Custom Plywood Structure: CNC Routing

Let’s make a custom plywood structure at CNCROi.com using our Thermwood CNC router!

https://www.youtube.com/watch?v=tRvqTaVmB-I/

One of the first materials I ever used with a CNC router was quarter inch plywood, the same I used for this project, I also used ONLY that material for YEARS with my 3D modeling business CNCKing.com.

I only have great memories of spending all my time modeling, animating then releasing these models on my old business, then generating sales around the world for these models for other CNC machine operators to enjoy – and yes, I still have that ShopBot Desktop to this day and no, I never imagined in my wildest dreams that I’d have a shop with all the CNCs I enjoy now, back then.

Back to the custom plywood structure at hand, the finished model was too large to roughly assemble in the shop and the client was doing this anyways so I that’s why I used one of my earlier models to give you an idea of what this one was, it wasn’t my design, hence no 3D animation.

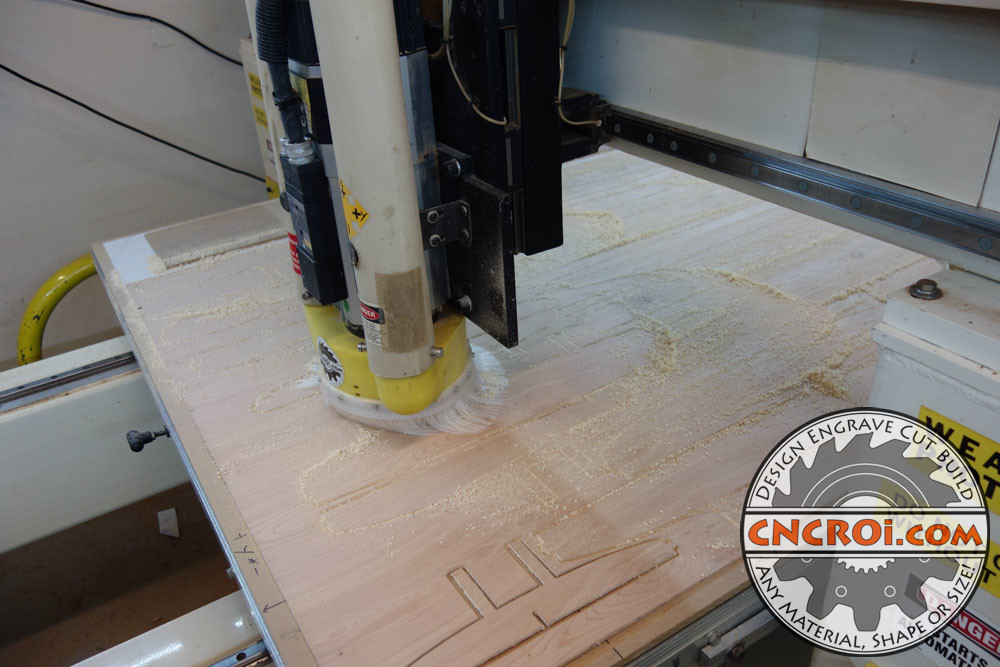

Although my Thermwood table is 5 x 10 ft, the sheet I put on it is 4 x 8 ft, hence all the other parts of it being covered with acrylic and other substances to maintain vacuum during most of the cutting, there was a lot being removed here, so I knew the vacuum would be having a tough time of it, so I also screwed it down and made tabs in the model itself to keep everything stationary during the production of the custom plywood structure.

As I tell customers, there is no perfect CNC machine, each has it’s plus and minus, it’s getting the best machine you can afford for the application you have at hand that matters.

Plywood is used for a variety of custom projects at CNCROi.com, from very large signage to models and anything and everything in between, it’s strong, easily acquired in a variety of thicknesses and grade with the best feature being durability for price ratio.

When it comes to plywood, it never comes flat, so having a powerful hold down that kept it that way was a wonderful change compared to my other CNC router in the shop, sure I can add endless screws to keep it down but vacuum is a game changer and a strong one is even more so at CNCROi.com for fast and efficient production of this custom plywood structure.

It’s truly endless what can be made at CNCROi.com, from Christmas to Corporate, we’ve got you covered!

I did one test cut to see what the edge quality etc. was like for this custom plywood structure piece and it was fine, so I cut the rest of the project out – as I recently got this Thermwood CNC router, all my settings need to start anew, along with larger bits so a bit of testing always helps to make sure I produce the best results for the client.

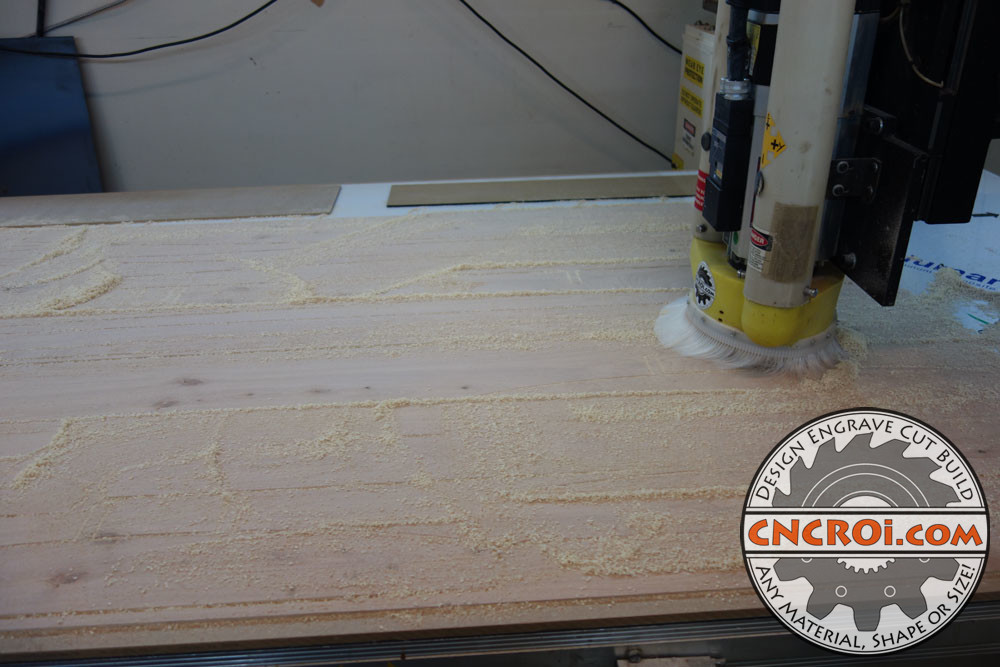

Although I have a dust system, I kept it mostly off during the production of this custom plywood structure because I wanted the debris to fill the voids left from the CNC routing, it makes the whole job a lot more messy looking but it means the plywood will stay flat, longer, and the pieces are less likely to have any movement as well.

As with every project at CNCROi.com, each time work is done, new lessons are learned and applied to the next project, and this one was no different.

I’ve been routering even before CNCROi.com came into existence, or was even a thought, through the years, we’ve done some certainly interesting projects!

It may seem like CNC routering, like using any other CNC at CNCROi.com just involves pressing a button to make the project reality but there is a lot of programming involved before anything is cut and even more hardware optimizing before anything is made at the shop, I wish it was just pressing a button.

You can clearly see how all the voids are being filled quite efficiently by the table vacuum system for this custom plywood structure, the vacuum is incredibly strong and sucks just about anything down, if you put your hand on it, you feel it being sucked into the table.

When it comes to CNC routering quarter inch plywood, it’s a relatively straight-forward process, the challenge though is to make sure you can cut all the parts before the board starts to move on you vertically or in any other direction, as it loses strength pretty quick the most holes you put in it, screws and vacuum systems can only do so much.

Strange thing with Thermwood CNC routers is that the sacrificial board just sits on the table, the vacuum system holds it in place, so this process is never done, it makes things easier.

Thanks to the flexibility that CNCROi.com can offer across multiple platforms, if you wanted this made out of stainless steel, Corian, plastic or anything else, it would have been no problem for us.

CNC routering is a lot of fun, after all the programming and optimization is complete, it just takes a while to get comfortable with a machine that can literally rip your limbs off without a second thought or sweat if you do something wrong around it.

At first, I found the table moving to be a little disconcerting as all my other CNC routers had the gantry move instead, but I’ve since found this actually a better method of production and safer, it greatly reduces vibration and maintenance as it simplifies the entire machine and allows for a far heavier machine as extra motors aren’t required to move said gantry back and forth.

It may be hard to see from all the dust, but these custom plywood structure parts are really coming out great, the saw dust is doing a wonderful job holding everything together and the router is powering though this like the plywood wasn’t even there at CNCROi.com.

I’m sure this could be accomplished using my Thermwood as well, but CNCs can of course, play music too!

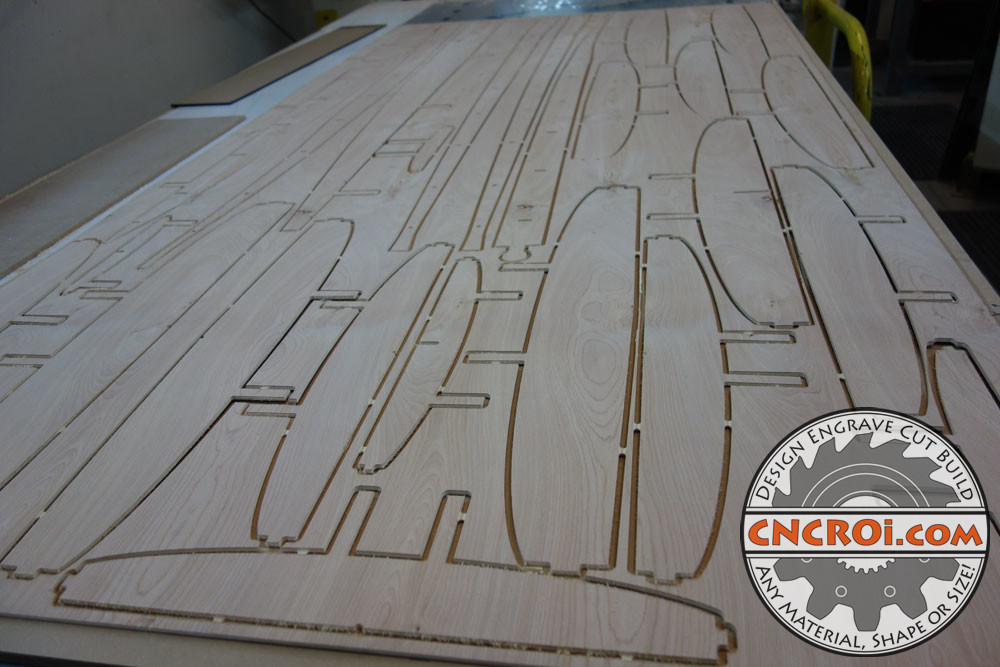

Now that this custom plywood structure is finished being made, I ran the vacuum system over everything to clean it up and show you the final results of what was made at CNCROi.com.

These parts look great, you can see some small parts raising up, as is to be expected once the vacuum system is off and the dust cleaned-up.

Overall, I’m very pleased with how the whole thing went, it makes me want to cut some of my own models at a far larger size… if only my shop had enough room in it to store them at CNCROi.com!

Looking for custom design through fabrication of plywood projects? Contact CNCROi.com right now!