Wooden Box Personalization & Silhouette Cutting

First video in the new shop! Today, we’ll take a look at some projects we did before the move, wooden box personalization & silhouette cutting.

First of two projects we’ll be looking at are a series of boxes we CNC laser engraved information onto the surface of. The wood in this case is bamboo and we used a font to make it look a bit worn.

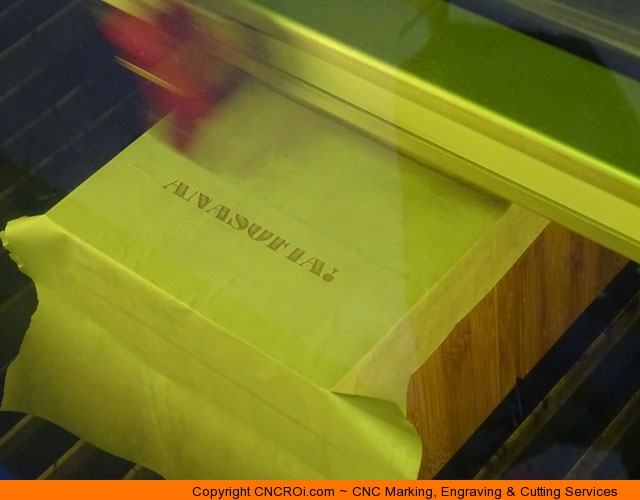

The first step before any engraving is done is to use masking on the surface, this protects it from the smoke and debris that is removed during the laser engraving process. This is medium tact paper, so it doesn’t leave any residue of its own on the finished project.

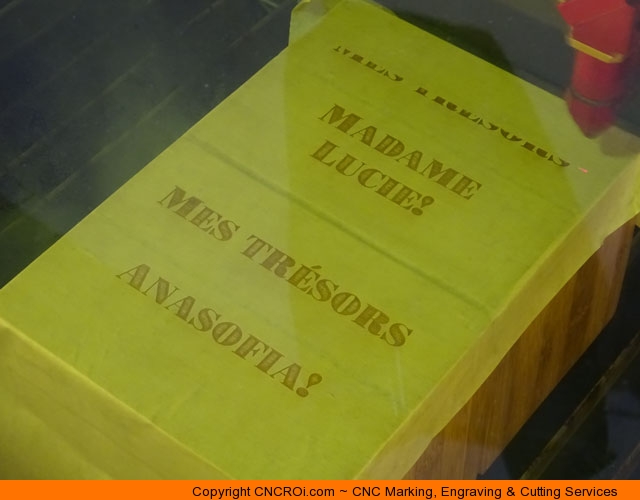

The CNC laser engraving process can now begin on the wooden box, after the focus has been set to produce optimal results. These are personalized with the student’s name and their teacher.

As the two boxes in the photo are identical, they were done at the same time to increase efficiency which leads to a higher ROI for both us and the client. On some projects, doing multiples at once saves a significant of time and money because we don’t have to spend our time loading and unloading the machine.

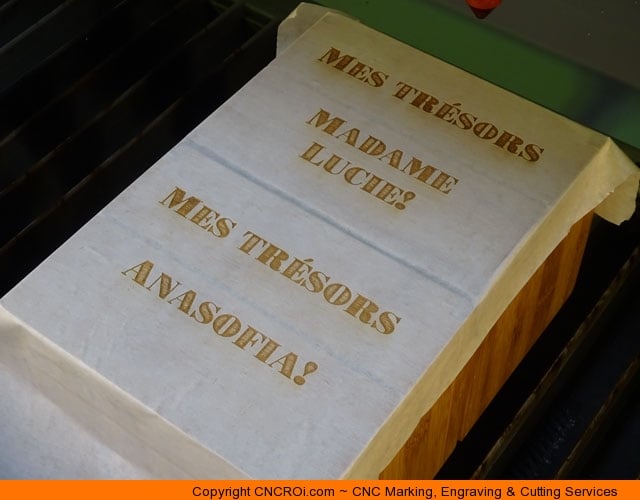

The CNC laser engraving is now done, all that’s left is to remove the tact paper. All of our processes are permanent, so any spelling mistakes or errors during production cannot be removed.

To remove the possibility of typing errors, we send digital proofs to clients to approve before production and if there are a list of names, they are given to us in database format which means we don’t need to retype names, dates and other relevant information.

In this case, we were looking for something subtle, yet still permanently engraved. It looks like those boxes were always engraved, and that was the goal!

Taking a closer look at the laser engraved wooden boxes, you can see the font gives it added depth and perspective, a slightly worn look that suits these boxes and their context. We can of course make darker engravings but in this case, it wasn’t needed.

Our client was very happy with the results of the laser engraved wooden box. Next up, was some silhouettes for the students. In the following case, old plywood boards that predate the rise of Rome were found, they were nicely scratched and used which is perfect for silhouettes that needed to be painted anyhow.

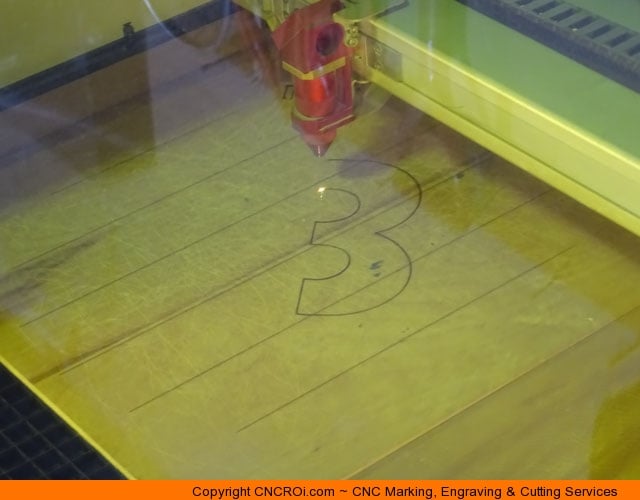

Vertical lines were cut first, but not all the way though, this way the students had a physical template to follow, allowing them to paint within the lines for their Christmas gifts. The letter represents their last name.

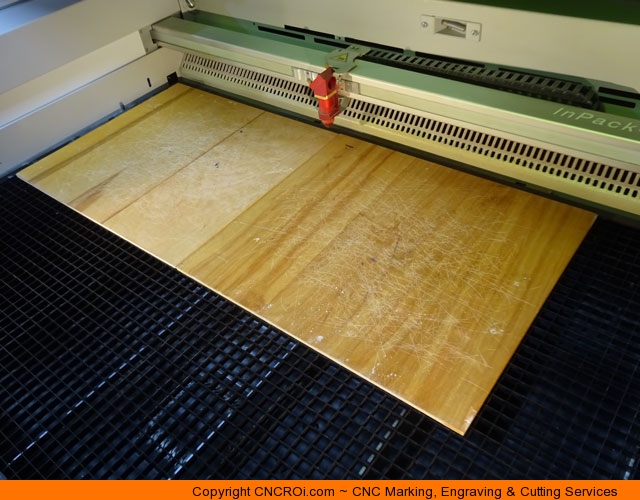

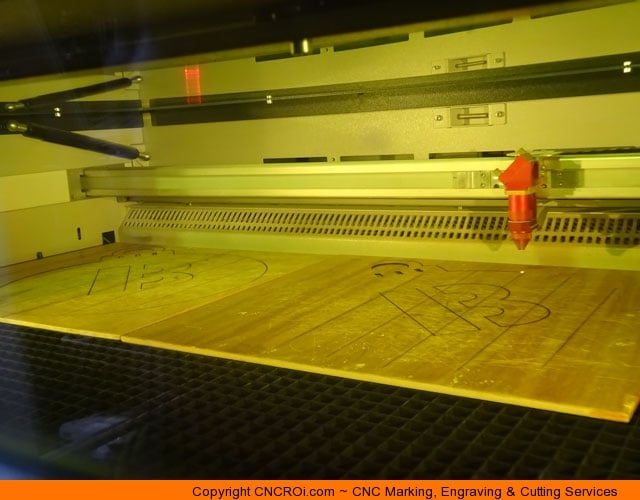

The boards were small so we were able to comfortably fit two in the machine at once. Our Austrian CNC laser has a 110W CO2 tube, plenty of power to engrave and cut just about everything.

After the initial lineage, it was time to cut out the inner letters before proceeding with the perimeter. This allows everything to stay straight, organized and accurate start to finish.

Taking a look at this from another angle, you can see we have plenty or room both X and Y and if you had something thick, we have up to 13 inches or vertical play.

After the letters were cut out, you can see how precise the machine was, that’s why we imported an Austrian dual-sourced laser, when things need to be done right the first time, that’s what we do!

The cut was right through without any issues, you can see how solid the cut is as well in this laser cut plywood. If you put these two Bs together, they would be identical in every way.

We did a lot of other letters as well, well over 20. The vertical lines could have been removed from the inner letters but the programming required simply wasn’t required as those were to be thrown-out anyways.

The letters had to be positioned slightly differently so they were as central as possible, it required a bit of play to get right but nothing onerous or difficult.

The plywood in this case was about 1/4 inch or 6 mm, we can easily cut through material twice as thick to give you a reference of our capabilities and with our CNC router, thickness isn’t an issue at all. For many projects, we actually combine the laser and router capabilities.

We did run out of old worn board so it’s a good thing we have stock of plywood always at hand to pickup where the material left us. In this case, it was the final two letters. These will be painted by the students so nobody will be all the wiser that a different material was used. It was plywood at the same thickness.

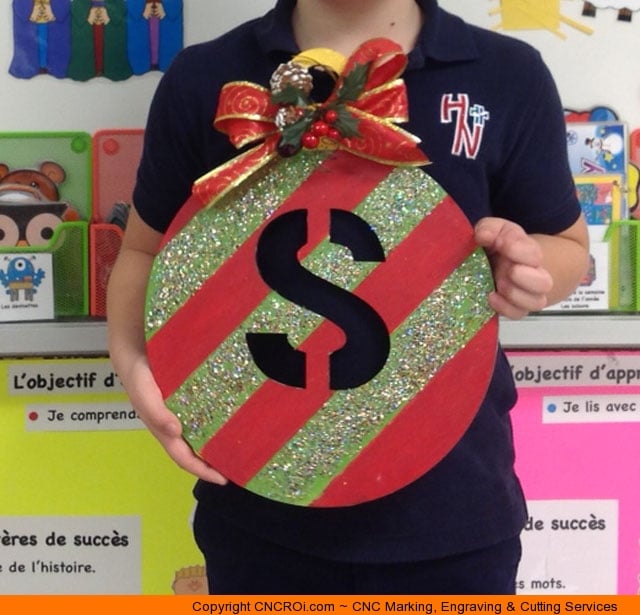

If you are wondering what the finished project looks like, here’s a photo after it’s been designed by a student.

As mentioned in the video, we can use your boxes that you sourced or create unique boxes here in the shop using a variety of materials. The possibilities are endless with CNCROi.com! Contact us!