Polycarbonate: Fiber Laser Marking and CO2 Cutting

Very few materials showcase the incredible advantage CNCROi.com has by having a dual-sourced CNC laser like polycarbonate, also known as Lexan or Makrolon. Why? Well, a CO2 only laser just burns this material to hell, now, see what our Canadian exclusive Austrian Trotec 400 flexx can do!

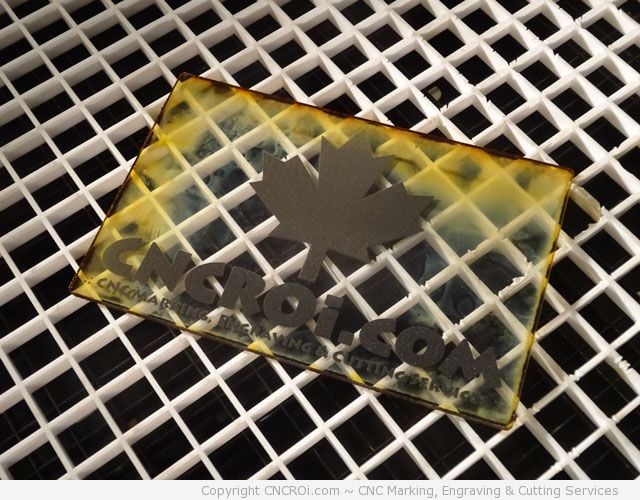

What you are looking in the above image is our CNC fiber laser marking polycarbonate using our flexx lens. Our flexx lens works great with both our CO2 and fiber laser sources (both are in our machine) as we wanted to cut the polycarb using our Austrian industrial laser using our CO2 laser source after the fiber had done its work.

You can see the fiber marking came out fantastic but the cutting of polycarb looks very rough, this is why polycarb is a tough material to cut or engrave using a CNC laser. Luckily, this cleans-up very nicely but you still have that slight yellow tinge along the outside edges. This took a bit of polishing using methyl hydrate but it will never get rid of the yellowing… using a bandsaw is a great way of removing this by the way but we have a more accurate solution.

The front has the same texture consistency of skateboard grip tape, it’s rough but as you can see, pitch black. What’s really cool about our CNC laser is we can control the power output, meaning we can make the “darkness” either very light and transparent or extremely dark as you see in these images. Of course, we can play with the settings to no end, so make the image using a grayscale for darker outlines and lighter “insides”.

Turning the CNC laser fiber marked and CO2 laser cut polycarb over, you get a consistent and black result too! Why is this so awesome? Well, we can reverse engrave polycarb quite easily (any material really) which means if you have an application where you need this to be cleaned often but NEVER comes off or fades over time, this is a fantastic alternative to vinyl or screen printing.

Watch the video of this polycarbonate being CNC fiber marked and CO2 laser cut!

I dislike that yellow edge!

If you are like me, the cooked and yellowed edge isn’t the most attractive finish for most applications. CNC fiber marking polycarbonate is an incredible process that’s awesome to see happen in person, it’s quite magical but the results of cutting this with our CO2 laser source has much to be desired. Solution?

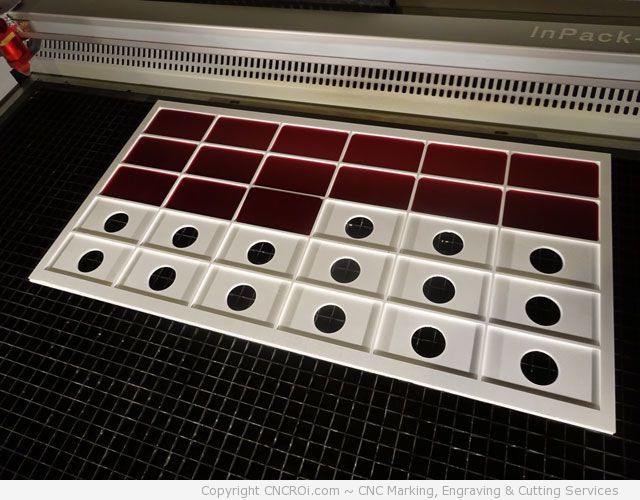

Yep, that’s why we have an industrial CNC router too! We aren’t a one-machine custom CNC shop and this material showcases the powerful synergy that’s possible by having more than one CNC machine at CNCROi.com!

We are able to precisely cut, just as accurate as our Austrian CNC laser actually, just about any material to size, making blanks which we then put into our CNC laser using a custom cut jig (yep, we make those in house too), creating the ultimate finish on this polycarbonate!

I hope this offers just a glimpse as to what CNCROi.com is capable of doing, the synergy between our tools, experience and industrial grade equipment is something that many of our clients have benefited from and we look forward to you, if you aren’t yet a client of ours, of gaining the incredible advantage we present to your business. Keep in mind though, we only take-on the best clients!

Contact us and let’s get the ball rolling!