Custom Clocks: Live Edge Maple & Carbide Saw Blade

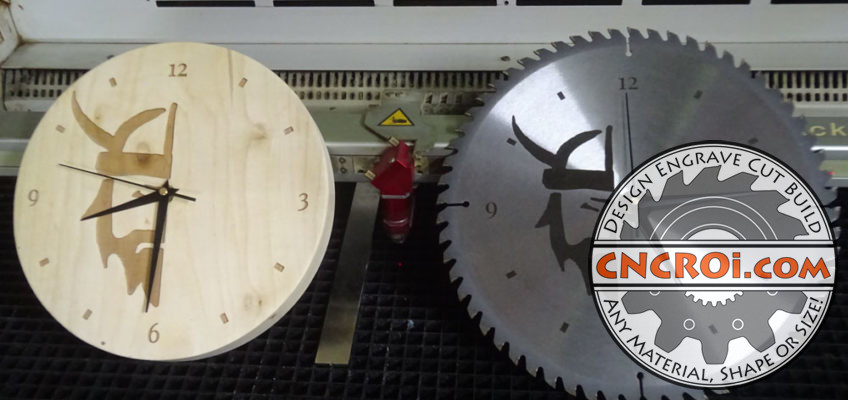

CNCROi.com can make custom clocks any size, any shape and any material or combination thereof, here’s just a quick illustration using two very different processes and materials showcasing this capability.

Having a range of custom CNC equipment and processes allows us to have incredible flexibility when it comes to making custom clocks for all our clients regardless of end-application, whether it’s for an anniversary or corporate gifting.

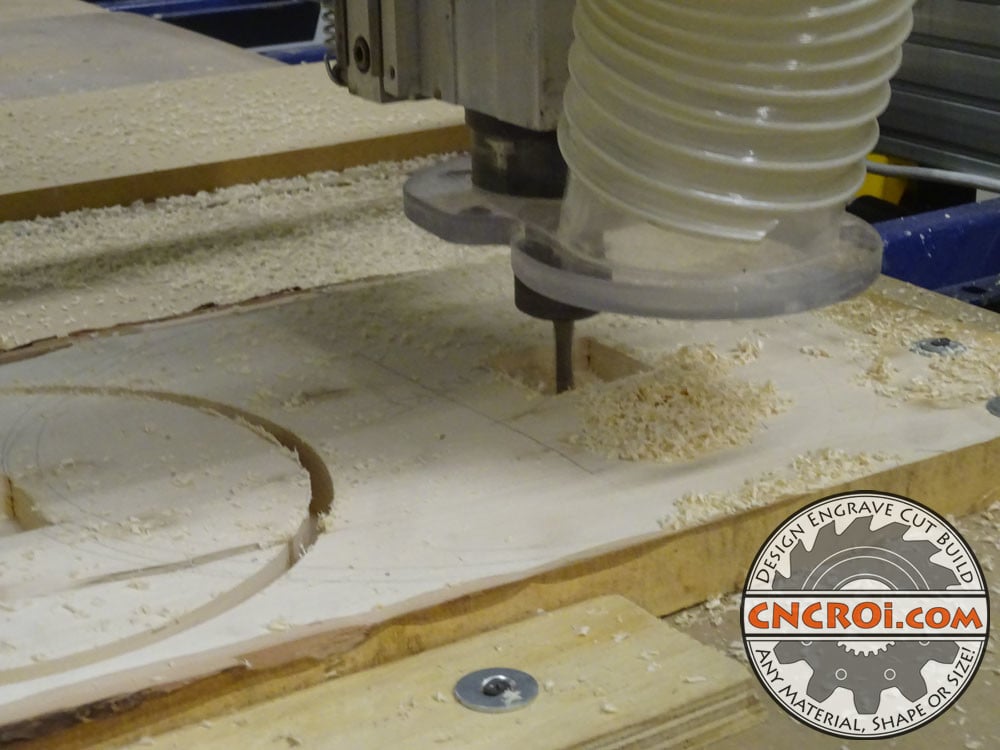

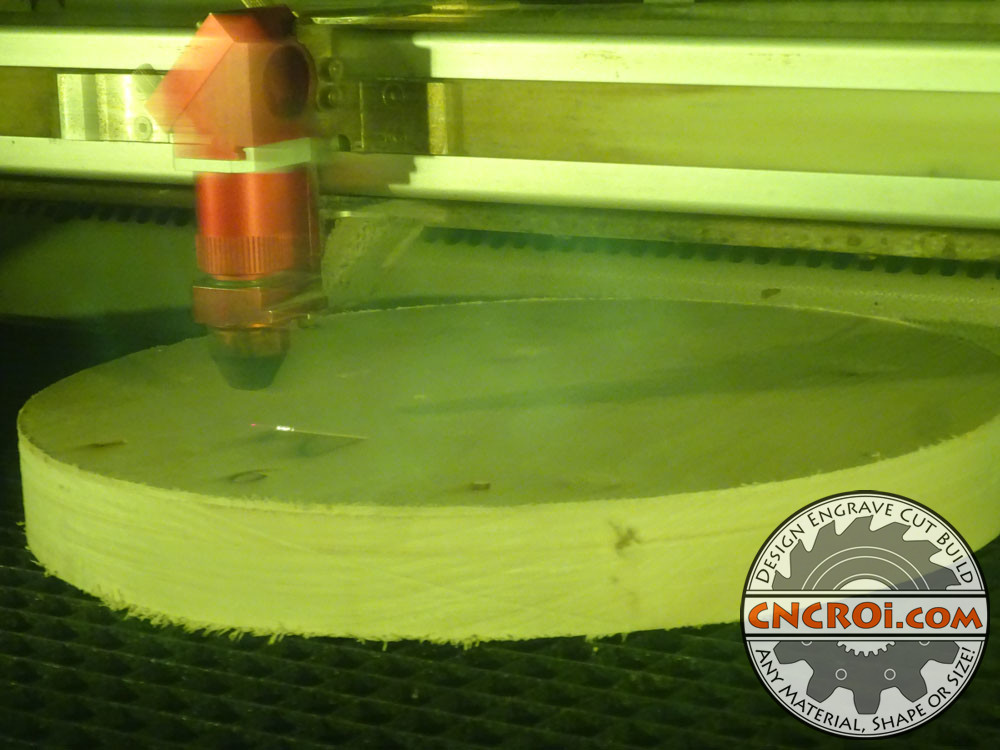

For custom clocks made out of wood, CNCROi.com can make them out of any wood species you have a budget for, in this case, it’s a live edge slab of Maple that we are CNC routing out the pocket for the clock mechanism and the round clock shape.

When it comes to shapes and profiles, your options are endless, from American States to animals, you want it, CNCROi.com can make it.

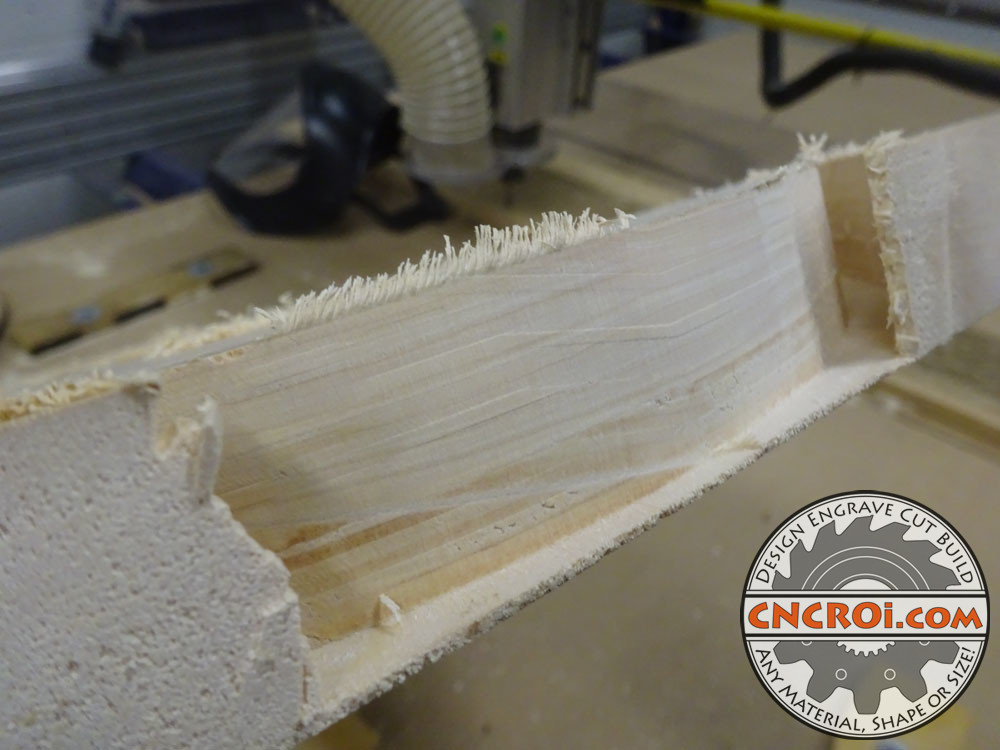

We didn’t have to use live edge, but it’s nice to have a thick and even surface to work from when it comes to clocks but if you wanted it made out of reclaimed wood or plywood even, the steps would be very similar for CNCROi.com to manufacture them.

All this mix of saw dust and wood chips reveal a beautiful custom Maple clock once it’s all cleaned-up and varnished, we made a few blanks at the same time for this production run and the pencil marks you see on the live edge Maple are there just so we know what project this specific Maple slab was to be used for.

We make a lot of custom cottage and wooden signage, live edge is a wonderful material to work from and the results are always spectacular!

I really love using our full sheet CNC router, it’s an amazing beast capable of incredible production runs and accuracy regardless of what we throw at it, it does a wonderful job for us across a variety of projects at CNCROi.com.

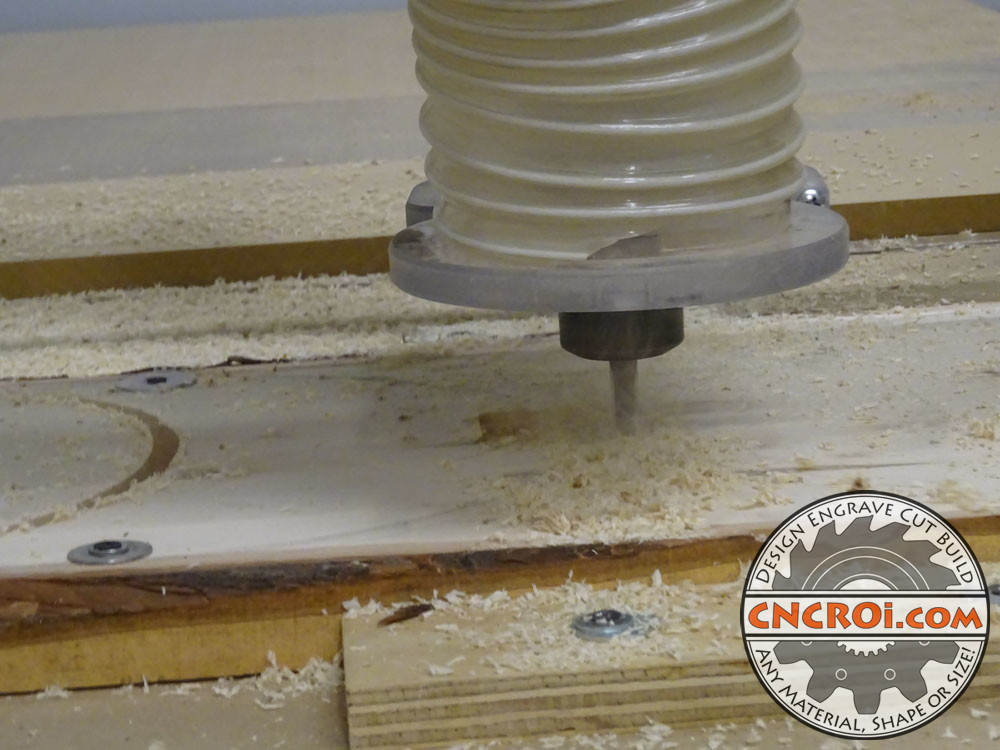

As this is a live edge slab, and our full sheet CNC router was going to fill it up with holes with pushing and pulling axis in all three dimensions, I figured I might as well bolt it to the table AND put blocks all around just to make sure nothing moved on me, live edge is a special animal that an over-abundance of caution is well called for.

Live edge flattening is another process we do a lot of, this is where our joy of live edge at CNCROi.com originates, and since then we’ve expanded this capability and inventory exponentially!

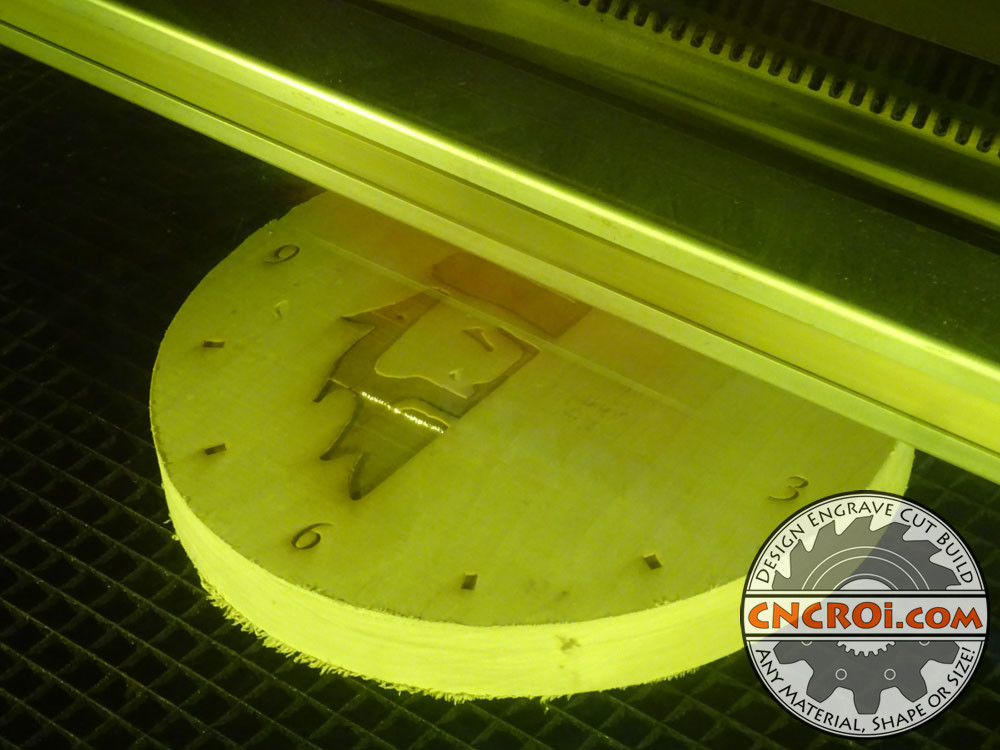

What you see in the picture below is actually the back side of the custom clocks, the holes you see in the middle are two-fold, one to hold the mechanism with battery that will rotate the clock handles and the smaller hole a reference for a perfect drill bit size for said column of clock hands.

As an additional precaution when it came to making these custom clocks, I left about 1/16″ or mm of material which we will router out, shapes such as these are very easy to move around during production and this ledge of material holding it down is very quickly removed.

Regardless of what technology we use at CNCROi.com to make your custom clocks, the process is an expression of your joy for Father Time, always clicking away forward in time.

The first step was to liberate all 3 custom clocks from the Maple slab, a quick process for our amazing bandsaw to perform, and it’s quite fun to diversity processes and systems when making custom projects for our customers at CNCROi.com – it keeps things interesting!

Now a little router compared to our CNC beast will quickly trim the extra material off after our bandsaw cut them roughly to size and out of the big slab, these custom clocks were a lot of fun to make and lots of saw dust was made in the process from a solid slab of Maple live edge.

I have a huge amount of experience both with lasers and CNC routers, my background is actually designing kids toys which I did for over a decade before founding CNCROi.com cutting plywood projects and showcasing them cut through assembly.

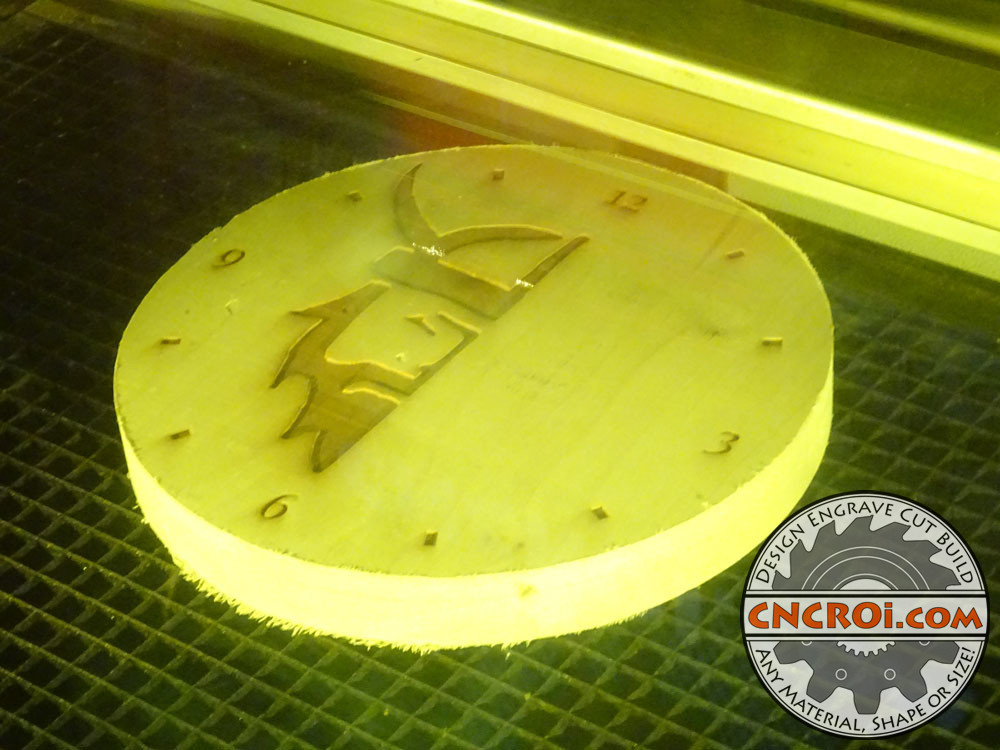

Now that we have the shape and style our customer wanted with these custom Maple clocks, it’s time to jump to yet another machine, our wide-format industrial Austrian CNC laser, to brand them as per spec.

Laser engraving the custom clocks faces is another process that could have been done in several ways but the most efficient was our laser over using our CNC router with a required paint fill process, the laser engraves and builds contrast at the same time!

Wood is an amazing material, my shop has done so many projects using various species that I’ve lost count but it really never gets old.

I performed several passes to darken the laser engraving, unlike paint fill, the only color choice when it comes to branding the front of these custom clocks is brown, light brown to dark brown.

The bright light you see is from the instant vaporizing of the live edge Maple off the custom clock face, the resultant smoke is quickly evacuated from the machine to not gum-up the electronics and optics that make laser engraving possible.

The results will look a lot nicer after a thorough sanding and clean-up, there are a few dents on this live edge which will be sanded out, that’s why I engraved a bit deeper than usual to allow this additional flexibility.

The process you are about to see on the solid Carbide saw is the same branding technique we used on this 316 stainless steel samurai.

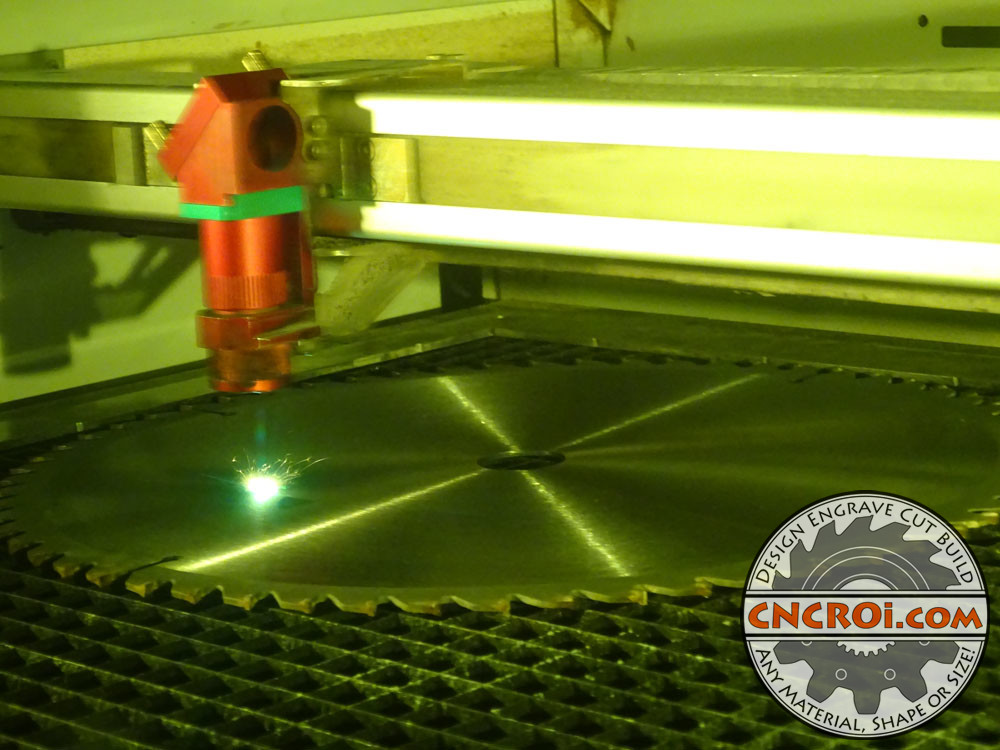

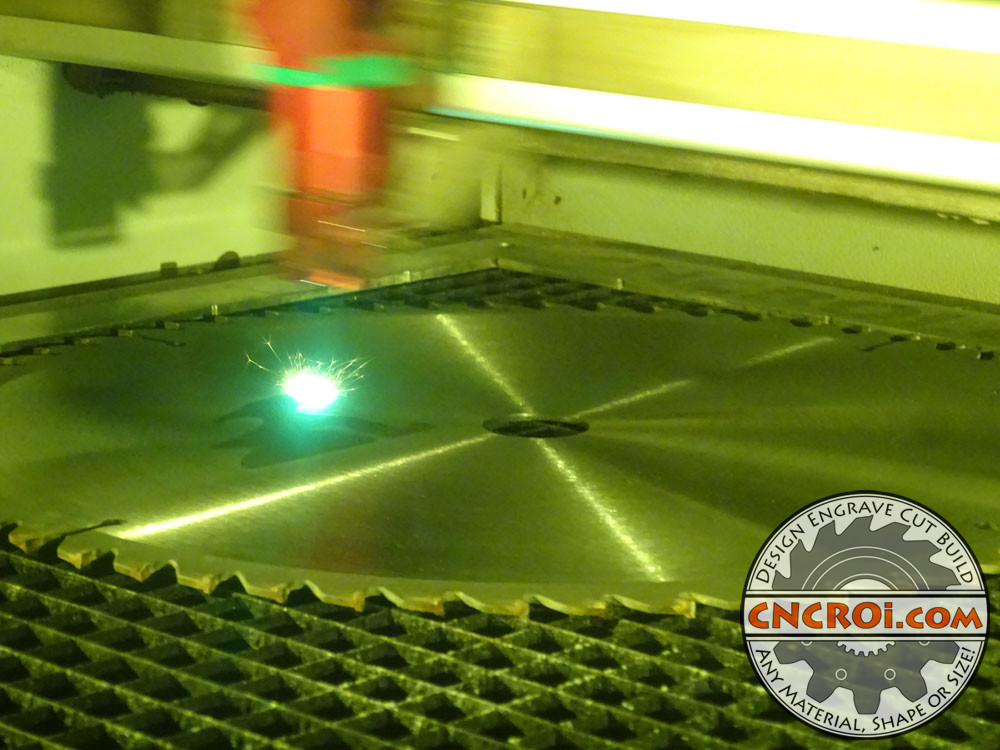

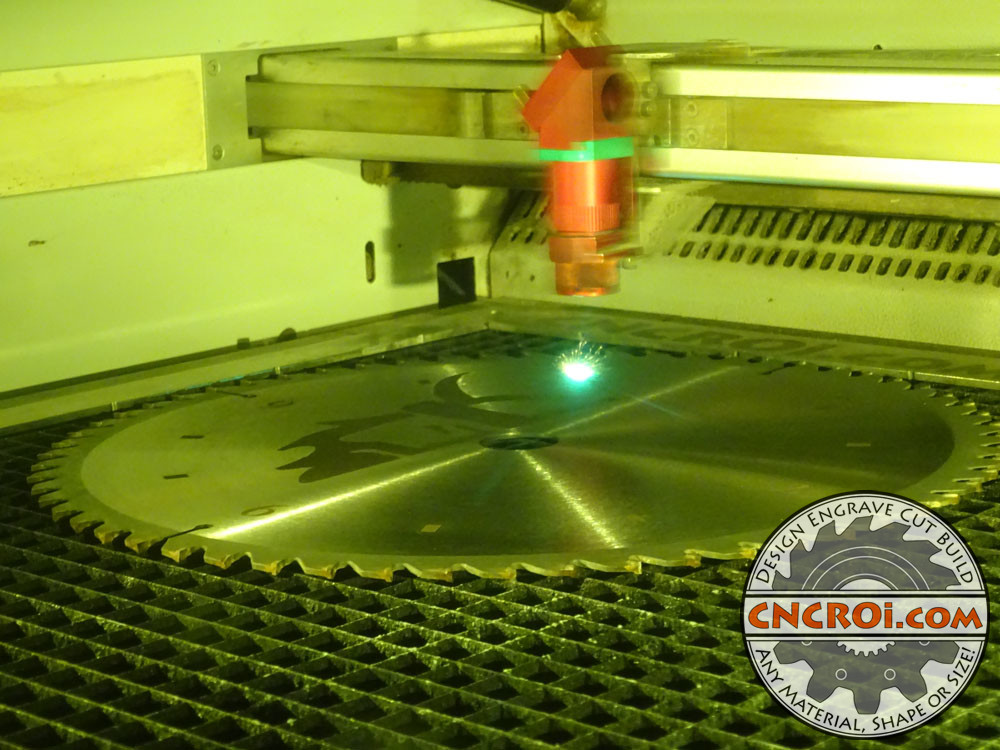

Next up on the custom clocks project, an old Carbide tipped saw blade that I hit one too many nails with in the shop, the fiber laser etching is doing a wonderful job of permanently branding the steel.

Custom clocks, regardless of the process, is a fun creative exercise for CNCROi.com because the design options are endless, so it’s just a matter of working with the client as to what they want and what works best on any given material.

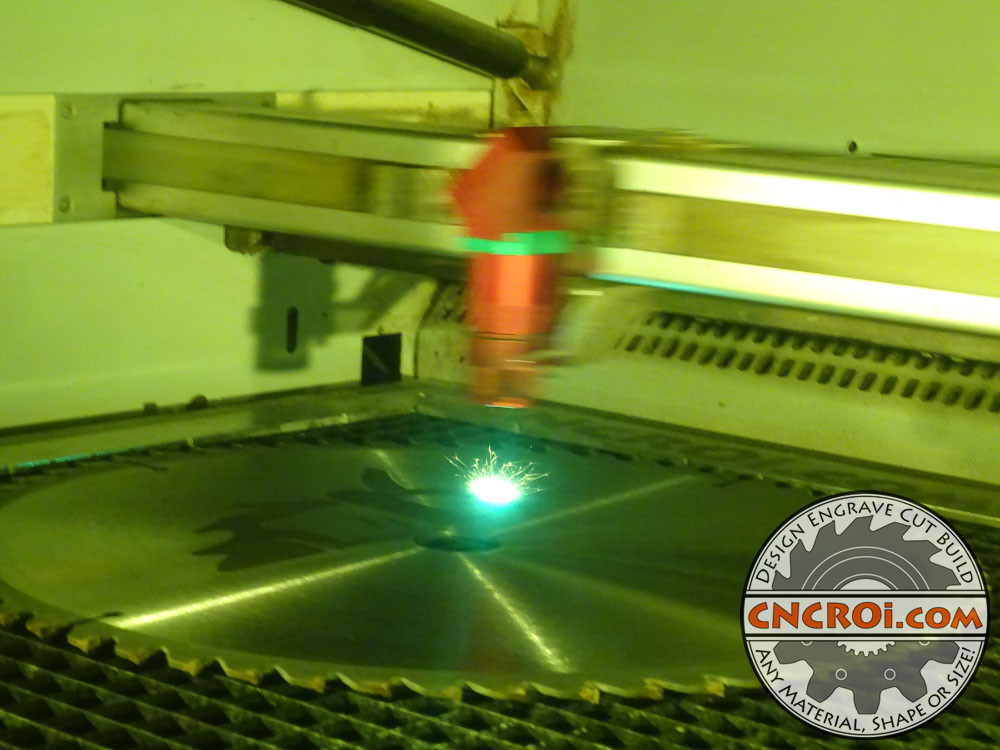

Fiber laser etching is a unique process, we are actually vaporizing metal just like wood but the light is a different color and the beam used is a lot narrower.

When it comes to stainless steel specifically, we can make a whole variety of items from custom plaques and tags to prototyping.

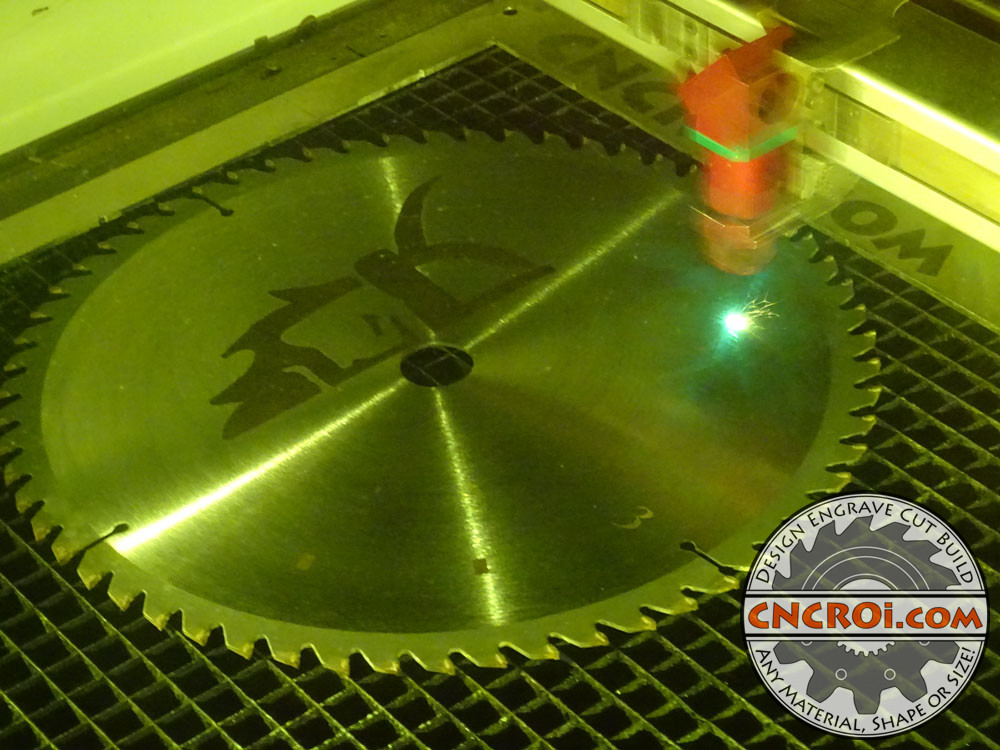

CNCROi.com didn’t just brand the logo but also all the numbers going around the clock, it just happens that the hole in the middle of the Carbide saw blade works perfectly for a custom clock!

CO2 or Fiber laser sources are invisible, it’s like magic, a head move over the material and you see the results, but no indication as to how it happened and the light is incredibly intense for the fiber laser especially compared to our CO2 laser source on wood.

CNCROi.com has a lot of flexibility when it comes to metal, from cutting to branding, you tell us what you want and we’ll make it for you and ship right to your door.

Right out of the machine there is some flash rusting that’s quickly washed away from the surface of this solid steel custom clock that’s now permanently branded.

After washing, this custom saw blade clock is looking amazing, I’m very impressed with the results and love the look and feel of the overall blade now.

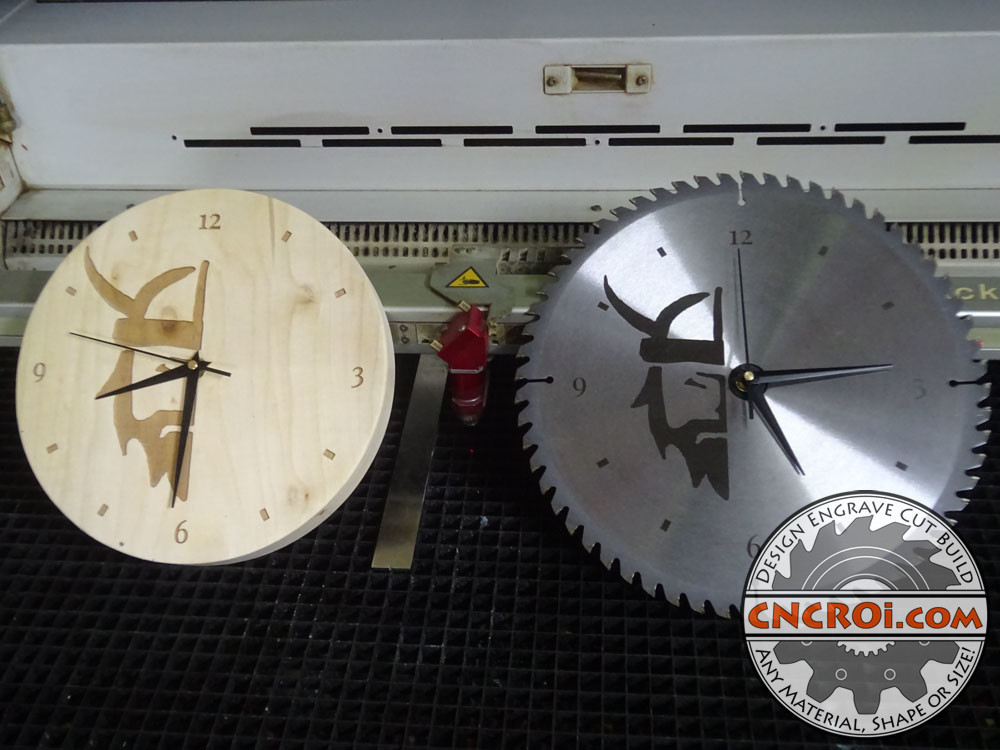

Here’s a side by side comparison of the live edge Maple slab CO2 laser engraved and the Carbide tipped fiber laser etched metal, both are amazing custom clocks.

Need a custom clock? Any size, shape or material, contact CNCROi.com right now!