Custom Plywood Stencils: Router VS Laser

Custom plywood stencils can be made by CNCROi.com at pretty much any size or thickness using a wide variety of design parameters and CNC machines.

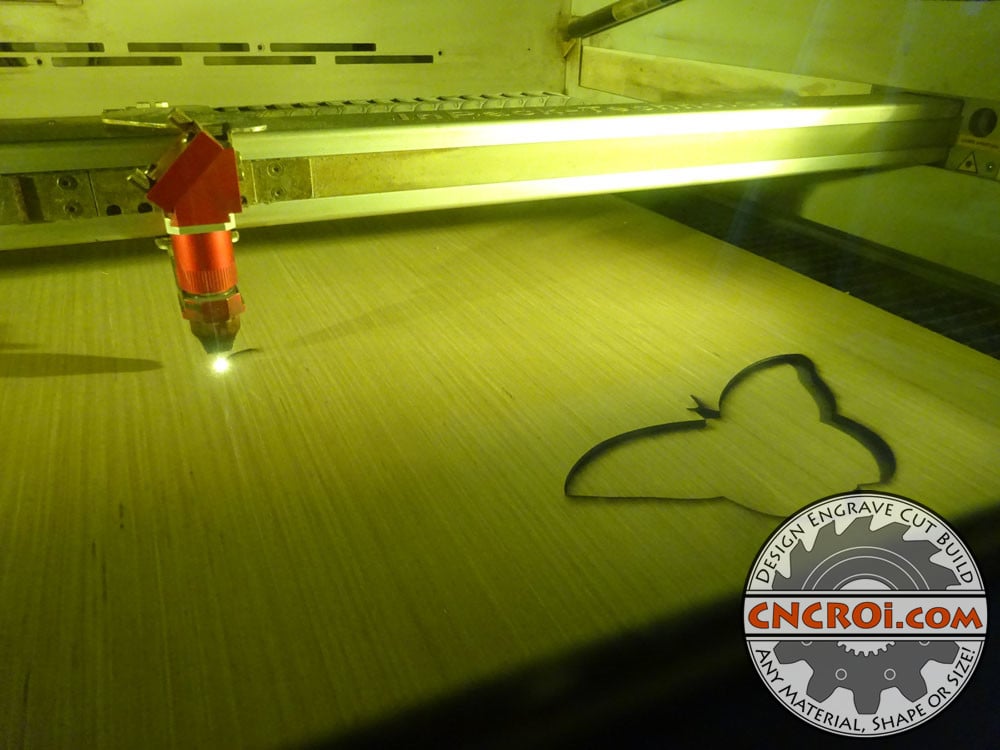

For these custom plywood stencils, we were alright making some of them using our CNC router and another batch using our CNC laser due to the design requirements.

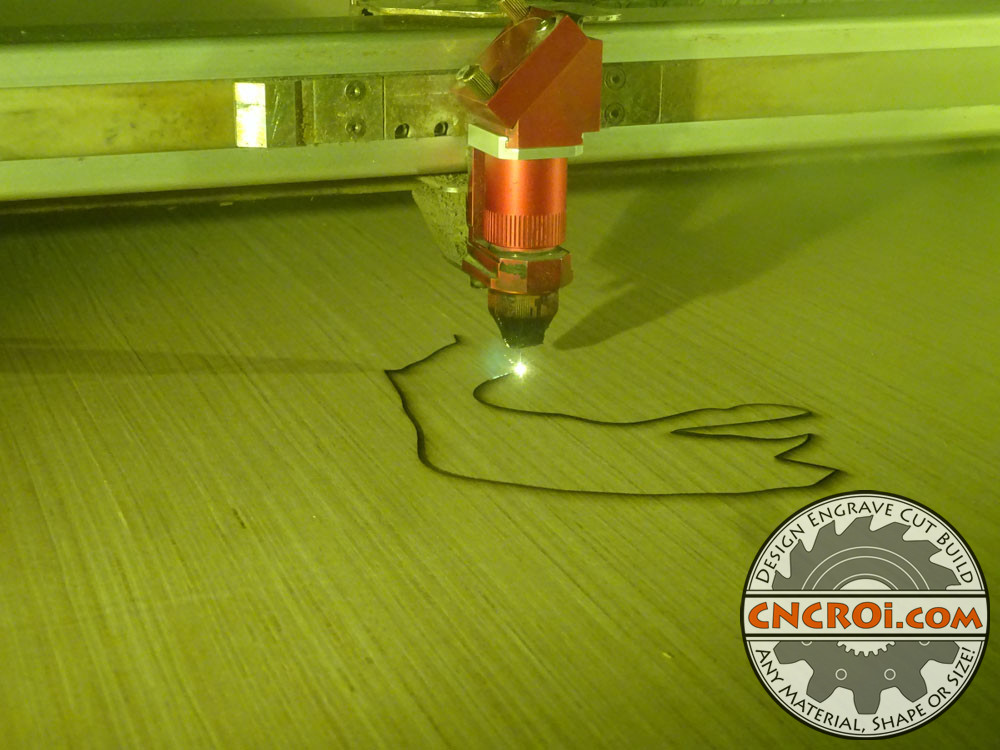

Essentially, CNC routers are faster than laser for custom plywood stencils of this design but you lose on sharpness which is something you gain with CNC lasers, there is no perfect machine, just optimal for the given application.

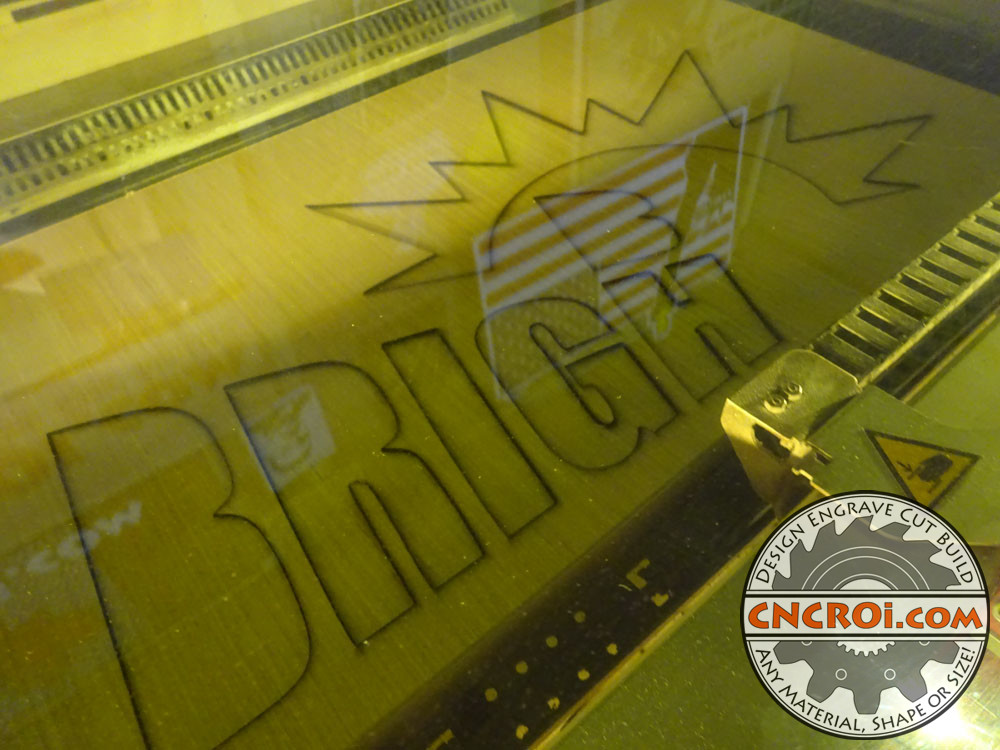

As such, for some designs, there were sharp inner corners, triangles and squares being cut out that I wanted to actually look like these rather than ovals and rounded parts, as such, the laser was used for sharpness while router for speed.

If you are wondering what the difference between the CNC laser and the CNC waterjet, this video above explains it very well.

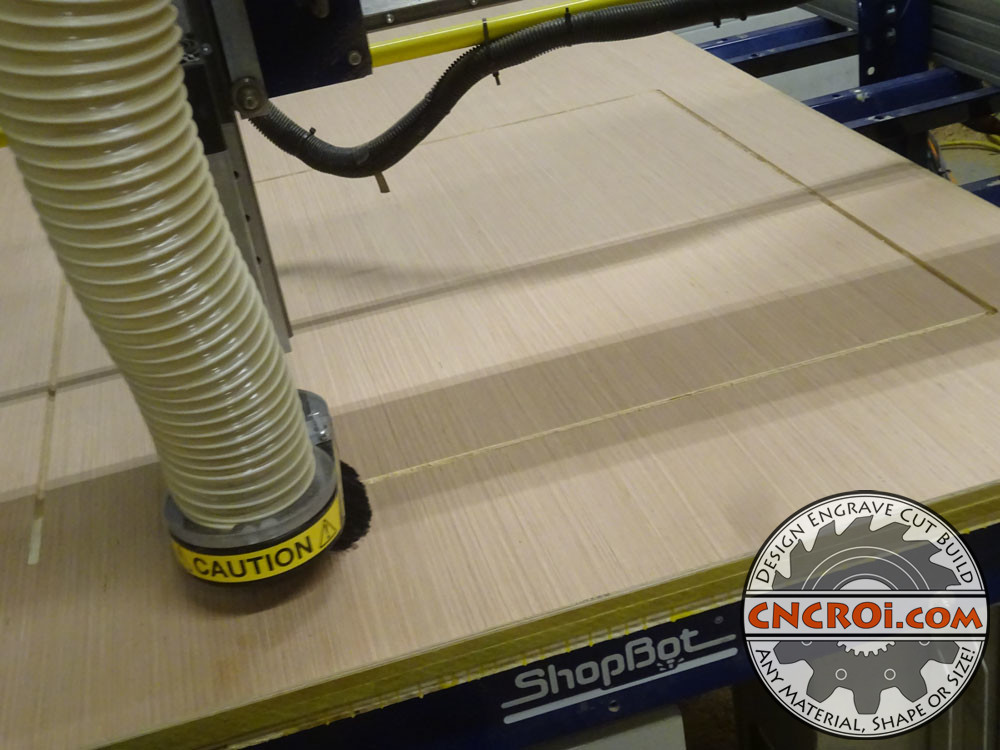

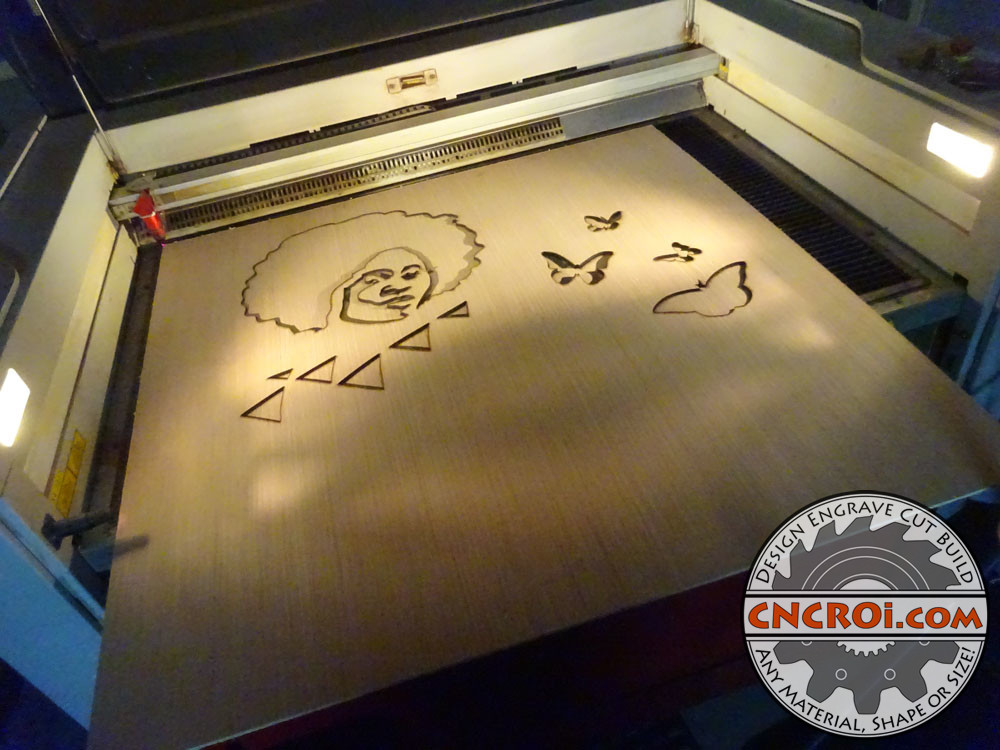

Regardless of what was used for the end cutting of these custom plywood stencils, it was more efficient to cut these stencils down to size, 3ft square, using the CNC router and then use the laser or router to cut the inside parts depending on the design being cut out.

Having a full sheet CNC router is an amazing tool, it saves us so much time in the shop for specific projects that fit within it’s parameters, at the end of the day, the precision of the laser, router or waterjet are essentially the same, it’s just the diameter of cutting or material thereof that’s the differentiating factor between all these amazing CNCs.

Having a variety of CNC machines is the reason why CNCROi.com is so flexible when it comes to custom production of various projects, passion for customer service and the production cycle itself also helps!

For these custom plywood stencils, I had to turn off the dust collection system that’s sucking the dust out of the cutting area temporarily during the cutting process because of the small parts that would otherwise be sucked-up into the dust system.

Although not a stencil specifically, signage by CNCROi.com can be a mix and match of different materials, so if you wanted one stencil made out of metal and the other wood, using the same or different design, no problem!

It really doesn’t matter all the extra dust left on the table once the dust collection system was turned-off, I still have a vacuum table working sucking the parts down but if they get sucked into the dust system, they can damage the fan blades.

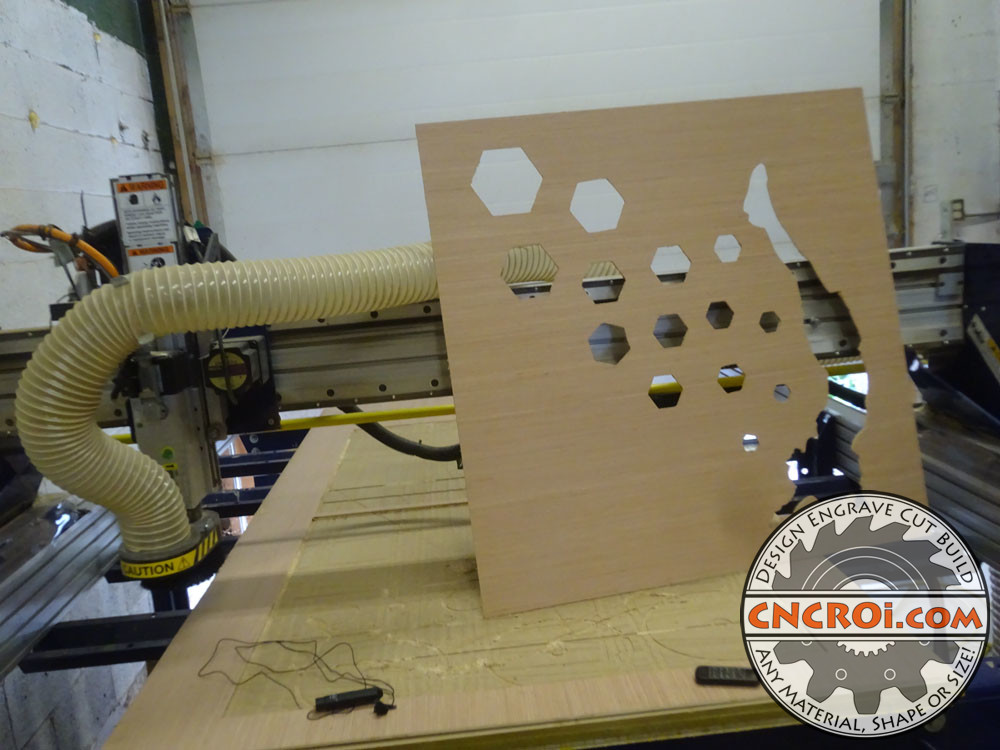

For this run, I was able to cut out a full custom plywood stencil and then had a few cuts of just the outline of the stencil as it would be finished-up in our industrial CNC laser.

The results look spectacular, again, the limitation with the CNC router is the bit diameter while with the laser, it’s the speed of thicker materials, there is no perfect machine, just best for a given task.

Polycarbonate is a wonderful material for custom stencils, it’s incredibly durable but the one massive advantage to it is that you can literally see straight through it, making positioning a breeze.

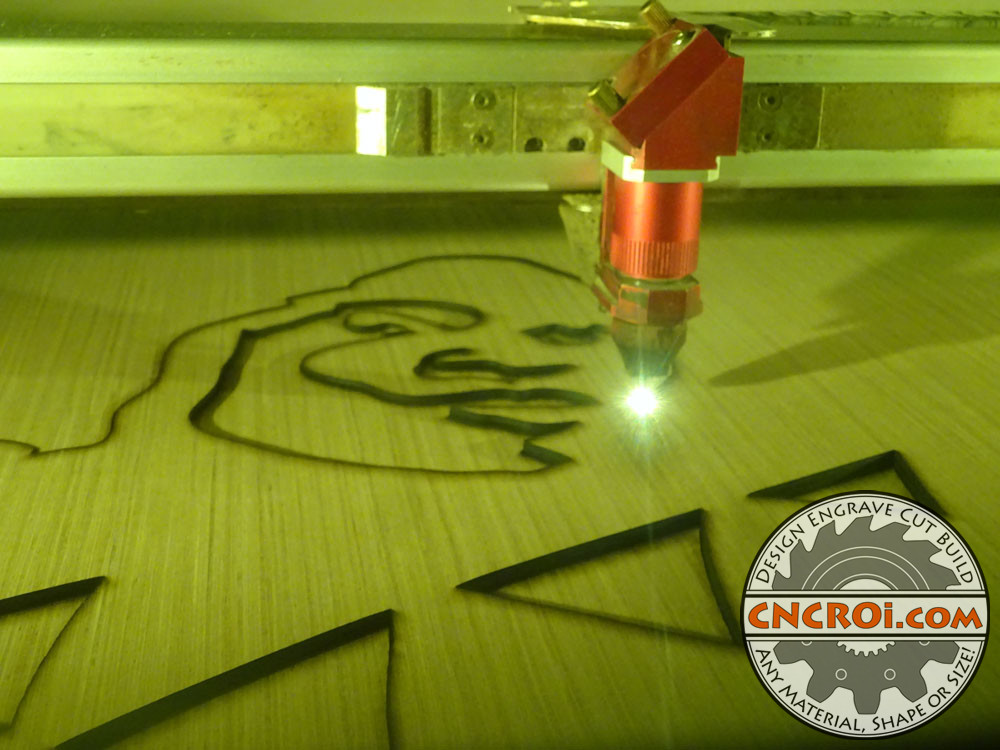

You can see the sharpness in what was laser cut would have been impossible even with a far smaller diameter bit on our CNC router when it came to making sharp custom plywood stencils.

The dead giveaway that one CNC was used over the other isn’t just the sharpness, but also the smoke, CNC lasers cut by burning while CNC routers cut by cutting.

CNCROi.com has extensive experience with both CNC laser and CNC routers, as such, it’s second nature to know right away which design is best for what machine and what changes need to be made in order to suit a specific budget using a given material.

When it comes to making custom stencils that are the ultimate in durability, metal, whether mild or stainless steel, pose no problem for CNCROi.com to fabricate for you in any quantity at any size or thickness.

CNC routers aren’t really affected by material thickness but CNC lasers are greatly influenced, the thicker the material, the slower the laser cutting process is while with the CNC router, it’s so fast that it really doesn’t make much of a difference in the grand scheme of things.

The CNC laser does produce a cleaner result though you do have soot along the edges and underside which isn’t present with our CNC router cutting, again, no perfect machine, just best for a given application at CNCROi.com.

CNCROi.com also makes custom stencils out of metal and polycarbonate (bullet proof glass) if you need something ultra-durable or that you can put a flame onto.

This project did pose an issue though, I don’t have a full sheet CNC laser, only a full sheet CNC router, as such, I did half the stencil, rotated the design and material 180 degrees then did the other half of the custom plywood stencil.

If the stencil was just a little bigger, this wouldn’t have been possible, I’d then just remove the back of the laser and feed the custom plywood stencil through the machine, so essentially, I have the capability of a full sheet laser, just not in one pass like I have with my CNC router or the waterjet.

Stencils can be made using a variety of plastics, from thin acrylic to super strong polycarbonate, whatever you want, CNCROi.com can make a stencil out of it.

The CNC waterjet wasn’t employed for this job because it uses water and sand, two things that plywood isn’t great with, it’s about the same speed otherwise as the CNC router BUT with the sharpness roughly equivalent to the laser BUT it is a wet process.

You can now see what the finished stencil looks like, sharp and perfect just like all the other custom plywood stencils we made during this production run at CNCROi.com.

Need a custom stencil any size, shape or material?

Contact CNCROi.com right now!