Custom Manifold Tags: Black Anodized Aluminium

Custom manifold tags can be made by CNCROi.com to just about any spec you require, from material selection to sizing.

Whether your manifold is made out of steel or aluminium, we can offer tags that match the base metal’s general chemistry, which means, you can weld them in place, or rivet, without fear of galvanic corrosion – the breakdown of dissimilar metals when put into contact with one another.

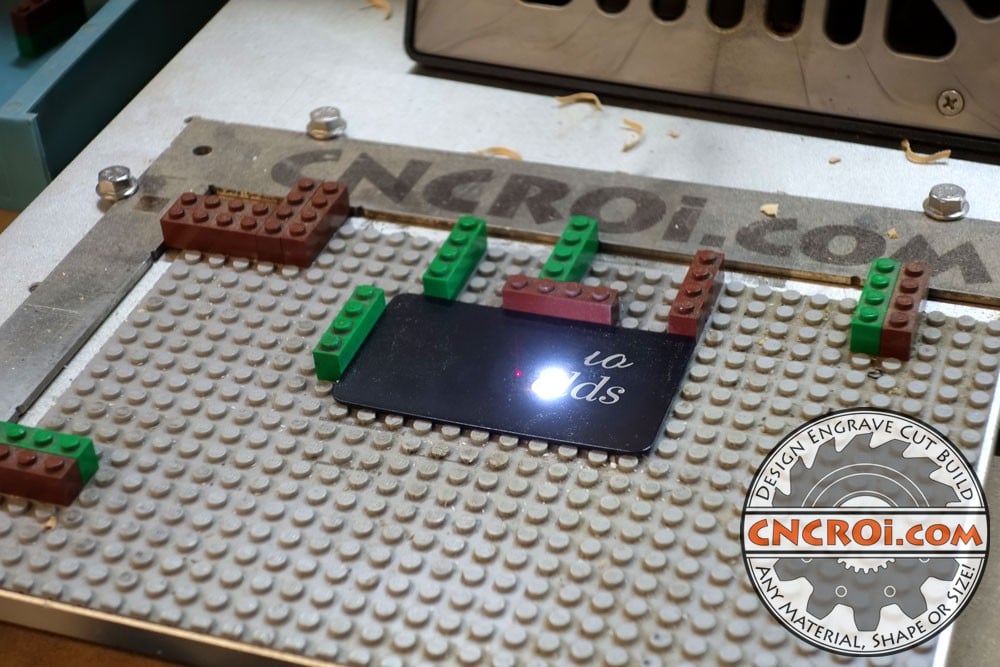

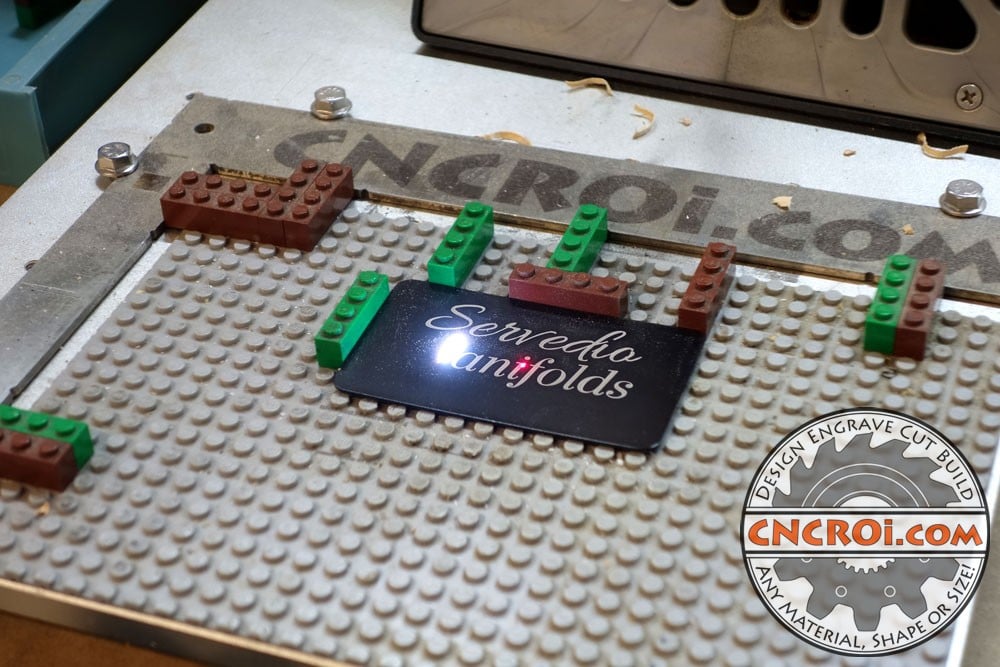

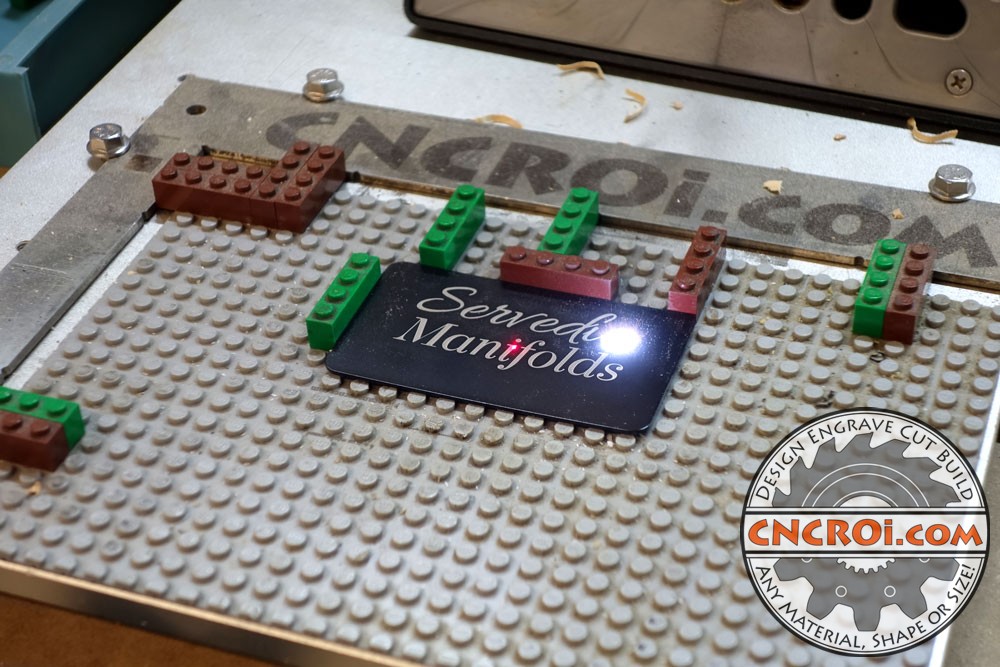

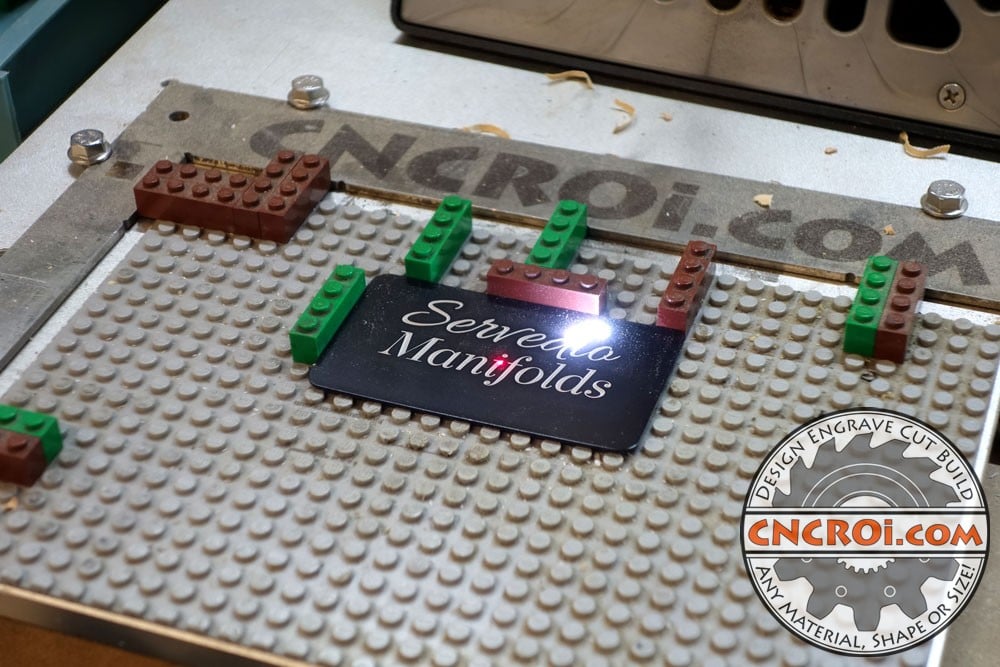

For these specific custom manifold tags, they are made from aluminium (the manifold is aluminium) and for contrast, they are anodized, roughly the size and thickness of a credit card.

The additional nice thing about these aluminium custom manifold tags is that if the customer wished to rivet them down the line, it’s very easy to punch or drill holes through these tags using just rudimentary tooling like a drill or manual hole punch.

Although not automotive related, this shows you the processes we have in order to make just about anything custom.

The black anodizing on these custom manifold tags provides the best contrast available for very good durability characteristics, not as good as fiber etched stainless steel, which CNCROi.com can fabricate as well but going back a few paragraphs, you want to match your base metal to your “tag” to prevent excess corrosion.

When it comes to fabricating custom manifold tags, quantities can be pretty low if you are OK with our selection of blanks we keep in the shop for just this purpose, but if you want to go totally custom spec, CNCROi.com can fabricate those for you as well.

When it comes to custom tags, just about anything is possible, the above video shows you how we make them using laser cutting.

Laser engraving has a few advantages over mechanical engraving in this case, the biggest, is that very fine details can be put into the tag, as the diameter of the laser is infinitely smally by comparison to any bit available.

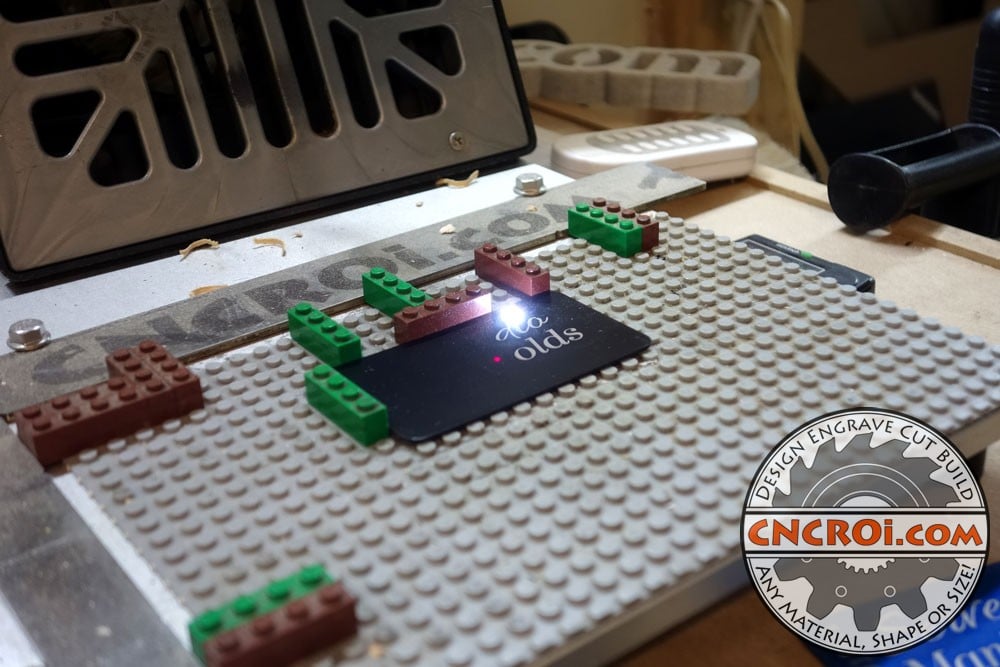

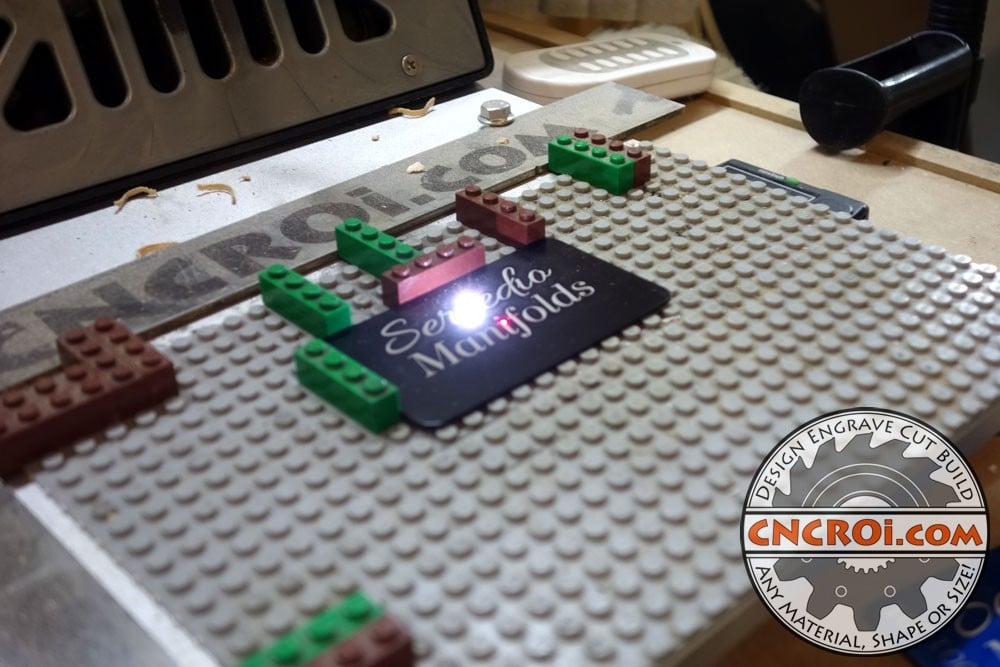

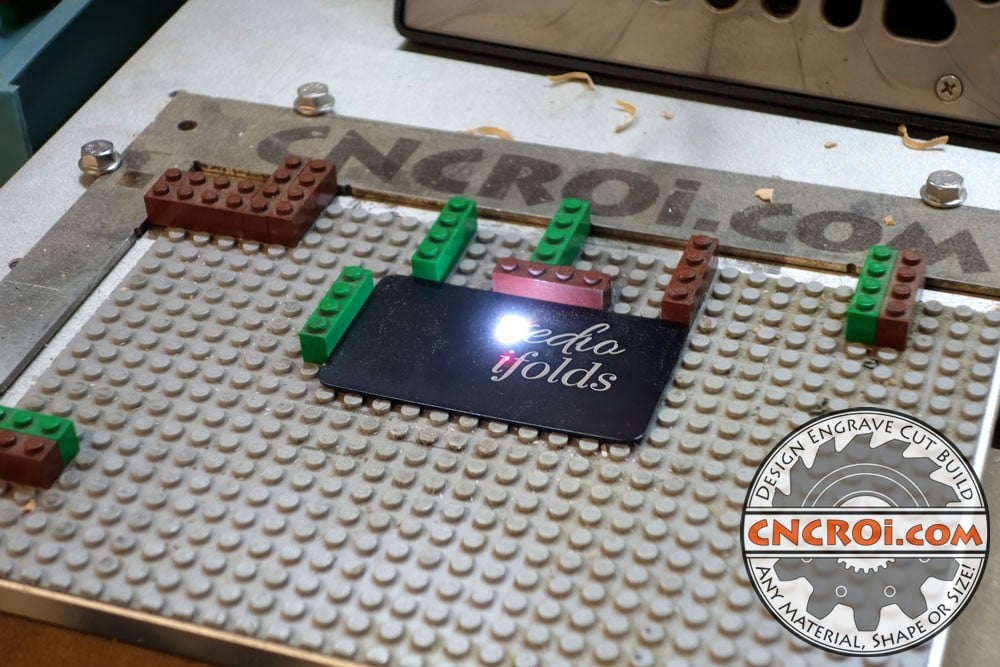

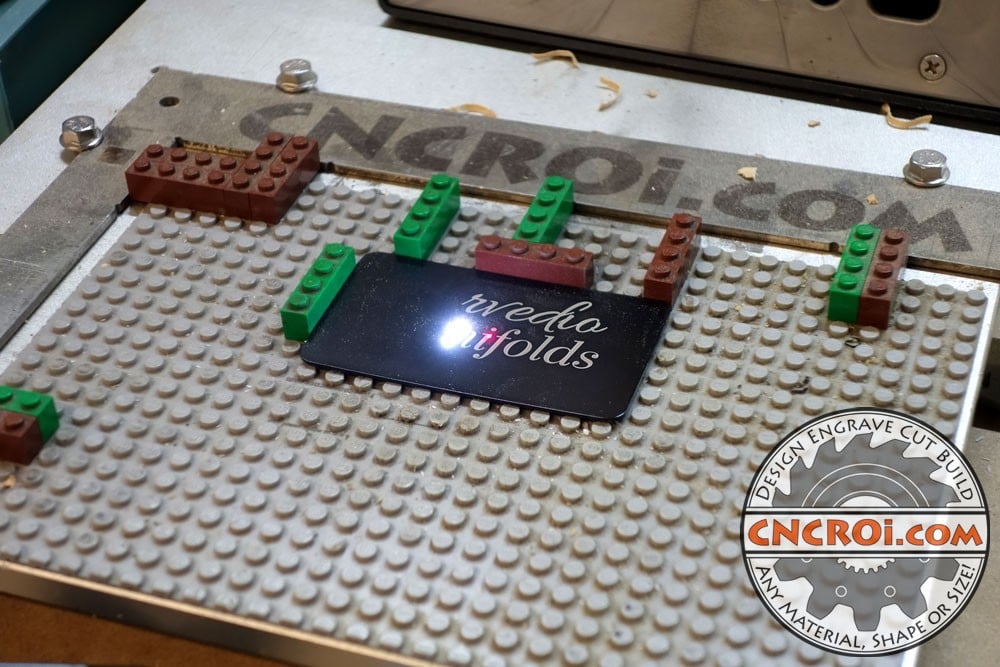

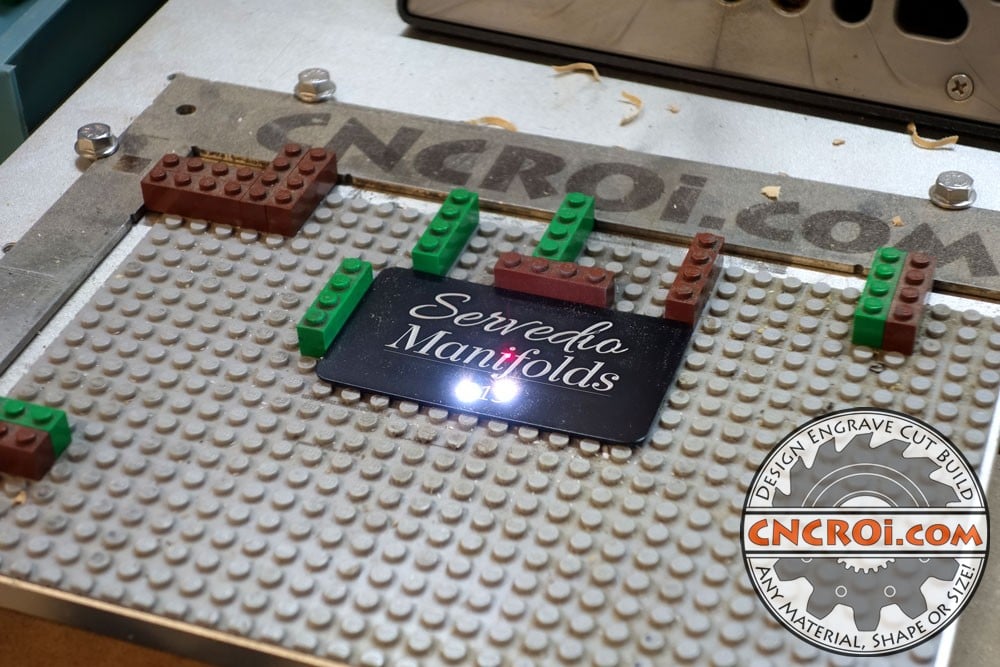

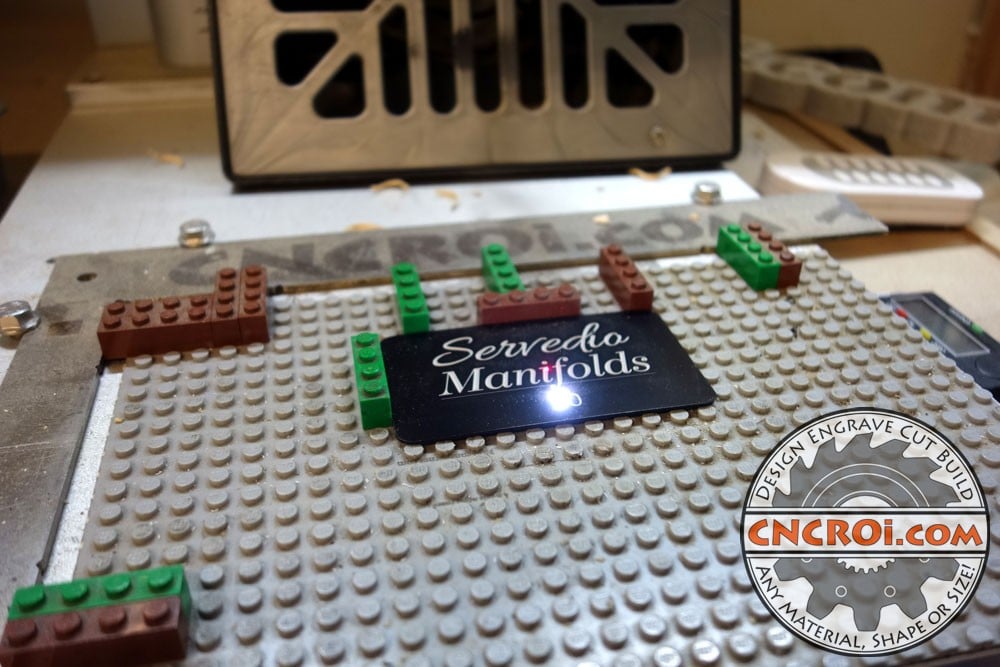

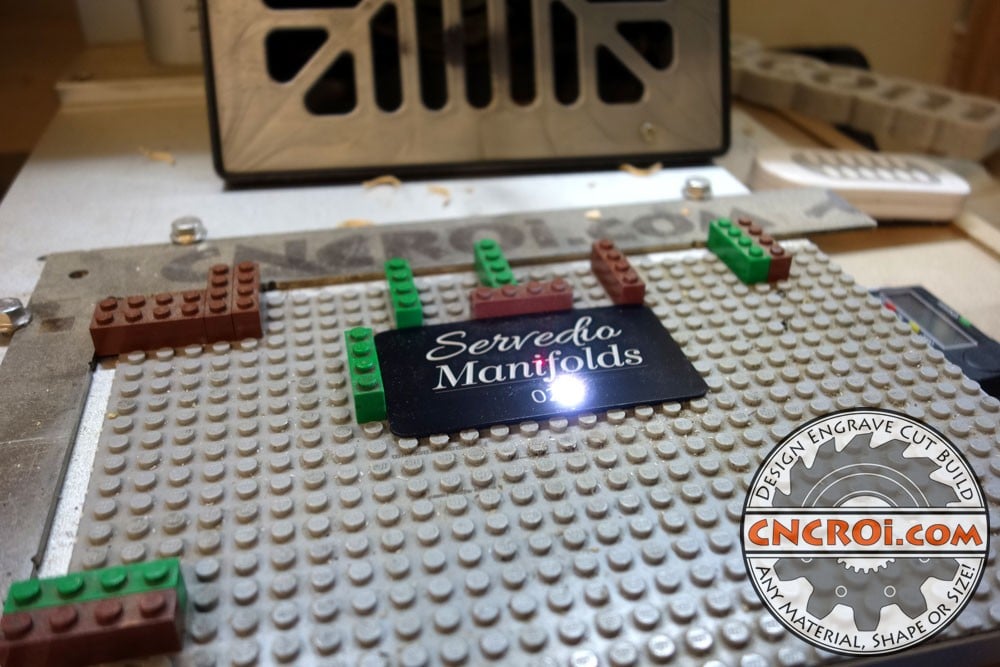

Additionally, lasers are a non-contact method of production, meaning hold-downs and other tools of the trade to make sure things don’t move aren’t required, in this case, you can see the LEGO is only used as a repeatable jig to make sure each tag is placed in the same place, not to actually hold it in place.

Aluminium has incredibly good conductivity, unlike stainless steel, as a result, there really is no heat build-up on the tag that can cause it to warp or bend from the laser engraving process – something that I have to be very careful about at CNCROi.com if these were stainless steel custom manifold tags.

This shows you how we make custom “other parts” that are automotive related.

When it comes to quantities, if you choose one of our blanks, a one-off is fine, but generally, things start to make more economic sense after quantities of 25-50 units and for totally custom, above 100 units depending on the specs of course.

As mentioned in the video, each of these tags have the company branding at the same place on each one but they are sequentially numbered, that’s the numbers you see from 1 to 25, on the bottom of the custom manifold tags.

If you wanted instead of sequential number but alphanumerics, bar or qr codes, CNCROi.com can make the custom manifold tags just as you wish.

CNCROi.com can etch just about anything you require onto these custom manifold tags, additionally, we can also cut through it if required.

CNCROi.com can also etch tags deep, if required, depending on your application.

The bright light you see is the result of the laser etching off the anodizing from the black anodized aluminum oxides, you never actually see the laser, that’s completely invisible.

These custom manifold tags are as high contrast as you can get, the results from our fiber laser is basically the same as our CO2 laser, they both do the same thing, using different waveforms.

Once one custom manifold tags is etched, the next one is put in the same place and then etched, the only difference is that the number on the bottom of the tag goes up by “1”.

The vast majority of the work at CNCROi.com is done using NDAs, so you never see any documentation about it, that being said, lots of work that isn’t covered by that still never sees the light of day because it’s repetitive but for these few projects that fit the format that makes these videos and blog posts worthy, it’s fun to documen the work we do and how we do it.

The big vent you see in the back of the LEGO jig is on during the entire process, any vaporized anodizing and aluminium is quickly evacuated from CNCROi.com.

The above video shows you what custom tags would look like using fiber laser etched stainless steel.

As a result, dangerous fumes never build-up and more importantly, the lense of the galvo laser doing these custom manifold tags never gets gunky.

Once the last custom manifold tags is finished at CNCROi.com, it’s time to take a picture and ship it off to the customer.

The light hits the anodized tags pretty well, stainless steel is even worse to photograph, but the end results looks spectacular in person.

Need custom manifold tags? Contact CNCROi.com right now!