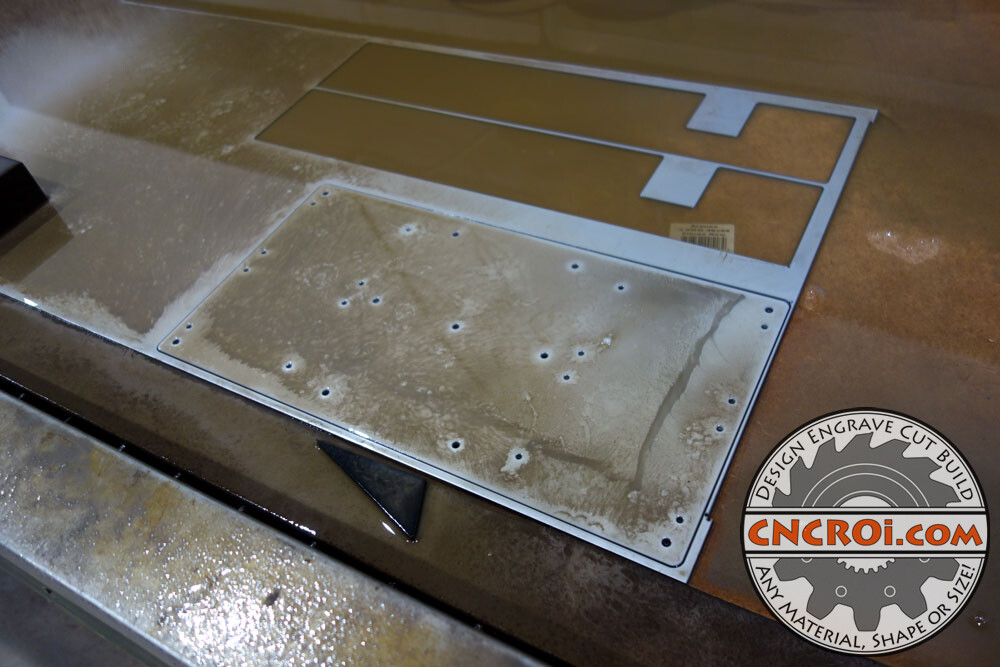

Waterjet Cutting a Steel Part: 11 ga 2B 304 Stainless Steel

Waterjet cutting a steel part from 11 ga (~1/8″) 2B 304 stainless steel is something CNCROi.com has done a lot of over the past few years, for small intricate details where heat may become an issue, it’s the perfect CNC platform for the project.

The nice thing about waterjet cutting a steel part is the beautiful sanded finish you get on all the edges, for some projects, this isn’t what you want, but for some, it is, and it’s a dead giveaway that a part was cut using garnet and presure vs melted away as you’d see with plasma or laser.

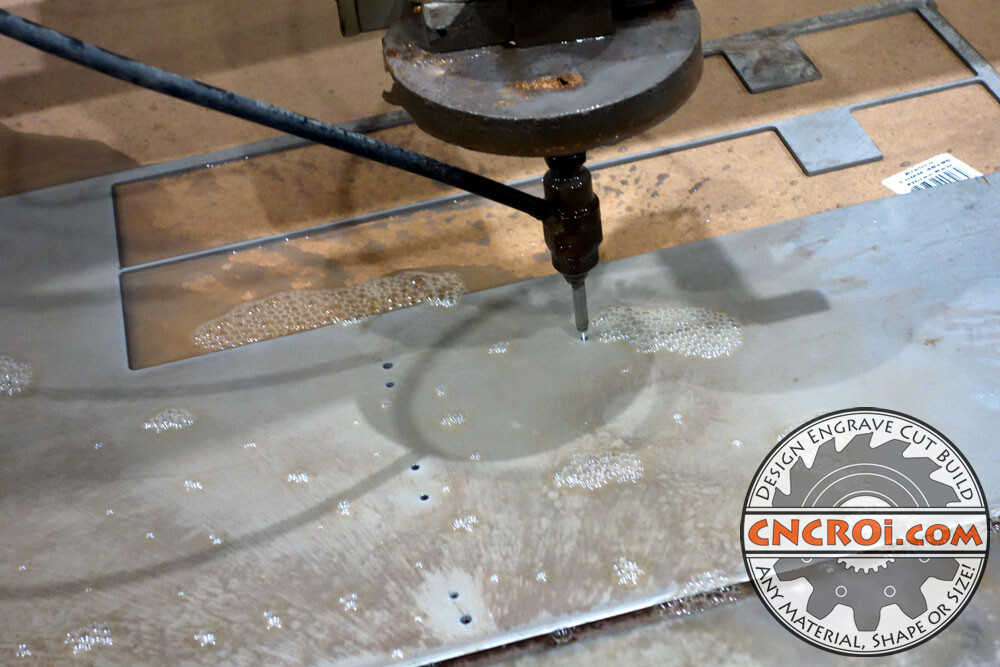

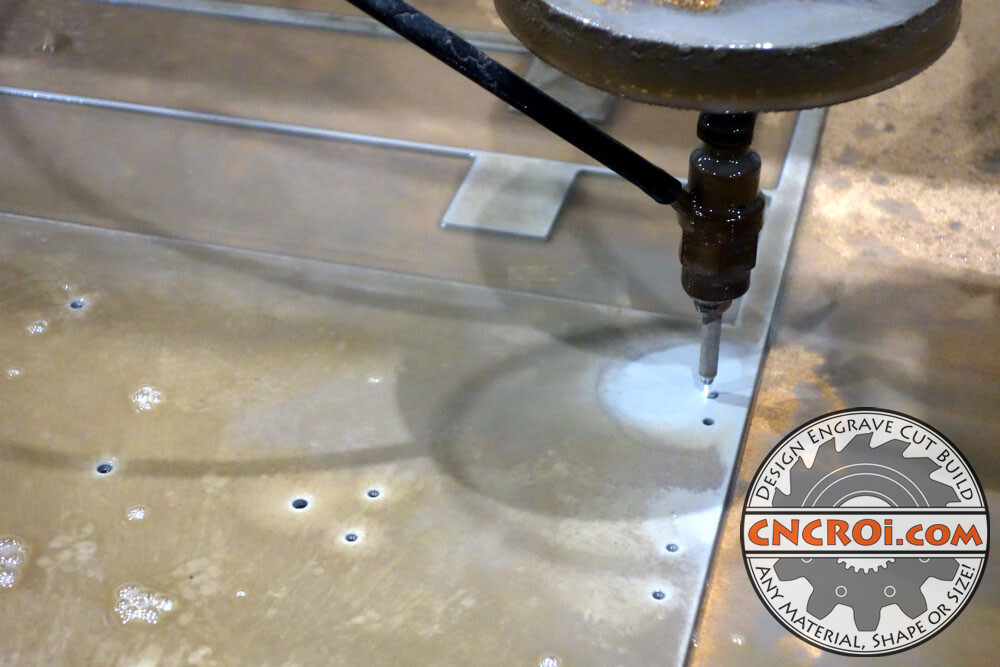

Regardless of the CNC platform CNCROi.com uses to cut your steel parts with, there is always a piercing that is required to get through the material initially, this is where a peak output is performed as it takes a lot more energy for the initial dig than it does for the continued cutting action.

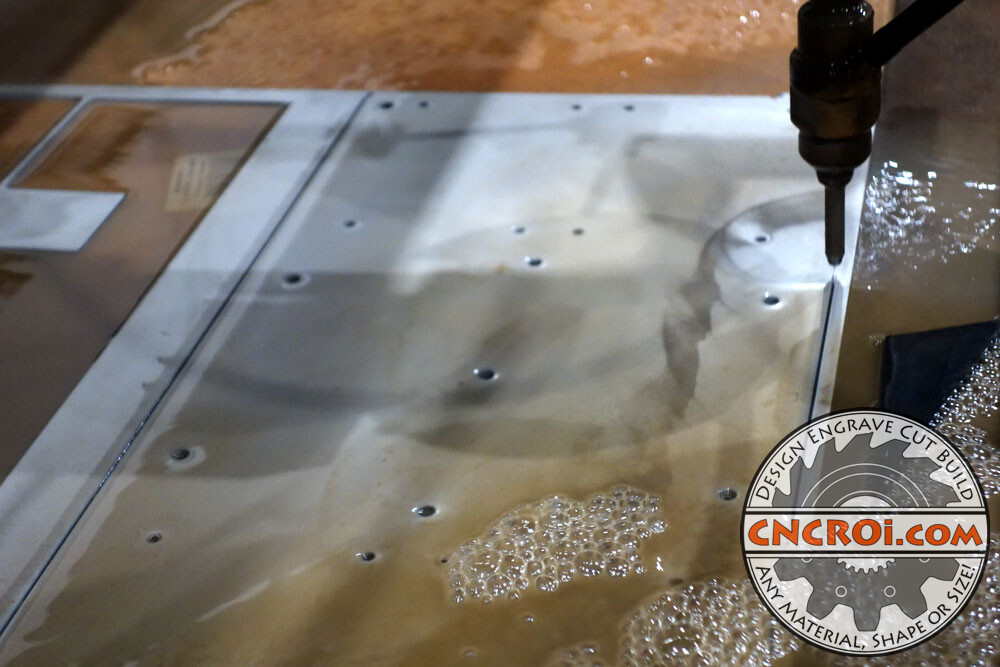

Unlike the other cutting methods CNCROi.com employs to complete customer projects, waterjet cutting is a wet process, as a result, there is some clean-up required afterwards in order to remove the garnet from the part, that’s the mud you see build-up on the top surface of the waterjet cutting the steel part.

Waterjet cutting can be a very high precision method of cutting metal, it excells in very tight tolerances that would otherwise possibly go “out” if heat was introduced during the cutting process.

There is quite a bit of summilarities when it comes to CNC cutting processes, which is why at CNCROi.com, we can use so many different platforms, but in an optimal way.

If this was laser, router or plasma, the steps and design files are basically the same, just the speeds, feeds and consumables are different, in this case, the initial holes before cutting the entire part out would also be done first.

There is no perfect CNC platform when it comes to cutting a steel part, it’s just that the waterjet ticked more boxes than the alternatives we have available at CNCROi.com.

Of course, CNCROi.com can cut non-metal items using the waterjet as well, marble is a great example of something that’s thick yet cannot be cut at tight tolerances using any other technology out there.

Each and every CNC platform is a joy to work with, there are nuances between them all regarding capabilities, speed and finish qualities that I just find so enjoyable to produce with.

When it comes to the process of waterjet cutting a steel part, all CNCROi.com needs is a digital file that is essentially a line file, the waterjet then follows these lines, inside, on or outside, in order to cut out the part from the (in this case), 11 ga 304 stainless steel.

As waterjet cutting is a wet process, it’s limited to materials that don’t mind being getting soaked, as a result, waterjet is an amazing tool to cut items like stone, metals (though you get some flash rusting of mild steel), some plastics and thicker items that would otherwise be out of range for most CNC platforms.

Regardless of what is cut using the waterjet, it can be easily painted using just regular enamel paint or powder coated if it’s steel for a little more corrosion and abrasion resistance.

In order to avoid vibrations and underspray from the waterjet cutting process of this steel part, a sheet of MDF was put underneath, it also gives a lot more support to the metal, giving a better cut for 11 ga stainless steel.

You have to keep in mind that during the piercing process, the water and garnet is shooting all over the machine until it goes through the material, then you get overspray randomly here and there as the abrasion process is occuring, you get a similar process with plasma cutting but with sparks and laser, but those processes are so fast that it’s not as apparent at CNCROi.com.

Waterjet cutting a steel part can be done an infinite amount of times, one part or a thousand, they will all have the same tolerances and be identical through the production cycle, CNC machines don’t get tired and are always happy to cut, etch or engrave whatever CNCROi.com throws at them.

CNCROi.com regularly mixes and matches processes as well, as the tolerances from one machine to the next are essentially identical.

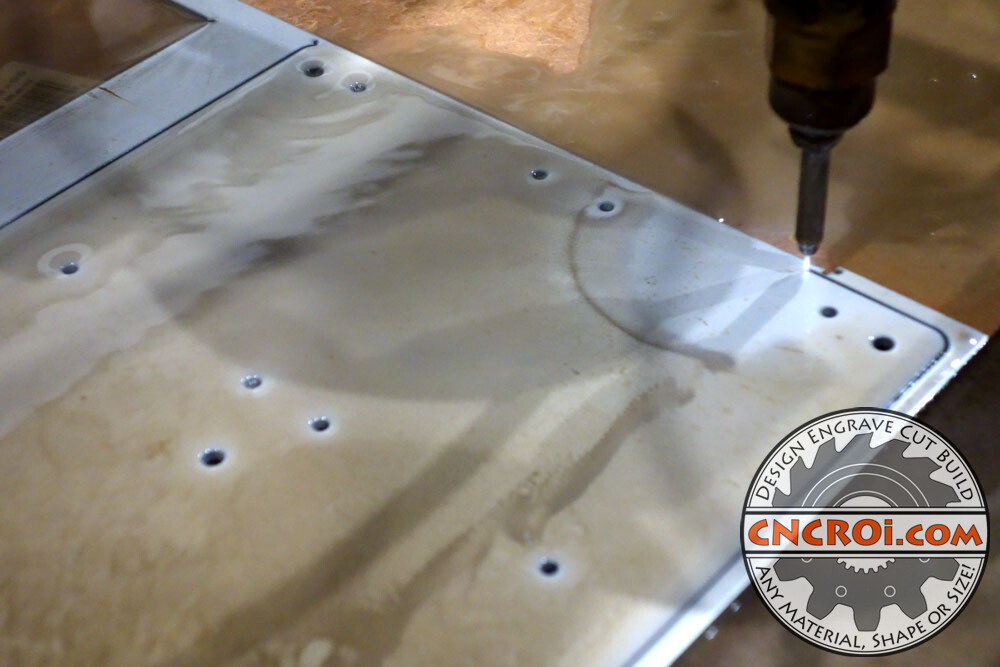

After all the inner holes are all cut at tight tolerances, the waterjet then proceeds to cut the entire steel part out from the sheet of 11 ga 2B 304SS.

Waterjet cutting a steel part can be done in short order by CNCROi.com, generally our turnaround time is a few days, which is roughly the same regardless of the machine we use but of course, larger projects take a bit longer as volumes increase.

When it comes to waterjet cutting a steel part, just about any design can be cut in any quantities you want and each design can be the same or different as the previous one as each is essentially cut one at a time.

Here’s another great example of mixing different CNC platforms, in this case, it’s plasma and fiber laser etching.

Unlike laser or especially plasma cutting 11 ga stainless steel, there is no heat generated during the cutting process, as such, we don’t need to worry about heat affected zones.

Small holes are also a challenge when it comes to plasma cutting, a laser would have no issue with the tolerances required on this steel part though as the diamter of the beam is so much narrower.

I’m happy how wonderful this part came out, I really enjoyed waterjet cutting this steel part and I know the cutomer will love receiving this in the mail.

The cut looks sharp and the details are all absolutely precise, well within tolerances for this customer and this was shipped shortly after the pictures were taken.

Need custom metal cutting and fabrication services? Contact CNCROi.com right now!