Laser Etching Raw Aluminum

It has been a while since we did some laser etching raw aluminum on CNCROi.com so let’s revisit it with a small piece of scrap and see what happens!

Almost all of the aluminum CNCROi.com processes is anodized, it protects the surface from the easily corroded aluminum by creating a barrier and as far as laser etching and bleaching, it brands relatively fast for similar results to what you’ll see in this post focused on NOT anodized laser etching raw aluminum.

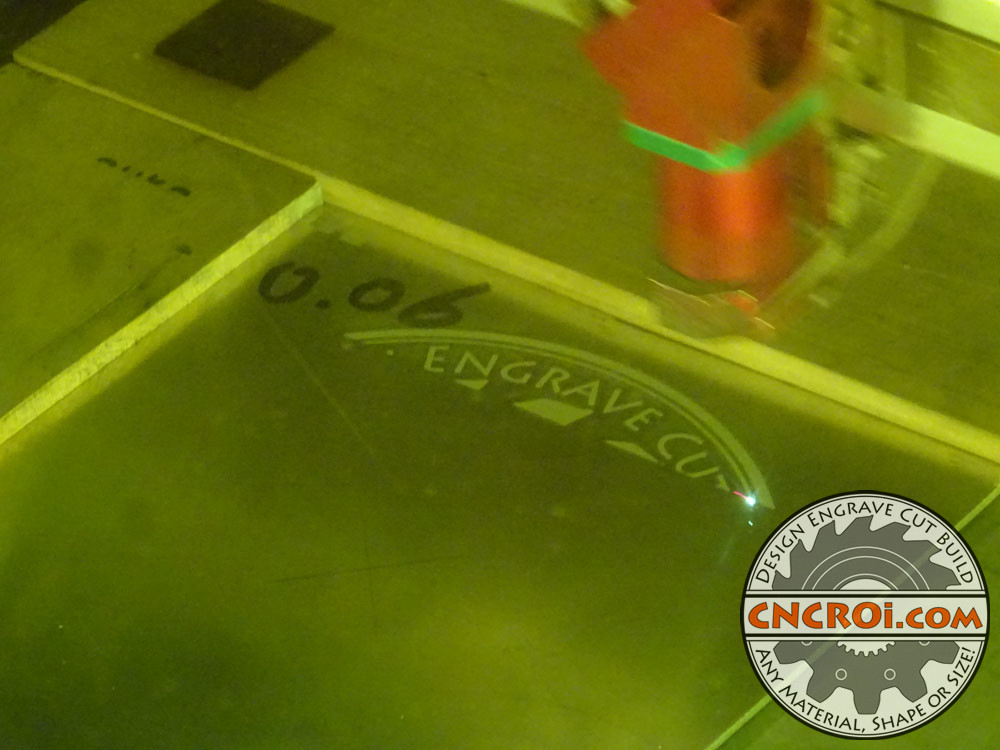

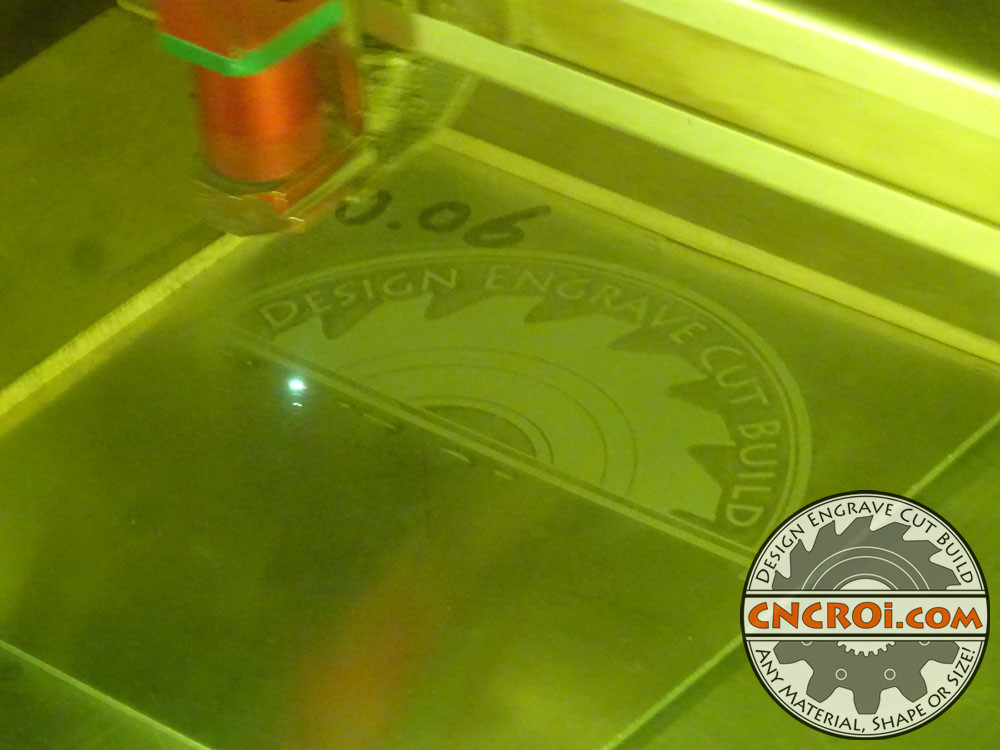

The challenge with laser etching raw aluminum is that it doesn’t hold any heat, and heat is how we affect the aluminum as far as what happens on the surface, as such, what you see takes an incredibly long period of time compared to any other more efficient method of production at CNCROi.com because we need to give the laser time to build-up heat in specific areas in order to create the abrasion you see here.

Generally, our customers are given the choice of their application made out of stainless steel or anodized aluminum.

If we go too fast for this laser etching raw aluminum, nothing happens and if we go too slow, CNCROi.com has angry customers asking why their project has been delayed a month.

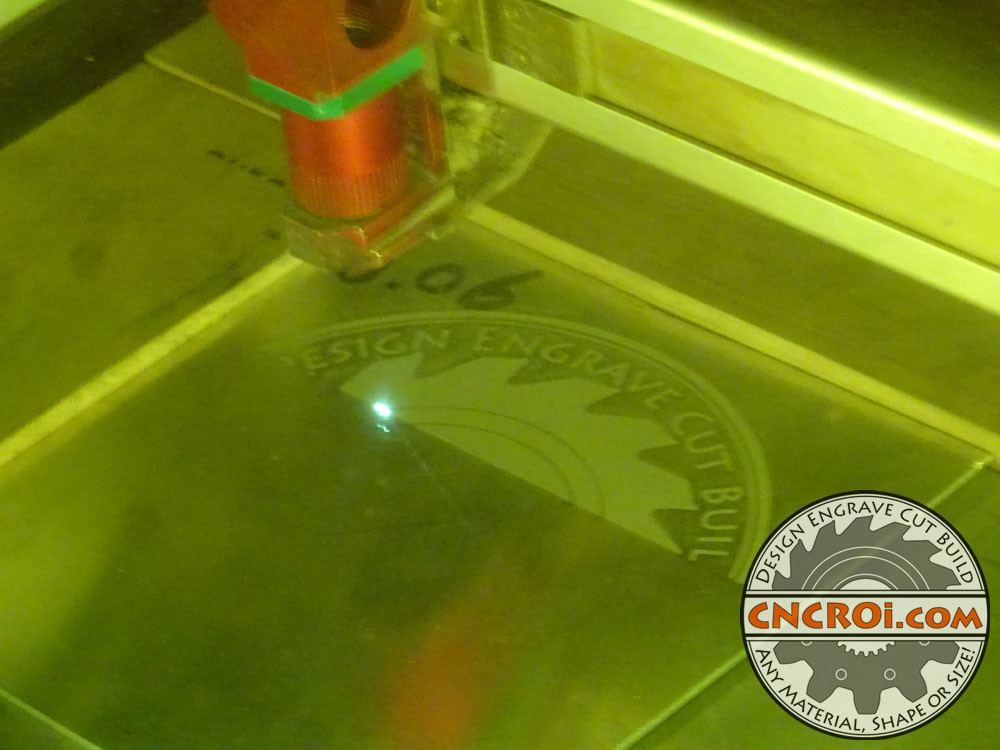

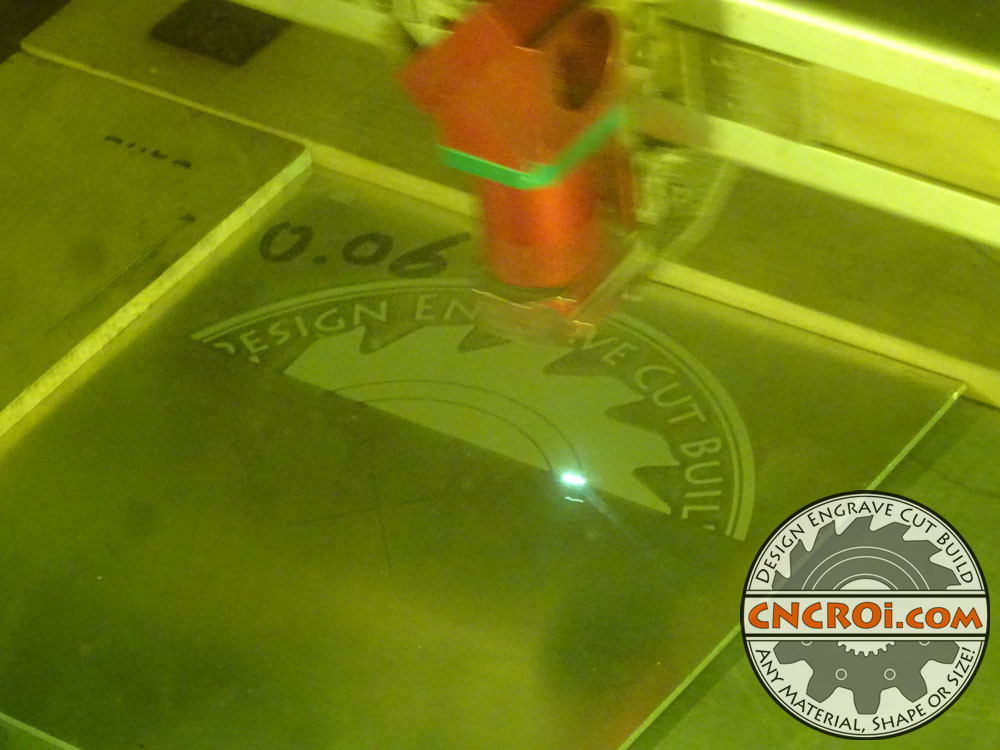

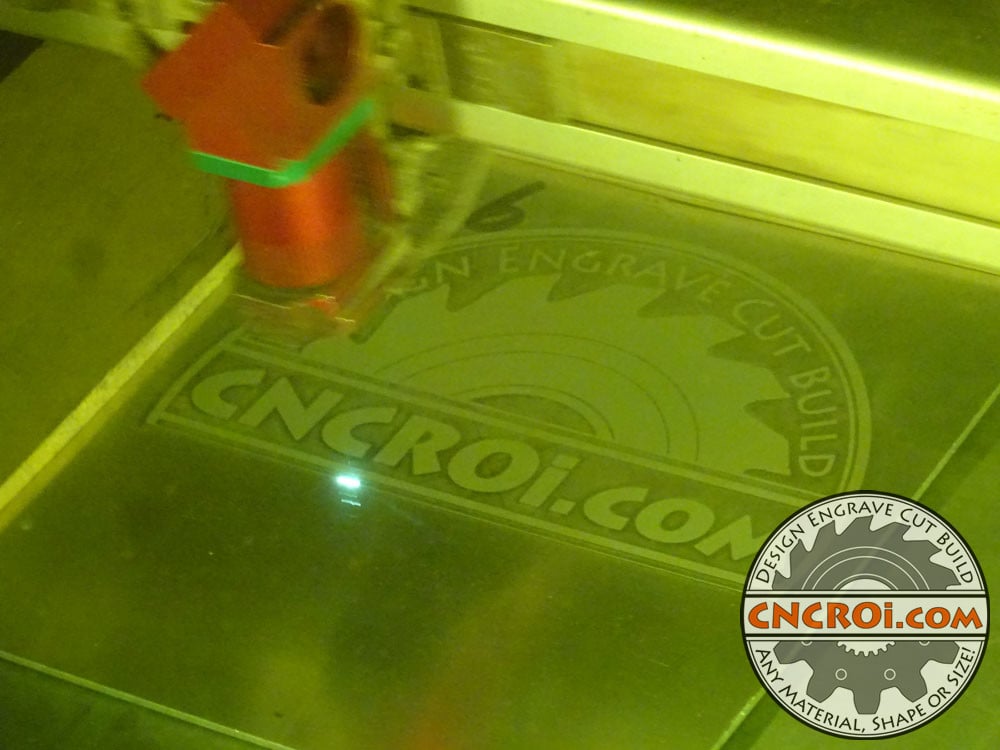

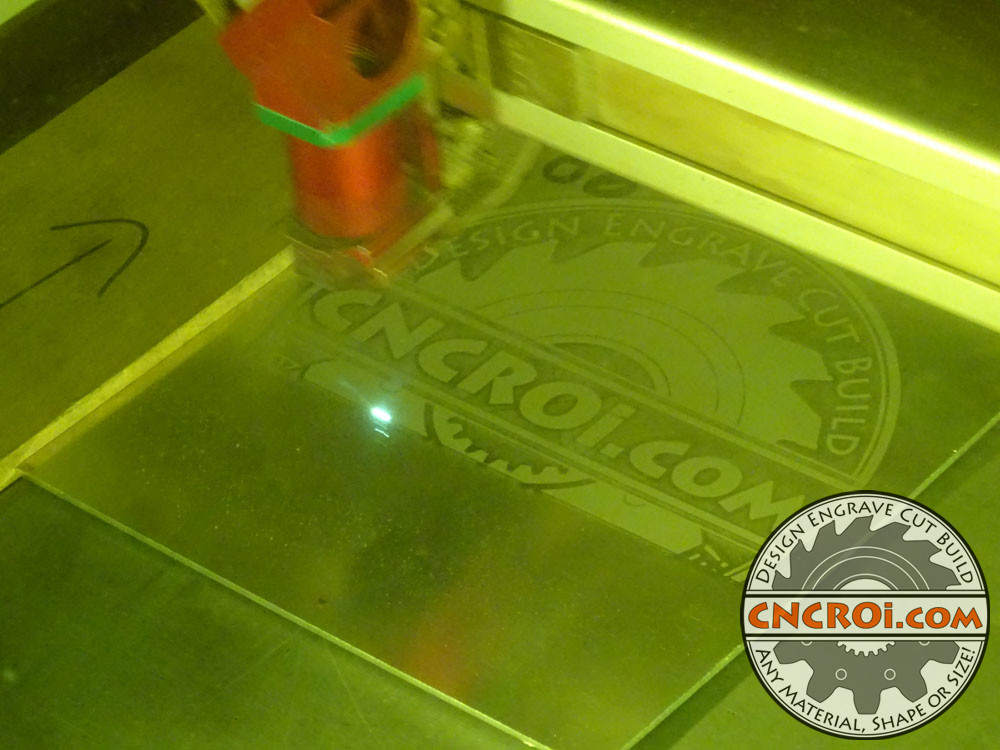

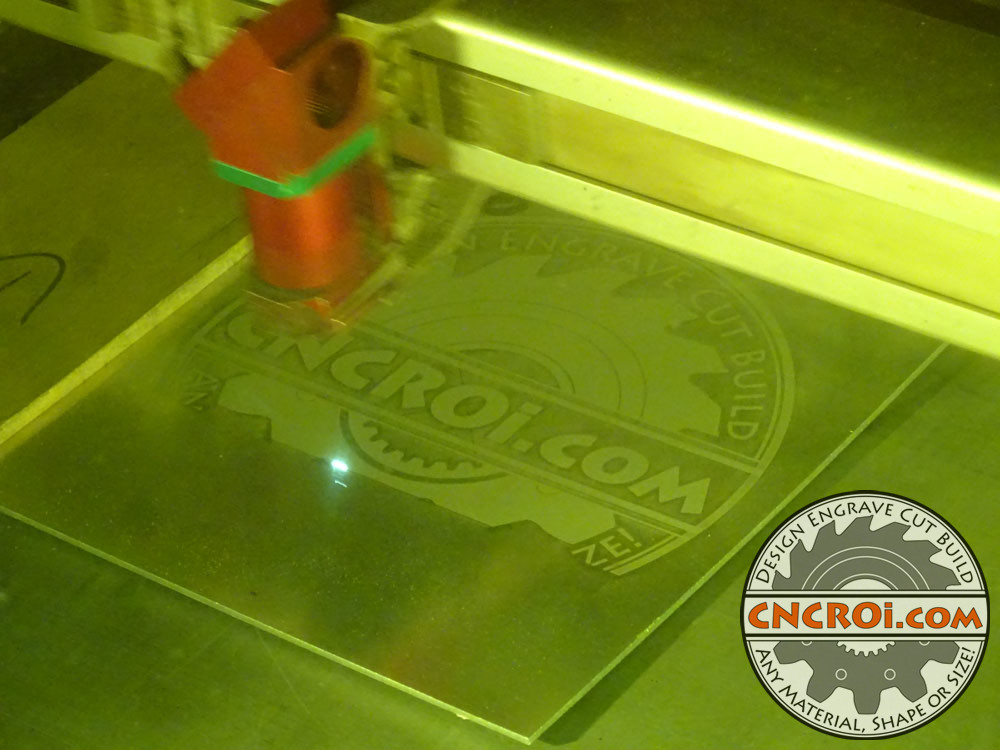

So when you are looking at these photos, yes, we are instantly vaporizing some aluminum but the effect that we are producing is more of a very scratched surface, when you run your fingers over it, it’s like 600 grit sand paper.

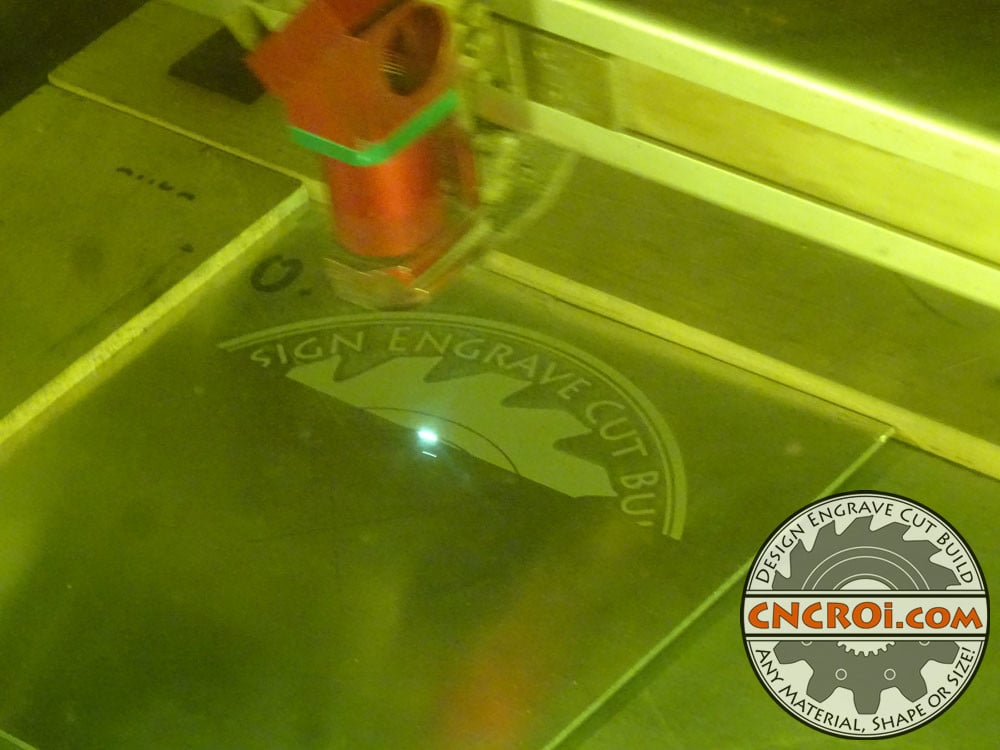

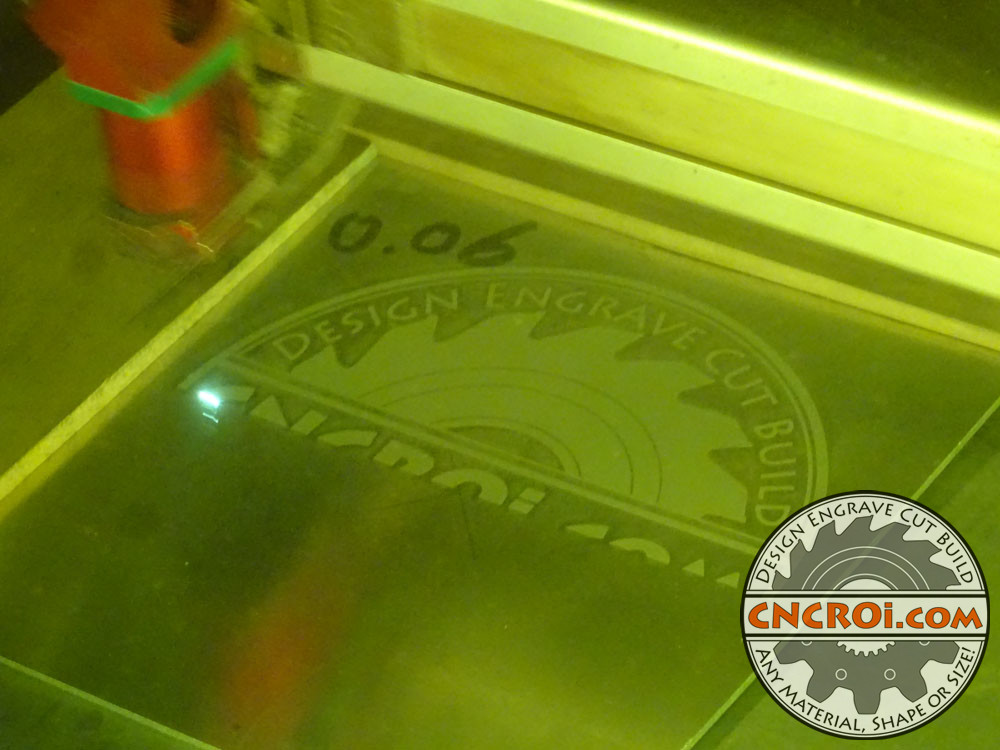

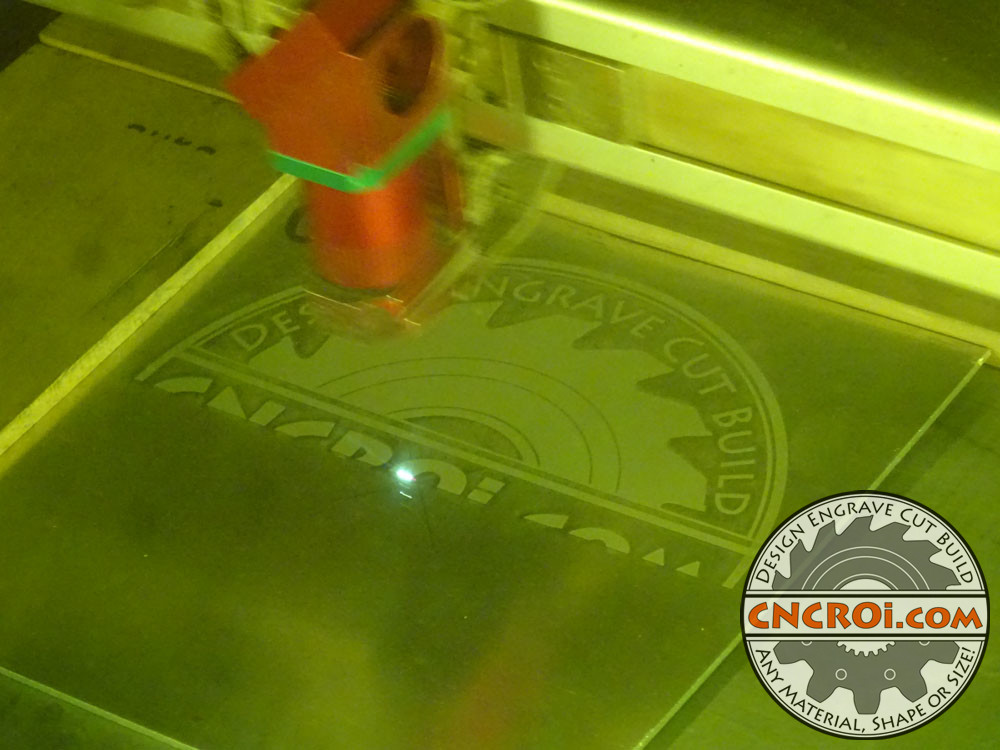

Regarding the resolution CNCROi.com can achieve branding using laser etching raw aluminum, it’s the same as if it was anodized or this was stainless steel, everything is precisely done and sharp without any rounding other than what’s present in the digital file.

The durability of each process is tested at CNCROi.com in this video.

The major advantage of aluminum over other metals like stainless steel is weight, it weighs practically nothing by comparison and the branding process is a lot faster on anodized aluminum over any other metal type we have at the shop.

I don’t quite know too many applications where not anodizing aluminum would be a benefit but for those applications where this is the only way, CNCROi.com can cut out the material from sheets and do the required branding and ship it right to your door.

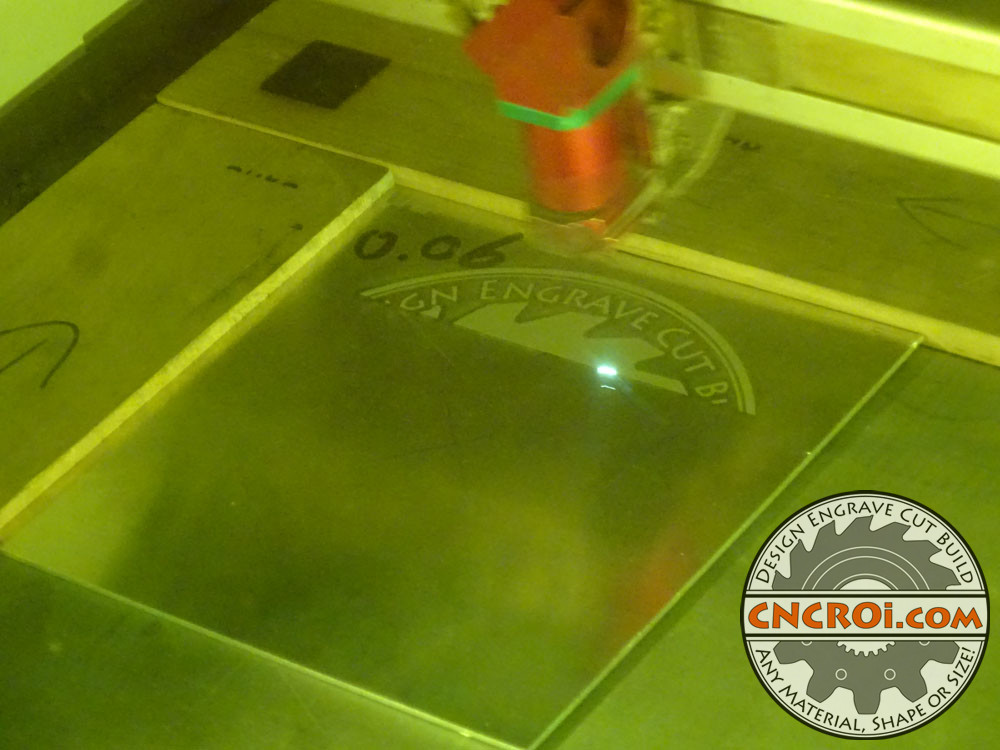

The thickness of this aluminum in hindsight is a little thin for this specific case usage, as you can see the bottom corner actually warps up from the heat and abrasion occurring over the entire surface of the aluminum.

How does aluminum compare to a lamacoid? Watch this video.

Ways around this would be to just tape it down or put some weight on it to keep the laser etching raw aluminum sheet flat, but as I rarely work with this process on this material in this fashion, it never occurred to me that this would even be an issue, the benefit of this is NOW I KNOW!

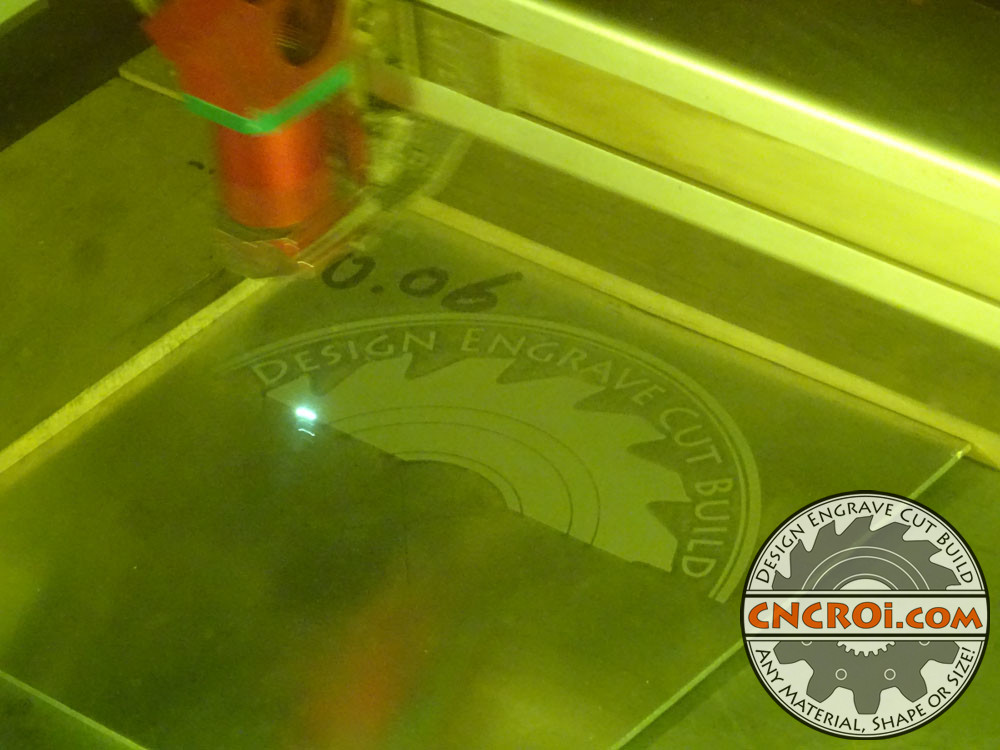

The thickness of this sheet of aluminum is 0.06″ or roughly 1.5 mm, I’d say if I was to do a lot of full coverage laser etching raw aluminum, the thickness should really be doubled, generally thicker material has enough rigidity that any heat or abrasion simply isn’t enough to warp the underlying material.

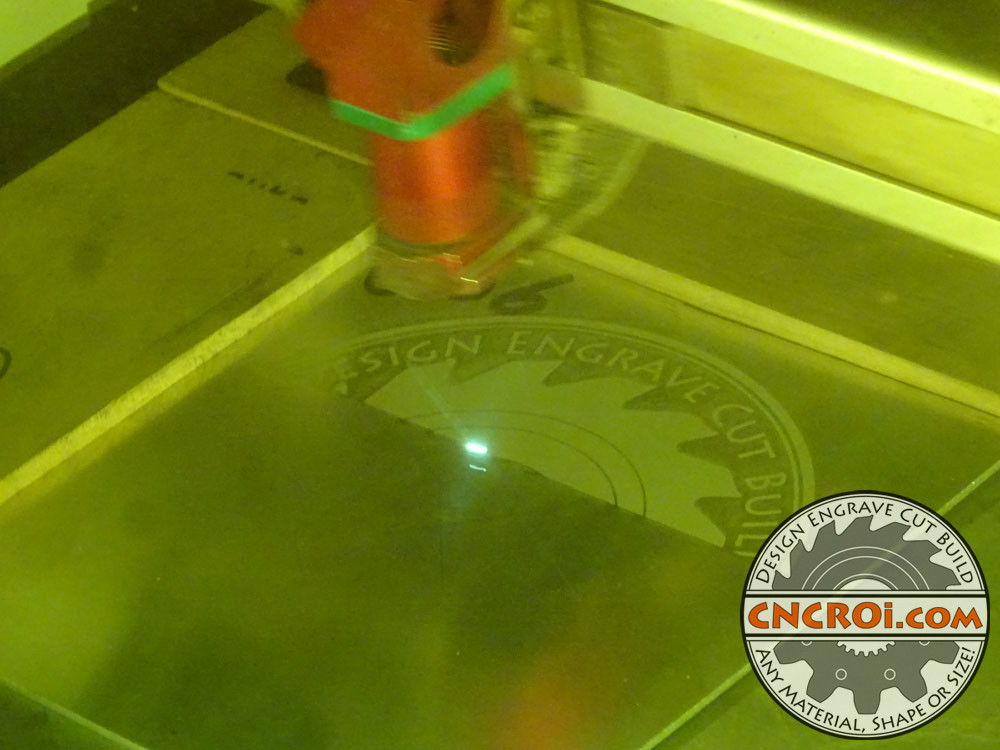

You can easily compare the logo that’s being etched into the aluminum to the branding logo on the photograph in the bottom right corner, they look just about identical minus the dust that builds-up on the surface.

CNCROi.com can employ waterjet cutting or plasma cutting to produce the shape you want for your given application using aluminum.

If the CNCROi.com logo was a bitmap, you’d see a degradation in the resolution of the logo and thus, the etching we are performing, but as my logo is a native vector, things remain sharp regardless of scale or application.

Due to the fact that CNCROi.com has a plasma cutter, we can easily process aluminum into any shape or size you need it for your particular application, this allows us to produce high quality work with very fast turnarounds.

Whether you need one or a thousand units produced, all the same or different, it makes no difference to CNCROi.com as production is production and each one of the plates is done one at a time regardless of the machine or process we employ for any given production run.

Coasters and business cards using anodized aluminum are always a popular choice.

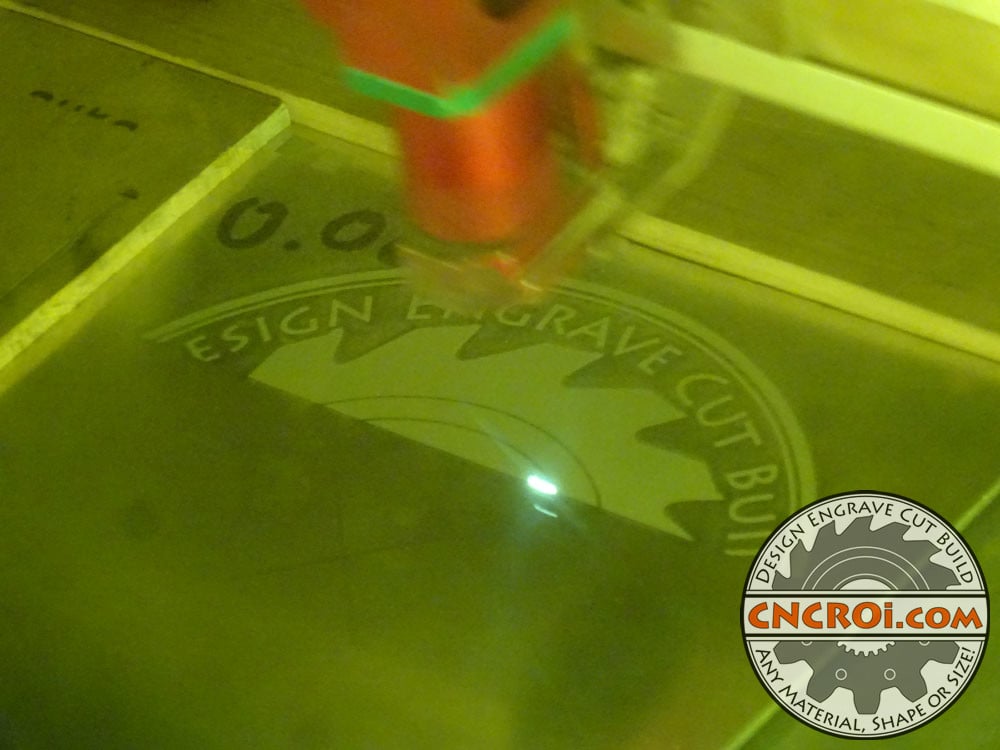

CNCROi.com has both a CO2 laser source and a fiber in our machine, as a result, we can use either source to produce custom branding on literally any material you may need this done upon, in this case the CO2 does literally nothing while the fiber laser source is the one that actually produces something on the surface during the laser etching raw aluminum process.

Fiber laser etching is a far slower process than doing the same work with our CO2 laser source, 30W vs 140W makes a tremendous difference in production speed though CNCROi.com is in the process of acquiring more equipment to narrow that production gap considerably.

Of course, CNCROi.com also has other non-laser equipment that can brand aluminum as well, like our CNC routers with a diamond drag bit which produces a different effect all together on the surface of the aluminum.

The other advantage of aluminum over stainless steel is the color, it can be anodized to whatever color you want and the results are always an off-white.

It’s a little hard to see in the photographs but in the video, you can definitely see the bottom corner of this aluminum plate slowly lifting, this did cause a production issue in that the focal distance between the head of the laser and the material changed, thus the process went from laser etching raw aluminum to laser polishing raw aluminum.

Looking at the results though, they are certainly more than acceptable, everything is sharp, unlike using a peen to do the same process, etching is always a nicer result than smashing.

Looking at the laser etching raw aluminum results from a few different angles really helps to better showcase what we did here.

The challenge with raw aluminum is production speed to achieve these results, and there are a lot of far more cost-effective alternatives out there that can produce a superior result.

Looking for custom metal work? Contact CNCROi.com right now!