Custom 12 ga Mild Steel Signage

Let’s build a custom 12 ga Mild Steel Signage for a property entrance!

https://www.youtube.com/watch?v=VtkLvlrHuZU/

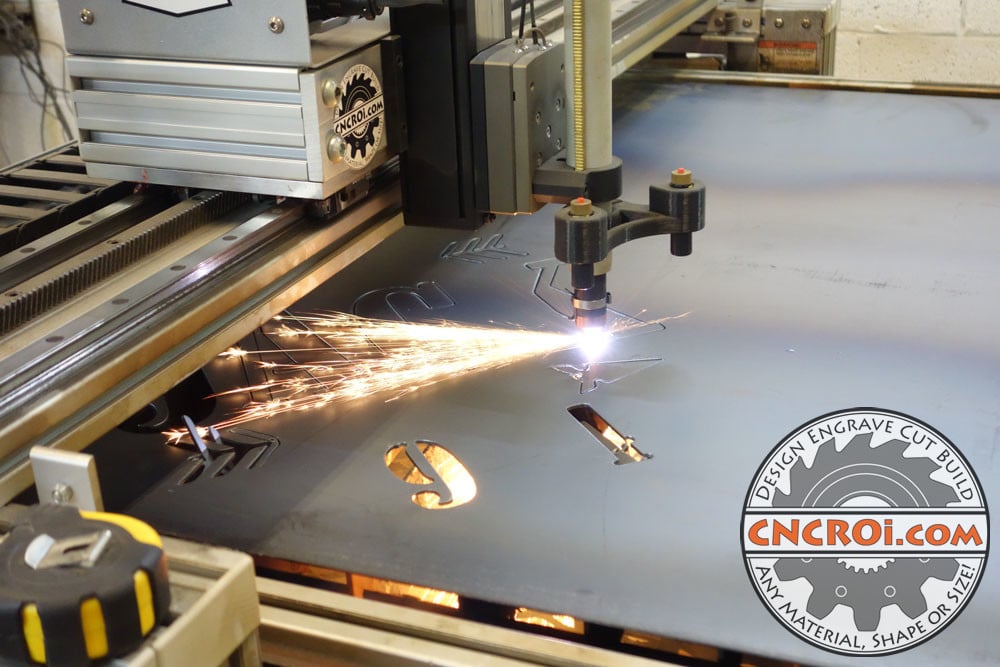

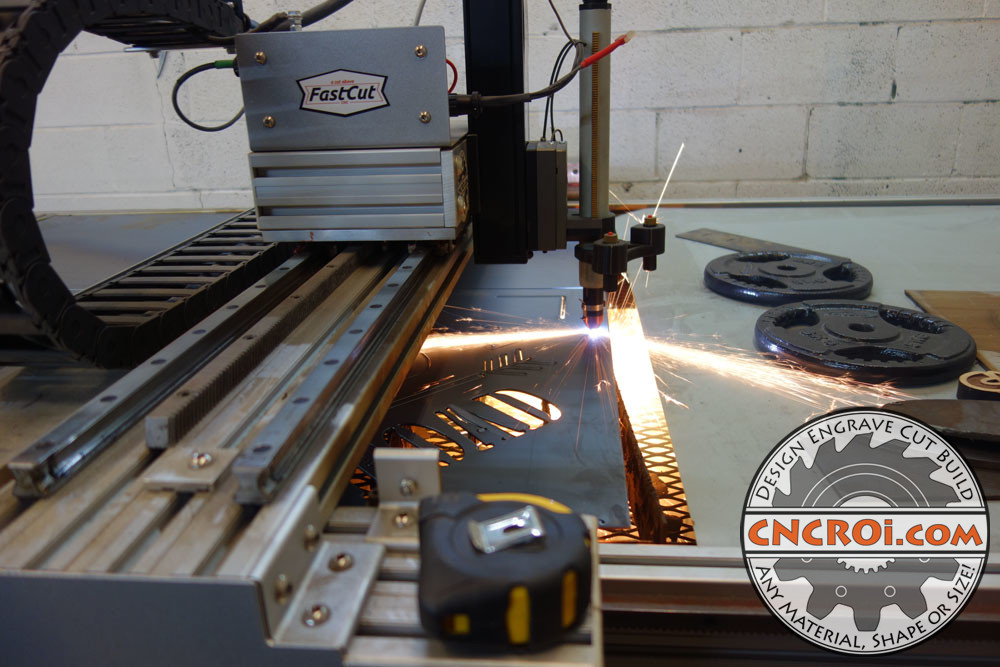

The first step involved with cutting 12 ga mild steel signage is booting-up CNCROi.com‘s plasma cutter after all the designs are sorted out and have it start vaporizing steel!

Like a molten knife through liquid butter, this posses absolutely no issue for our plasma cutter, quickly and efficiently processing through the 12 ga hot rolled steel until the mild steel signage is liberated from the sheet.

The fire underneath of the sheet is massive, you can get glimpses of it in the holes that the plasma cutter cut through, it’s incredible the power that’s generated by this machine and how easy the work it produces looks, I use to do this stuff by hand at CNCROi.com!

Coat hangers can be easily produced using the same thickness and spec we used for this custom steel signage job by CNCROi.com.

https://www.youtube.com/watch?v=fRarSjTywmU/

Essentially, with this plasma cut mild steel signage, the sheet is in the way of the plasma arc, between the torch head and the table below, the fact that steel is there is a minor inconvenience to a powerful PowerMax85 we have running on this project.

The only issue with cutting metal specifically is that sometimes little pieces stick-up, the sheet is held-up by the slats on the table and sometimes they flip and get stuck instead of falling through or being held-up by the slats themselves.

I could pause the machine to remove them but I find this more trouble than it’s worth as another one might pop-up anytime, so it’s best to just let things run and in between cutting processes on this mild steel signage, I just stick my hand out and try to remove it quickly.

Even very intricate designs can be easily plasma cut at CNCROi.com, using a variety of metal types and thicknesses.

https://www.youtube.com/watch?v=3Tkn8fuTcCM/

The nice thing about plasma cutting is the edge quality, it’s amazingly smooth, especially at 12 ga, so although this project will be powder coated, the aesthetic leaving the shop on the way to the customer from CNCROi.com is top notch on this mild steel signage.

The sparks quickly turn into dust as they cool on their trajectory from the sheet of hot rolled mild steel, they are no different than embers caused by a wood fire, just a bit worse tasting and the dust is more durable.

Although the shop processes a lot of stainless steel, mostly for signage or memorial plates, we can also etch the surface using a variety of methods in order to produce the finished product you want that’s incredibly durable and long-lasting.

https://www.youtube.com/watch?v=B0463p1ovBw/

The sparks from the cutting of the mild steel signage are also a lot heavier than those found in a wood fire, they don’t shoot up but sideways and downwards, literally bouncing of anything they come into contact with, except clothing, for that, they burn a hole into it.

In these two photos, you can really gain an appreciate of just how hot and how much light is emitted by the plasma as it cuts out the mild steel signage.

What I find most fascinating about cutting metal with plasma verses any other tool at our disposal at CNCROi.com is how smooth the results are, the plasma moves seamlessly and by melting through vs cutting through with other approaches, the results are incredibly consistent with very little kerf on all the edges.

Whether you want custom mild steel signage that’s bigger or smaller than what you see here, the steps involved are essentially the same, and this also holds true if you want it cut out of stainless steel, aluminum or other materials, including woods through plastics using our lasers or routers at CNCROi.com.

CNCROi.com can not only cut metal, we can also etch right into it!

https://www.youtube.com/watch?v=rWeM9-VUOII/

How much material is vaporized during the process of plasma cutting 12 ga hot rolled steel for this mild steel signage? Slightly more than 1/32″ so it’s almost nothing at these thicknesses.

The initial piercing through the metal is a bit more, roughly 1/16″ but once the torch starts to move, this quickly narrows down, as the heat from the plasma is more spread-out rather than concentrated in any one given area.

Now that these two mild steel signs are finished being plasma cut, the next step is removing the mill scale so that they can be powder coated by the customer.

CNCROi.com is not limited to just steel, we have machines to easily mix and match processes to create very unique household items.

https://www.youtube.com/watch?v=VAasMmiPvy8/

I’ve done endless hours of angle grinding at CNCROi.com so this time around, I decided to try something new, chemical removal of the mill scale rather than abrasion based for this mild steel signage job.

After about a day in the vinegar, the sign from above becomes that of below, with the mill scale literally peeling off, it can be removed with a towel verses a 40 grit abrasive disk.

Just using a rag, it’s amazing how easily the mill scale comes off, muriatic acid would have taken 20 minutes what vinegar takes a 24 hours to do but vinegar won’t dissolve my hand and flash rust all the metal in the shop, so for CNCROi.com, this is the better choice by far.

If you are wondering what rusted mild steel looks like, and how easily CNCROi.com can cut that too, check out the video below.

https://www.youtube.com/watch?v=PI0PIukb5ME/

You can see the dissolved mill scale in the photo below, that dust would represent hours of angle grinding for this mild steel signage.

How do I know when it’s time to remove the mild steel signage from the vat of vinegar? I had a test in a bag, once the mill scale comes off the metal in the bag, it’s a piece of scrap from the actual mild steel signage job itself, then the same holds true for what’s in the vat.

The results flash rust immediately, but it’s only on the very top surface and easily wipes off, the powder coating company will quickly resolve this at their end.

The other mild steel signage made at CNCROi.com looks just as great, if this was left as-is, after a week, it would be covered with surface rust, I cleaned these with baking soda and water, so the acid was neutralized, stopping the process caused by the vinegar, though the acidity of the vinegar is so low, the results would take a very long time to mine into the hot rolled mild steel.

Need custom signage? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=Ln9EXslzc04/