Puzzle UV Jig: 3/4″ MDF Routing

CNCROi.com made a puzzle UV jig because otherwhise, the UV printer jig would have been hard to manage by the customer and more prone to warping, this being MDF and all.

The added advantage of a puzzle UV jig is that you can mix and match the jigs based on the production schedule that day, so if you have two big things and two small things, some round, some square… you can just put together what you want and get right to it.

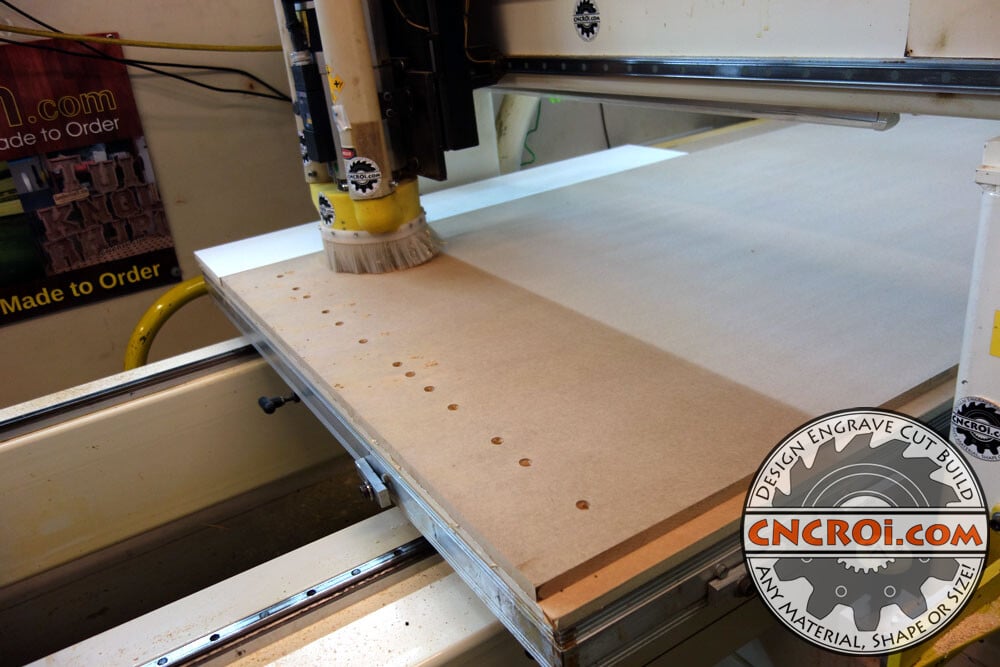

The depth of these “tracks” was 3/8″ and the work was done onto 3/4″ MDF using our Thermwood CNC router.

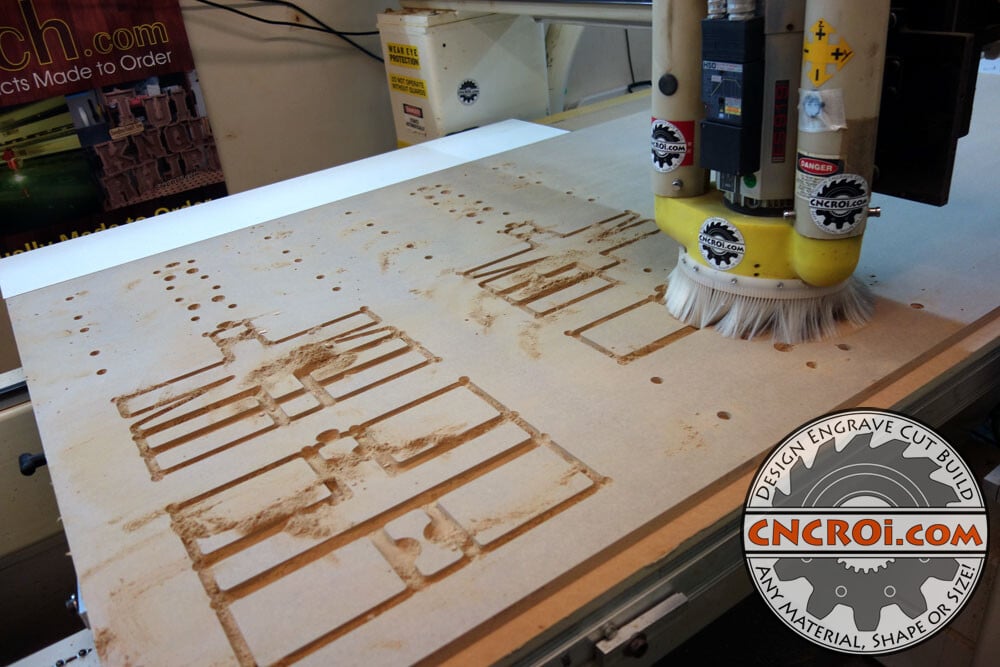

As the design was suited to long profile cuts, but with some voids where there was an intersection of paths, I decided to make things easier for me and just carve out the intersections and then go ahead and cut all the paths that would make-up the final puzzle UV jig.

There are a ton of different ways to fabricate things using CNC machines, even on similar projects, lessons learned on one is applied to the next but generally, you want to keep the whole sheet as ONE SHEET as long as possible for dimensional stability and accuracy.

Custom UV printer jigs can be made to any spec you want, size, shape or material… makes no difference to CNCROi.com!

This puzzle UV jig had lots of intersections, so lots of holes were carved out, these will dissapear once the paths are done across the jig and as such, the dust build-up on the machine makes no difference to a half inch bit, though we are using a vacuum table.

When carving out MDF or any material for that matter, you want to take a light approach to it, this makes sure the material doesn’t move on you (this is rock solid with the vacuum system we have) and although MDF produces dust with little heat extraction as there are no chips to come out with it, maintains the bit from getting too hot and wearing out prematurely.

There is quite a bit of dust created during the production of this custom interlocking UV printer jig.

I’ve lost count of how many custom UV printer and wider, jigs in general, that CNCROi.com has fabricated across all our machines, we make them out of wood, plastic and even metal.

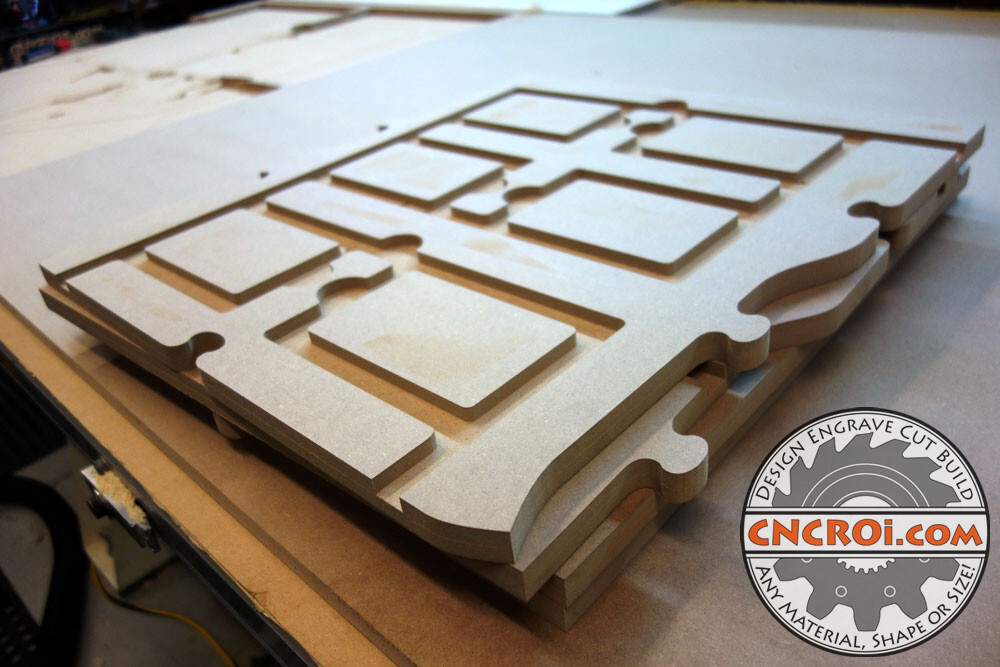

As we made these in a set of four, the puzzle UV jig pieces were roughly 24″ square but the original jig was meant to be 48″ square which, at CNCROi.com is no problem, we have a 5 ft x 10 ft table, but for most UV printers out there of that size, the vacuum table is willfully underpowered, so I had some very deep concerns about making a jig that big that would remain flat over the long term.

Regardless of the material, you have to keep in mind that if you carve out only one surface of whatever, even aluminium, there are internal pressures within the material itself to want to curve and bow because there is no material in the way to prevent this from happening.

For a custom puzzle UV jig that was 48″ square, the only option I could think about was a mechanical hold-down in addition to the vauum table (though redundant, why not use it too) but the customer had the idea of making it into puzzle pieces and it worked AMAZING for them after they got the chance to use the jig in their production environment.

Whether you require one or thousands of jigs, all the same or different, CNCROi.com can make them for you!

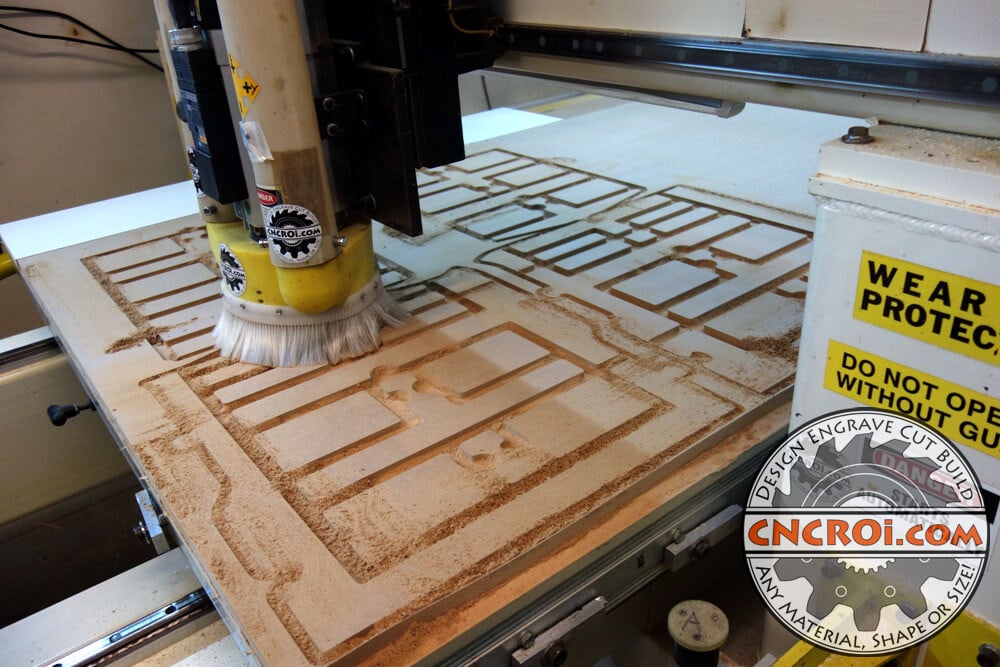

My CNC router had no problem maintaining tolerances for this puzzle UV jig no matter where on the sheet it was, as a result, everything came out looking great and as it should be.

After all the intersections and paths were complete, it was time to cut it out from the full sheet you see on our CNC router at CNCROi.com, again, we have a powerful dust extraction system but there was so much dust created during the production of this puzzle UV jig that it had trouble keeping-up.

When it comes to carving, CNCROi.com has done tons of that through the years as well, the trick to getting a solid result is having a solid machine that’s overbuilt, and I absolutely love my Thermwood as it does what I tell it to, when I tell it to, how I tell it to without fail.

Jigs made out metal can also be produced, it really all depends on what your application is.

Cutting out the puzzle pieces was actually quite fun, because after this, I need to stick it back together to see how the overall puzzle works, without absolute precision, a jig this large just wouldn’t be possible and yes, a lot could have gone wrong fabricating this puzzle UV jig that didn’t because of experience doing this type of work at CNCROi.com.

Seeing images like the above and below really make me want to upgrade my dust system but rarely is it pushed this hard, but if I keep getting jobs like this with lots of intense carving, it’s on my list of things to improve upon at CNCROi.com.

When it comes to custom puzzle uv jig production, the options are endless, we can cut out of thicker material or other material as well, such as Corian, Aluminium or laminated hardwood or even plastics.

Puzzles are fun to make, regardless of their application.

I couldn’t cut the jig without the middle parts because I had to account for the thickness of the bit, if this was laser cut, there would be no separator, but with a CNC router, it must be kept in mind.

Just love how absolutely perfect the puzzle UV jig came together, there was a little fine tuning required but it was minimal in order to achieve a perfectly snug fit that wasn’t too tight… we wanted a jig that came together and apart with a little give.

I essentially shipped this puzzle UV jig as you see it below with a few separators and lots of padding, although MDF is easy to fix if it’s dented or damaged, I prefer things to arrive at the customer as perfect as possible by overpacking rather than underpacking the product.

Need a custom UV jig any size, shape or material? Contact CNCROi.com right now!