Whiteboard Shield: CNC Router VS CNC Laser

When it comes to making a custom whiteboard shield, CNCROi.com has a few machines up to the job so let’s compare how the results would be using each of them or even a combination of them.

The first part of making a custom whiteboard shield is the design, whether it’s going to be cut with a CNC waterjet, CNC laser or CNC router, there are some fine details that need to be optimized for the machine we’ll use to make it with, today we’ll just focus on the CNC laser and CNC router as those are the ones most people are familiar with and they are the closest to one another versatility wise.

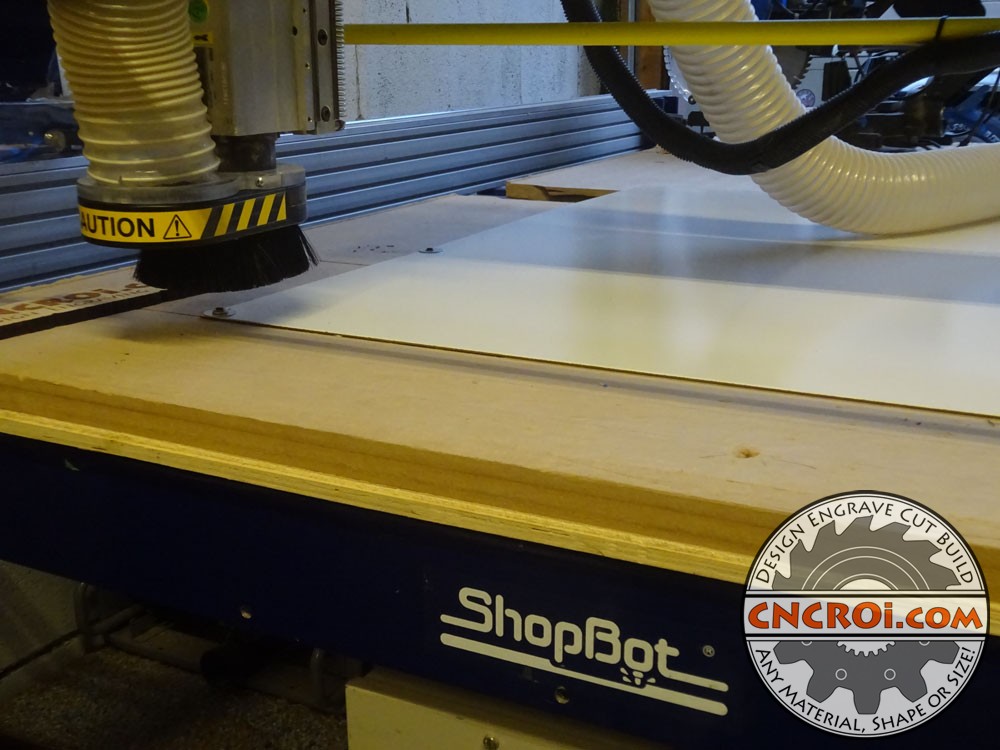

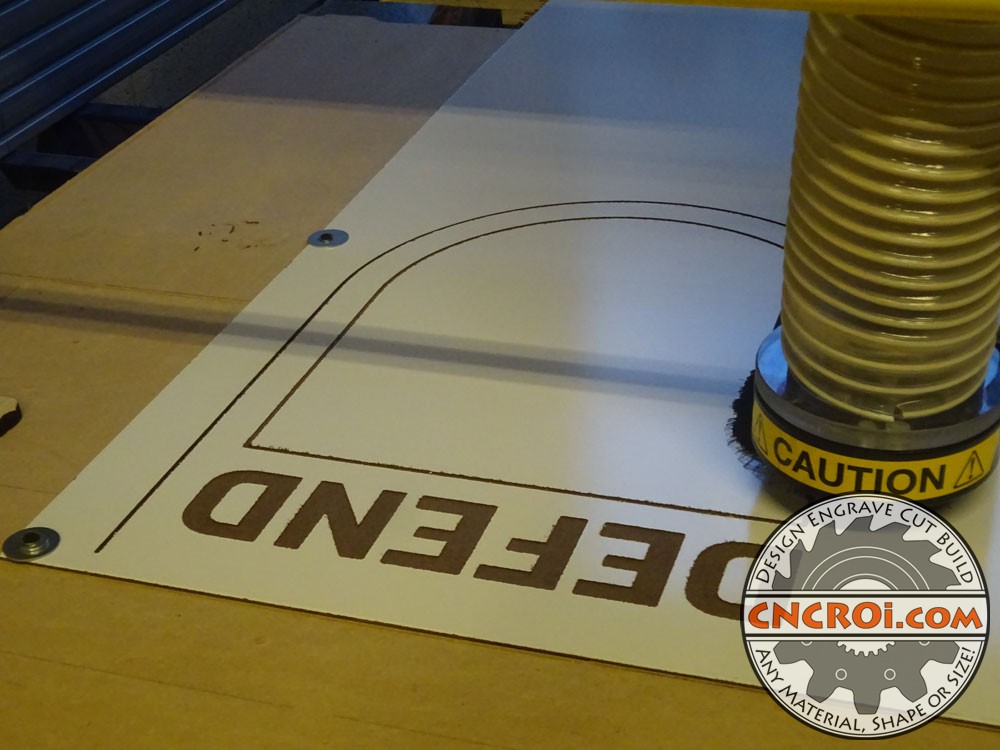

We’ll start with our ShopBot PRSAlpha which is a full sheet CNC router with industrial spindle, it can make very quick and precise work of a custom whiteboard shield using a spinning bit eating away at the material at the assigned depth.

When it comes to our CNC router, the custom Cedar tray below would be just about impossible to do with our CNC laser unless we used layers of material, glued it together than sanded it extensively, with the CNC router, it’s just cut and sand.

Unlike our Trotec Speedy 400 flexx, our CNC router knows exactly how deep it’s going as there is a two-way feedback system for depth, while with a laser, there is no such thing, it’s just dependent on power and speed settings.

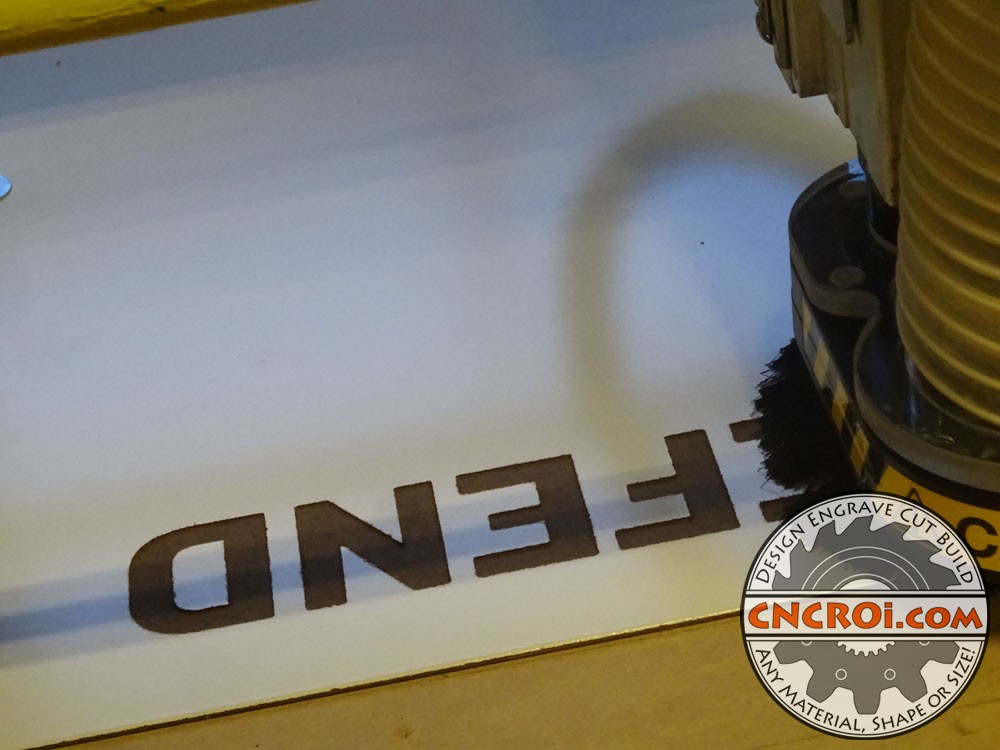

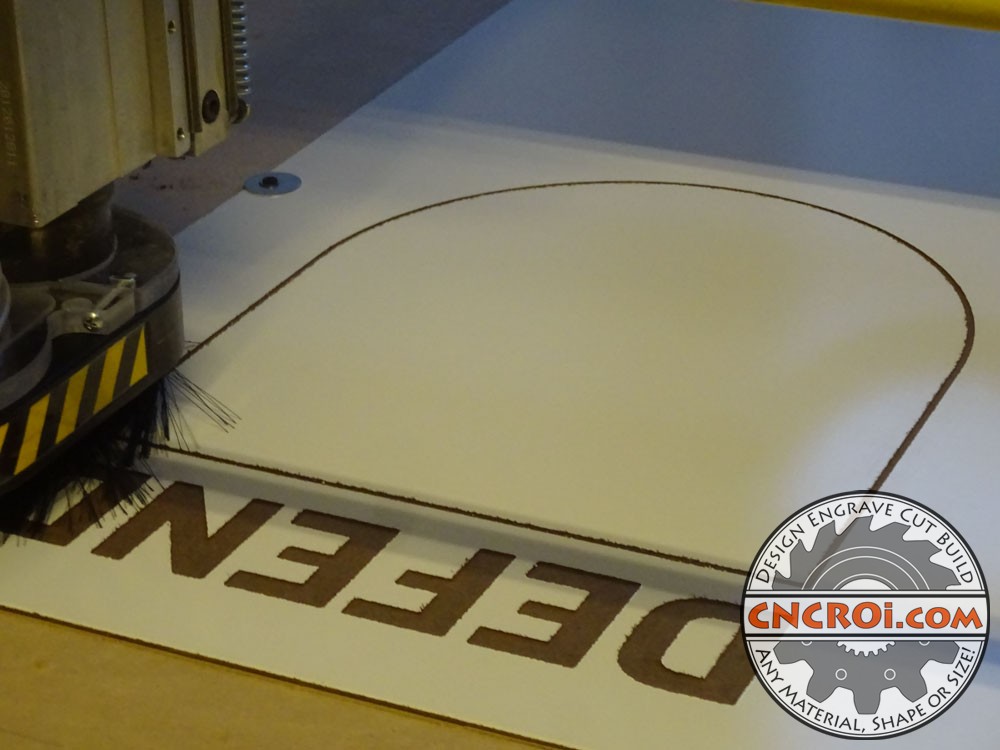

Not to say our CNC laser is a slouch, notice the edge of the carving CNCROi.com is doing into this whiteboard shield material, it’s a bit rough, we aren’t using an optimized bit on purpose to exaggerate this aspect but when you have a bit pushing and pulling through material, you do get a bit of roughness.

With our CNC laser, we can do very fragile fabric such as felt and paper which are not possible using our CNC router, the fine detail wouldn’t be possible either even if we stuck an orbital knife onto our CNC router.

The roughness you see though can be severely reduced to almost nothing using the correct bit but the end-product will always require a little sanding regardless to fine tune the quality of production we produced, no different from the laser in that respect when it comes to general work we do at CNCROi.com.

The one major drawback from our CNC router is having to hold things down, again, things like bolts, screws and vacuum can be used to lessen this but it’s always a consideration while with our laser, it’s a non-contact production method meaning there is no need to hold things down.

Engraving and cutting acrylic could technically be done using either our CNC router or laser but the router would require more work to achieve the flame polish with our CNC laser does it all in one process.

For this custom whiteboard shield, the production of a unit is exponentially faster than what we can make with our laser for the same design, the router literally cuts through material while our CNC laser vaporizes to produce the same result.

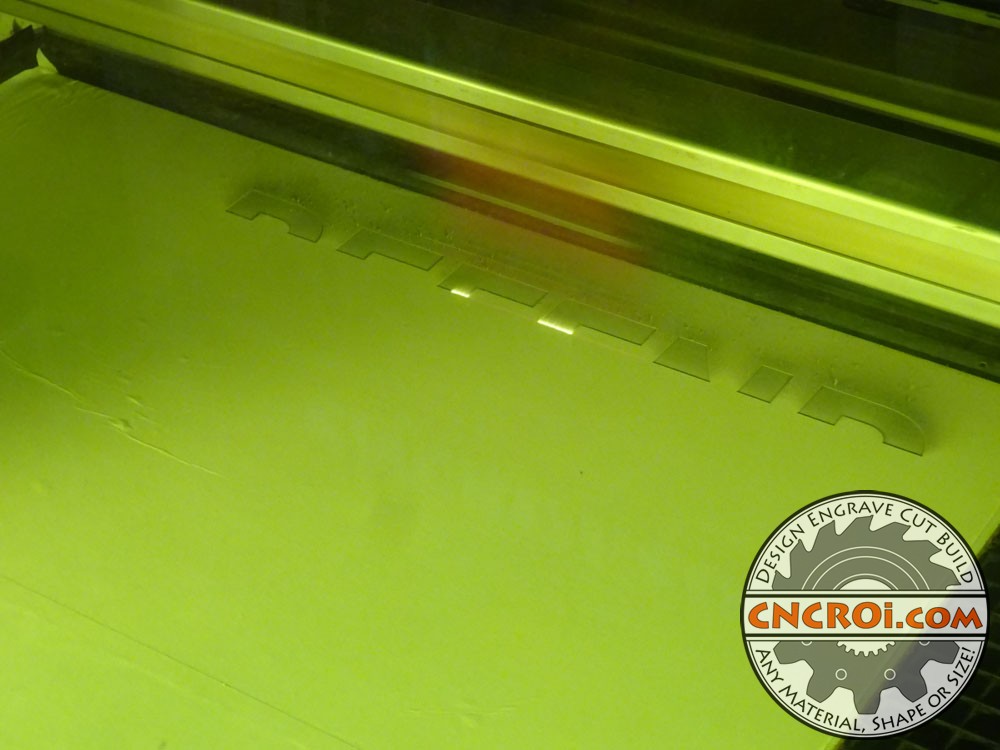

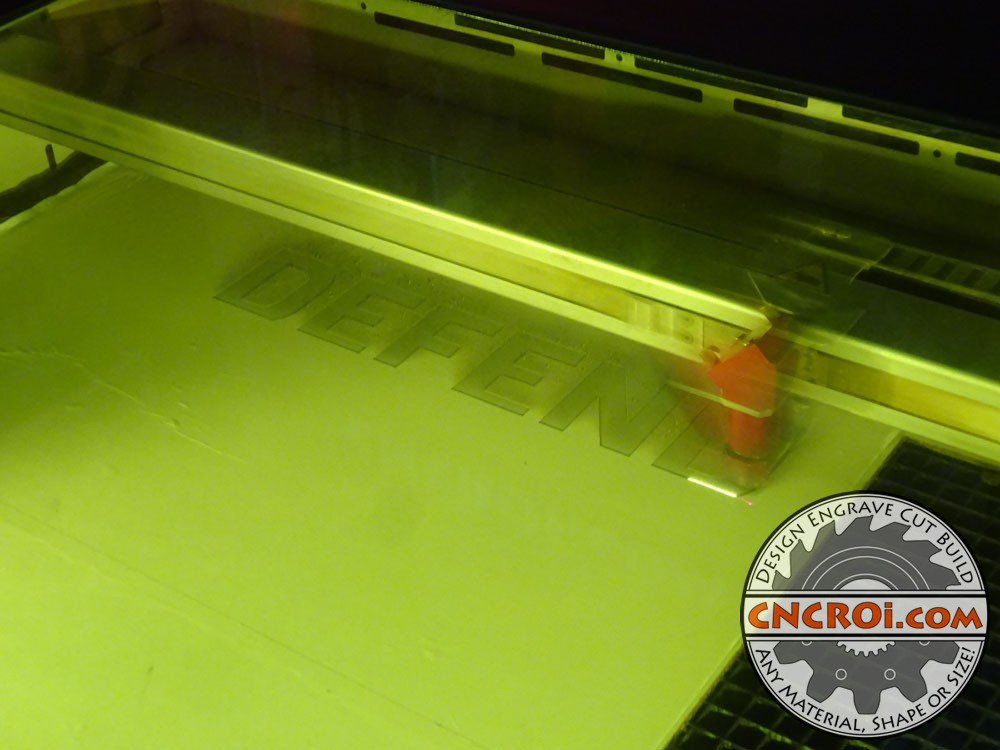

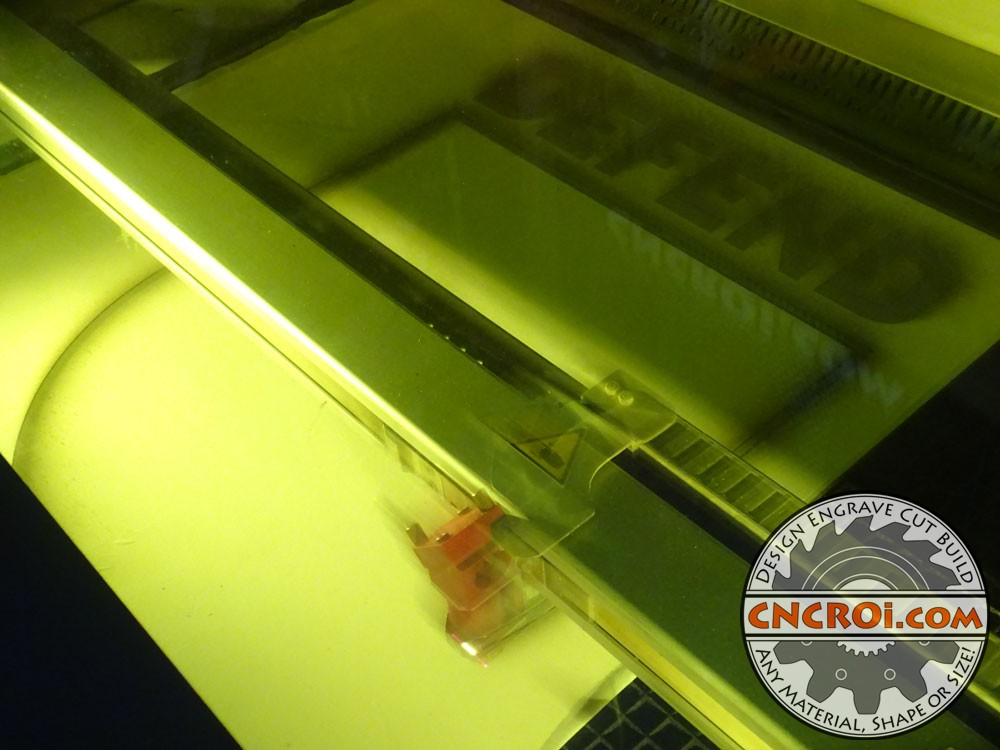

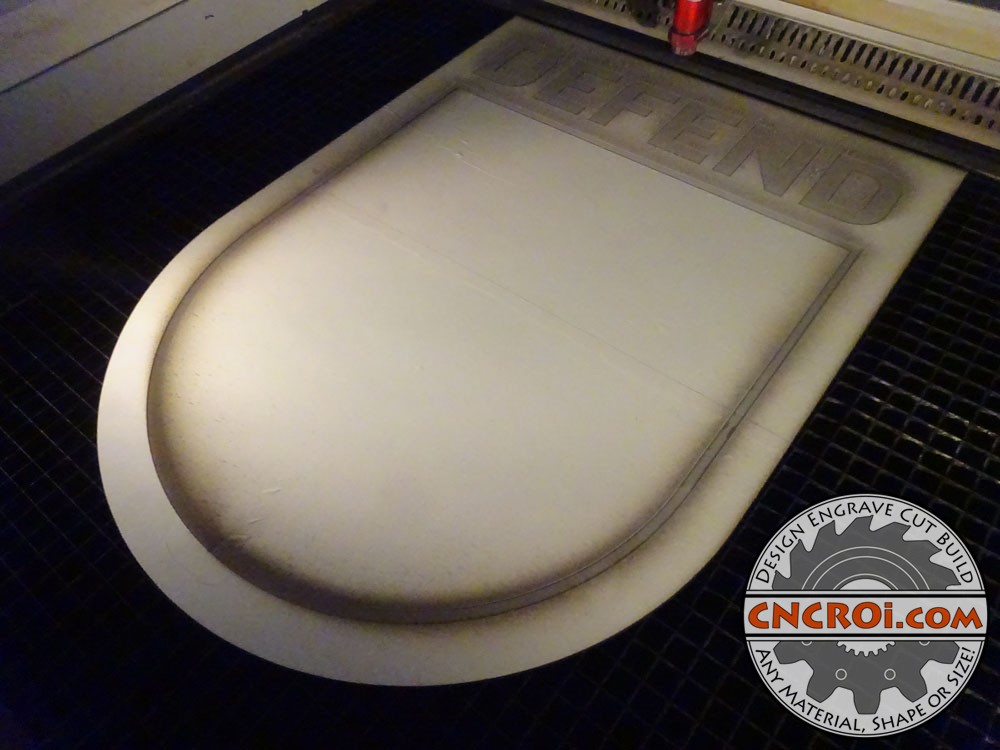

Now let’s look at the custom whiteboard shield being made in our CNC laser, you notice right away the difference, the head is a lot smaller and there is fire being produced from the material vaporization.

Our CNC router can make tooling inserts in one solid piece but can’t do the same for foam, again, each CNC machine has their plus and minus.

Very precise cuts with sharp inner corners are not possible using our CNC router while for CNCROi.com‘s CNC laser, that’s no problem at all!

Unlike our CNC router that makes wood and material chips, the laser produces smoke and some of that settles on the material during production for this custom whiteboard shield.

Unlike our CNC router, the resolution is up to a thousand DPI and the engraving is thinner than the diameter of a hair while with our CNC router, we are limited by the bit diameter (radius in inner corners).

With our CNC laser, leveling live edge isn’t possible but engraving is, though we have depth control and speed for that process clearly in the favor of our CNC router as well.

As the laser works at such a fine resolution, it takes longer than our CNC router to do this job but requires less work after production to clean things up.

Also notice I had to use a mask to make clean-up faster with the laser while with the router, it’s more of a sanding pass to do the same as there is no fine particulate and smoke settling on the custom whiteboard shield.

The lightness of the color will come off over time as the particulates fall out for the CNC laser work, for the CNC router, after a quick sanding, it looks pretty good but there is still some slight chipping that is just part of the process.

Having both machines allows CNCROi.com to really optimize production, if you wanted these custom whiteboard shields to be an inch thick, we can cut them with the CNC router and engrave them with the laser for instance.

Need custom whiteboards? Contact CNCROi.com right now!