Custom Pottery Stamps: Lasering 1/4″ 6 mm Acrylic

Custom pottery stamps by CNCROi.com can incorporate any design elements you wish and we can also make them using other materials such as rubber or wood.

https://www.youtube.com/watch?v=AndwUMu-Jbw/

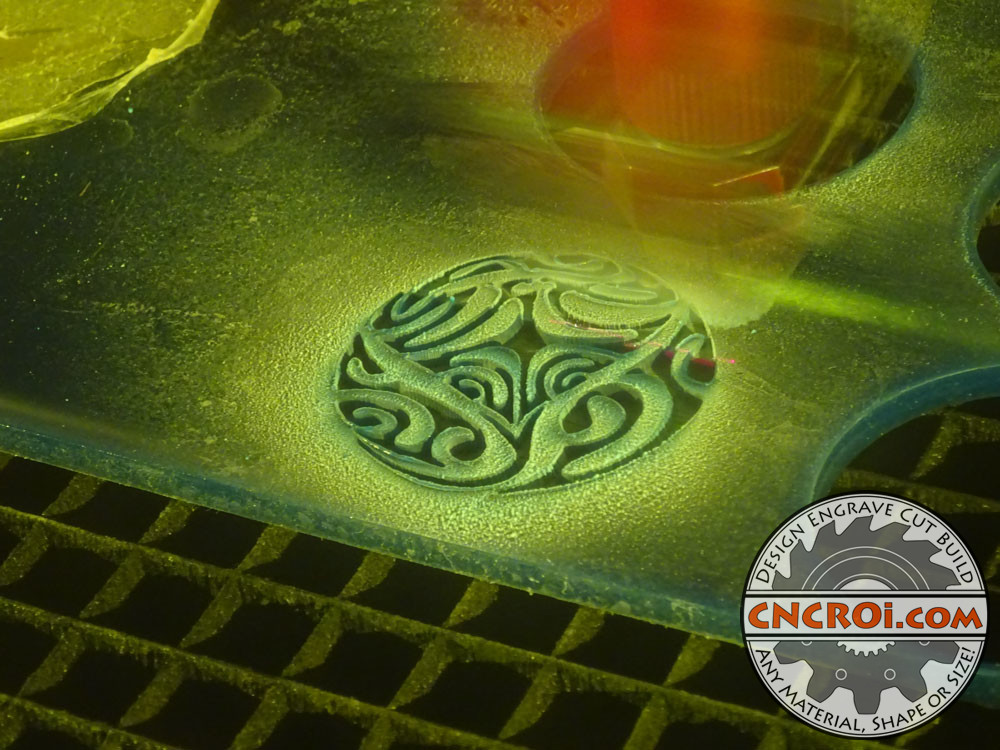

The way custom pottery stamps work is before kiln drying your push this pottery stamp into into the clay then baking it will make the embossing permanent.

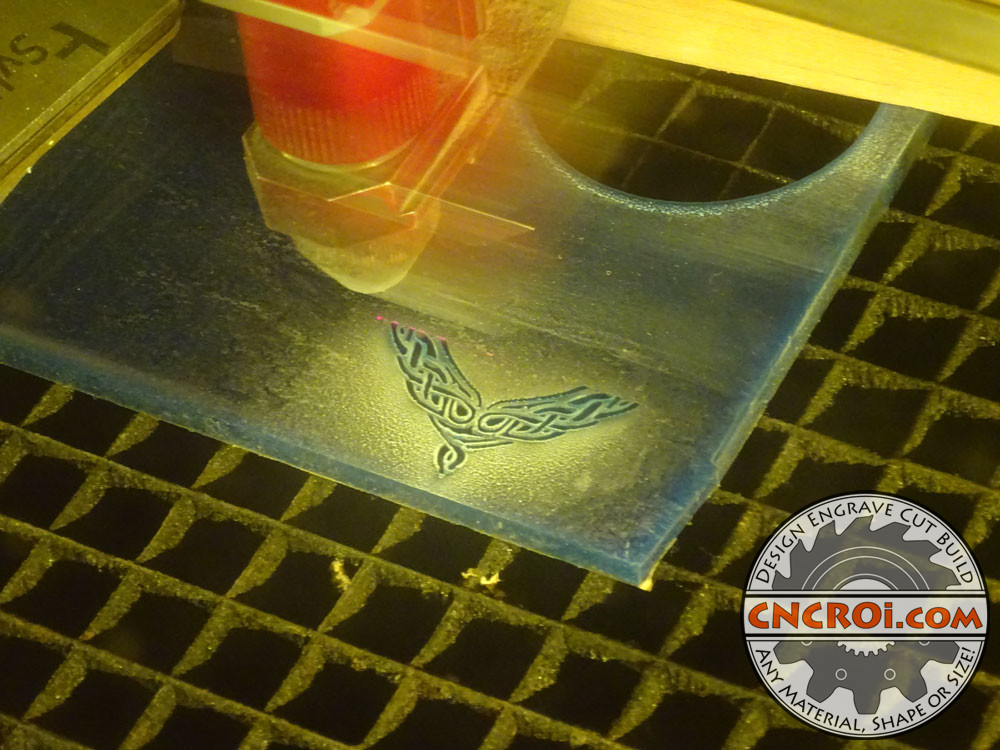

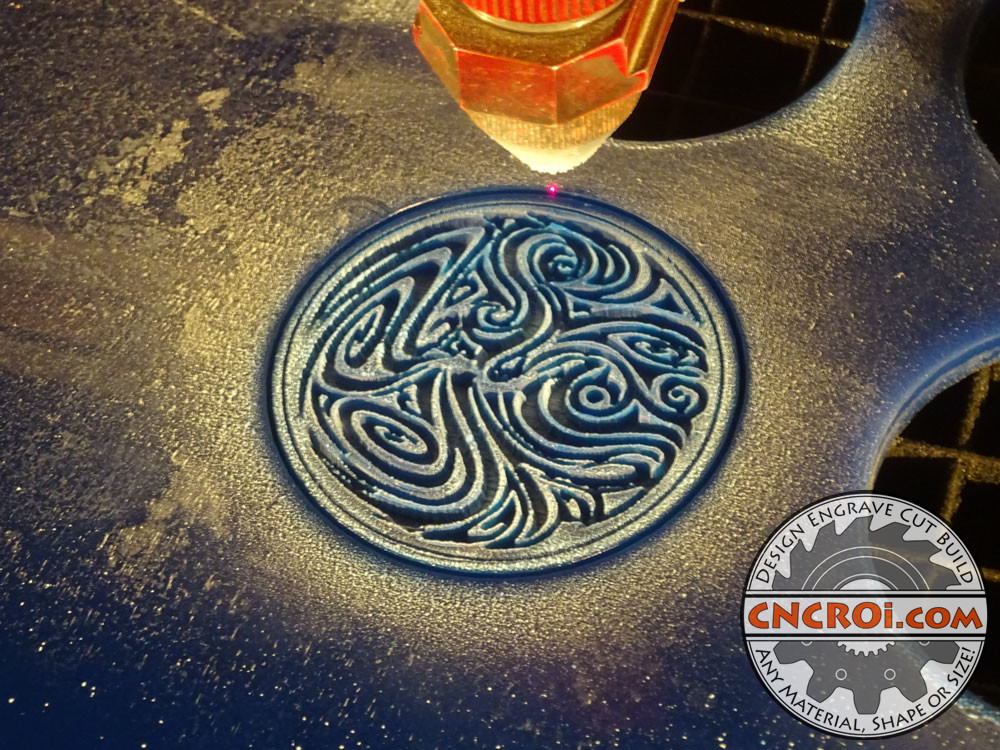

CNCROi.com made these custom pottery stamps using acrylic, it’s a very solid material, plenty strong for the application and works fantastically with our laser which digs out the design from it.

If you wanted something a lot more solid than acrylic, CNCROi.com can also make custom pottery stamps using Corian, a solid surface material.

https://www.youtube.com/watch?v=jb-rQCDsIwM/

The laser allows CNCROi.com to quickly and cost effectively recreate your black and white image into a shape that can be used in your pottery shed or business so that your work can be branded with your logo or other creative touches.

As you see in this blog post and video, the design options are endless, whatever you want, CNCROi.com can make it into a custom pottery stamps for your use.

The nice thing about custom pottery stamps is that they are a one time cost, especially with acrylic, you can do thousands of impressions without wearing out the stamp itself, and when you are done with it, it can be easily recycled.

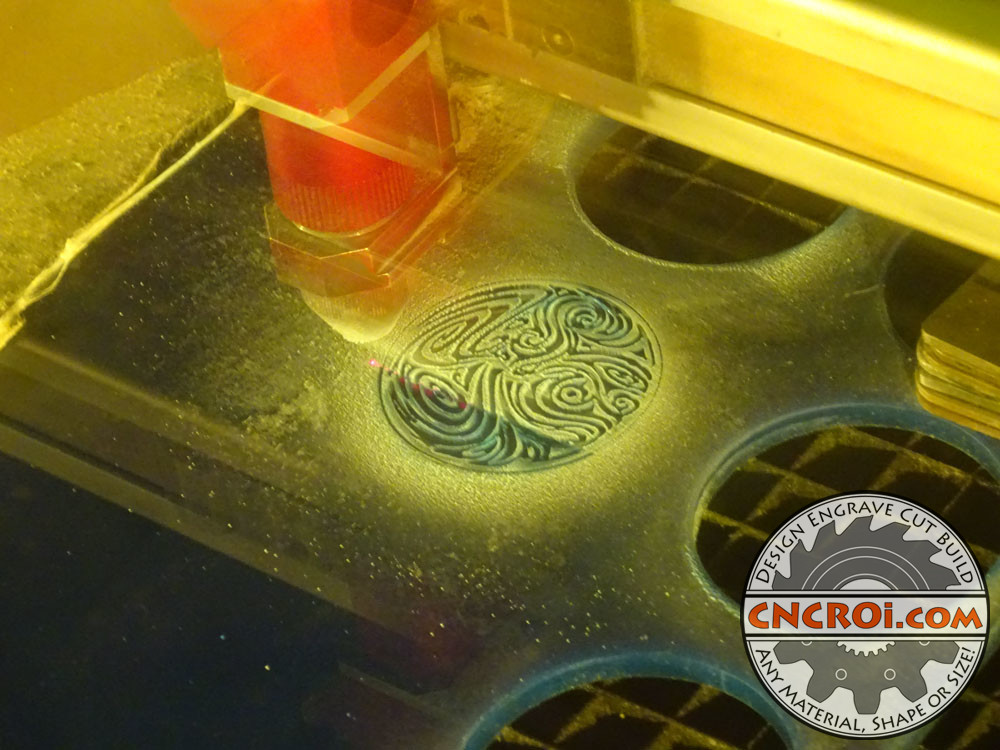

One thing to keep in mind when it comes to clay embossers such as these are that the finer the detail, the more “watery” your clay has to be so that the embosing comes out great.

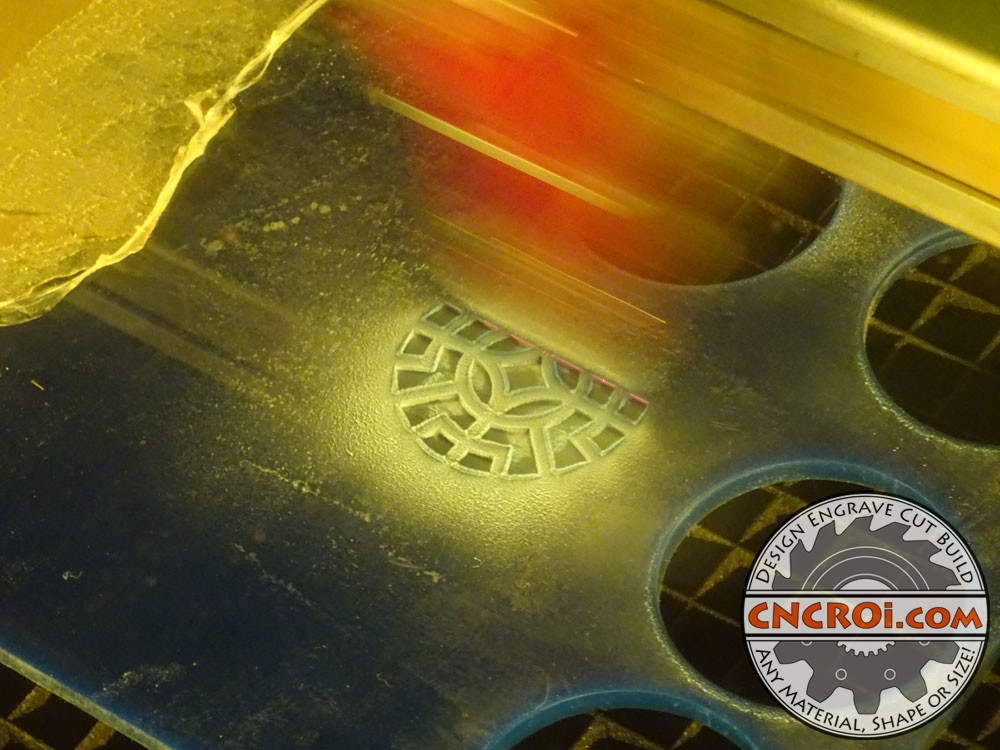

Just to give you an idea of the level of detail we can work with at CNCROi.com, here’s our networking badge that isn’t getting any use this year.

https://www.youtube.com/watch?v=xmfVf66fd7w/

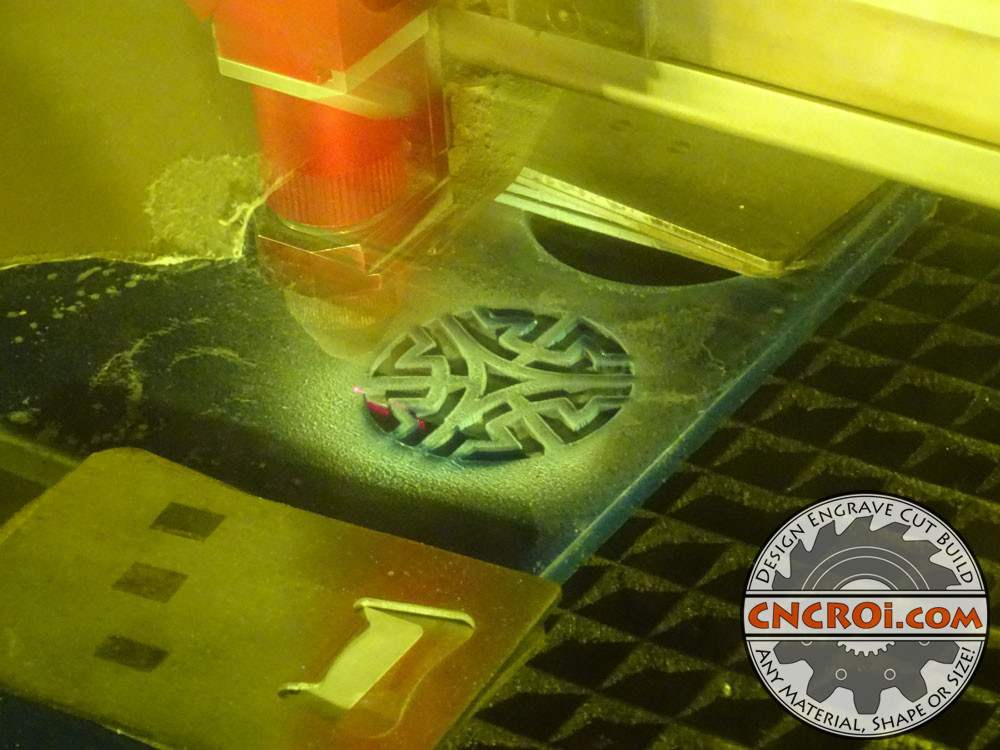

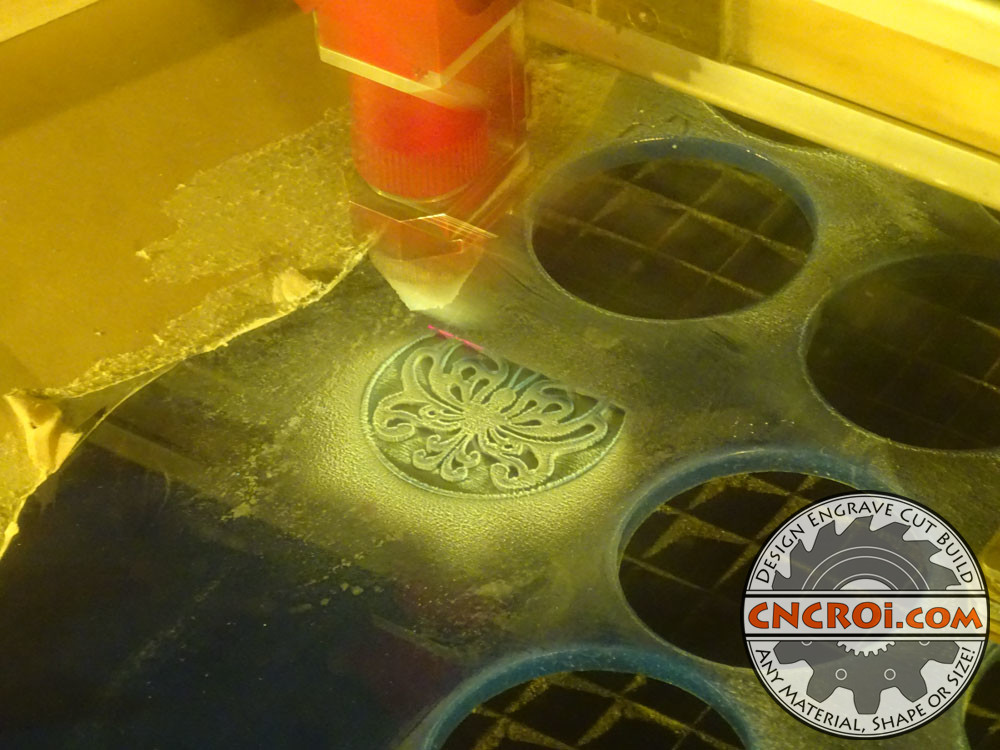

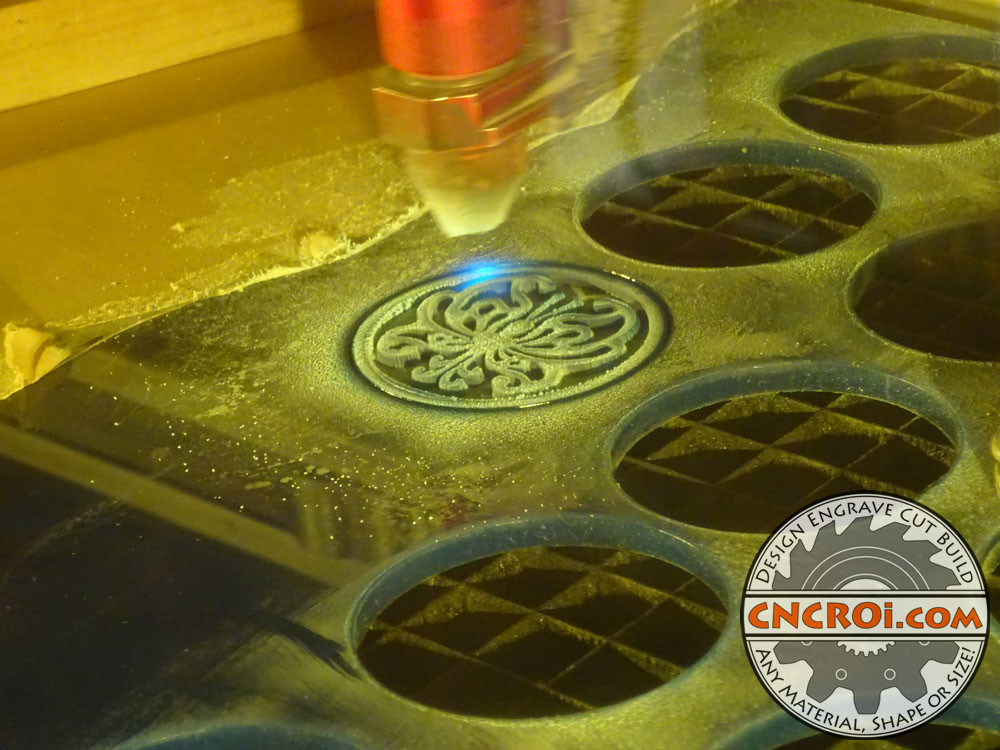

The laser engraving process can be done using any design but regardless of what we are engraving, the process is the same, we engrave first and then cut out the shape, in this case, a circle, but that can be anything, square, rectangular or whatever you can imagine.

All the details in these custom pottery stamps are sharp because the laser is digging into the acrylic using a very small diameter beam, the limitation generally isn’t CNCROi.com‘s equipment when it comes to embosing results, it the design itself working with the potter’s clay consistency.

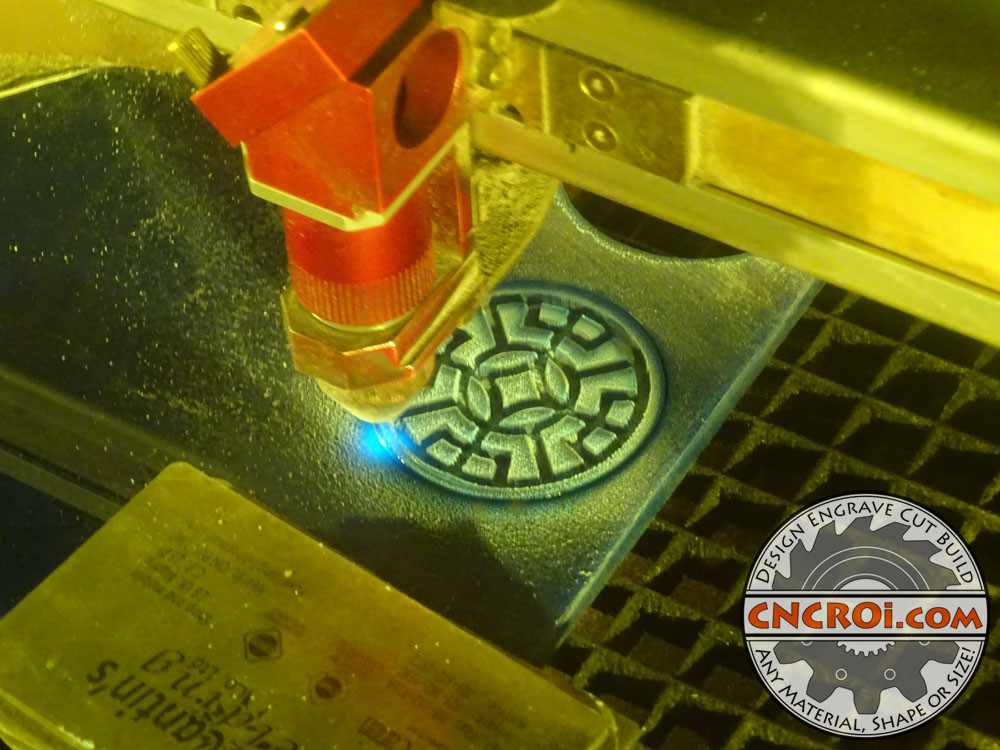

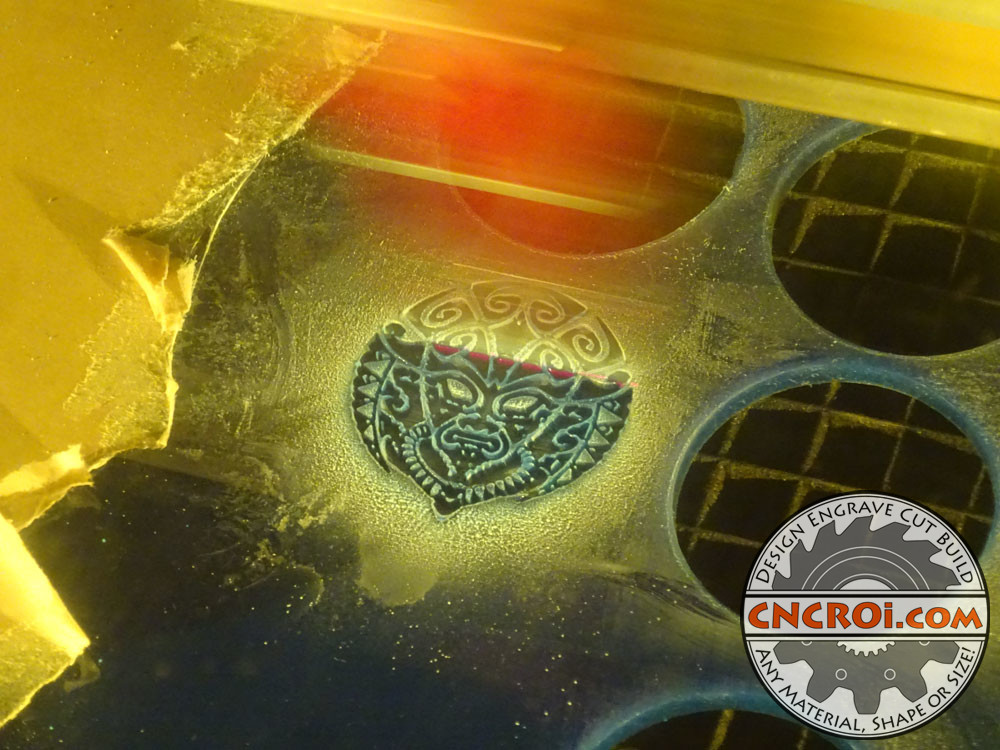

The flame you see under the part in the above picture is real fire, this is basically solid gas that we are cutting into, as a result, lots of fire is produced and we have a powerful extraction system to make sure these custom pottery stamps can be safely done, otherwise, this can be worse than an oil fire in no time flat.

CNCROi.com can also make just regular shapes for you to cut your clay to, so it’s not just stamps we can make but also templates to make your work easier and more efficient.

https://www.youtube.com/watch?v=j9ZR2ItBWhQ/

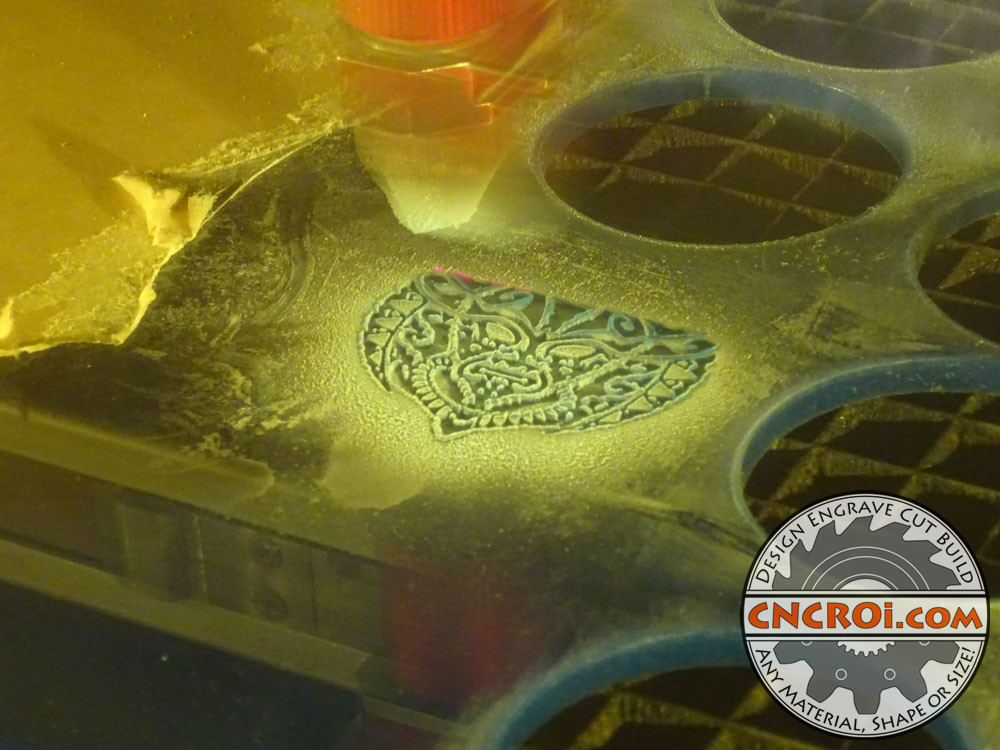

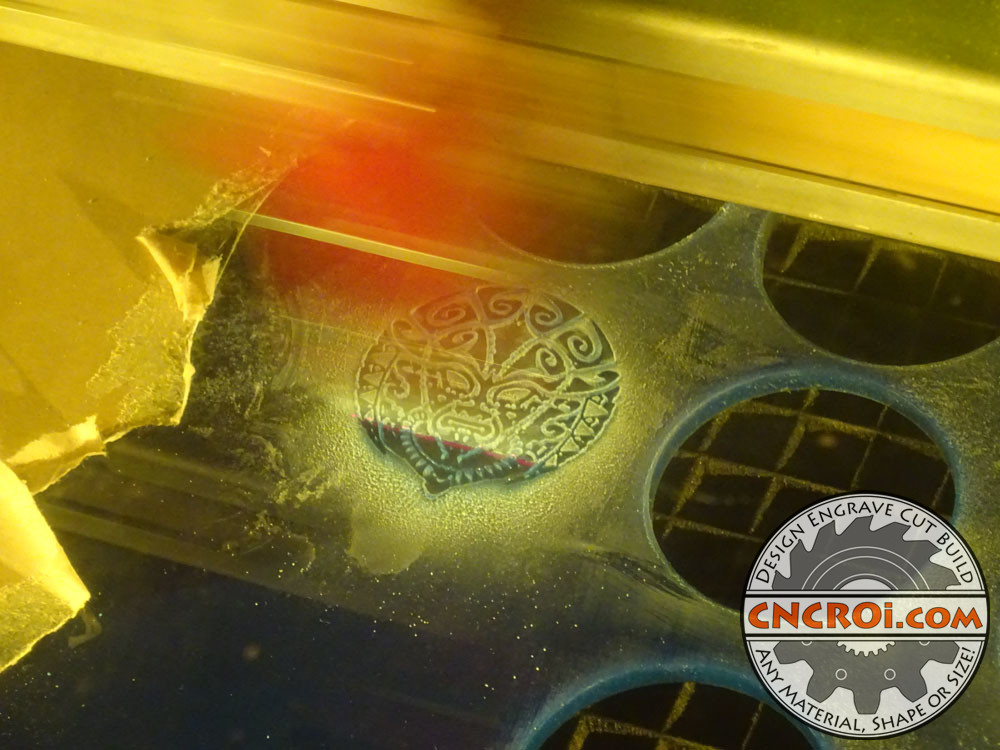

The reason why CNCROi.com uses black and white vector images for these clay stampers is because they come out the best, grayscale tends to muddy the result, especially with clay, you want clear and defined boundaries, not slow elevations in the design.

The fine powder you see above and around these custom pottery stamps is the result of the instant vaporization of the acrylic, it has the same consistency as sand and is easily removed from the mold after production.

When it comes to sizing, your options are endless as well, so there are no real limits for shape, design or sizing other than what is practical at your pottery studio when it comes to branding your work.

Unlike stencils, these custom pottery stamps don’t need support material to hold the shape together as it has a solid bottom, but this does prevent chipping that might occur if you drop this on the floor and when it comes to details, thick or fine lines are fine but be sure to leave enough room for the clay to fit within and around them.

These acrylic coasters could have just as easily been used for pottery stamps.

https://www.youtube.com/watch?v=i-goog1LXmE/

Although CNCROi.com could easily perform this engraving in one pass, we do two passes so that a little less power is used, meaning there is less melting where none is wanted, this produces a sharper result for our customers.

The acrylic used here is 1/4″ or 6 mm and we are going about half way into it with the laser, thus the overall custom pottery stamps are very strong, you’d have to work actively to try to break them.

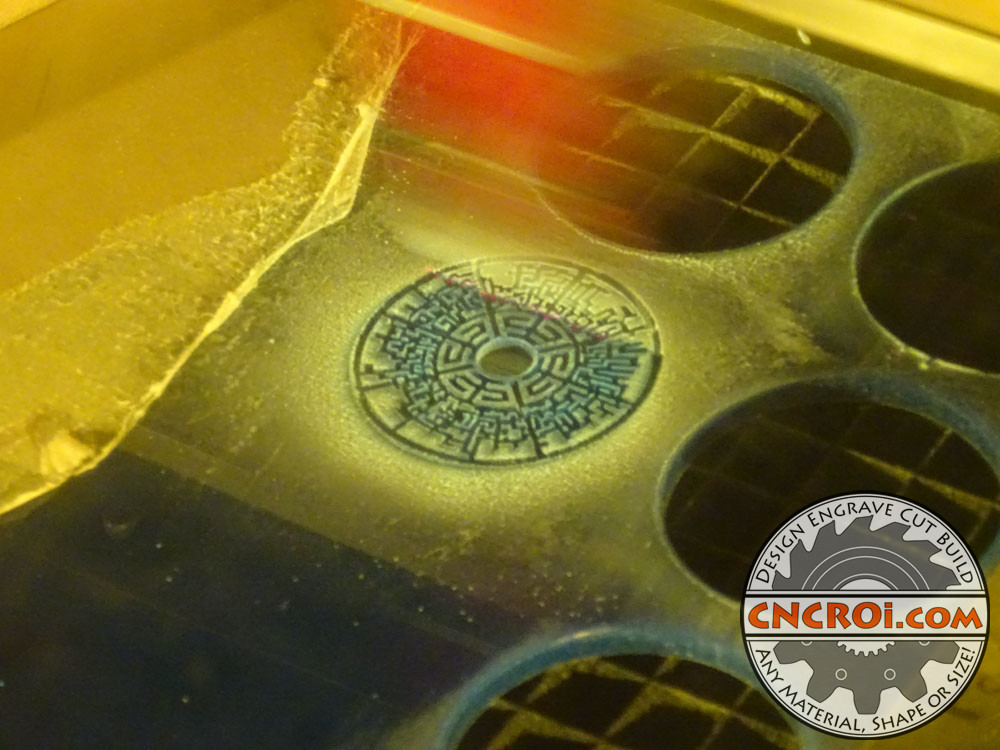

The laser cutting process removes about 1 mm or 1/20″ of material so let’s say you wanted custom pottery stamps 2″ round, they’d be slightly less than that after production, but it’s so minimal, it doesn’t really have any concerns, especially considering the application they are used for.

When it comes to rubber, we’ve found they work OK with clay but really, a harder substance works best for this specific application.

https://www.youtube.com/watch?v=sam21Oxj6Eg/

Because this material specifically is acrylic (we can use other materials), the clean-up is very easy after use, just water is fine with a fine brush if any clay gets stuck in it, do not put them in the kiln as they will melt.

Take a look at the maze design above, it’s very intricate and just about impossible to produce using any other technology, you’d need a very break easy small diameter bit with a CNC router to produce that and even then, it can’t produce sharp inner corners.

Sharp inner corners are perfect with a laser but so are flowing lines and curves, and of course you can mix and match these elements in your design.

CNCROi.com can also make matching designs for your packaging to match your custom acrylic stamp, using rubber.

https://www.youtube.com/watch?v=N3AO0Nuxvn4/

When it comes to text, you can also use just about any font you wish, from sharp ones to hand drawn, they all work fine with our processes when it comes to making custom pottery stamps.

Making these stamps is a fun and easy process, you send us the black and white vector, PDF works best, and then we produce it, where black is the engraving, and ship it right to your door.

It may seem like the second pass is cleaning-up the first, which is a little true, but it’s really digging beyond the first engraving and the heat generated actually remelts acrylic dust around it.

CNCROi.com has extensive experience making custom stamps, any size, shape or material.

https://www.youtube.com/watch?v=6K8zyrGy_FI/

The results of these laser engraved and cut custom pottery stamps are fantastic and will be great for years to come.

If you need custom pottery stamps, contact and and we’ll make them and ship them right to your door!

After cleaning then up in the shop, you can start to appreciate just how accurate CNCROi.com is in custom pottery stamps reproductions based on your design.

Send us your design, we’ll make it and ship it right to your door!

https://www.youtube.com/watch?v=N_js9h_OU_o/