Huge Thermoforming Mold Production: Laminated 2x6s

When it comes to making huge thermoforming molds, CNCROi.com can make them to just about any spec you require for your own needs.

Through extensive material testing, we’ve concluded for limited run thermoforming mold production, the simple 2×4 and 2×6 are more than adequate as it’s material that’s easy to find, very cost effective and easy on machinery (so we can go FAST!).

For this specific huge thermoforming mold, CNCROi.com chopped-up and laminated a bunch of 2x6s due to the size and depth requirements for this project, anything larger and it would have been 2x10s or even even custom wood slabs directly from the mill.

As with making all molds, there is a process of lamination where the wood is cut down to size, flattened and then glued to make the perfect blank for the project at hand.

This might seem like a lot of work, and it is, but it produces the very best result as I can control what goes into making the blank and the final blank specs themselves from which I machine the mold out of, there is a lot of rejected wood that you don’t see, due to holes, knots and other issues that never make it to the final blank production at CNCROi.com.

Of course, these custom molds can be made as negative or positive to suit your given application however you wish.

As I’m machining this blank into a mold, the only thing I can use to stick it together is glue, I’d love to use stronger things like rods and bolts but the stresses involved with thermoforming don’t warrant this much hardware built-into the mold itself.

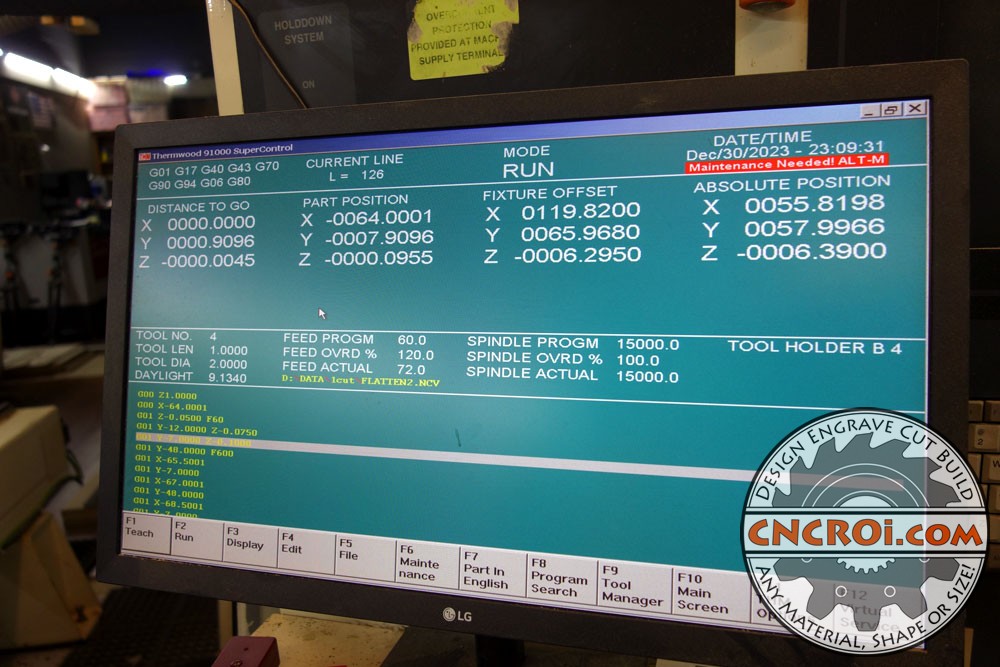

Although my old machine (in these videos and photos) was capable of moving a lot faster and with more power, I kept it down on purpose because the bits that I use for this huge thermoforming mold are pretty long and tend to break or shatter if they are loaded-up with too much material to bite-off in one shot.

Once all the 2x6s as cut to size and flattened, it’s time to glue it all together into one huge blank, not only is this BIG but it’s also HEAVY, which works in my favor for mold production because the heavier the mold blank, the easier it is to stay put during production at CNCROi.com.

Glue tends to make a mess of my CNC router table but it’s quickly skimmed-off by the router itself, a process I have to do anyways before making this huge thermoforming mold because there is no point having a dead-flat and parallel blank if the table itself isn’t also dead-flat and parallel to the gantry.

These molds benefited greatly from the experience I had making custom banks for SandboxRanch.com customers using a variety of different wood species, there are a lot of steps involved that can each affect the final outcome.

After one side of this huge thermoforming mold blank is machined flat and parallel to the table, I flip this monster oer and flatten the other side before starting production, I don’t really need to flatten it because I’m machining into the blank, but I like to have a clean surface to work from, it makes taking measurements easier and more accurate.

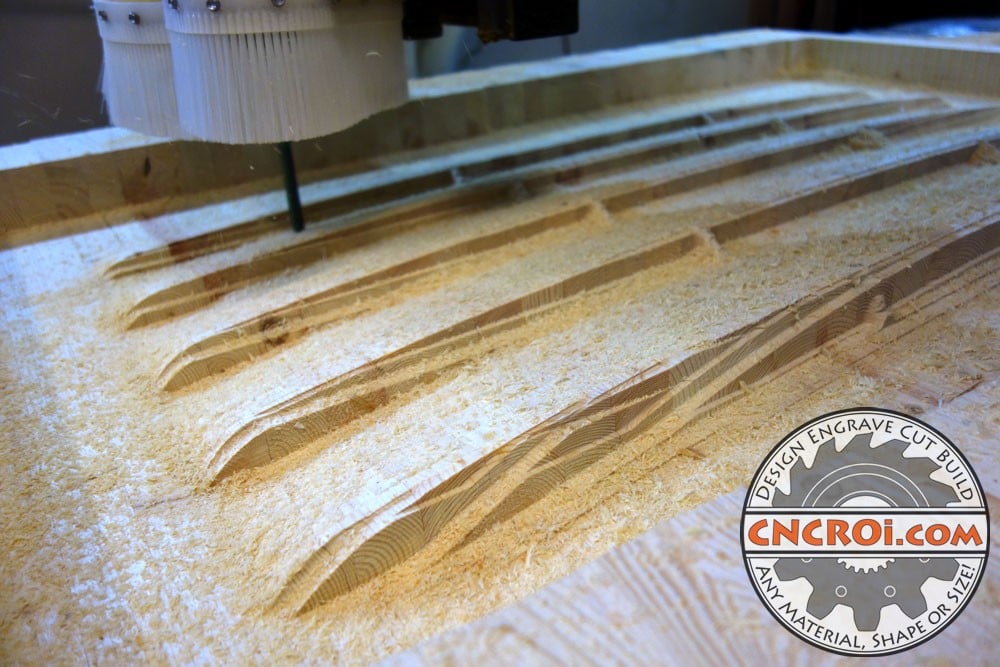

There was a tremendous amount of saw dust made during the production of this huge thermoforming mold, even more than an anticipated but it was a very enjoyable process to watch take place right infront of me at CNCROi.com.

To give you an idea, due to the depth requirements of this huge thermoforming mold, I had to resort to HUGE tooling as well, this tool is half an inch in diameter and 6″ long and it -just- made it depth wise into making this mold, any deeper, and I would have had to make this custom mold in layers that would then be glue-ed up together.

Regardless of the mold I’m making, or carving in general, there are generally two passes, one with the roughing bit to clear as much material as possible and the other to clean everything up.

For very small molds, generally used for pottery, CNCROi.com offers just as much flexibility as these larger ones.

To give you an idea of perspective, the table this huge thermoforming mold is on is 5ft x 10ft, and you can see, it’s taking-up quite a big part of it!

You can see just how much “stickout” I have with the half inch clearance bit in the picture below, this is very dangerous for the bit because it’s spinning and any bump will instantly make it break, if this was a harder material, I’d have to resort to a shorter bit and making the mold in parts that are then glued together.

It really never gets boring seeing a mold being made, it’s quite an intensive process where I’m constantly measuring depths and triple checking settings throughout the substractive process, there is a tremendous amount of thing that could go wrong and the earlier I notice it, the more options I have to fix it.

Having laminated wood with very tight and glued seams really does seem to add a tremendous amount of strength to the overall mold, it doesn’t seem like it, but modern glues are basically welding the wood together and like welding, the seams are the strongest parts, the wood prefer to break where there isn’t glue, so I add more than needed to make sure I have absolute full coverage of all surfaces.

Custom molds can be made using a wide variety of materials, it really all depends on your application, timeline and resolution requirements.

Having a powerful machine really pays huge dividens when it comes to making accurate huge thermoforming molds such as this one, there are no bit harmonics, no slop in the X, Y or Z and everything is cut cleanly using very sharp bits to minimize ripping of material.

As mentioned, there is A LOT of saw dust created throughout the mold making process, blank to final product, especially when you realize that I have my dust extraction system running full-on, wood chips are always larger than the wood they came from.

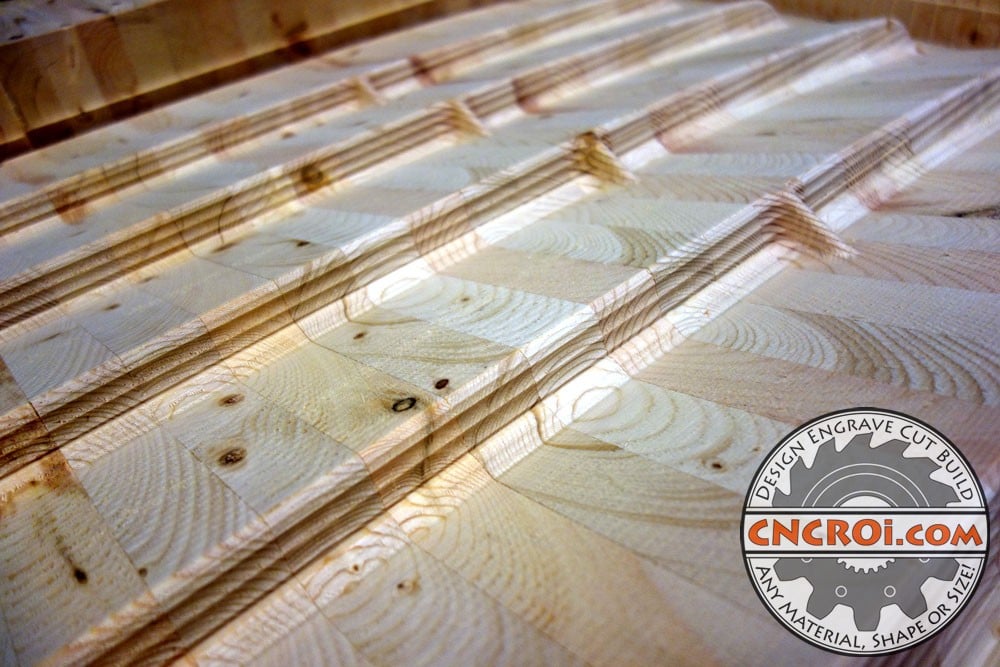

After the roughing bits have done their work, it’s time for the finishing bits to do theirs, by the time they are done their work, it’s almost like a hard shield is added to the wood surface, the removing of basically a fine dust over the entire mold while polishing it with the ballnose bit gives it a nice denser skin, sort of like the surface of MDF before you start machining the surface away.

You can see the before and after in the image above, it always blows my mind as just how precise the process is and repeatability, it’s easy to go over an area once, but to go over it twice, in the same spots, is always an impressive sight.

When in comes to molds, CNCROi.com can also make shapes that work together for negative molds in order to make your very own positive mold.

As you can see, even more sawdust was created during the finishing process, and the bags from the dust extraction system were also filled-up.

Once the fine dust is removed from the mold, it’s like looking at a brand new car, everything is perfect and pixels have been converted into wood which will then be converted into plastic products by the customer.

There is also a nice shine to the wood, again, the polishing action of the finishing bit really helps to make things pop but sadly, this goes away after a few hours once there is a little oxidation from the natural environment hitting the wood.

Looking at these close-up picture of the huge thermoforming mold, you can see why it’s vital to have very tight seams during the lamination process, the customer will be doing a fine-tuning using bondo and sanding but the better and cleaner a mold I can provide to them, the easier their job will be.

In the image below, you can really gain a perspective at just how deep this mold is an how much of a chunk of material those half inch diameter roughing bits take out at CNCROi.com.

Need a custom mold? Contact CNCROi.com and we’ll make it for you and ship it right to your door!