Underwater Metal Signs: Waterjet Cut 11ga 316SS #4 Finish

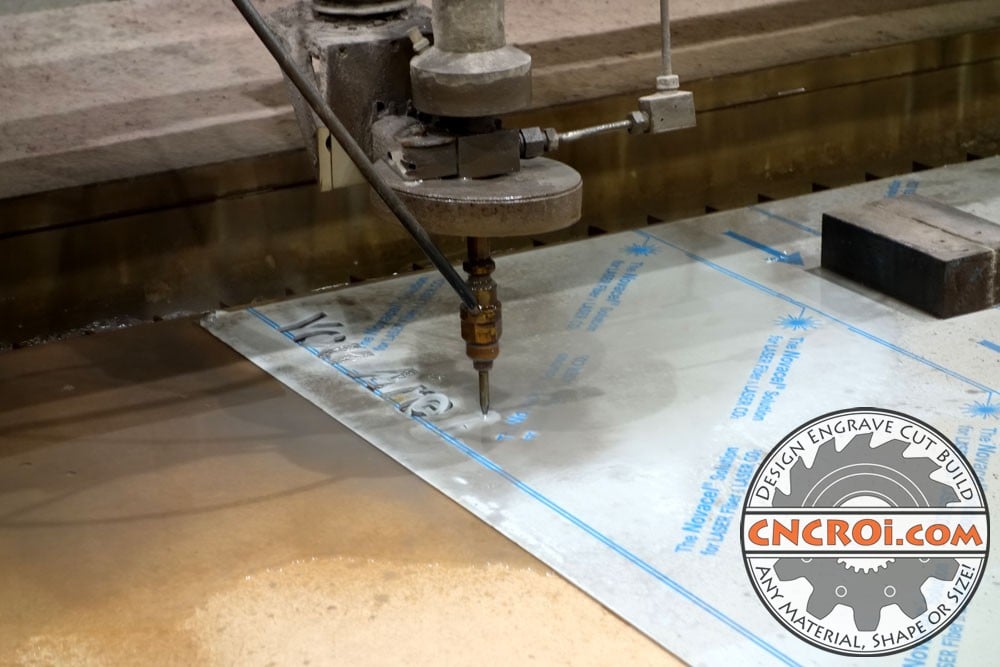

At CNCROi.com, the team dove into an exciting project involving the waterjet cutting of underwater metal signs, specifically using 316 stainless steel in 11 gauge. For those keeping track, 11 gauge measures just over 1/8 inch (around 3 mm), sitting almost perfectly at that thickness.

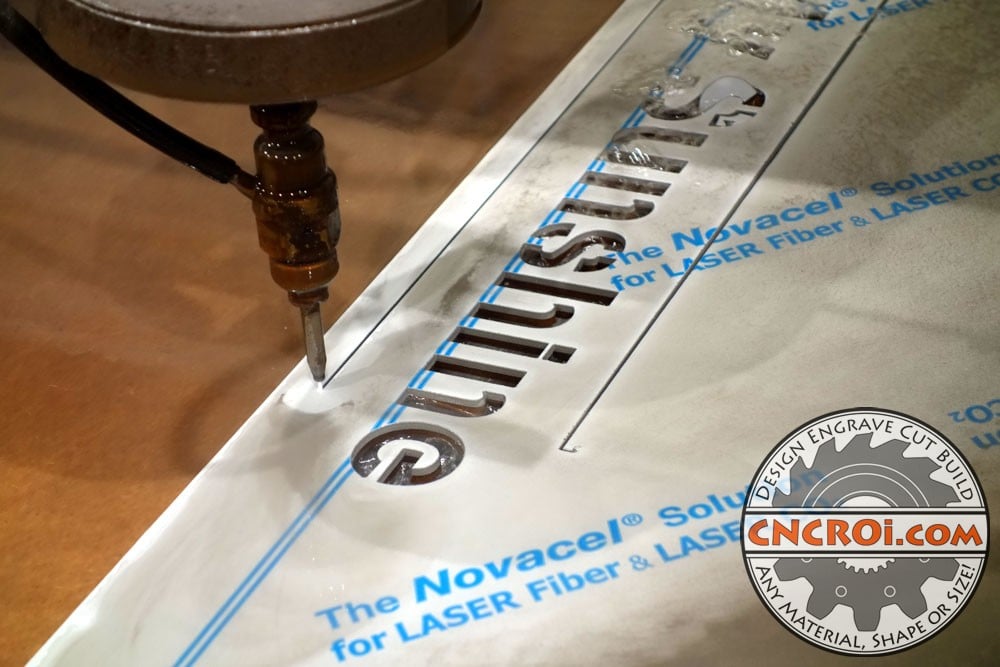

It’s interesting because 10 gauge would be slightly thicker and 12 gauge slightly thinner, but 11 gauge hits a sweet spot. The waterjet cut pieces got a light orbital sanding afterward to smooth out the faint burrs left from the abrasive process. Even though the burrs are minimal, CNCROi.com takes pride in delivering clean, professional results — no rough edges to catch fingers or ruin the visual appeal of these underwater metal signs.

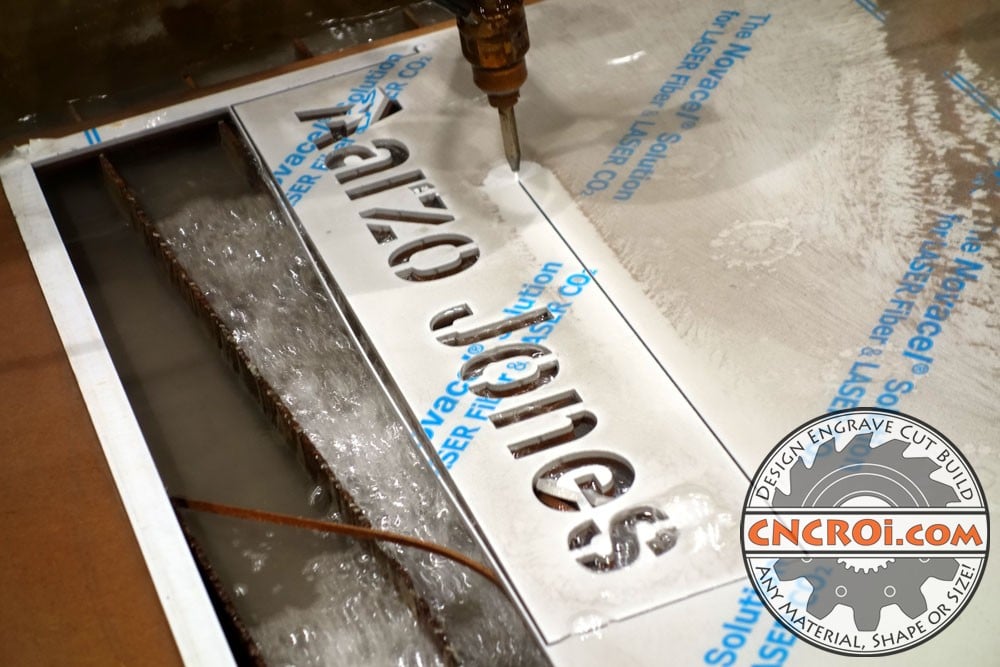

From the front, the signs had a beautiful number four stainless steel finish, meaning the brush lines ran consistently in one direction, offering both aesthetic appeal and functional durability. During shipping, the team ensured this finish was protected by keeping the protective film on.

For a peek underneath, they showed off a small leftover cut-out — in this case, a letter ‘A’ — to demonstrate how precisely the waterjet cutter removed material, leaving a remarkably clean gap with minimal waste.

Another point highlighted was the intentional cutting technique. Rather than starting the waterjet directly on the main part, CNCROi.com always begins slightly off the final shape. This method avoids leaving an enlarged piercing hole on the part itself — a tiny but visible blemish if not managed properly.

The same strategy applies whether it’s waterjet cutting or plasma cutting: lead into the main cut to protect the finished piece. This is especially critical when crafting high-quality underwater metal signs where every detail matters.

Unlike plasma cutting, waterjet cutting avoids introducing heat into the material. Plasma cutting would require careful spacing between cuts — sometimes moving 300 to 450 mm (12 to 18 inches) away between cuts — to manage heat buildup and prevent warping, particularly at these gauges. But with waterjet, the cold cutting process eliminates any risk of heat-induced distortion, allowing CNCROi.com to cut letters or intricate designs right next to each other with perfect precision.

Interestingly, the project was originally planned for plasma cutting, which would have involved cutting out simple rectangular shapes for the signs and then fiber laser etching the details. The fiber laser would allow for any font or design since it only etches the surface, not cutting through the material.

However, since they shifted to waterjet cutting, they needed to use a stenciled font to prevent internal letter sections (like the middle of an ‘O’) from falling out. CNCROi.com emphasized how their multi-machine setup gives clients endless design flexibility, from cutting to etching to engraving across various materials — a one-stop shop for custom underwater metal signs and beyond.

For those curious about the number four finish, CNCROi.com peeled off a bit of the protective film from a scrap piece to reveal the signature brushed texture. This finish gives 316 stainless steel its sleek, brushed appearance, adding to its visual and tactile appeal. Whether looking at a scrap letter that resembles an ‘E’ or a ‘G’ (depending on the angle), the team made sure to cut the pierce points within the scrap, ensuring the final parts came out flawless.

The decision to use 316 stainless steel instead of 304 stainless steel was no accident. Since the signs were destined for Hawaii and would be exposed to ocean environments, 316’s superior corrosion resistance was essential. While 304 stainless steel can corrode more quickly in saltwater, 316 holds up far better, making it the obvious choice for durable underwater metal signs. CNCROi.com knows their materials and selects the right one for each project to guarantee longevity and performance.

Stainless steel can be tricky to photograph because it reflects its surroundings, but the CNCROi.com team managed to show off the brushed texture clearly. They explained how this brushed finish runs uniformly across the surface, adding not just aesthetic polish but also a touch of class to the underwater metal signs.

Whether it’s 316, 304, titanium, wood, or plastic, CNCROi.com stands ready to craft custom signage tailored to each customer’s needs, shipping it straight to their door with care.

Each underwater metal sign created at CNCROi.com benefits from the synergy of design, material expertise, and cutting-edge machinery. The team thrives on blending design flexibility with machine precision, ensuring that every cut, etch, or engraved detail meets the highest standards.

This multi-capable approach lets CNCROi.com take on projects of all shapes and sizes — from a single custom sign to large-scale production runs. And yes, they encourage everyone to get in touch for projects they can help with; they’re always eager to hear about new ideas.

In the world of underwater metal signs, material choice is key. 316 stainless steel, with its molybdenum-enhanced corrosion resistance, performs excellently in marine environments, where salt and moisture are relentless. CNCROi.com understands these technical details and ensures that each piece not only looks fantastic but holds up under real-world conditions. Whether crafting signage for resorts, aquariums, boats, or public installations, they deliver pieces that endure the elements while looking sharp.

The waterjet cutting process, particularly for underwater metal signs, offers unbeatable precision and versatility. CNCROi.com’s equipment can slice through thick metal sheets, intricate designs, and delicate curves without introducing heat, preserving both structural integrity and visual appeal. This flexibility opens doors for clients seeking everything from simple nameplates to elaborate, multi-layered signage installations.

Beyond the cutting process, CNCROi.com adds value through post-processing expertise. Once the waterjet has done its job, the team applies techniques like orbital sanding to remove any leftover burrs, polishing the edges to perfection. This attention to detail elevates their underwater metal signs beyond basic cutouts, turning them into finished products that are ready for installation, presentation, or display.

Shipping is another area where CNCROi.com shines. The company takes steps to protect sensitive finishes like the number four brushed stainless surface by leaving protective films on during transit. This ensures that when customers unpack their underwater metal signs, they receive them in pristine, showroom-quality condition, free of scratches or blemishes.

CNCROi.com thrives on combining machine capabilities, material expertise, and creative design. Whether a project calls for waterjet cutting, laser etching, or CNC routing, they have the right equipment and the know-how to bring even the most ambitious ideas to life. Their workshop is a place where raw materials transform into custom solutions, always tailored to the client’s vision and needs.

The company’s commitment to client satisfaction runs deep. They emphasize close communication and a collaborative approach, ensuring that every underwater metal sign they produce aligns perfectly with the customer’s expectations. Whether providing design suggestions, material recommendations, or shipping advice, CNCROi.com approaches each project with the same level of enthusiasm and professionalism.

Every underwater metal sign CNCROi.com produces is the result of meticulous planning and execution. From choosing the right material (hello, 316 stainless steel!) to fine-tuning the cutting process and applying the finishing touches, the team ensures that nothing is left to chance. This comprehensive approach guarantees that customers receive signs that look stunning and perform flawlessly, even in harsh marine environments.

Clients come to CNCROi.com not just for their cutting machines, but for their holistic approach to sign-making. They offer everything from design services and prototyping to final production and shipping, making them a one-stop destination for underwater metal signs and other custom projects. This end-to-end service model simplifies the process for customers and ensures consistent, top-notch results.

What sets CNCROi.com apart is their blend of technology and craftsmanship. While machines like the waterjet cutter handle the precision work, the human touch ensures that every sign meets the highest aesthetic and functional standards. The result? Underwater metal signs that not only meet technical specs but also impress onlookers with their design and finish.

CNCROi.com loves tackling new challenges and welcomes customers with unusual or complex requests. Whether it’s a one-off custom sign for a beachfront property or a large order of underwater metal signs for a marina or public installation, they have the tools and experience to deliver outstanding results. And yes, they’re eager for you to contact them for any project you think they can help with!

The company’s ability to work across a range of materials — from metals like 316 stainless steel and titanium to non-metals like wood and plastic — makes them a versatile partner for all kinds of signage needs. Their waterjet cutting capabilities open up endless creative possibilities, allowing for detailed shapes, fine text, and complex designs that other methods might struggle to achieve.

In every underwater metal sign project, CNCROi.com balances aesthetics and performance. Their designs are meant to withstand the rigors of underwater or marine exposure without sacrificing visual appeal. This dual focus ensures that their signs not only survive but thrive in their intended environments, delivering long-lasting value to customers.

CNCROi.com’s workshop is a hive of activity, where metal sheets, plastic panels, and wood blanks transform into custom creations. The team’s passion for making high-quality underwater metal signs shines through in every step, from initial design consultations to the final, carefully packaged shipment. Their commitment to excellence and customer satisfaction keeps clients coming back for more.

While waterjet cutting takes center stage in many projects, CNCROi.com also offers complementary services like laser engraving, CNC routing, and fabrication. This broad skill set means they can handle complex, multi-step projects entirely in-house, streamlining production and ensuring a seamless customer experience.

At the end of the day, CNCROi.com wants customers to know they’re ready to help with any custom signage project — especially when it comes to underwater metal signs. Their mix of cutting-edge equipment, material know-how, and design savvy makes them the go-to partner for anyone seeking durable, beautiful, and precise signage solutions. So don’t be shy; reach out and let CNCROi.com bring your vision to life. They might even make you laugh along the way!

CNCROi.com doesn’t just cut metal — they craft stories into every underwater metal sign they produce. Each project reflects a balance of client ambition and technical mastery, where even the smallest detail matters. Whether it’s a sleek brushed finish, a perfectly cut letter, or a custom shape designed to withstand salt, waves, and sun, the team pours care and precision into every phase.

Their customers don’t just receive a piece of metal; they get a durable, eye-catching sign ready to make a splash (sometimes literally) in marine or underwater settings. And with CNCROi.com’s friendly approach, customers know they’re working with a team as passionate about their project as they are.

From large commercial signage to quirky personal projects, CNCROi.com is all about making dreams into tangible, lasting products. Their waterjet cutting capabilities combined with sharp design instincts and premium materials make them the top choice for underwater metal signs that need to perform under pressure — both figuratively and physically.

So, if you’re floating around with an idea, whether for stainless steel, titanium, or even wood or plastic signage, there’s only one place to steer your ship: contact CNCROi.com. They’ll help navigate your project from concept to completion with precision, a touch of humor, and an unwavering commitment to top-tier results.