Don’t Skip Kiln Drying! Bugs & Massive Warping

Kiln drying is essential for lumber, whether it’s live edge or dimensional lumber and this slab is a prime example as to why this needs to be done.

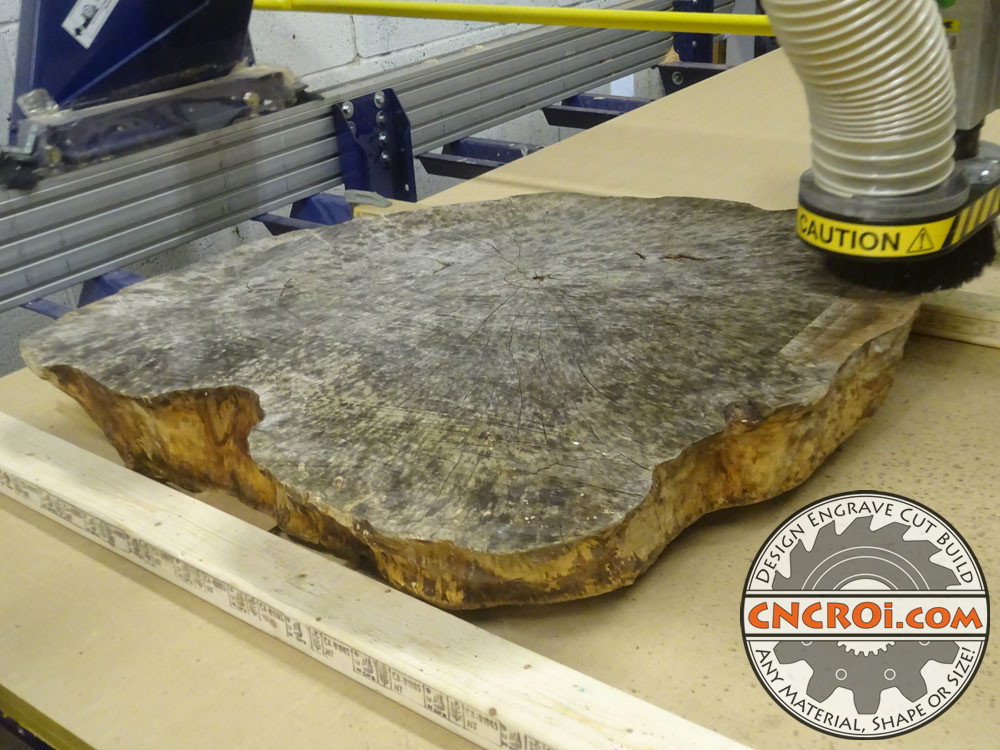

A customer approached me at CNCROi.com with a piece of wood that had a really rough life but had some sentimental value, as such, being naturally “dried” in a field, it had moss, mold and extensive warping across the entire surface of the slab.

Their goal was to just have my company flatten the slab, originally one one side but as I got through it and saw how extensive the warping was, I ended-up doing both sides because otherwise, it would have been very difficult for the customer to make much of anything, there were pockets of rot, pockets of bugs and pockets of mold on this piece of NOT KILN DRIED lumber.

Kiln drying is incredibly important, I’d argue the most across the whole process of converting a tree into furniture and this is a prime example as to why, first, I had to removed A LOT MORE MATERIAL than otherwise I’d need to because the wood wasn’t evenly dried which caused extensive warping.

If you look closely at the video of CNCROi.com flattening both sides of this not kiln dried wood, you’ll also see bugs walking across the surface at various points of this process, kiln drying would have killed them.

https://www.youtube.com/watch?v=1ODtKCwwDmk/

Having a flat piece of lumber is a joy to work with, the slab that I flattened on this blog post was fine, it’s still fun to do this type of work regardless of the wood involved or it’s quality, but if I had to do anything but just flattening this, it wouldn’t have been fun.

Third, the importance of kiln drying also allows you to preserve the surface of the wood, you’ll see that the surface of this Maple is very rough start to finish, it will require the customer to do a lot more sanding than otherwise required because the wood fibers weren’t tight and dry but in various states of dryness.

CNCROi.com uses kiln dried lumber for all it’s work, this solves so many problems in the production process that if this customer would have asked me to actually make furniture out of this slab, I’d refuse because the warping on this isn’t done, in a few months, things will not fit tightly or too tightly, there will be wobble and so forth.

The secret to making wonderful work using wood is having a wood that is dry and bug free, that’s literally half the battle as there will rarely be anything close to the initial extensive warping a piece of wood will be subject to when it goes from tree to kiln dried log.

Once kiln dried, lumber is a lot harder as the water has been almost all removed, the quality after flattening is better and very little sanding is required.

For this piece of not kiln dried wood, I did the moldy and bumpy side first, not that the other side was any better a starting point but at least I wouldn’t have to remove as extensive a layer of material as this side with the huge chainsaw mark going across the surface.

So if you don’t skip kiln drying, what can be made using live edge wood, slabs through off-cut pieces? Well, something pretty popular which I use myself are custom live edge cutting boards.

Additionally, because CNCROi.com has an industrial laser, we are also able to personalize it with engravings of your choice.

Other ideas for kiln dried lumber include dog bones for small dogs which we can bring to a flat using our CNC router, then cut into a dog bone shape then laser engrave.

https://www.youtube.com/watch?v=67DOfMCacBk/

It’s just incredible what CNCROi.com can fabricate using the right material and processes and equipment behind it.

Taking a look at this piece of lumber that skipped the kiln drying process, you can see that regardless of the wood quality, our industrial CNC router is able to make quick work of it, converting what would be days of strenuous work into just hours on our equipment and the advantage we offer is that the spindle is stronger itself to any hand held CNC router on the market, so it’s REALLY FLAT.

The reason to flatten both sides is to make a parallel piece of live edge lumber, whether this is kiln dried or it skipped the kiln drying process, what’s left after CNCROi.com has done the work is a really nice piece of wood to improve upon, you’ll just have a lot more sanding to do if it isn’t kiln dried.

Once the process of flattening parallel this piece of skipped kiln drying lumber, it lost about half it’s weight and what was left was dramatically easier to work with regardless of it’s condition.

When it comes to the ledge you see in this piece of wood, at first I thought of completely removing it but once I have the underside completely flat and flipped it over and started to do the same on this side, I realized that I’d have to remove an additional inch of material, it wasn’t worth it as this can just be the underside of the customer’s table and thickness is more important than a gouge on the underside.

https://www.youtube.com/watch?v=7cBaZgqYO18/

It always amazes me that the same machine that makes huge chunks of wood flat is also able to make delicate production runs of shooter trays, ash trays and many other smaller items.

Those little black dogs you see on the top of the ledge are actually bugs that I accidentally woke-up as I was cleaning-up their home using a carbide bit and the vacuum, they didn’t look too happy.

After CNCROi.com flattened this piece of live edge wood, I suggested to the customer to literally let it sit for a few months in a dry area away from the Sun, this will work out any warping left over which he can then easily sand flush once again as now the overall piece of skipped kiln drying lumber is about half of the thickness it was before and newly exposed to the elements.

There were a lot of chips made during the flattening process of this slab, I could literally do this type of work all day at CNCROi.com because I get so much satisfaction transforming a rough piece of lumber into something manageable and quite beautiful.

Those lines you see going across are easily removed by doing some sanding on the surface, this ended-up being more extensive and will require more time as this slab wasn’t kiln dried so many fibers were ripped as they still had moisture in them, but sanding will even it all out.

Here’s the slab from another angle, again, what you see here will be the underside of the customer’s table and they were very happy with what was left over after I did my work at CNCROi.com.

Have something you want made out of live edge or dimensional lumber?

Contact CNCROi.com right now!

https://www.youtube.com/watch?v=SZbDwgCE8iw/