Polycarbonate Music Stencil

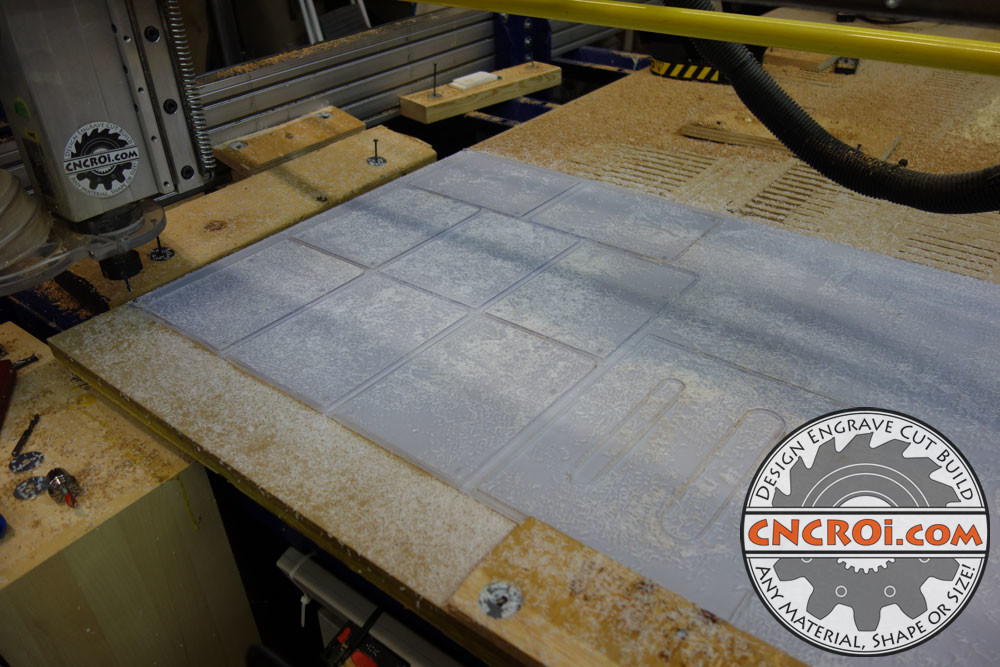

This polycarbonate music stencil is made with CNCROi.com‘s CNC router using quarter inch bullet proof glass.

https://www.youtube.com/watch?v=Th85vWh2FY0/

I’ve done a ton of polycarbonate work in the shop though the years using both our CNC routers and both of our CNC lasers, the machine used to process the project depends on the specs involved that the customer comes-up with.

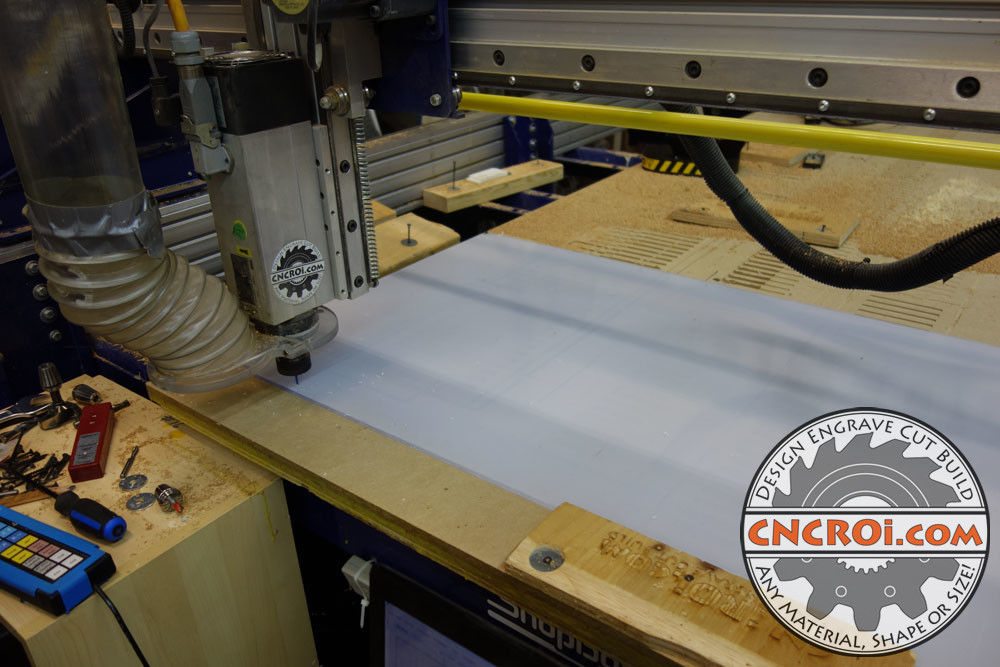

For this polycarbonate music stencil, the process was very straight forward, there wasn’t any branding requirements and what was being cut was relatively large, so there wasn’t any issue when it came to the process, our full sheet router was the best tool for the job and no laser work was required.

Having a variety of machine platforms to choose from when it comes to polycarbonate music stencil comes in very handy, it means we can handle massive jobs and little ones, one-offs as well as full production of many many parts, it all depends on what the customer has in mind.

Of course, if you want lyrics fiber etched onto stainless steel for a wall art, CNCROi.com can make that for you as well, or make the entire stencil or template out of metal.

https://www.youtube.com/watch?v=ctfZ2tPTA1M/

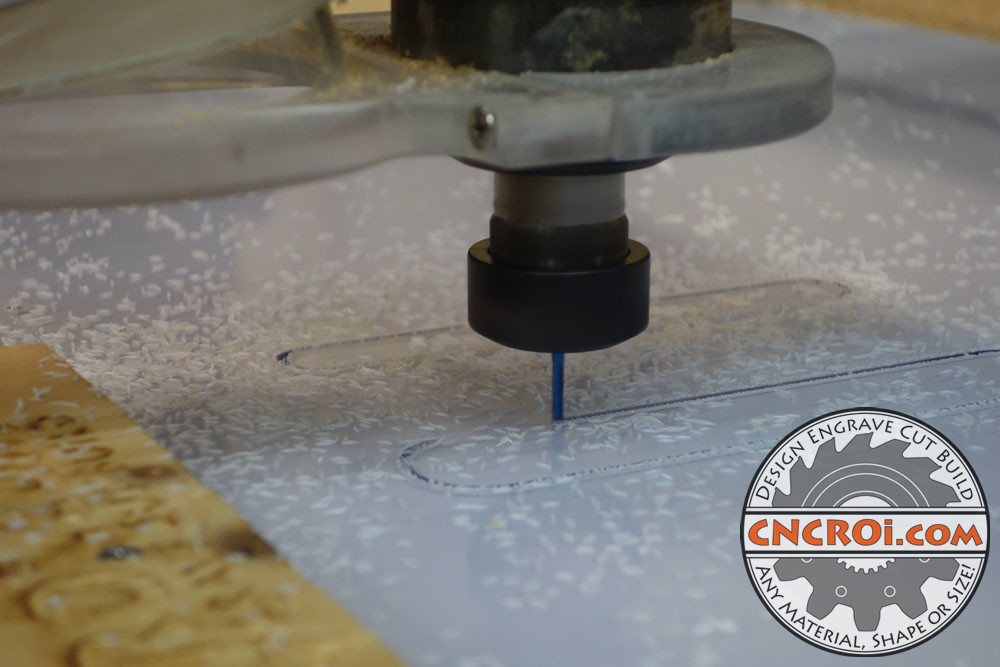

The consistency of what’s produced while CNC routering out quarter inch polycarbonate is very close to rice, it’s about the same diameter, length and weight though nowhere near as edible or delicious.

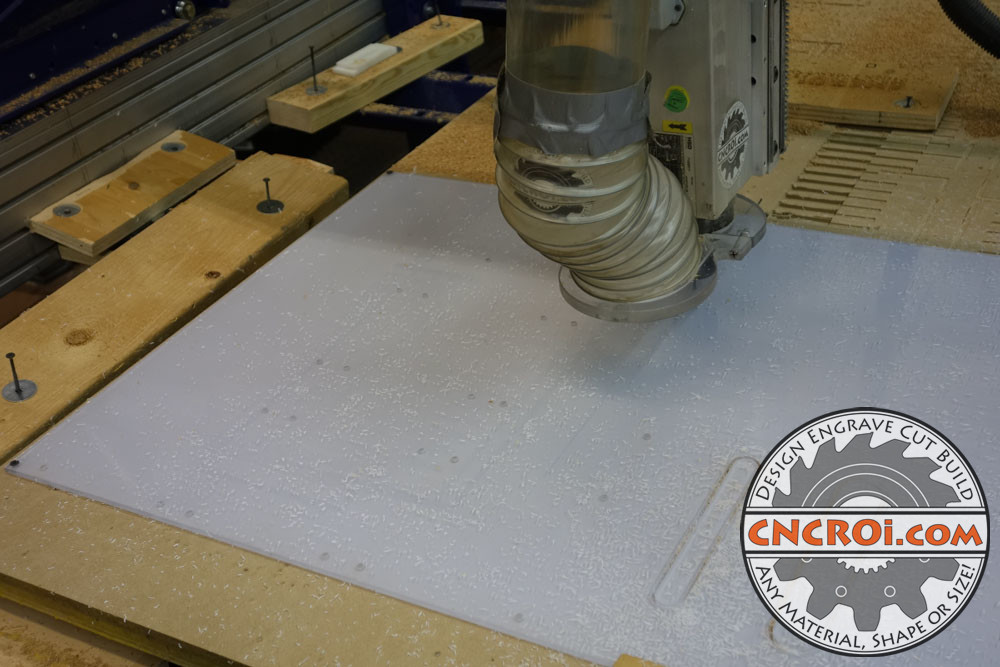

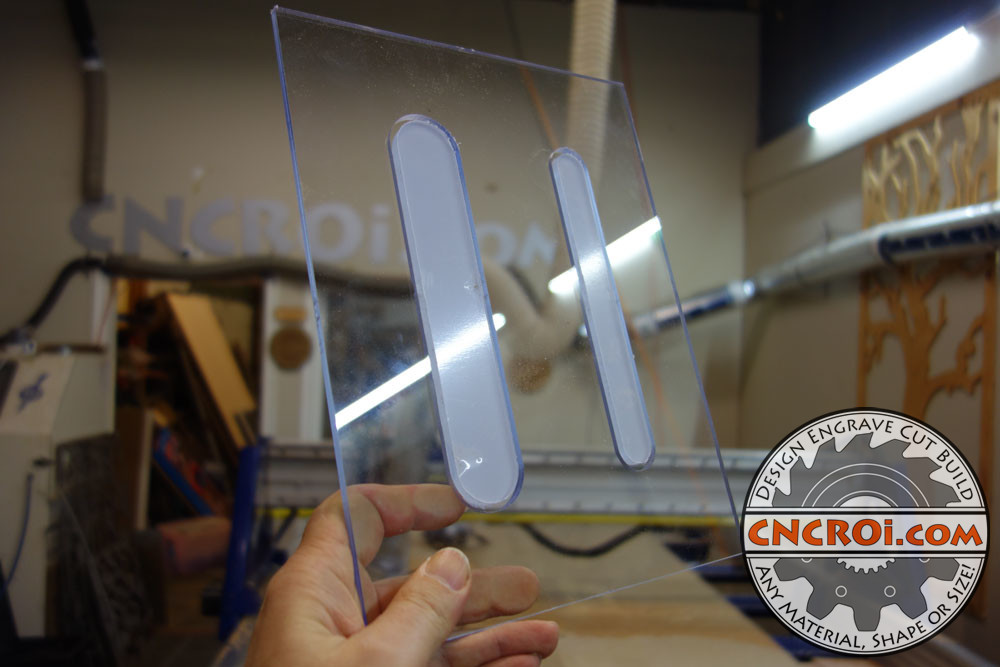

The edge profile from CNC routering this polycarbonate music stencil is very smooth, which is important because you want to guide a hand router along the edge and you don’t want a bumpy results when it comes to doing the wood working you need to do.

It doesn’t happen often, but in this case, the polycarbonate music stencil was made at the same time as another custom polycarbonate job that happen to have the same thickness and spec so I was able to cut both at the same time at CNCROi.com, which was great!

Of course, CNCROi.com can make music using our machinery as well.

https://www.youtube.com/watch?v=SFMIBM2omFs/

The issue I have with cutting this material specifically is that I had to use a very small bit in order to achieve the resolution required for the other job, as a result, many of these little pieces of rice get stuck under the sheet of polycarbonate as I’m routering out the shapes due to the vibrations produced using a small bit and thick material at CNCROi.com.

So you can see in the video of the polycarbonate music stencil production, I’m having to hold it down as the vacuum system is quickly made redundant as suction is lost and the screws holding the sheet in place are useless to hold the sheet down once you get to a certain threshold.

Luckily, this is a relatively small job that cuts relatively fast at CNCROi.com so hand-holding things down during production isn’t an issue, it can be done safely because the bit is so small and the router is moving in a very consistent and predictable manner.

You can see that the router at CNCROi.com is cutting out all the inside parts of the polycarbonate music stencil and the other project first, this makes sure that nothing moves, this causes no issues with the rice getting under the sheet as it’s relatively little material removed, it’s during the cutting-out that things want to move in every direction.

If you want to commemorate your favorite song with a very permanent plaque, CNCROi.com can make that for you, either on the surface or cut all the way through.

https://www.youtube.com/watch?v=f9dkteuy9No/

Luckily, quarter inch polycarbonate is very stiff, so even with a little vibration, there results are still totally fine as long as I hold it down, the vibrations happen all around the part and the edges, worse comes to worse, can be lightly sanded for this polycarbonate music stencil, which wasn’t required for this project.

The edge from laser cutting polycarbonate couldn’t be any different, it’s burned to a crisp while the router produces a relatively clear edge without any burning, the thickness of the polycarbonate and the design that needs to be made dictates which tool is used at CNCROi.com for this process.

With CNCROi.com, you aren’t limited to only polycarbonate, we can make custom polycarbonate music stencils out of any material, metal through woods so whatever works for you and your application, we can help you out.

We also make templates for guitars and other musical instruments at CNCROi.com using a variety of materials.

https://www.youtube.com/watch?v=UKUB_LRe9AA/

When it comes to transparent or semi-transparent options though, the options are rather limited to acrylic and polycarbonate, each has their cost and benefits but generally, I prefer polycarbonate as it’s a lot more durable, stronger and unlike acrylic, won’t shatter if you drop it on the floor by accident.

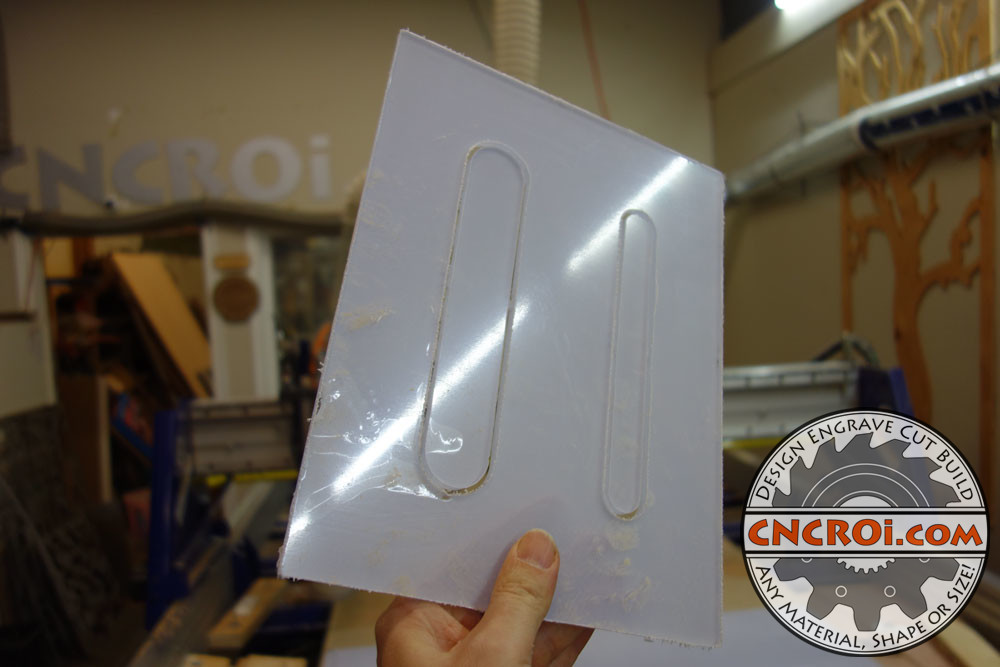

How does everything stay in place even after being pushed and pulled by our CNC router at CNCROi.com? Well, we have tabs holding all the parts together in place, both inside (for the polycarbonate music stencil) and outside, otherwise, they’d all be flying all over the place in the shop.

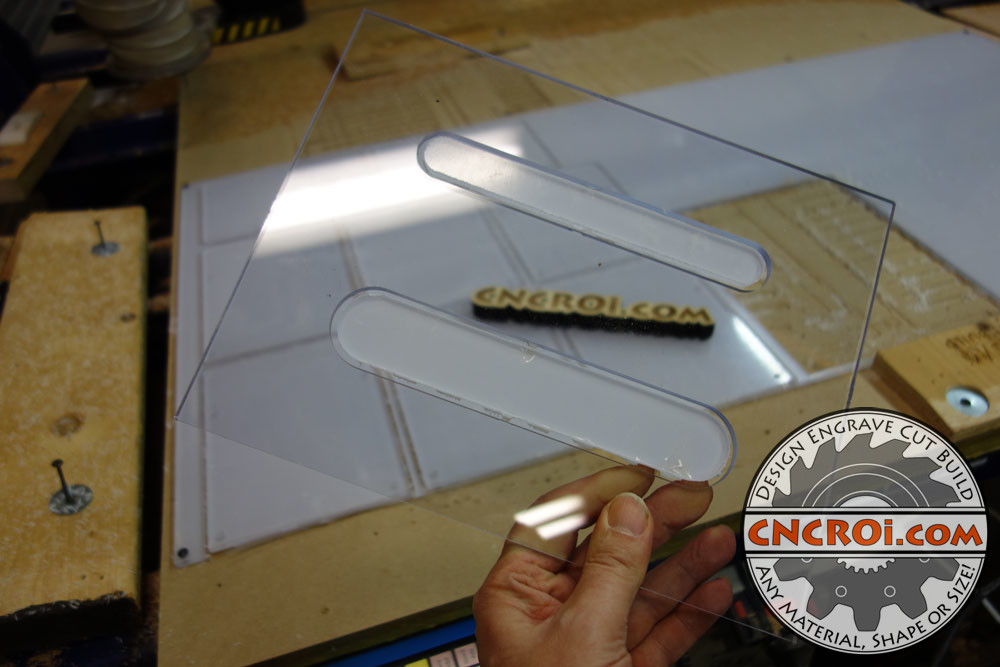

The polycarbonate music stencil is looking great, although aesthetics don’t matter when it comes to stencils that are used in a woodworking shop, it’s still nice to work with something that you are proud to show others when it comes to your own social media campaigns.

No shop is complete without their very own guitar wall clock, made with both our router and plasma cutter.

https://www.youtube.com/watch?v=vqiPA6lVGN0/

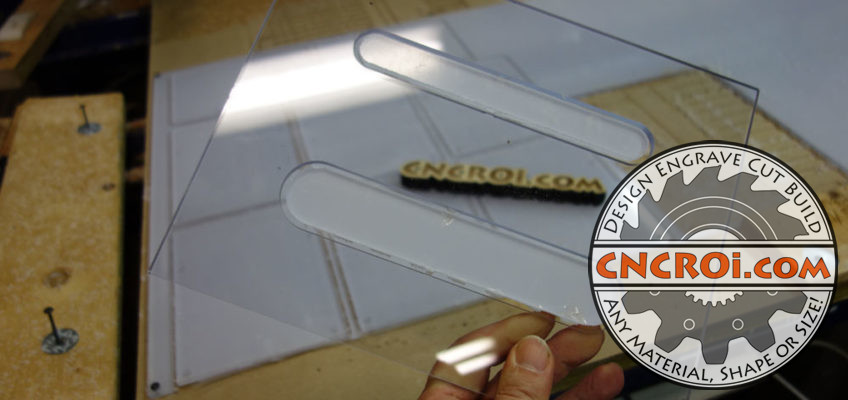

I left the inside parts of the polycarbonate music stencil in place with tabs for shipping, it just gives it a bit more rigidity and who knows, the customer might find a use for it somewhere in their shop.

After taking the masking off the front and back of the polycarbonate music stencil, you can see how clear this material really is.

This polycarbonate is incredibly durable, especially at a quarter inch thick, the surface is also nice and smooth, which makes routing a joy unlike other grittier materials we have at CNCROi.com.

Need a custom polycarbonate music stencil? Contact CNCROi.com.

https://www.youtube.com/watch?v=OuU5GmomNPM/