Custom Mild Steel Router Stencils

Making custom mild steel router stencils by CNCROi.com is a very cost-effective way to mass produce your very own woodworking jobs at home in your own time.

https://www.youtube.com/watch?v=3hgRDaWNgSc/

Mild steel is a very strong metal, it can flash rust but if that is a big concern, we can also make these exact same stencils using stainless steel if you wish, or even plastics or wood for that matter.

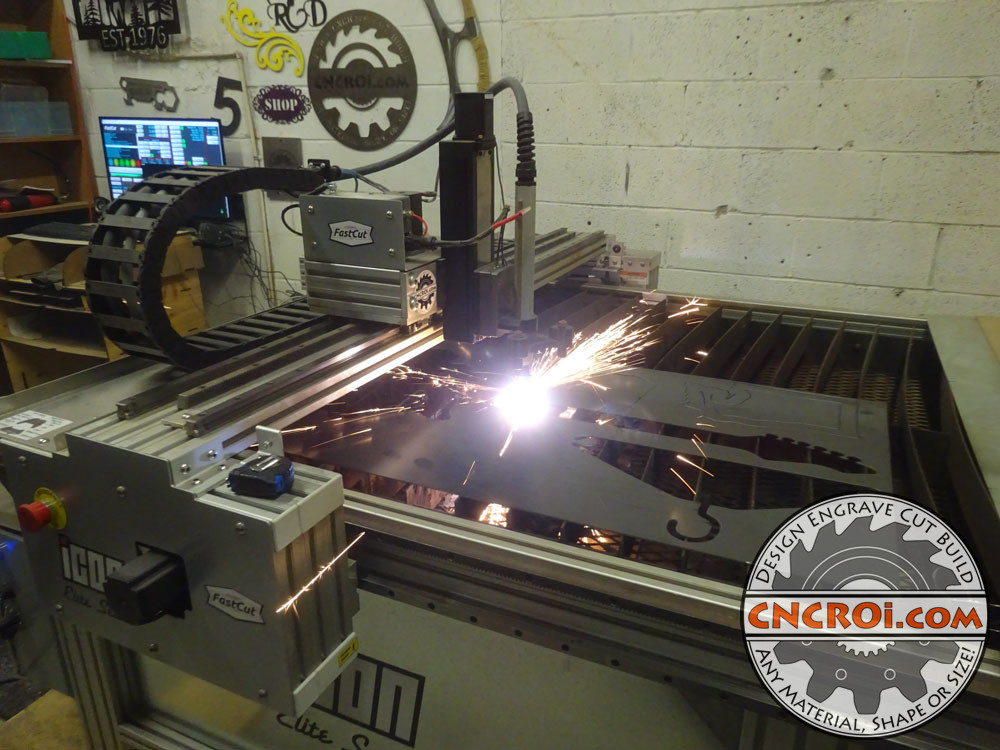

Our high quality CNC plasma cutter quickly transforms regular metal into an amazing stencil which can produce income for our customers, there is an upfront cost but this can be used to produce an endless amount of custom woodworking projects.

The major advantage of CNC plasma cutting is the speed and high quality results regarding edge quality, CNC waterjet cutting produces a nice sanded finish but is incredibly slow with ongoing garnet consumables and thus, not as cost-effective.

When it comes to custom mild steel router stencils, the design options are endless, meaning we aren’t limited to only cutting Washington State stencils, this can be bees, zebras, letters, numbers or whatever else you can ever imagine.

If you are wondering what the difference is between metal and plastics, in general, check-out the results and what’s possible in the video below.

https://www.youtube.com/watch?v=xxFljG9iFJY/

The one caveat with stencils is that you have to make sure you have bridge material to support inner parts of letters, numbers and images because otherwise the inside parts of the custom mild steel router stencils will fall out without supports.

CNC Plasma cutting uses electricity as the consumable to cut through the metal, basically, an arc is created from the head of the plasma cutter want and the table, whatever is between these two items gets vaporized into smoke and dust almost instantaneously.

As there is no direct contact with the metal itself, unlike a CNC router that would have direct contact with the bit into the material, the overall table gantry doesn’t need to be super rigid (though it’s plenty strong to not bend from it’s own weight), that’s why the heft isn’t anywhere near the same as with our CNC router.

The sparks and flames you see in these photos is the vaporization via the plasma of the quarter inch hot rolled mild steel, it’s an incredible sight to behold and even cooler to appreciate after years of cutting this stuff out by hand with saws of various types.

Of course, if you want highly detailed stencils, CNCROi.com can make those as well, though they are generally used with propane rather than spray paint due to the heat generated by the flaming process.

https://www.youtube.com/watch?v=mEDJyj24G_8/

As for durability of these custom mild steel router stencils, I’d easily argue that even with daily use, they will outlast your power router, mild steel is incredibly dense, strong and highly resistant to damage but if you wanted something more robust, we can cut these out up to 2 inches thick no problem using our CNC plasma.

When it comes to the possibilities with CNCROi.com‘s plasma cutting capabilities, we aren’t limited to only mild steel, titanium, hot rolled, cold rolled, stainless steel, brass, copper… literally any type of metal you can dream about, including adamantium and unobtanium can be cut with our machine.

The edge quality from plasma cutting is very smooth, because we used a CNC machine for consistent pathing, doing the same by hand produces an uneven edge profile because your hand, no matter how much you practice, cannot maintain an exact feed across an entire project.

For some projects, MDF is perfect for custom stencils, even woodworking stencils, because the volume count is incredibly low where the higher cost of metal doesn’t make sense as durability isn’t an extreme requirement.

https://www.youtube.com/watch?v=ZsfqMnXtoIY/

I really enjoy plasma cutting at CNCROi.com, it’s a loud, smoky and dusty process but the results are fabulous as our machine moves incredibly smoothly across the sheet of metal and adjusts height automatically to keep the same distance from the torch head to the surface of the material.

In the image below, you can get an idea of how much smoke is being produced but no worries, we have a very powerful extraction system that sucks it right up before it spreads across the shop, it smells like melted metal.

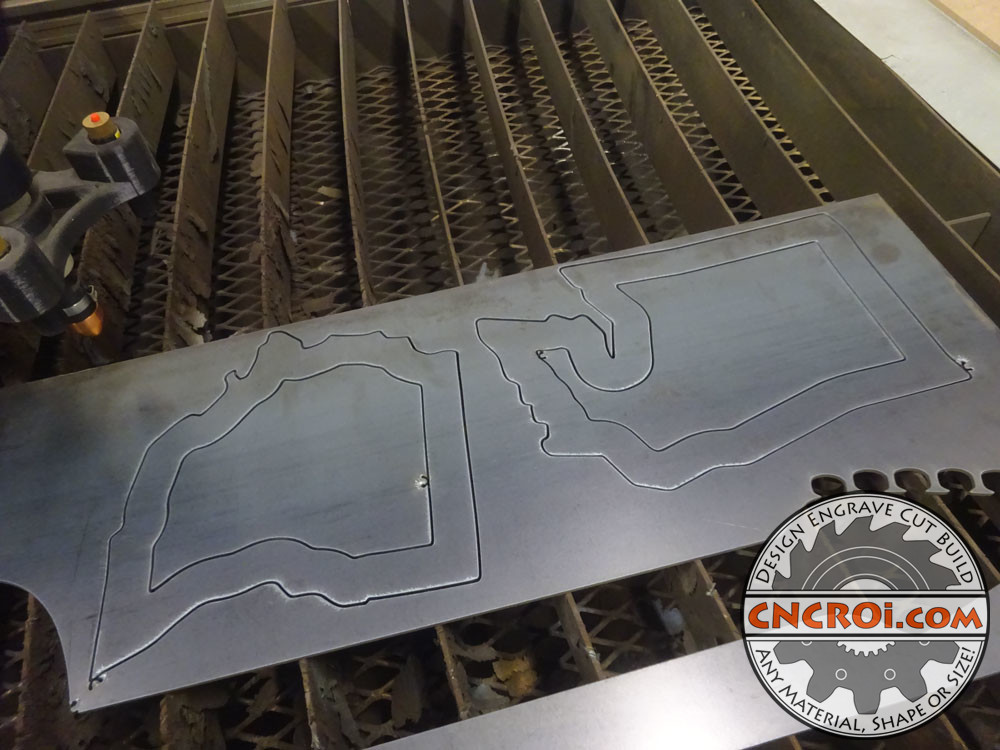

The stencils being cut today are of two states, including Washington, the customer uses these to make custom wooden cigar ash trays using a variety of woods, so these

Stencils are made using a variety of materials at CNCROi.com there is no point going with a plasma cut metal stencil for items like t-shirts, there are better choices, but at least with us, you have the choice of materials and thickness that makes your project the easiest possible.

https://www.youtube.com/watch?v=dwEyYkcdJy4/

CNCROi.com has a variety of custom CNCs, power tools and manual tools, which allows us to cut literally everything out of anything at the shop and this is an incredibly synergistic power because it means we can take jobs from start to finish in one fell swoop.

There are a lot of possibilities when it comes to custom metal fabrication, from cutting custom mild steel router stencils through to large welded furniture and novelty items which we do mostly on an NDA basis for large companies across North America.

After plasma cutting, you can see in the images below just how much material is removed, the inside parts as well as the outside is “scrap” so that’s where we have the lead in and out plasma arcs when the plasma is drilling through the metal, that hole is a bit larger than the traveling plasma arc.

These custom stencils are amazing though, the customer loves them and built a business around CNCROi.com‘s machines so everybody wins.

Need custom steel router stencils for your side business or in your day to day millworking job? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=BrE6GhW6W2A/