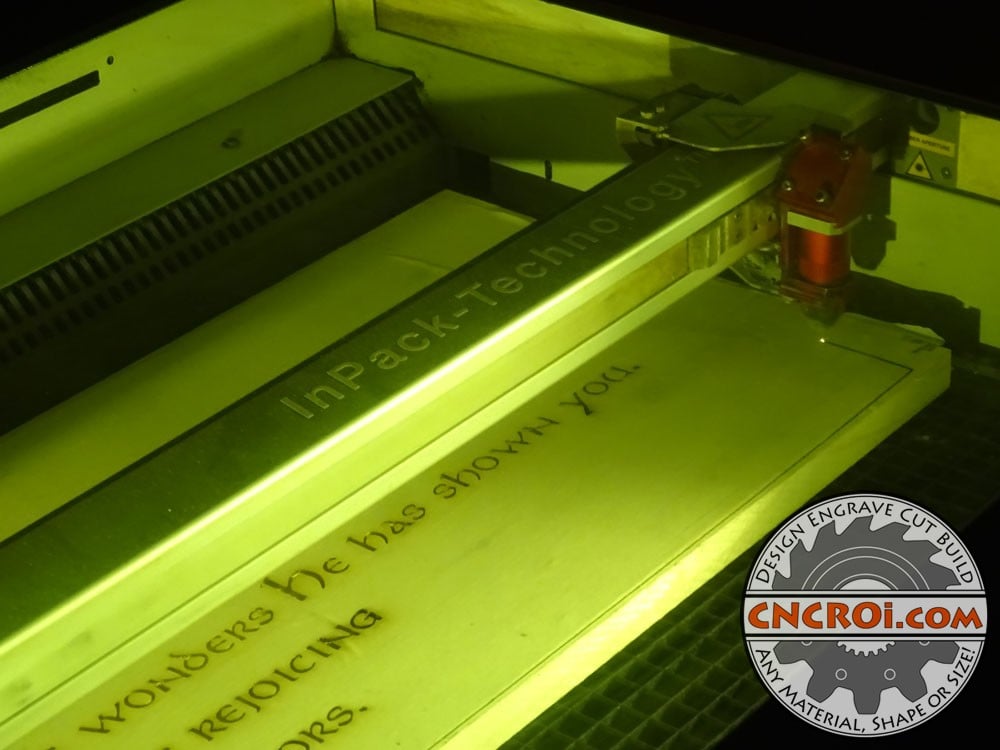

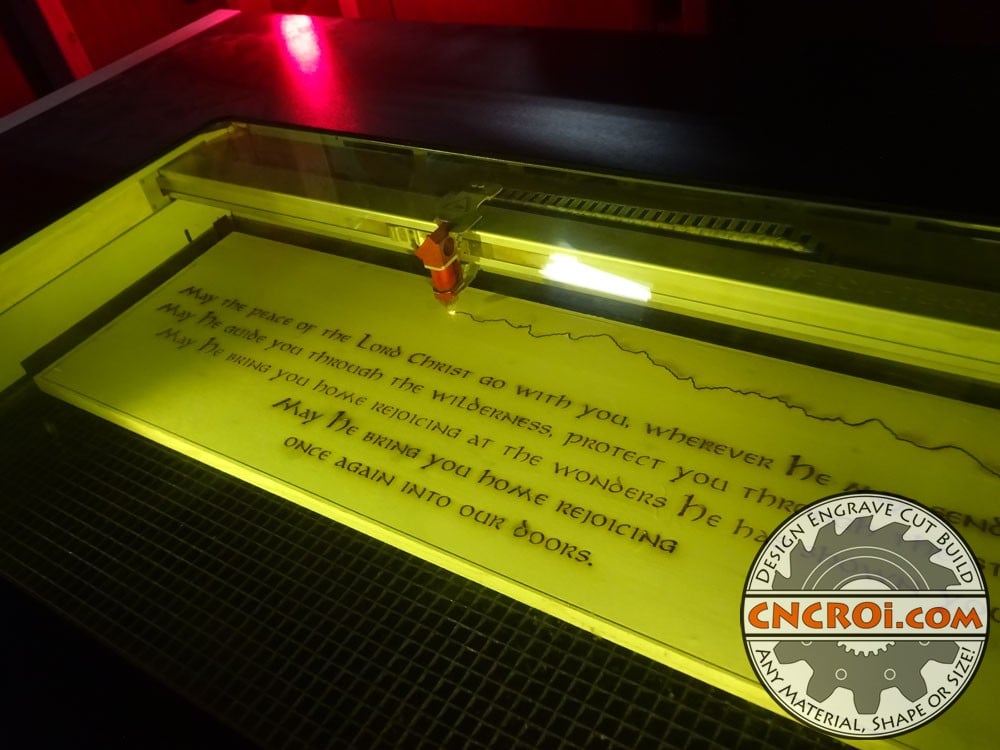

So the process of fixing this broken exit sign was pretty straight forward, get wood in the shop, engrave and cut then ship back to customer. Easy!

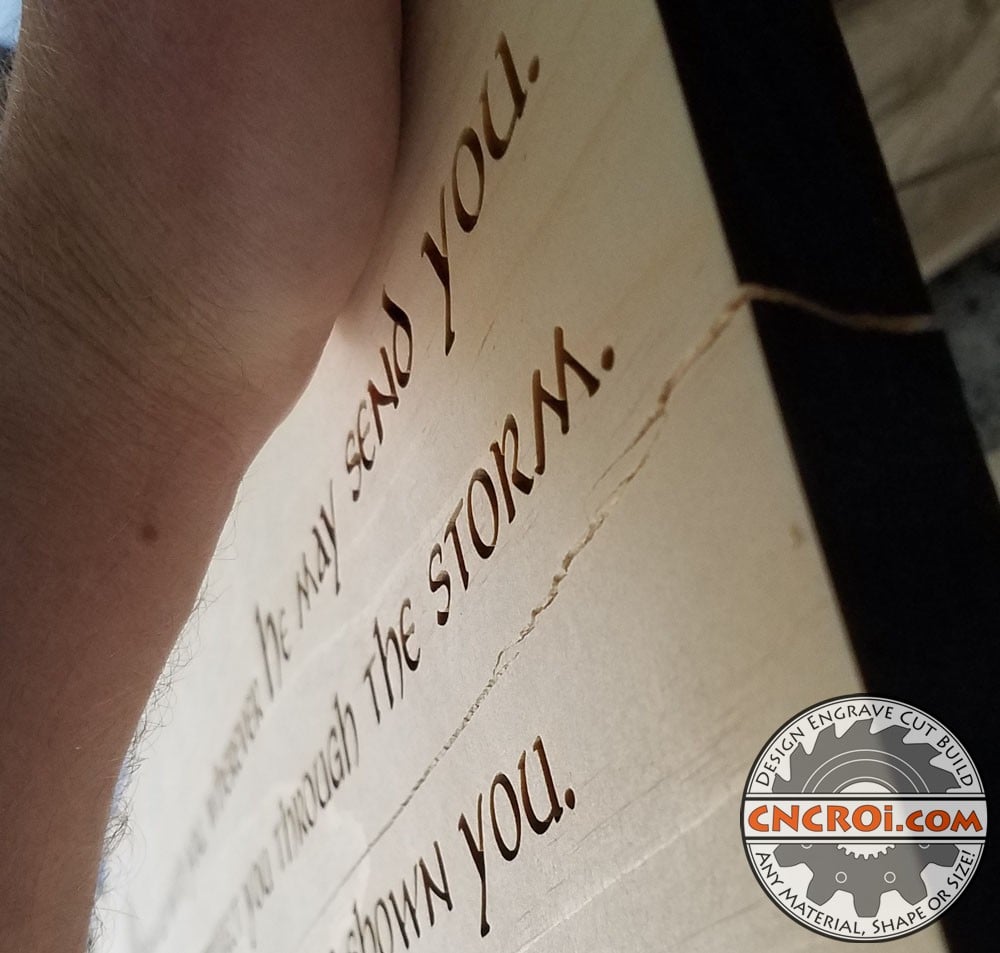

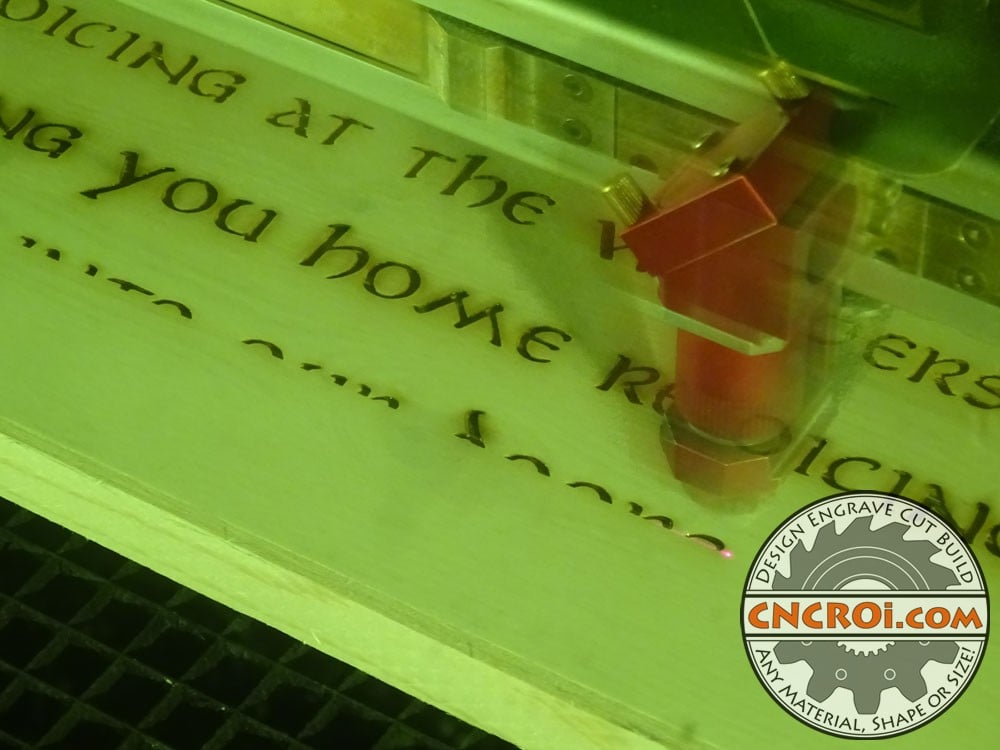

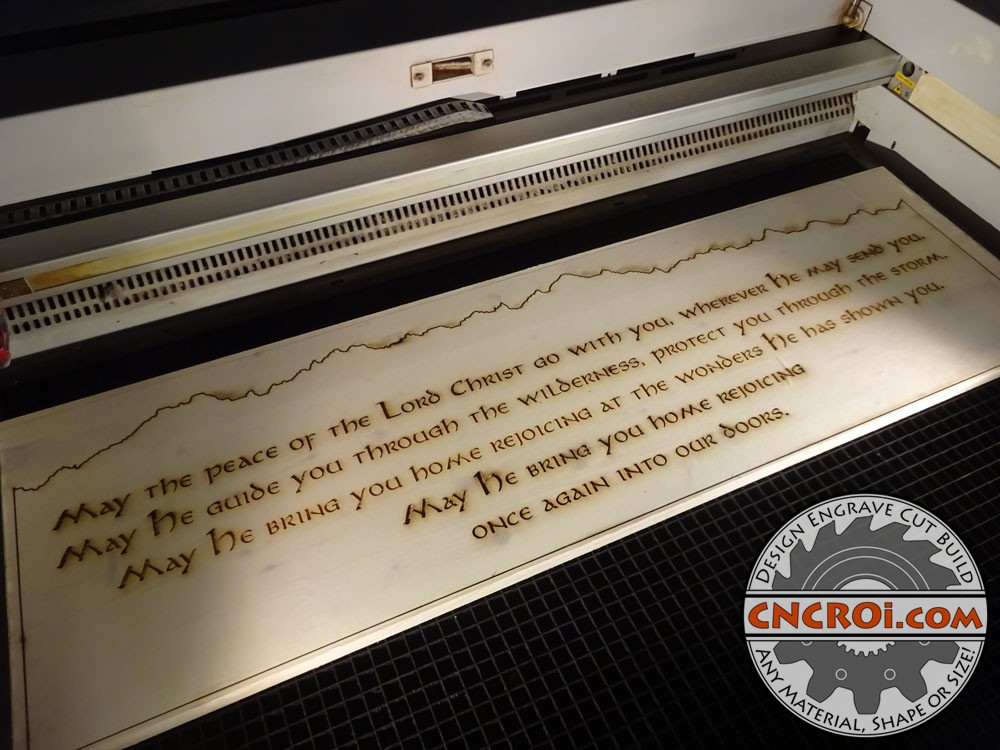

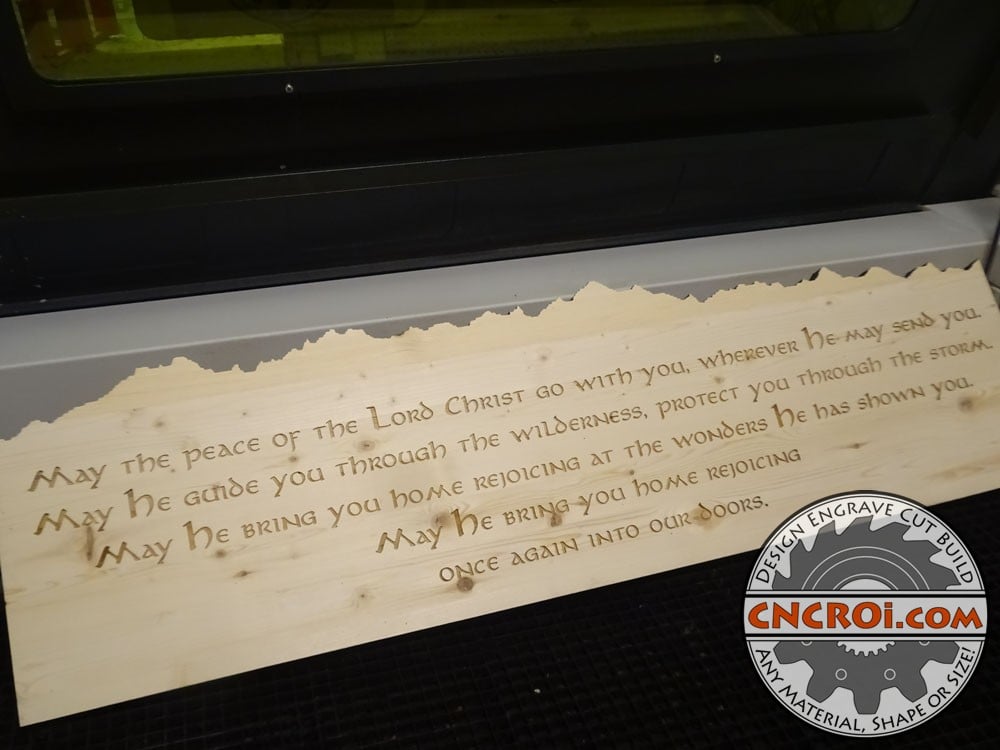

This is also a good opportunity to see how the same sign looks using the same natural material, Pine is Pine but the variances in knots, grain and so forth are all unique to each piece.

Although the laser engraving is the same speed and power, these natural variances in Pine density do produce a slightly different result that’s unique all its own.

The process of laser engraving wood is essentially the same regardless of the type of wood (Ash, Maple, Cherry, etc.), here’s a look at another wooden sign we made.

When it comes to customer service, my focus is to make sure we produce the best results using the best material for optimal results for our customers.

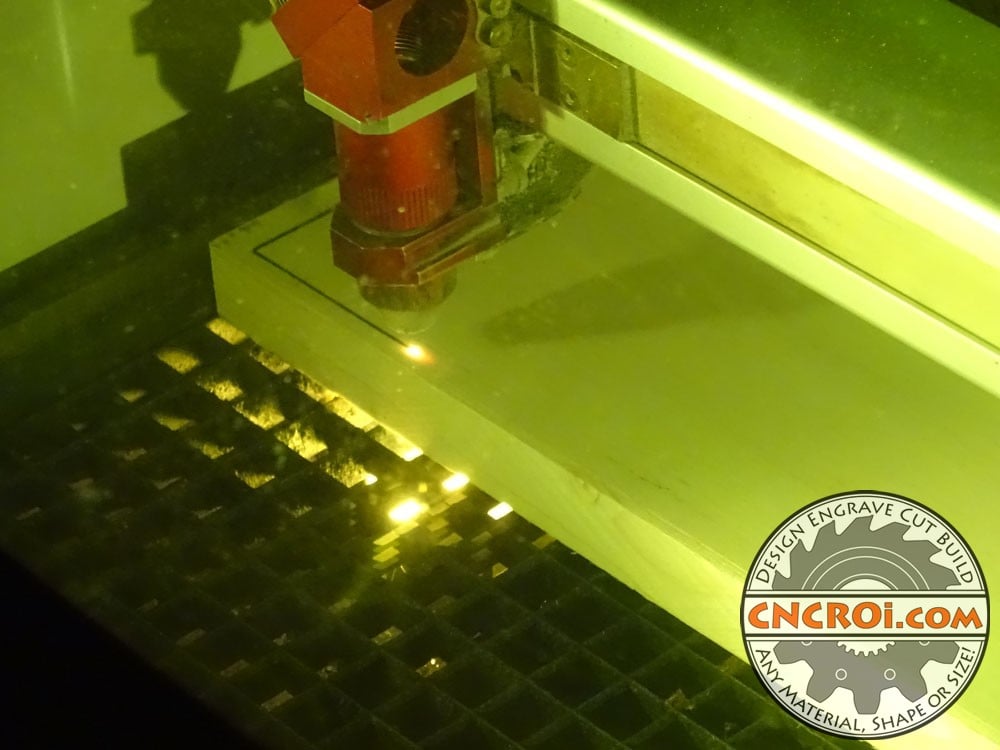

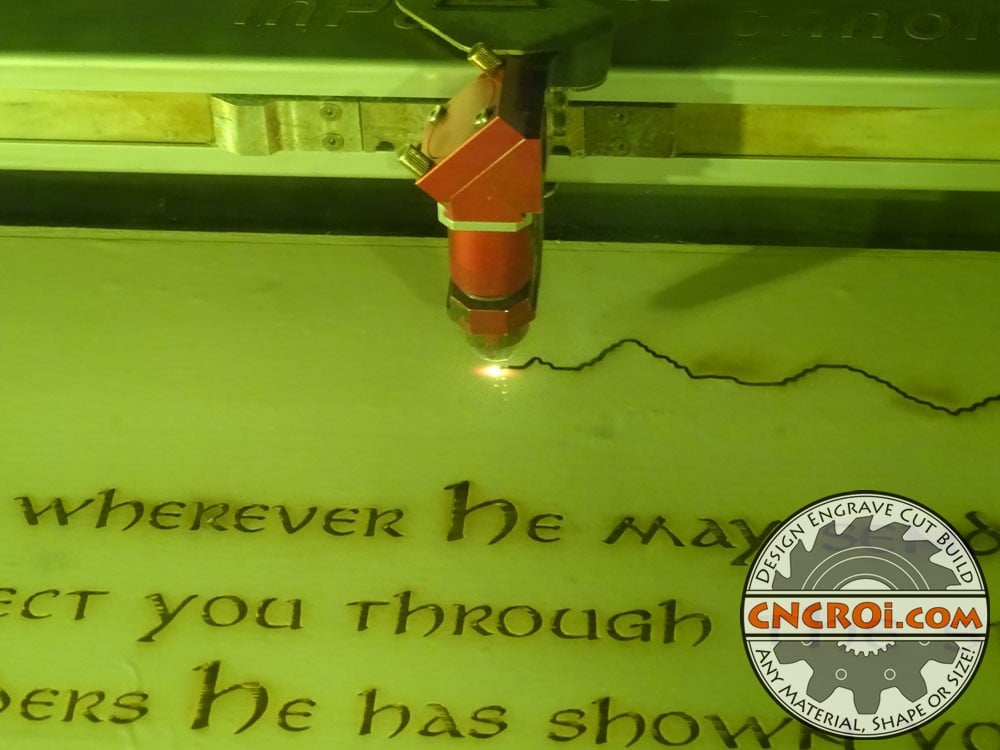

Our CNC laser can easily cut through this 3/4″ Pine, you can see the stream of fire under the board in these pictures.

This steam of fire is always present under the board, regardless of what we are cutting, as we have highly compressed air shooting down to make sure the fire is pointing DOWN and not UP.

You can see that stream of fire more clearly when CNCROi.com is cutting clear acrylic, our laser has a vacuum table so the fumes and other items gets sucked right up.

Our laser is specialty optimized for cutting things SAFELY, I wouldn’t attempt cutting acrylic if I didn’t have the machine that I do have as I’m essentially using a match to cut through gas.

Like the previous blessing exit sign, the Colorado mountains are a huge feature that was suggested by our customer to go along the top of the Pine sign and I just really love that idea!

Just to give you an idea of what CNCROi.com can produce, when I mention any size, shape and material combination, I mean it, take a look at the same Pine we used for this blessing exit sign for this earlier M4 gun key holder.

That’s another point when it comes to customer service, having an open mind is very important, quite often, an idea from our customers will actually help make what we have developed together BETTER more often than not.

I know enough to know that I know nothing, as such, there is never any harm in trying something new and innovative and worse comes to worse, it doesn’t work and what we end-up doing is just making another version without that feature, all the wiser in the process.

There are many ways of engraving and cutting the same design, check out this example using Pine and leather, it’s night and day and this sign could have just as easily been reverse engraved too.

Running a custom fabrication shop like CNCROi.com, you realize one thing quite fast, there is no right or wrong way to make something, as long as you are making something the customer appreciates and is within the allowable laws of physics.

When it comes to producing a wonderful custom solid Pine sign, CNCROi.com can make one or a thousand, each with their own very unique character.

Just compare the above sign (original that was broken during shipment) and the new one below to get an idea of just how variable wood really is.

Need a custom wooden sign produced by a company that stands behind its custom fabrication?

Contact CNCROi.com right now!