Waterjet Cut Stainless Steel Stencil

Waterjet cut stainless steel stencil making has a cleaner finish than plasma but at a higher price point, there is no perfect machine, just optimal for the given application at CNCROi.com.

The major advantage to waterjet cut stainless is that it’s a cold process, meaning we don’t have issues with thin stainless steel related to heat warping and hot zones.

For this specific waterjet cut stainless steel stencil, the details were very small and the overall stencil was small, as such, it’s very difficult to plasma cut as there is little room for the arc due to it’s melting diameter.

Where the waterjet excels over plasma, it also has challenges, the first is that it’s very slow and is in constant need of “sand”, as without it, it won’t be able to cut anything using purely water on stainless steel regardless of the thickness.

CNCROi.com has access to many engraving and cutting platforms, as such, we can pick and choose what technology will best suit the application at hand, if this waterjet cut stainless steel stencil was double the size or required a thicker metal or any host of other design spec changes, the plasma would quickly become the winner as to who gets the job.

The reason why we don’t do many stencils using mild steel is due to the flash rusting that can and will happen, it will corrode a lot faster than any other medium, as plastic doesn’t rust, so yes, it does cost a bit more but you get a lot more as well.

CNCROi.com has made endless stencils using a variety of materials for a whole variety of applications, with metal, we’ve done projects with everything from stainless steel to mild steel, aluminium through titanium.

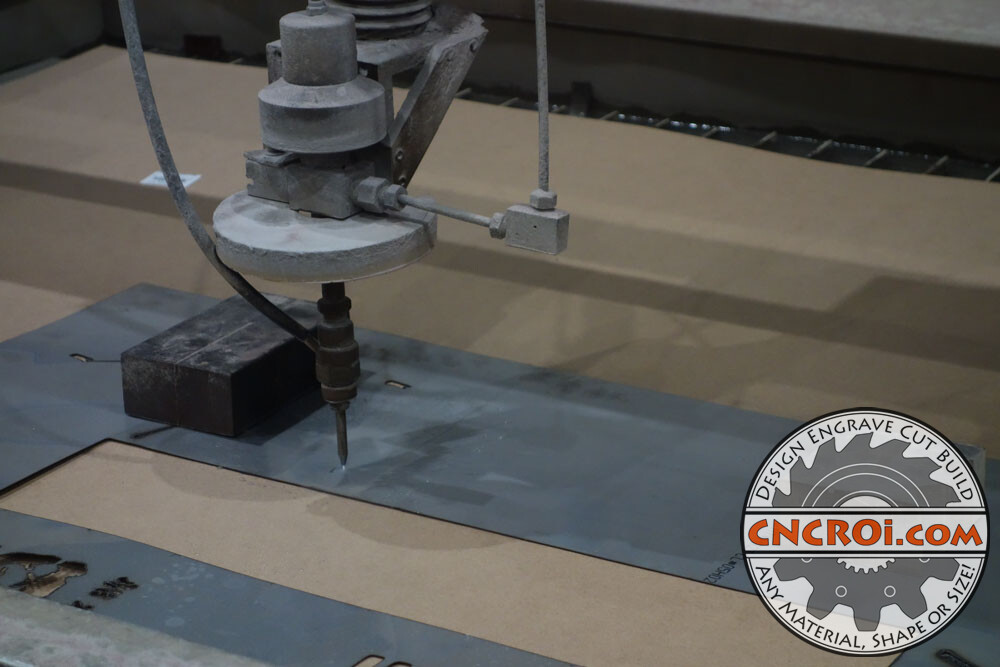

The water you see coming-up where holes exist in the waterjet cut stainless steel stencil is just that, there is a lot of pressure shooting DOWN and THROUGH the steel, and what goes down must come back up.

Regardless of the application for your custom stencil, CNCROi.com can help you with the design though fabrication process, and shipping is done via courier so you get it just a few days after production.

The challenge with waterjet cutting over plasma is, at least at CNCROi.com, waterjet is a wet process while plasma is a dry one, the clean-up is different but they both create a slight layer of dross on the underside, one from melting and the other from “pushing” during the abrasion process.

When it comes to a waterjet cut stainless steel stencil, the precision is the same as the laser, just the diameter of the “beam” is smaller than plasma, so although the movements are essentially the same, the resolution is different.

When it comes to custom barrel head stencils specifically, the question of what material to use is pretty straight forward, if you want to use a propane torch, then metal wins, if you want to use spray paint, then polycarbonate or mylar wins.

CNCROi.com has years of experience not only cutting using various CNC machines but also designing for them, so if you need help putting things together to turn your virtual dreams into reality, we can help from concept to finished product.

The reason we were cutting this waterjet cut stainless steel stencil using very thin metal, 22 ga actually, was because the customer was going to wrap this around a cylinder, as such, it needed to be strong and durable yet easy to bend around for their project to work.

Making stencils using waterjet cutting allows for very tight tolerances as there is no heat generated during the cutting process, unlike just about any other technology out there available to CNCROi.com.

What you see under the sheet of stainless steel is fibrous board, this helps to reduce the possibility of the thin metal vibrating from the water shooting back up after cutting and being pushed down from the waterjet cutting process itself.

As this custom waterjet cut stainless steel stencil is just about done the bottom part, you’ll notice CNCROi.com has two very heavy metal bricks on either side of the sheet of metal, this is because we don’t want the sheet to move during production, that’s the problem with waterjet, the pressure coming back up can lift and move items if they aren’t held down.

The last part of the waterjet cut stainless steel stencil before cutting it out is the upper wording, this is where the finest of details were found as they were letters, and as such, where the waterjet really shines due to small beam diameter.

When it comes to the level of detail you can achieve on a stainless steel stencil, it’s pretty much endless as long as you have inner parts properly supported.

What you see building-up all around on the surface of the stencil is actually the sand after it has been used under high pressure to cut through the stainless steel, it comes right off afterwards.

Inside letters such as “A” and “R” need supports to hold inner parts, as such, the final details are even tighter tolerances to make sure they stay in place during the cutting process and the customer at their end using fire to brand their wooden cylinders with this custom waterjet cut stainless steel stencil.

Most of the stencils that CNCROi.com produces are actually roughly 1/8″ thick, this does not bend by hand, which was the problem with this spec, hence going thinner, you could easily bend it and use tape to hold it in a cylindrical form.

Polycarbonate is a wonderful alternative to stainless steel or even mild steel, it doesn’t like fire so if you are using spray paint, it generally wins the game when it comes to custom stencil production material.

The nice thing about CNC machines is that they don’t get tired, meaning they can do the same or different custom waterjet cut stainless steel stencil day in and out without any decrease in quality.

CNCROi.com is cutting the inside first then it will be followed by the outside to liberate the waterjet cut stainless steel stencil from the sheet of metal so that nothing moves, accuracy and precision are always top of mind, even though this stencil doesn’t require such high level of production quality tolerances.

You can now see the finished stencil below, it looks awesome and I couldn’t be happier to ship this to the customer from CNCROi.com to their place of business so they can benefit from this ASAP!

Need a custom stencil? Any size, shape or material… contact CNCROi.com right now!