Metal Product Shipping Foam

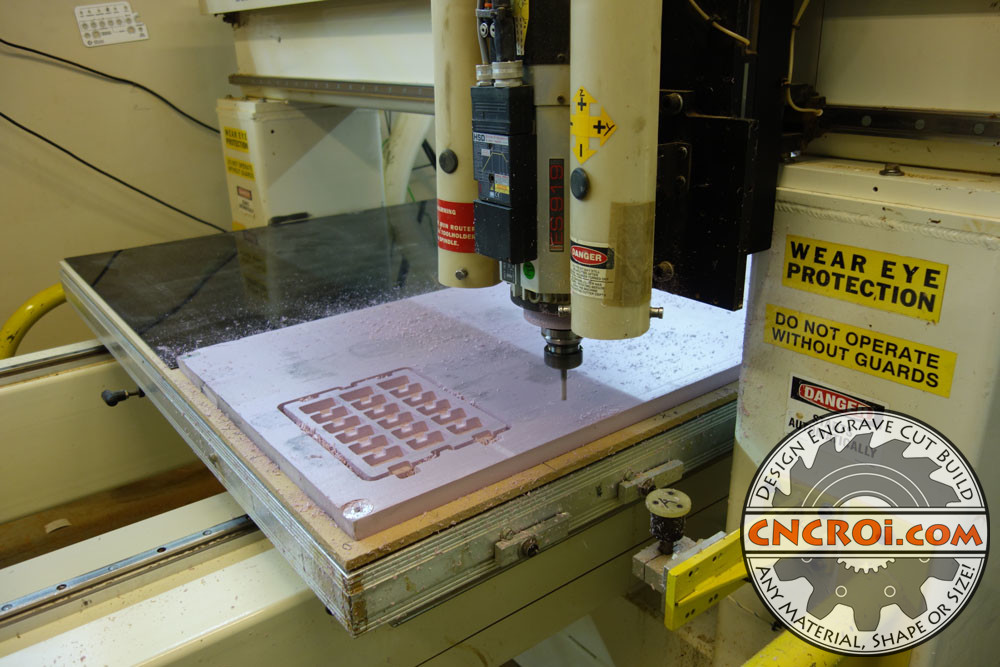

Today we’ll make another round of custom metal product shipping foam, I made these a while back with my other machine and this time around, we’ll use my new machine to do the same!

https://www.youtube.com/watch?v=NLiWkV7GRgg/

If you want to compare, the above is the new process and below, the “old”, it’s hard to tell, but the precision of both machines is the same, just the speeds and feeds are a lot faster with the new one due to weighing over 10 000 pounds vs about 1500 pounds.

https://www.youtube.com/watch?v=xsiZ4lDglfM/

Of course, there has been an evolution in this product, you can see here how the initial design looked like when I made the prototype.

Many of the advantages that the new machine have, such as a tool changer and extra rigid table, make no difference when it comes to producing products out of foam, the material has so much give that essentially, I’m just cutting through air at CNCROi.com.

As with the previous run using my other CNC router for this job, before I got the new one, the purpose of these foam inserts is to ship things back and forth from the anodizer, this makes sure that the parts are not damaged in any way during the transportation and handling at various companies.

Anodizing is a wonderful process but its such a thin layer that any scratches in the aluminium are clearly visible after the process, arguably, even more so, thus having as perfect as a part when it leaves the factory is vital!

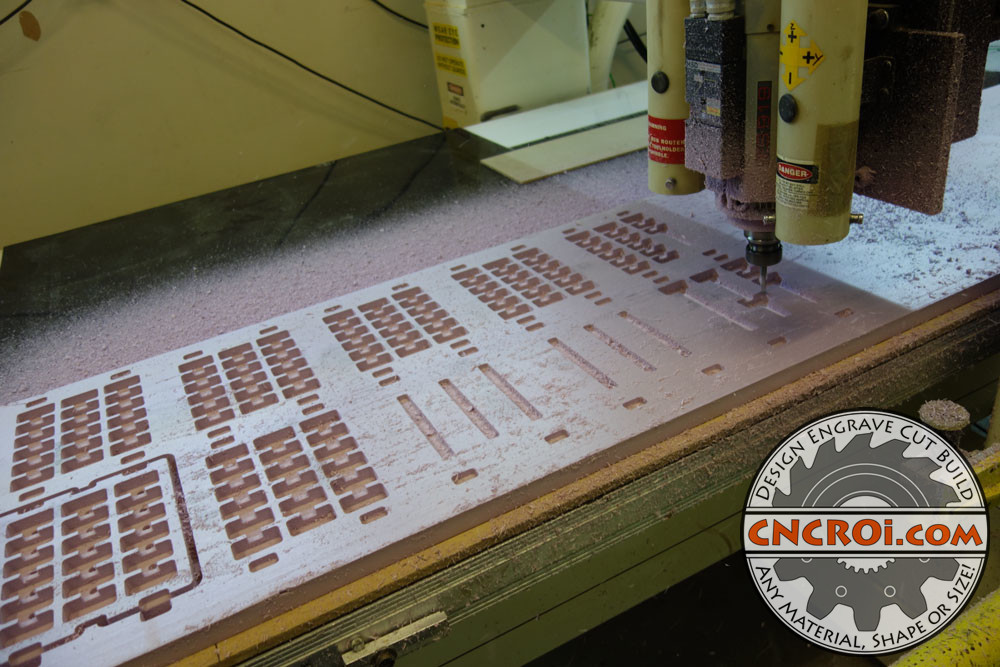

The foam used for these custom metal product shipping foam inserts is the same as the previous run, it’s just as clinging and messy, especially without a dust shroud over the foam to catch most of it during production at CNCROi.com.

My typical dust shroud used for my Thermwood can’t be used for this as it would scratch the foam too much as it’s too low, I’ve since gotten another one that sits a lot higher, and thus, this mess will not be repeated again at CNCROi.com when cutting custom metal product shipping foam.

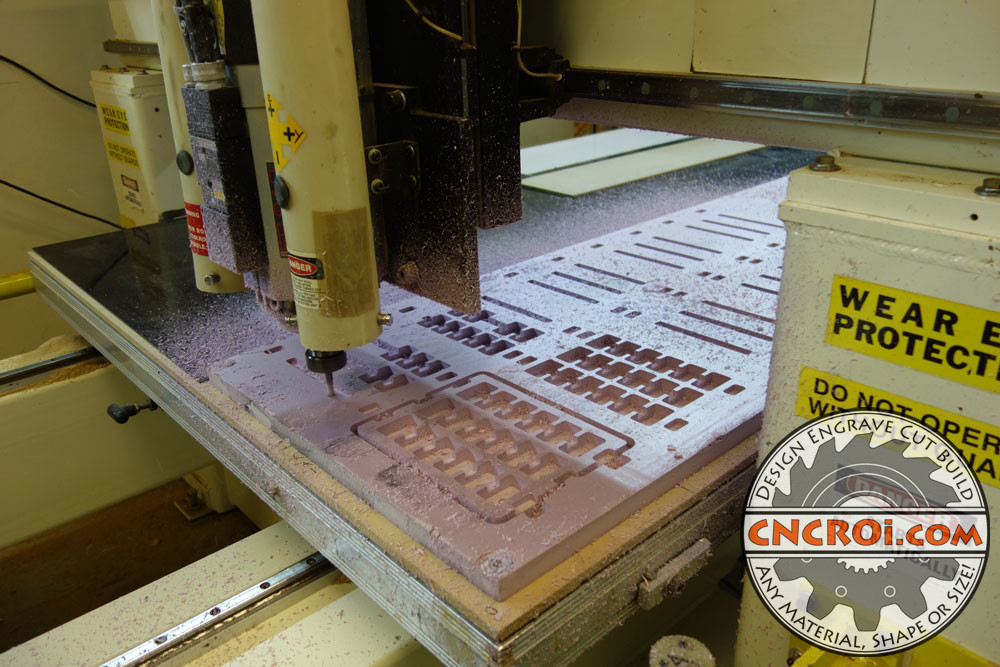

Of course, this isn’t an issue when I’m laser cutting foam inserts but I can’t do this type of precision z-axis-depth-carving with a laser, it must be the router.

Throughout the foam carving process that was creating these custom metal product shipping foam inserts, I was blowing and sucking the small foam dust that was accumulating all over the machine, this stuff literally gets everywhere, so the less of it I have in the shop, the better!

CNCROi.com has cut foam for years, each process has a plus and minus, in this case, the router does precise depth carving but the cost is small bits, almost particle size, all over the machine and shop, while with the laser, all that’s produced is smoke but I don’t have precise depth control and it’s very much a fire hazard during production.

The process of cutting these custom metal product shipping foam inserts went very well, this is a low volume but repeating project at CNCROi.com so I always have this foam ready to go when the customer needs more of them!

It may not to noticeable, but I do have the dust system going for this project, sucking little bits of foam that get too close to either of the extraction vents you see on the sides of the spindle, it did pick-up lots of stuff BTW, there is just so much of it, and it’s so small, that you don’t see it being sucked-up and away from the machine.

The process of cutting out these custom metal product shipping foam inserts couldn’t be more different than the process of cutting our red oak banks, which is the absolute opposite end of the spectrum when it comes to material hardness.

https://vimeo.com/728205113/settings

Cutting jobs out of a very hard wood require a lot of finesse, a very powerful machine and a very rigid one with proper tooling to pull-off correctly, all of which aren’t necessary when cutting out these custom metal product shipping foam inserts.

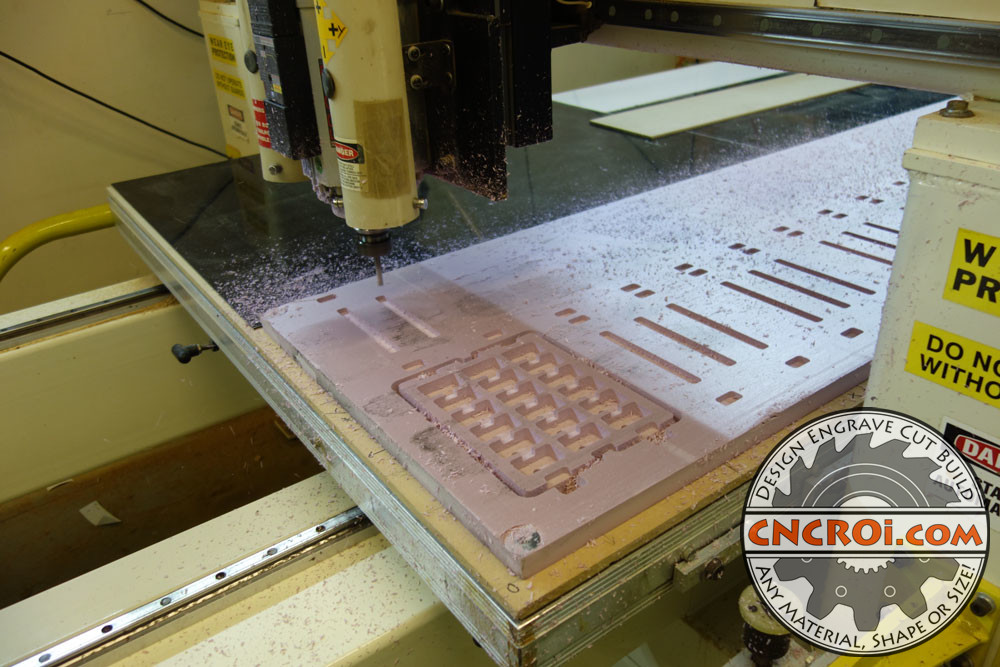

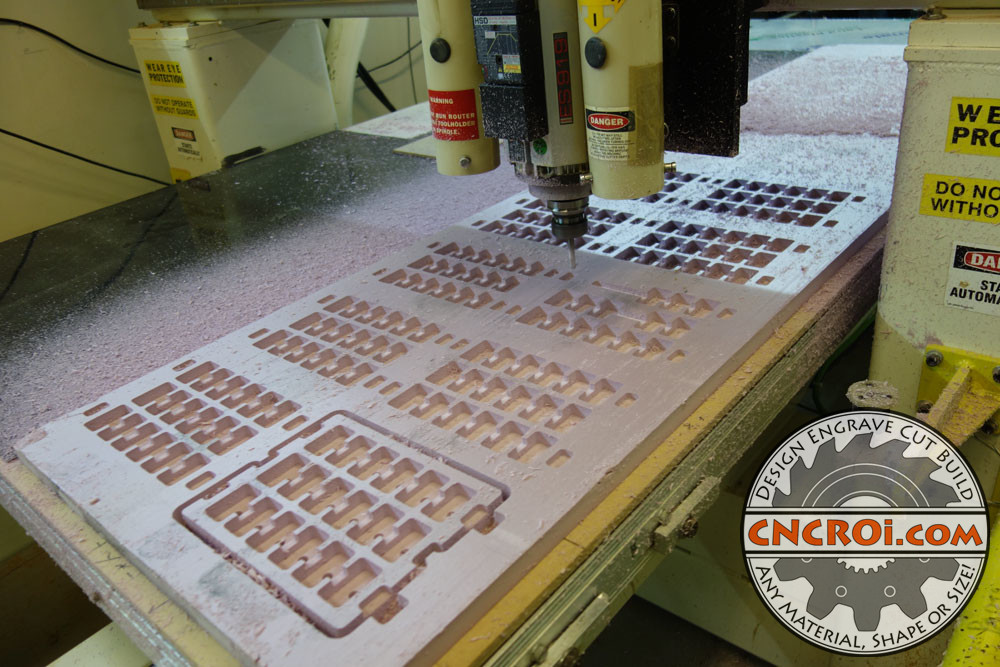

For hold-down methods used for this foam insert, I have both the powerful vacuum system and I screwed it in at all four corners, just in case, as the foam is very rigid and I wanted to reduce any possible vibration that can occur when cutting these out at the speed I was at CNCROi.com.

Foam can cut very cleanly using a router at very high speed, but you have to make sure the foam has zero give and is properly held-down, otherwise, you end-up with lots of fuzzies all over the place due to the vibrations in the foam itself produced during the cutting process.

Foam is a very versatile material, but generally, CNCROi.com uses it for applications where holding something else “safely” is required.

Each step of the production of these custom metal product shipping foam inserts is done with the same tool, they are just methodically doing different jobs one after another, so that there is as little movement as possible, that’s where having the table move rather than the gantry pays huge dividends.

CNC routing out these custom metal product shipping foam inserts involves a lot of little programming nuances, hence different paths to do different things, one at a time, otherwise, for instance, if you cut out the holes first, you are wasting machine time as you have to carve out those pocket anyways, doing the holes after the carving process means that you can plunge faster and not wearing out your bit doing redundant work.

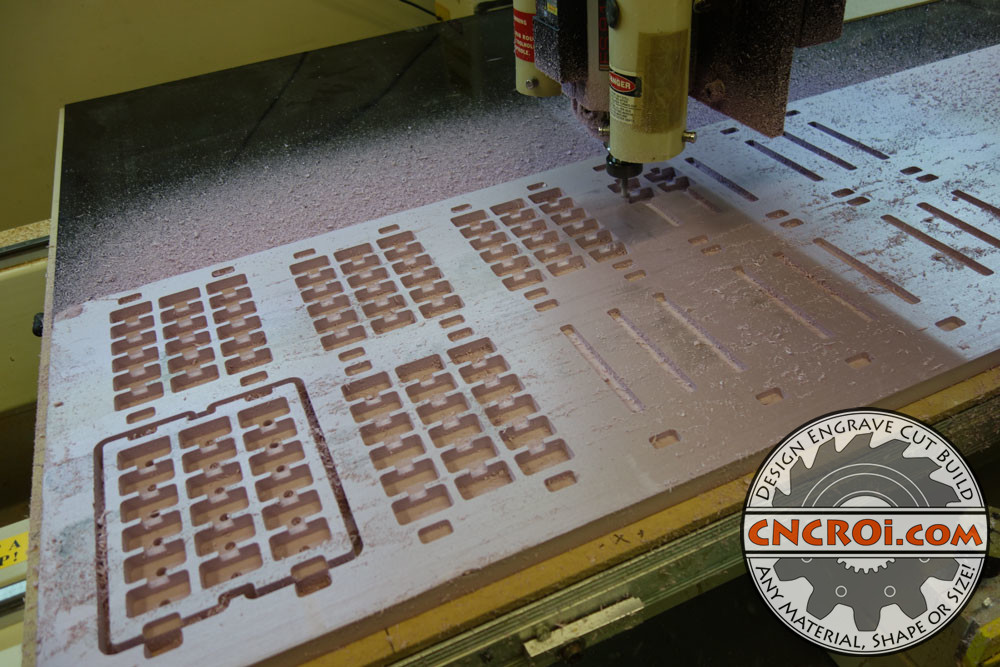

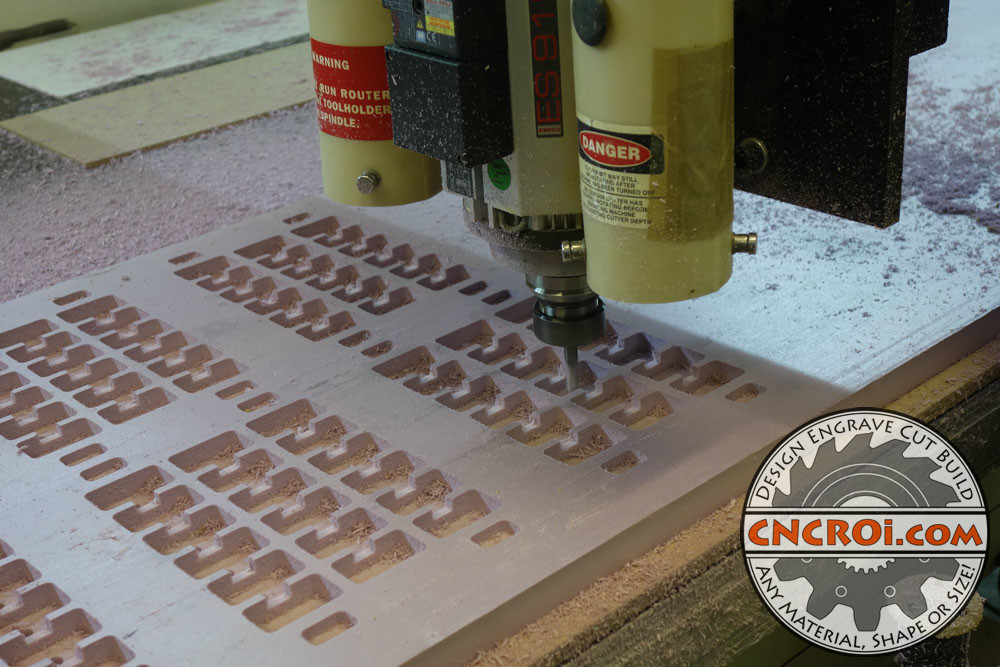

In the above picture, you can see the screw I put into one of the corners of the foam, I used a washer as well because otherwise, the screw wouldn’t hold anything as it would go right through, the foam is rigid but not super dense.

Here’s a video that I made over six years ago showing you how little the process has changed with CNCROi.com when it comes to laser cutting foam.

Now that these custom metal product shipping foam products are finished, you can see what they look like, they remain in place because of the screws and the vacuum system sucking it down onto the CNC router bed.

Each is identical to the last, you can more clearly see the tabs in the image below, they are those little protrusions that go from the “soon to be scrap” and the foam product I just made at CNCROi.com, those will be sanded off.

What’s great about using our CNC to produce these custom metal product shipping foam inserts is the repeatability, each one is as identical as the previous one made at CNCROi.com, whether there is one or a thousand, regardless of when they were made, the file integrity and resultant output will remain the same.

These still have a few little fuzzies from static cling, it doesn’t just stick to the machine, the table and me… but to the work piece itself! Need some? Contact CNCROi.com right now!