Oak Mold Prototype

When it comes to custom Oak mold prototype, CNCROi.com can make them for you at just about any spec you desire.

If the beginning of this looks familiar, this is actually how I make the custom banks and other woodworking products for my other business SandboxRanch.com so laminating boards together, regardless of the species, is something I have lots of experience with.

I had a bunch of thinner pieces of wood left over from several production runs that were too shallow for the banks so I decided to laminate a fresh one using this and make a few other items with it that were more apt.

On the left of the above laminated slab, you have poplar, which I’m going to make something else with, and on the right, Oak that will become the Oak mold prototype.

Of course, we can also carve items into other materials using our CNC laser too at CNCROi.com.

The reason for this Oak mold prototype was so that the client can test their thermoforming equipment using a hardwood vs the MDFs we made in the past in order to see which will perform the best over time and produce the best quality plastic pieces for them.

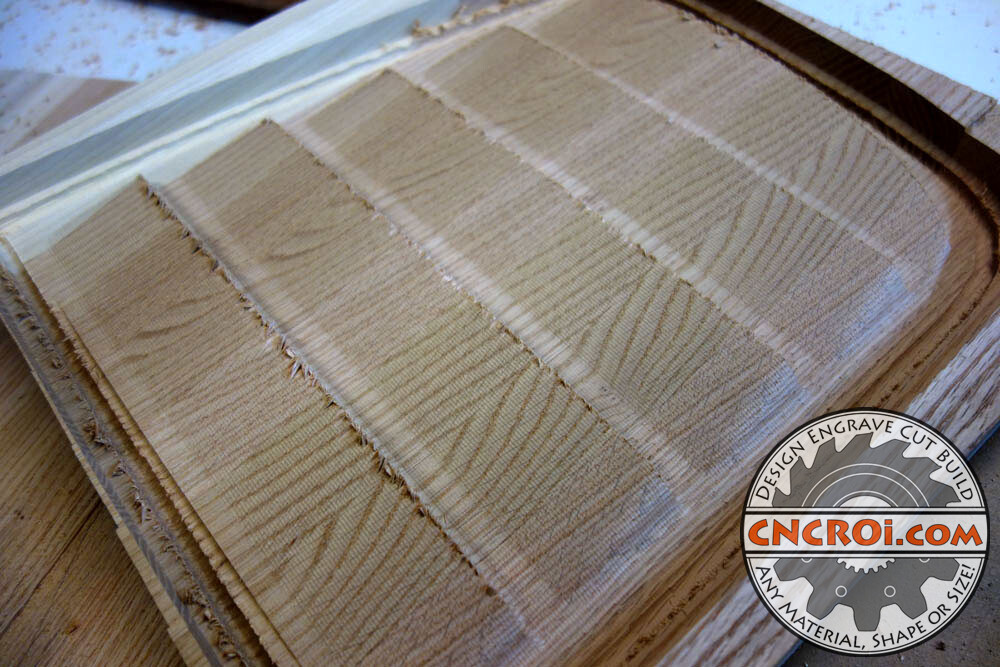

Before any mold can be made, I needed to flatten both sides of the laminated glued-up Oak and Poplar slab at CNCROi.com in order to make sure everything was flat and parallel to the moving table on my large CNC router for best results.

The first step of making this Oak mold prototype is to remove material that may get in the way of the carving bits, you don’t want the colet to hit the hardwood, MDF I can forgive a little but hardwoods, that’s just asking for trouble.

Once the material is removed around the custom Oak mold prototype, the carving can begin, this is the very slow process, first, the roughing bit will get rid of most of the material followed by the far smaller ball nose bit that will carve out a lot more details from the laminated Oak.

Positive, negative or just unique carving, CNCROi.com can make them all!

As this is a prototype, the scale is brought down quite a bit as it makes management of the overall piece a lot easier for testing purposes, also, a lot less sanding and finishing is required before actually putting this into use at the smaller scale.

There is quite a bit of depth, even in this custom Oak mold prototype, so several passes are required for the roughing bit, this isn’t required for the finishing bit because almost all the material is removed beforehand, so it can be done in one pass even if there quite a bit of Z movement.

After all the roughing is finished, you can sort of see what needs to be carved out, now it’s time to go-ahead with the very time consuming tasks of greatly increasing the resolution of the Oak mold prototype with the ball nose router bit at CNCROi.com.

As this is a hardwood, and Oak at that, there is some slight slight chipping but the nice thing about wood is that this is very easily fixed using glues, resins and a bunch of other methods to “fix” it up.

CNCROi.com has done lots of CNC carving though the years, sometimes complicated multidimensional work like you see in this blog posts, other times, simple flat work.

The speed of production, whether it’s a hardwood like Oak or MDF, is the same, the process can’t really be sped-up or slowed-down very much depending on the material as it’s removal of very little material with the ball nose while a lot is done using a very large bit in comparison.

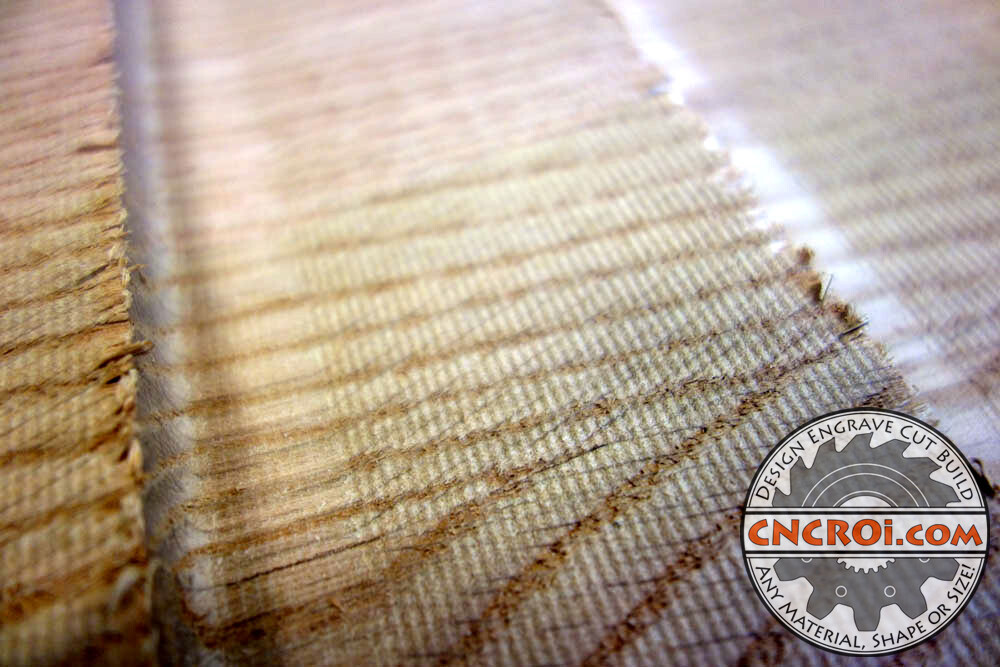

You can see just how much of a difference the smaller diameter bit performs on this custom Oak mold prototype now that the roughing pas is complete, if you look very closely, you can actually the see the “steps” of each pass, this can be of course, increased or decreased to suit the final application at CNCROi.com.

Of course, this will be sanded and finished-up by the client, so the steps you see here will pretty much disappear and moreover, are so minor even in their present form that they barely show-up in the finished testing.

What I really enjoy about the process of doing the final finishing pass on these carvings, regardless of material at CNCROi.com, is the revealing process itself, the higher resolution makes an incredible difference.

Although the router I have now is MASSIVE by comparison, I still use my little one to do small carving jobs.

Now that this custom Oak mold prototype is just about done, you can start to see what the almost finished mold will look like, the nice thing about hardwood or even MDF molds, over other materials like aluminium, is that it’s easily fixed using common tools and processes available in just about any shop.

You can really see the improvement I did in seeing the work as I’m doing it with the T8 LED lights not just above the machine but right under the gantry of my Thermwood CNC router.

Let’s take a look at the finished custom Oak mold prototype closer-up, again, the client is finishing this up to meet their internal specs, my job at CNCROi.com was to give them the structure for them to work from.

Here’s a close-up of the steps I mentioned earlier o the oak itself, they are less than 1/32″ in height, it’s just the lighting that makes them appear more significant than they really are.

Need a custom mold or carving? Contact CNCROi.com right now!