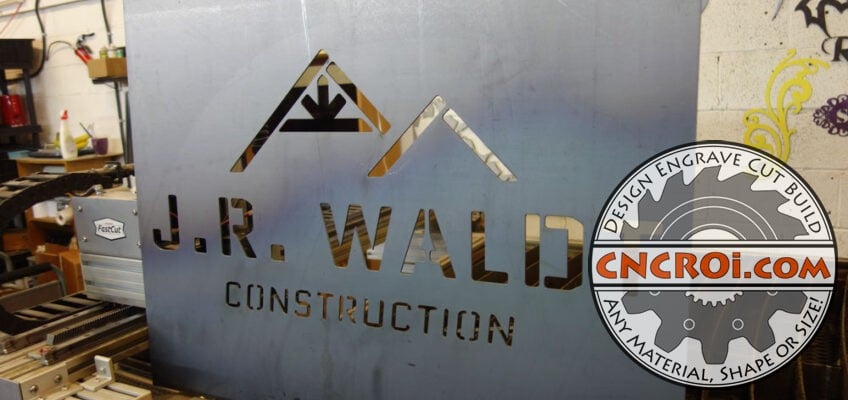

Plasma Cut Business Sign: 12 ga Hot Rolled Mild Steel

A plasma cut business sign is a great way to promote your business in all seasons and at night (backlight it!) using the benefits of metal durability and the speed and accuracy of CNC machines.

For this plasma cut business sign, the very first step bef0re cutting it was actually updating the design, this meant inner parts had to be given support material and allowances were made to convert pixels into metal.

It has been a while since I posted plasma cutting on CNCROi.com, the machine works as great today as when I first acquired it years ago and between full time welding school (now on summer break before returning in September) and other obligations, I’ve just falen behind a bit on posts with a very healthy backlog of videos to get through.

Even with the amount of welding I’ve been doing, stil nothing compares to the power you feel from a plasma torch, the laser is awesome for steel and so is waterjet but this really makes you feel like something serious is happening, you feel waves of heat, even with hearing protection, the thunder of the process itself and sparks flying everywhere… absolutely love plasma and it never gets old.

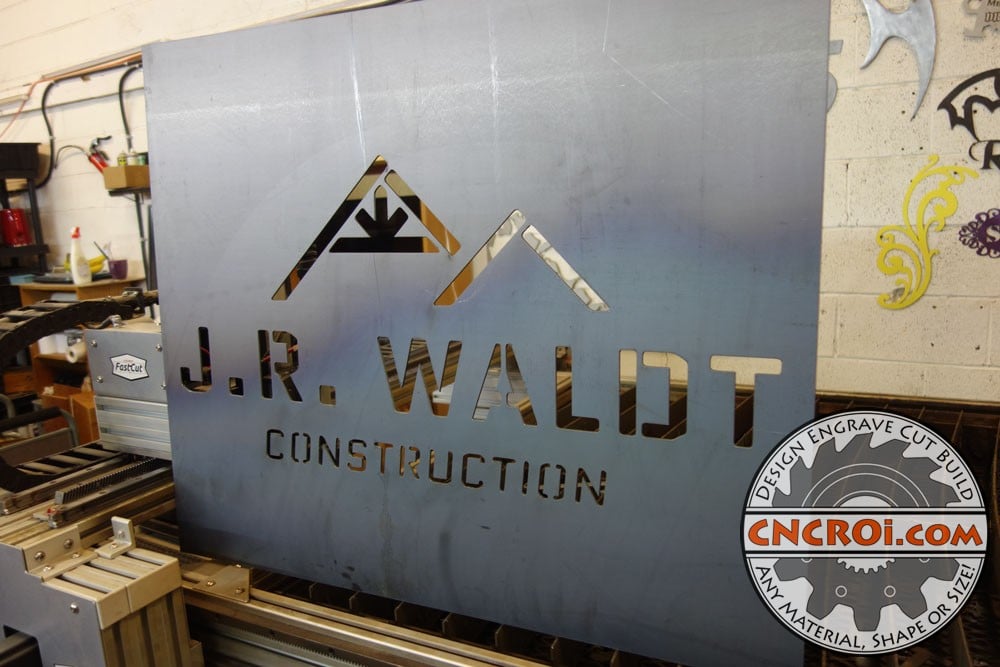

The nice thing about CNCROi.com‘s plasma torch is automatic torch height control, meaning if the steel moves up or down from all the heat being injected into it during the cutting process, the torch will follow it up and down, rather than slam into the material to produce the absolute best edge quality for this customer’s custom plasma cut business sign.

Regardless of the machine we employ at CNCROi.com, and they are many, we always cut the inside parts first before cutting the finished product out, the reason for this is simple, we don’t want anything moving, and the more you cut, the more it can move, so cut all the inside parts first then cut the plasma cut business sign outline last.

I make fun projects in the shop all the time during downtime, this is my favorite so far.

When it comes to the material we cut, the laser could have cut this project out, as well as the waterjet, the edge quality would have been slightly different, but the advantage of a downdraft plasma cutter is that nothing get wet (hence prone to rusting) and speed of lasers tends to go down exponentially as the material gets thicker.

This plasma cut business sign is right on the edge of speed to quality, the laser could have cut this just as well, but anything more than 12 ga, especially if it doesn’t require, as this sign didn’t, sharp inner corners, the plasma wins the CNC lottery and CNCROi.com‘s machine can cut up to two inch thick metal!

If you wanted something different than the typical signage options, consider a stone.

One thing to be careful about regardless of process or machine, are those inner parts like to flip-up right in the way of the torch, and if the torch hits it, it will drag the entire sheet over and thus, everything goes out of alignment and I have a nice piece of scrap metal.

When it comes to plasma cutting metal, there are a lot of fumes created, hence the advantage of a water table, but the mess it creates is just as bad so that’s why I prefer a downdraft table, this was the toughest decision to make when I spec’ed out my plasma cutting table but so happy I went this route.

Keep in mind that even if we laser cut this custom plasma cut business sign, there would be just as much smoke, vaporising metal is still vaporising metal and extraction to the great outdoors is always the best solution in that case.

Literally any conductive metal can be cut with CNCROi.com‘s plama cutter, from mild steel (which this sign is made from) to stainless steel, if it melts, and can hold a charge, it can be cut regardless of surface finish, such as rust.

A nice thing about metal signage is that you can paint it very easily to look like just about any other metal out there, while protecting it from the environment.

This plasma cut business sign is a relatively straight-forward project, after the metal is acquired and the design parameters are sorted, I basically press a button and the plasma cutter goes ahead and starts to cut out the steel at the speeds and feeds I told it to and afterwards, a little cleaning is required.

The nice thing about CNC machines is they do exactly what you tell them to, the bad thing about CNC machines is they do exactly what you tell them to, so years of experience really pays big dividends when it comes to producing problem free projects for CNCROi.com customers.

Regardless of the material or platform we use to cut out projects, a few things you want to keep in mind, the first, establish realistic budgets, the thicker the material, the higher the price, and this is doubly so true when it comes to steel, especially stainless steel.

Second, make sure you send a finished file, edits and other changes mid-production are a headache for all involved, CNCROi.com moves FAST, generally once a design is approved, in less than 24 hours, the project will be on a truck headed towards you… we don’t screw around when it comes to getting things done.

Metal can be mixed and matched with just about any other material, from wood to plastics, with excellent results.

Thirdly, consider aspects of your design that aren’t necesary, for this plasma cut business sign for instance, a detail that’s less than an inch would be lost on a design like this, think snow flakes or small trees or whatever, this is a sign that people are driving past at 88 MPH, you want the bare minimum.

Plasma machines make lots of smoke, in this case, mild steel smoke, but I prefer smoke to rusting and water when it comes to cutting metal, the extraction system does quick work of it for this plasma cut business sign.

When the design is complete, I review everything very carefully, alignment, design parts properly cut and the like, I don’t want to go through the expense of sending a sign just to have the customer come back to me saying there was an element that wasn’t cut.

Of course, if you had an application that called for metal signs but they were for indoor use, far away from any body seeing them, MDF that’s painted to look like metal might be a serious consideration.

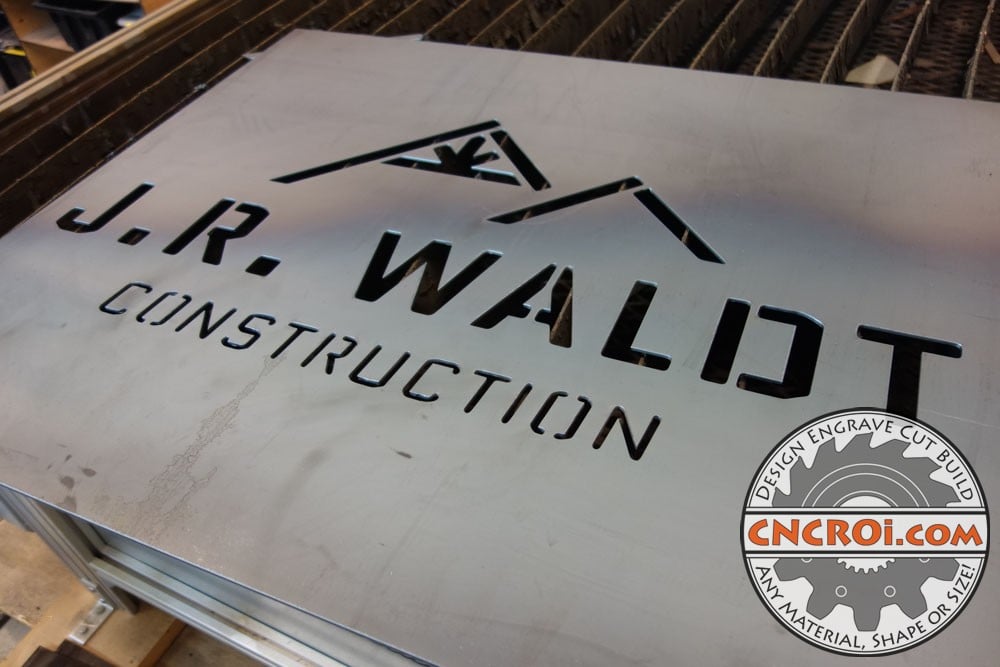

After removing the inside parts of this plasma cut business sign, you can gain a sense of just how well the edge quality comes out using plasma, a constant and consistent kerf and very little dross on the backside so clean-up is easy.

Here’s anothe rangle of the edge quality, just looks amazing at just how clean the cut is when you vaporise metal.

And the finished plasma cut business sign, at least as far as I’m involved, looks great!

Here’s what the finished sign looks like, with backlit LEDs, that the customer completed… this looks awesome!

Custom metal signs can be made using just about any spec imaginable and yes, we can also weld components to it like stakes if you wanted to stick it in the ground or tabs to bolt them to wooden or other objects.