Custom Inlay Template: Laser Cut 1/4″ MDF

Making a custom inlay template at CNCROi.com can be made using any design profile or material thanks to our CNC machine diversity.

https://www.youtube.com/watch?v=QlY9AJhzJlo/

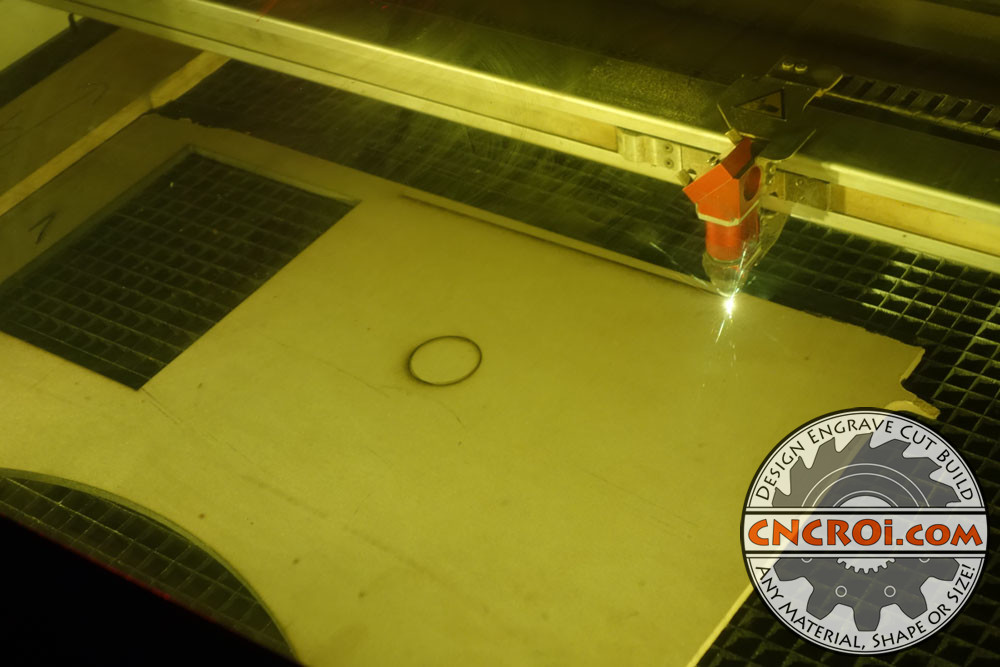

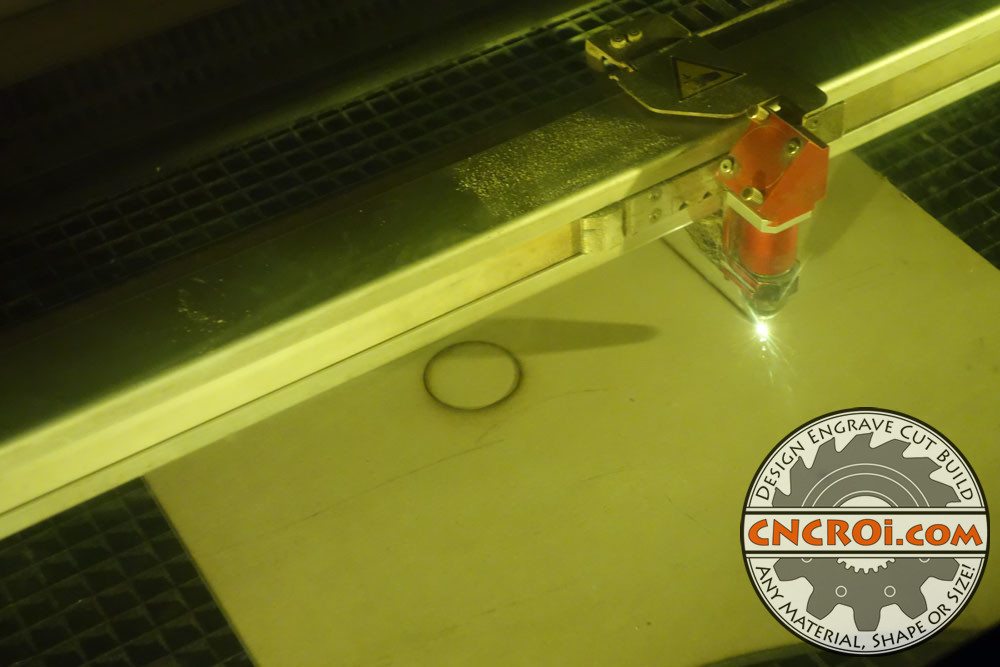

This this specific custom inlay template, we used quarter inch MDF, laser cut of course, though the same results could have been achieved using our CNC router.

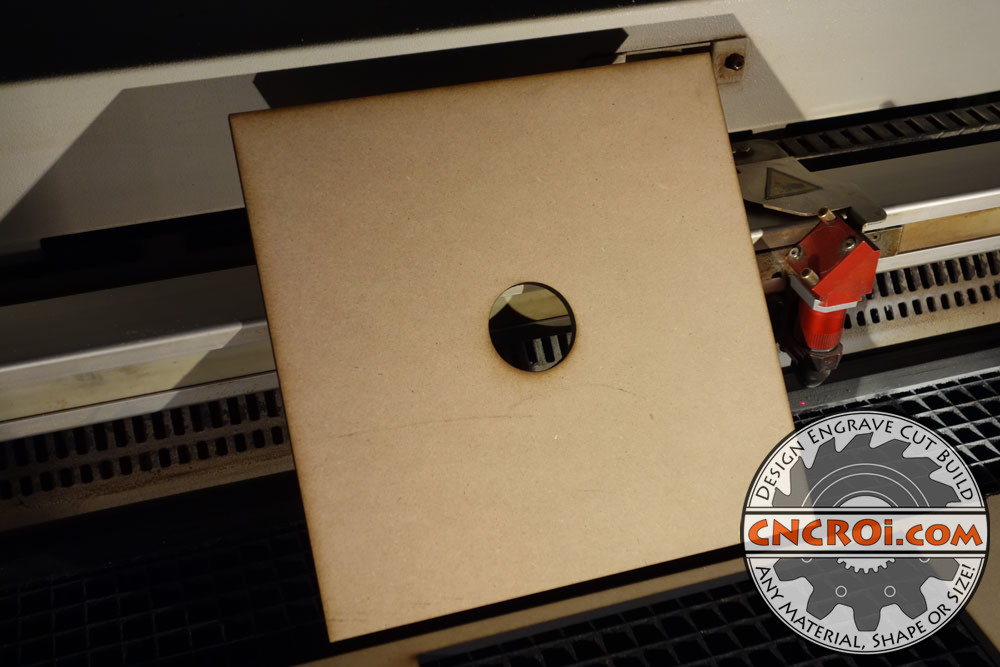

The way these custom inlay templates work is that the customer clamps down this MDF onto the surface they wish to work from and then, using a hand held router, they can precisely create a pocket to then introduce their inlay, it’s a great way to quickly and accurately achieve an inlay on just about any surface.

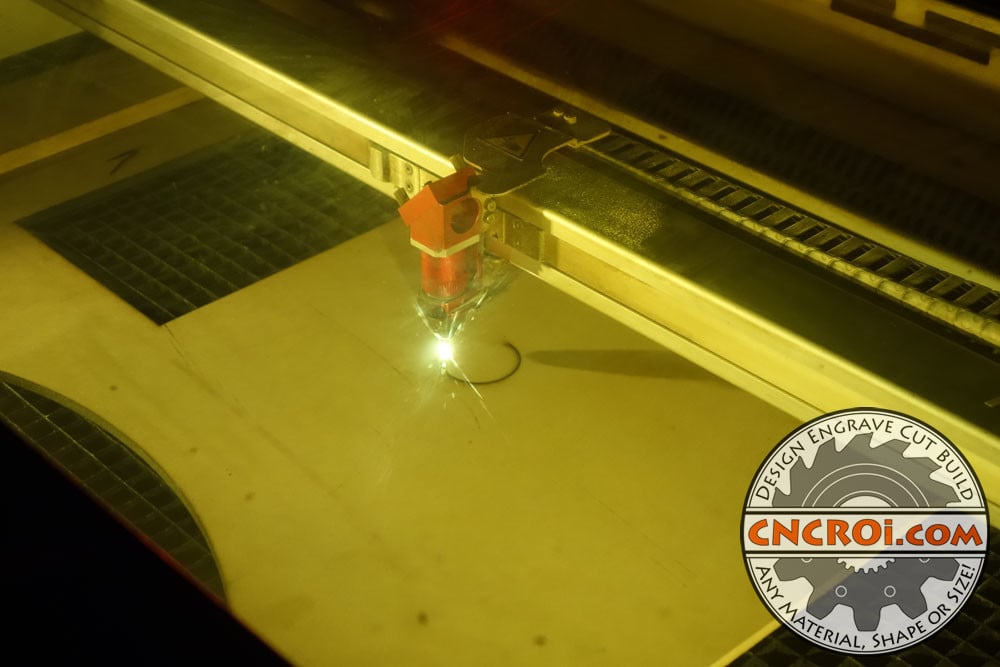

Laser cutting this custom inlay template was just easier when it came down to this project because the router was busy doing other stuff at the time, whether I used the laser or the router, you get the same precision and accuracy in the end-product at CNCROi.com, so in this case, they were very much interchangeable.

When it comes to making inlays, we can also make the inlay parts as well as the matching template so you can integrate them into anything you have surface wise.

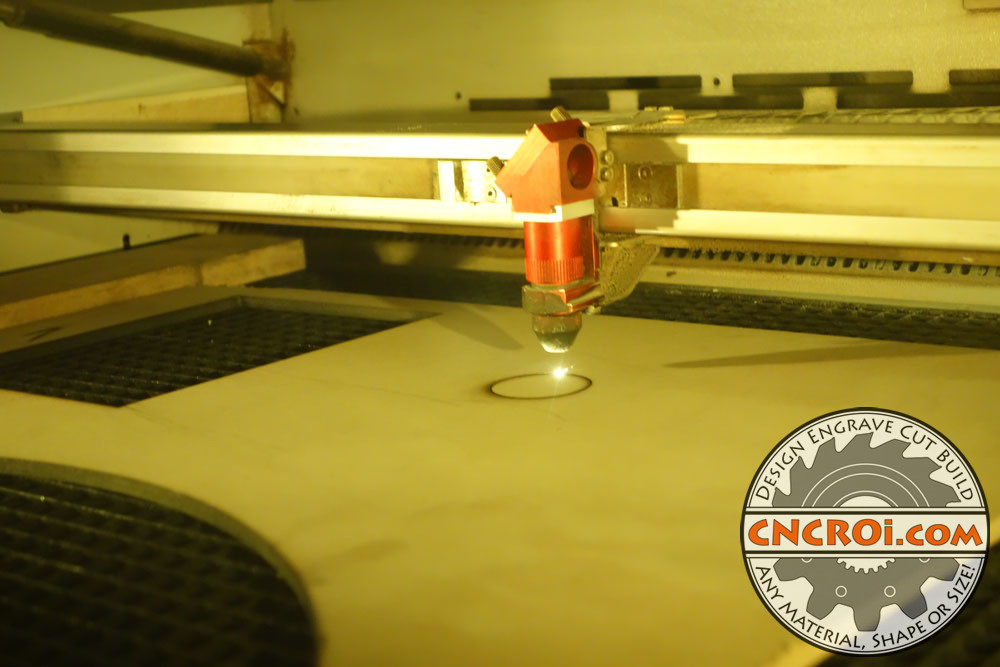

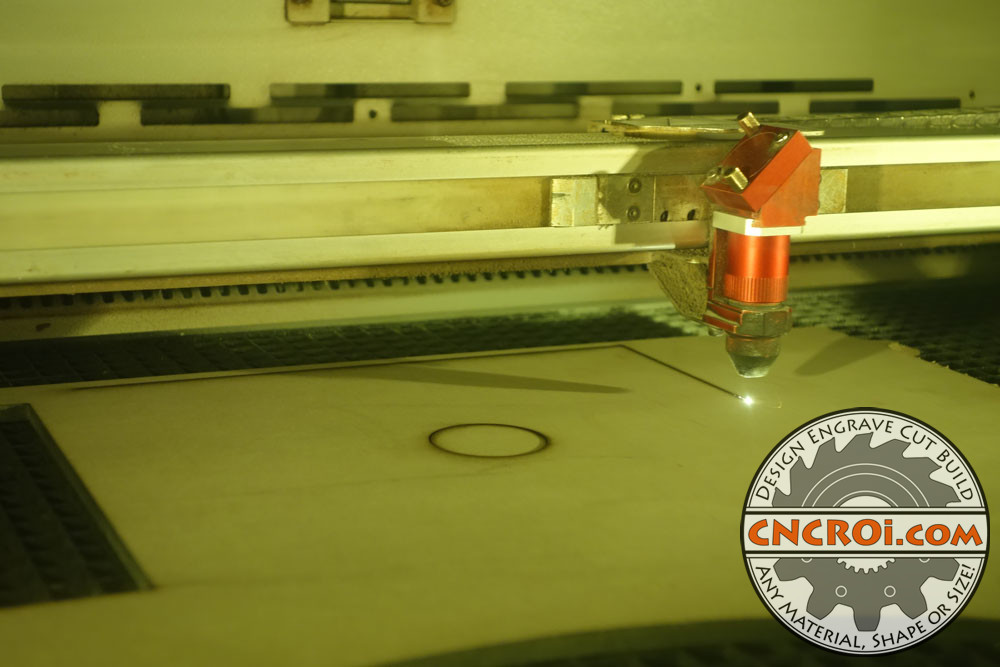

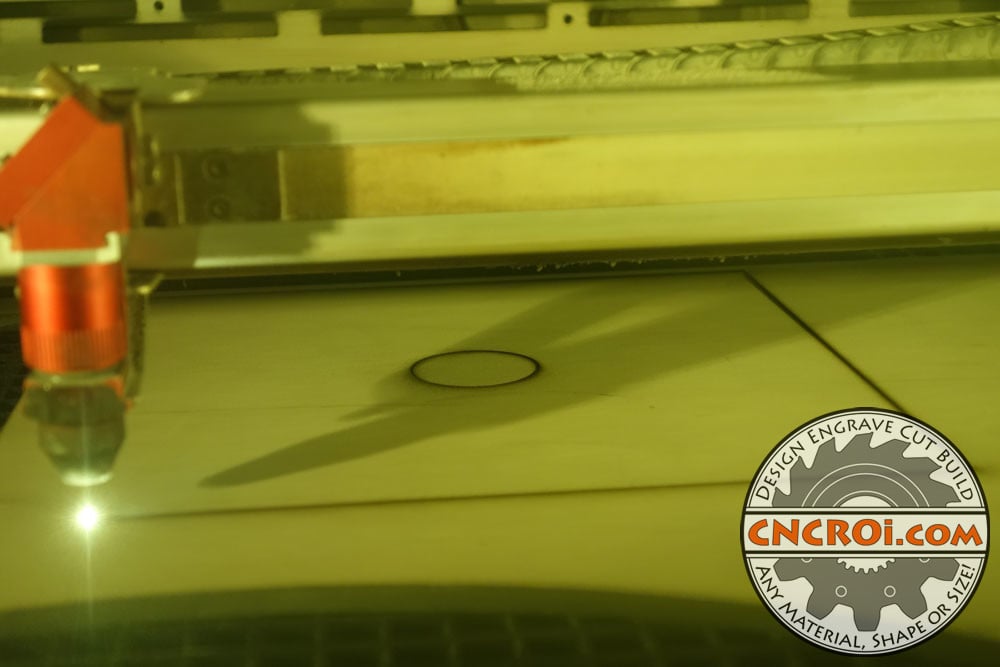

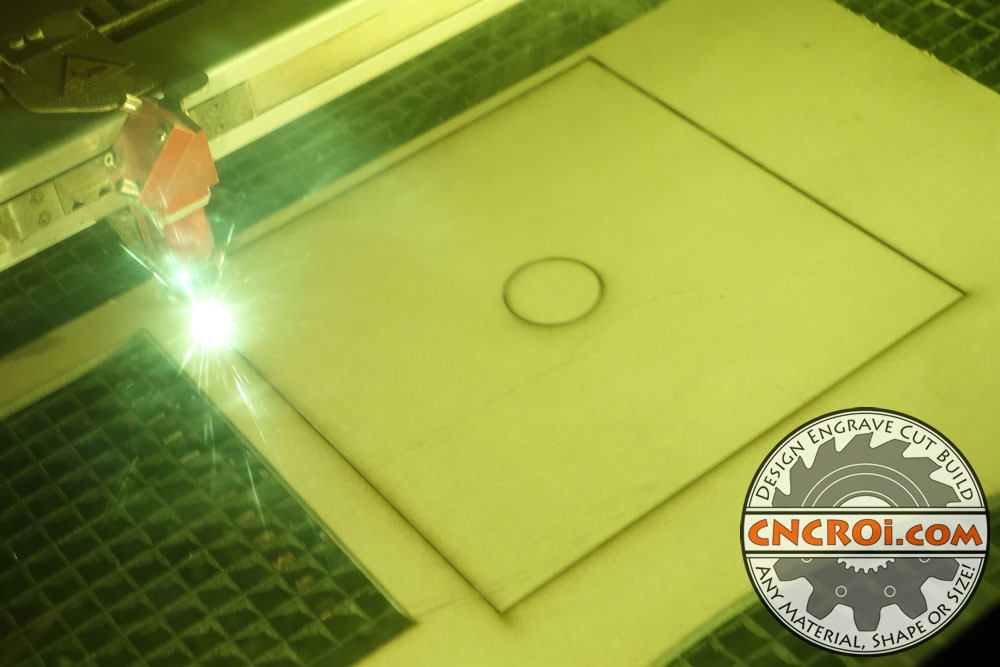

After the inside was cut out of the MDF, the outside is cut-out, for ultimate accuracy, again, makes no difference what CNC platform we use at CNCROi.com, the insides always get cut out first so that if anything moves during the cutting out process, no precision is lost in the process.

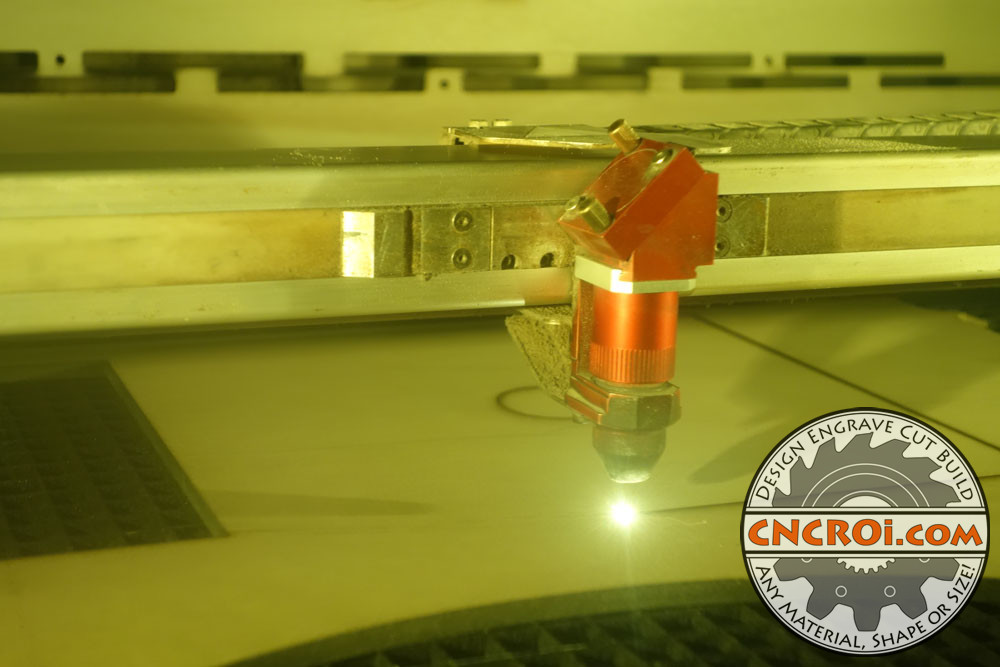

The one key difference between doing this project on a router vs a laser is that the router, I can pick, due to the diameter of the bit, if I’m going to cut on or beside the line, while with the laser, it always cuts ON the line, as the diameter of the cut is so small.

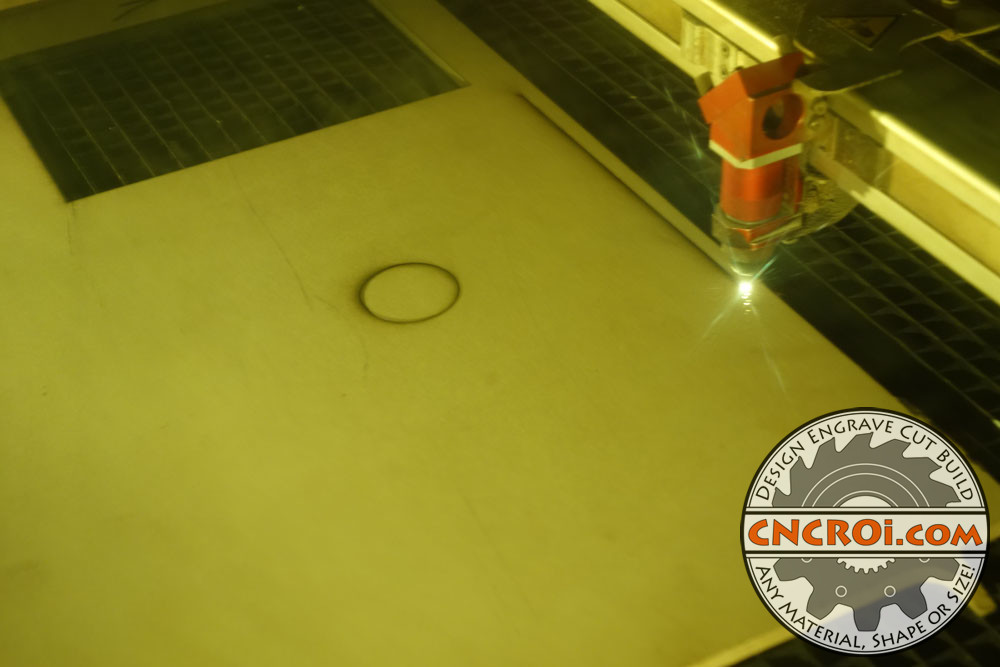

Cutting MDF is no different than any other material at CNCROi.com, it’s just the machine, feeds and speeds that change based on the design and materials, the precision is always there and it’s always consistent.

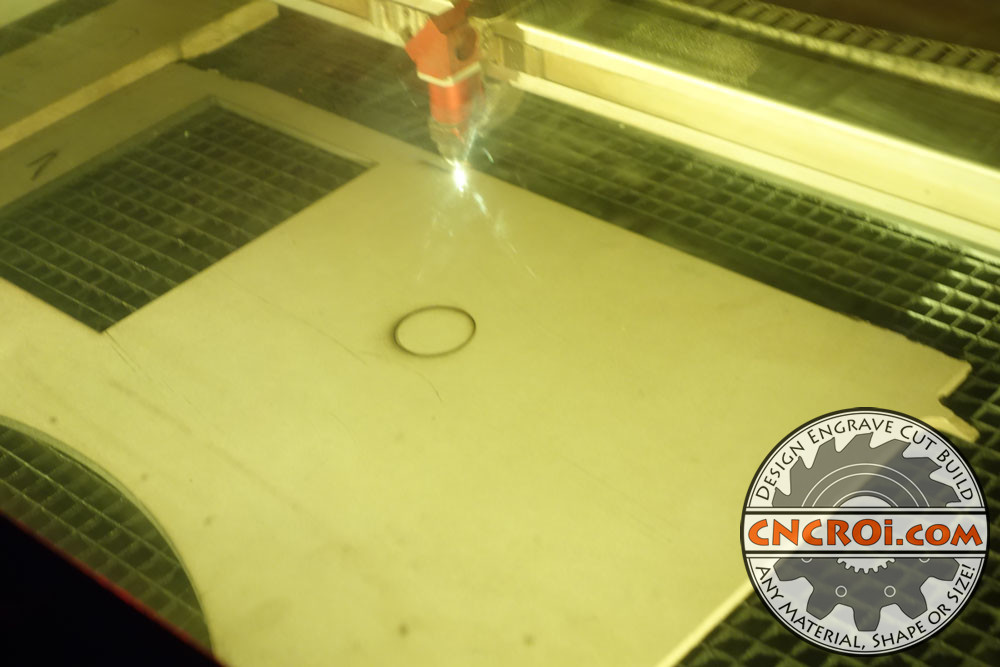

For this custom inlay template, it’s a simple round hole with a square perimeter, but this could have been any shape, size or thickness… or material for that matter, so you aren’t stuck with ONLY MDF, or only quarter inch stock or anything else you see for this specific job.

Inlays are great for a variety of projects, we use the often at CNCROi.com for projects, it really makes thing stand-out when you put everything together.

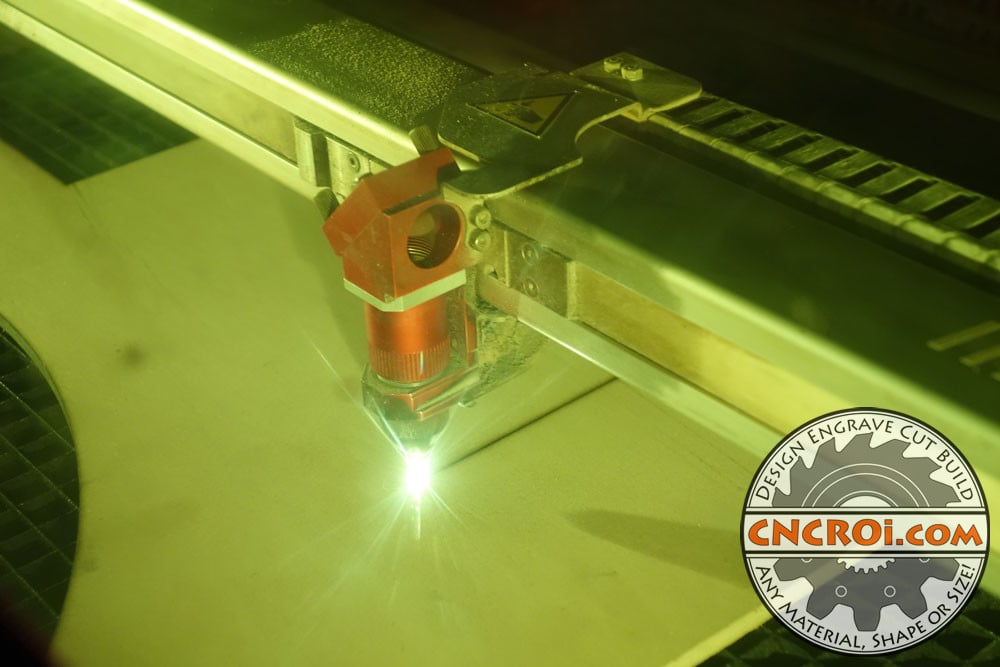

Laser cutting does have some advantages over using the router to cut MDF, the biggest is hold-down, there is no need to worry about it as laser cutting this custom inlay template is a non-contact method, while with the laser, you have a round spinning bit that can throw the piece across the shop if it wasn’t held down mechanically or using a vacuum system.

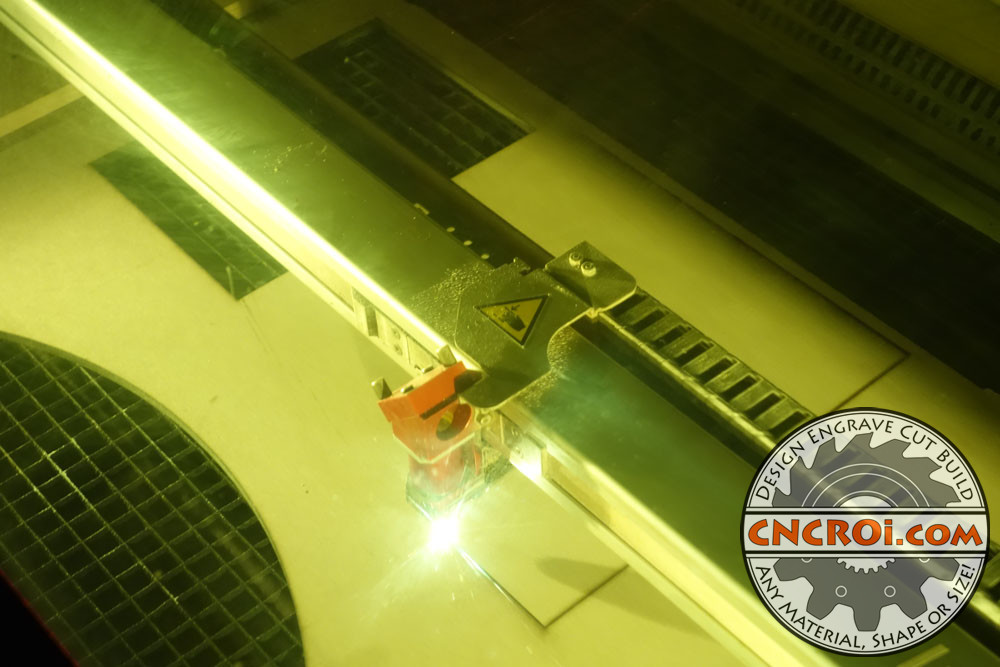

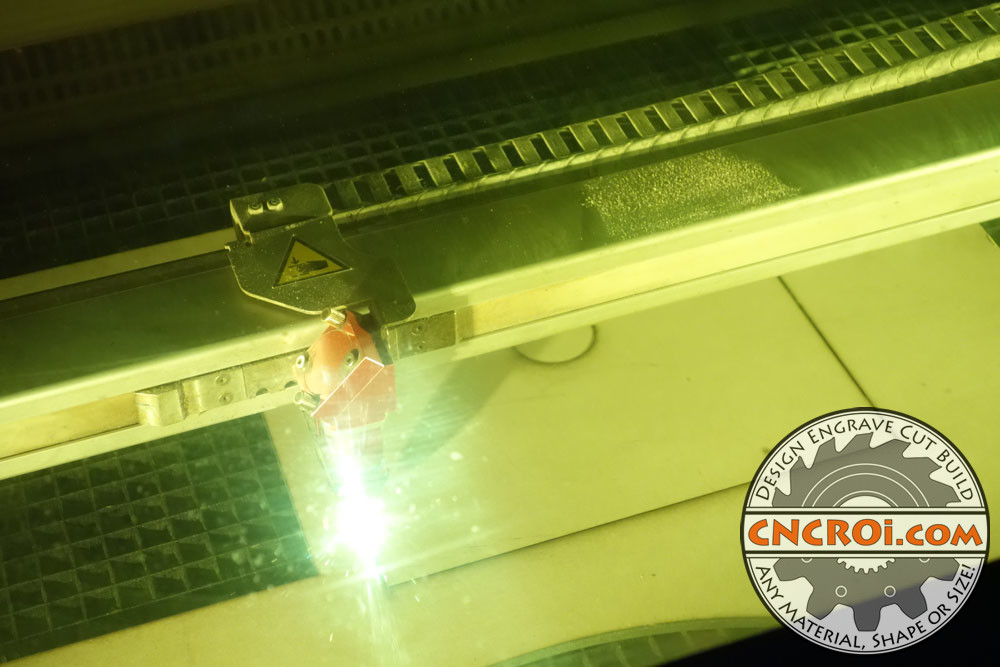

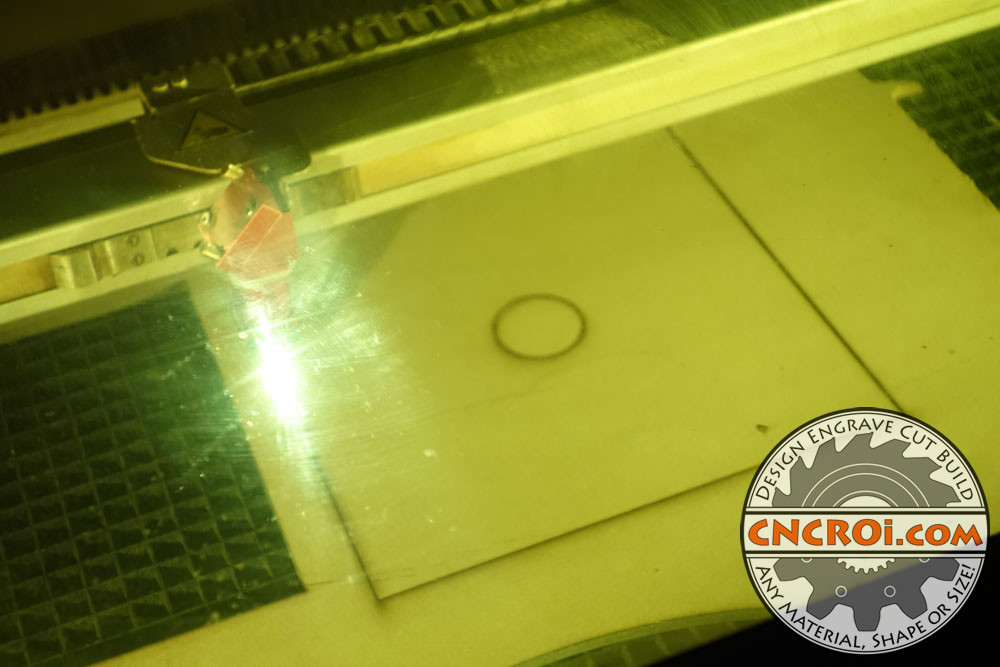

The bright light you see isn’t the laser in any of these photos, it’s the result of the laser cutting the MDF, the laser is completely transparent to our eyes, or that of the camera system I use at CNCROi.com to document these projects.

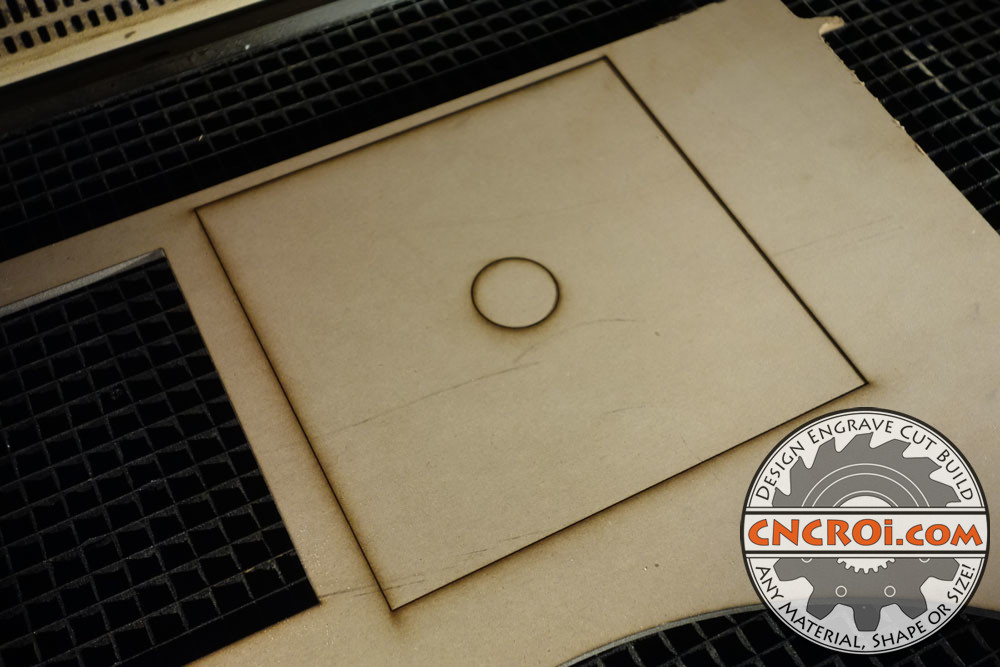

MDF is a good material for a wide variety of custom projects, it’s relatively inexpensive vs doing this project using stainless steel or even live edge hardwoods, stays FLAT as long as it doesn’t get moisture thrown on it and the cuts are clean with minimal soot.

CNCROi.com has cut trailers and trailers of MDF through the years, it’s probably the material we process though the shop the most as it’s so easy to find and work with using a variety of tooling.

Custom inlays can be made using any material with CNCROi.com and any combination of jigs and templates you require for your project work fine with us.

You don’t see much of any smoke production during the making of this custom inlay template, that’s because we have a powerful extraction system sucking the air out of the laser and a strong compressor throwing air down onto the work piece from the laser head, so any flames are quickly extinguished.

When it comes to laser engraving or cutting, literally anything works fine onto just about any non-metalic material – as such, if you wanted additional design elements on your custom inlay template such as orientation or other references, that isn’t a problem at all.

The nice thing about lasers is that the only output from all the work it does is smoke, while with the router, it’s dust that builds-up all over the shop even with a vacuum system working overtime.

When it comes to resin, it’s a wonderful choice for inlays, generally we make the templates and jigs for customers then they just pour their inlay rather than try to fabricate something out of wood to go into it.

The advantage of the router when it comes to custom projects like this inlay template, is that it would produce things much faster than the laser, but for one-offs, by the time the programing and set-up involve is done, they are about equal for this specific project at CNCROi.com.

Now that this custom inlay template is finished, you can see the product after laser cutting, there is almost no material removed during the lasering process, you can’t see light coming through any of it.

When it comes to custom templates of any size or shape or material, keep CNCROi.com in mind as we have done a ton of these in the past and will continue to do many well into the future for customers all around the world.

Nothing beats the precision of CNC, regardless of the project at hand, it can be done fast, precise and repeatable, so if you want one or a thousand units, they will all be as identical as your design file.

Need custom inlay templates? Contact CNCROi.com right now!