Laser Cutting Cardboard

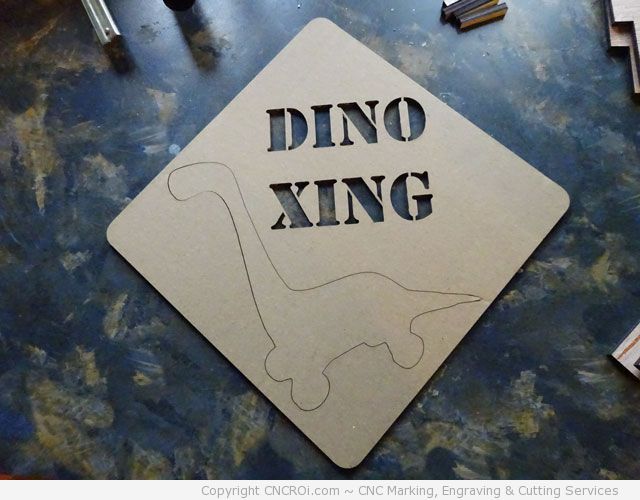

Laser cutting cardboard is even tougher to get right than paper. Why? Well, you can’t mask it as the masking will rip some of the surface off! This means you have to get your power settings dead-on. Too much power, you produce more smoke than necessary that will, more often thatn not, settle and stick to the surface of the cardboard. If you don’t use enough power, it just won’t cut through!

Luckily, we know what we are doing here at CNCROi.com so we got the settings just right and produced some great cutting!

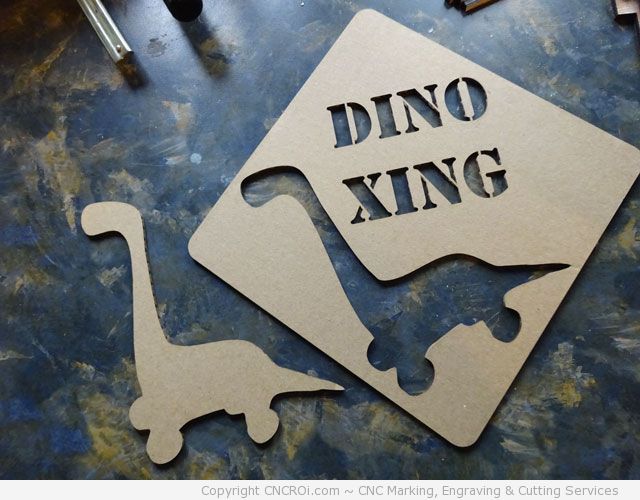

Just to show you how little material is vaporized, I stuck the dinosaur back into the stencil and as you can see it fits snug. There are no burn marks on either side of the cardboard because, in addition to optimizing our laser settings, our Austrian CNC laser also has a vacuum table sucking the smoke from underneith and extraction along the top, sucking the smoke from above… at the same time! How’s that for European machine multitasking!

If you are wondering where I got the dinosaur from, it’s actually a render of a CNCKing.com model that I outlined. It’s pretty incredible to think that the same laser that can cut through 3/4 inch laminate and anneal stainless steel and even engrave into cast aluminium can just as easily, cut cardboard, without any charring or smoke damage. It speaks volumes to the quality of our machinery.

If you are looking for a professional company that can cut, engrave, etch, anneal or mark your stuff, CNCROi.com is here to help! Yep, you can watch the whole thing in the video below.

CNCROi.com: Laser Cutting Cardboard