Prototyping Custom Polycarbonate Parts

CNCROi.com makes a lot of custom polycarbonate parts specifically, from custom stencils to spacers, there isn’t much that can’t be done using this very flexible material.

https://www.youtube.com/watch?v=JYyoi_VZzss/

Polycarbonate is a highly durable, impact-resistant plastic that is used in a variety of industries, including automotive, aerospace, medical, and electronics.

One of the benefits of prototyping custom polycarbonate parts is that it allows designers and manufacturers to test the form and function of the part before committing to mass production without having to resort to a lesser material in terms of durability or quality relatively cost-effectively.

This is a major advantage of taking the time to properly prototype something as it can save time and money in the long run by identifying any design flaws or issues early on in the process, even CNCROi.com has done extensively prototyping on it’s own products, from jigs to banks (as you can see at SandboxRanch.com).

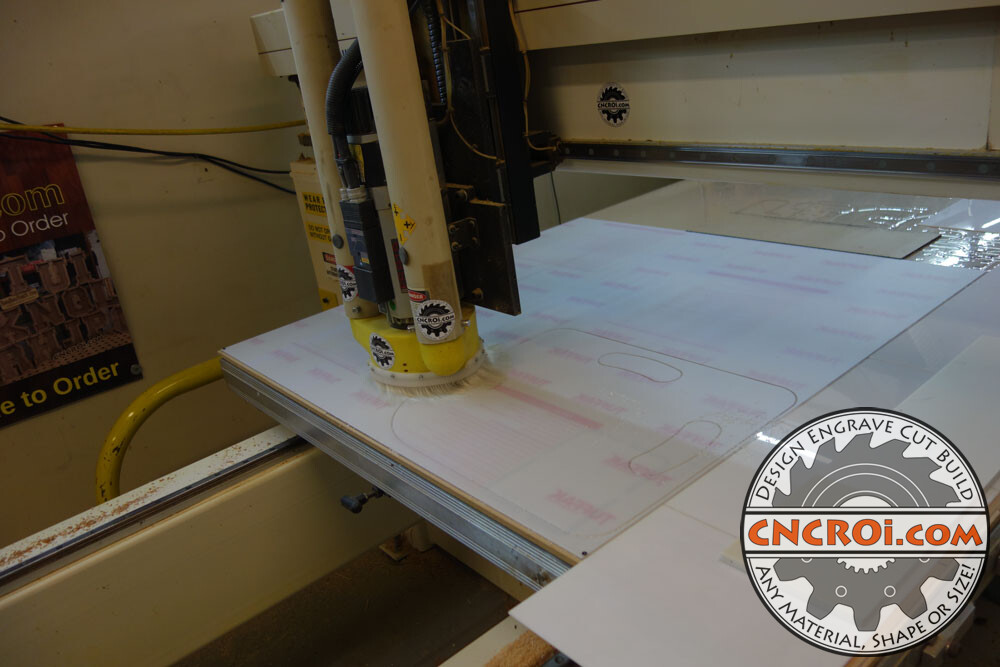

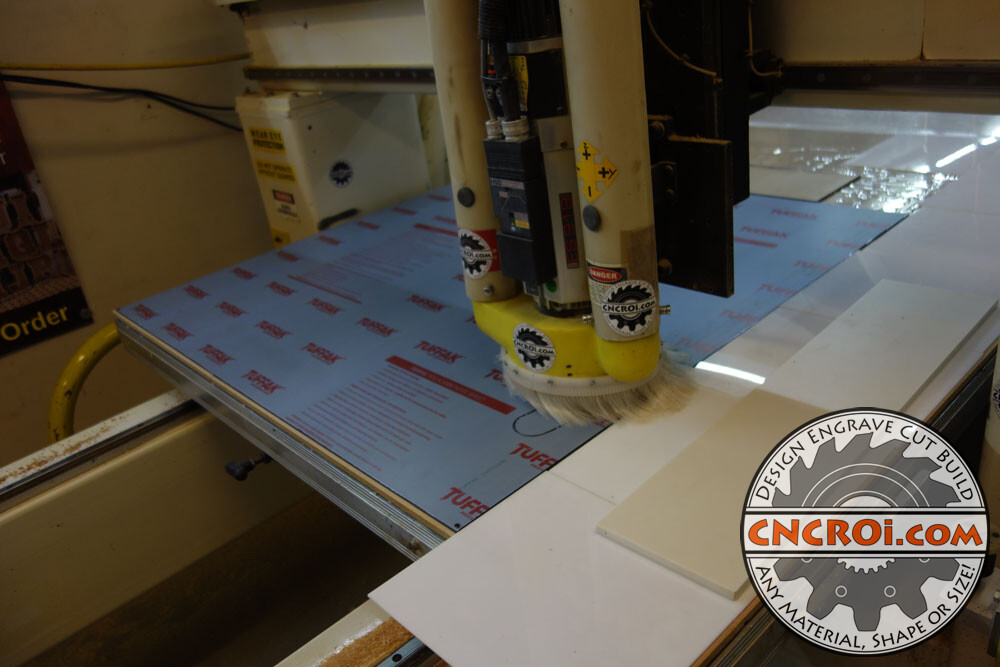

Ever since getting my full sheet industrial CNC router, I’ve been amazed at the quality of output I get with such as massive beast, it’s 12 000 pounds of router and the stability it gives to the bit to cut though just about anything at CNCROi.com is amazing!

There really isn’t anything that we cannot produce at CNCROi.com using polycarbonate when it comes to 2.5D parts, big, small, curved or straight, chamfered or cut as smooth as a knife, we can do it and ship it right to your door!

The nice thing about custom polycarbonate parts is how highly resistant to impact, making it an ideal material for applications where durability is critical, such as automotive parts or safety equipment.

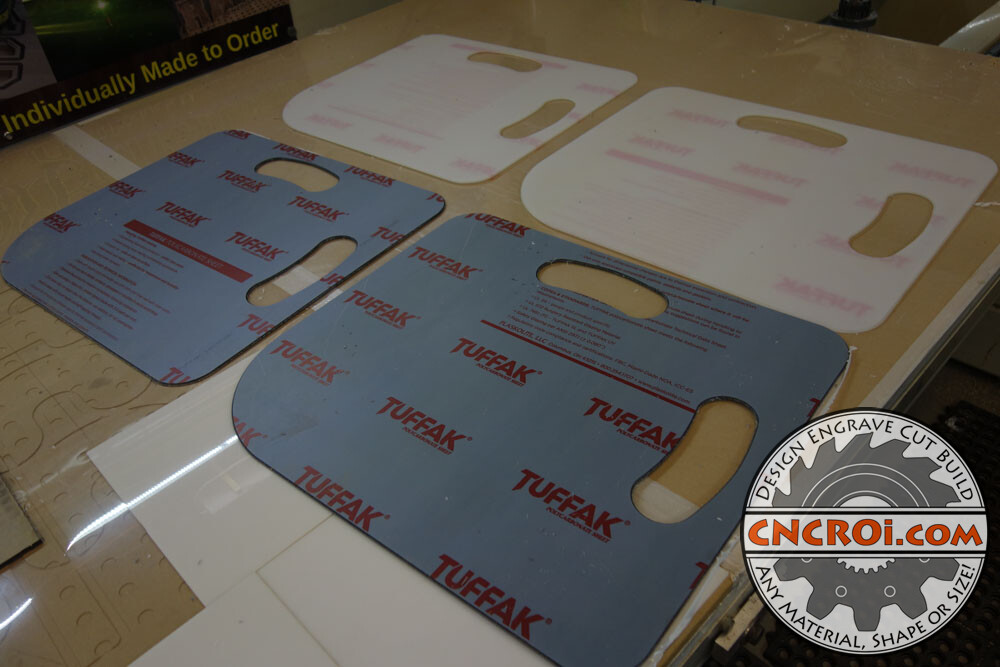

Additionally, custom polycarbonate parts can be had in both optically clear and solid black colors, meaning if you want something you can see through, it fits the bill, and if you want something you can’t, it can do that too!

CNCROi.com can color change polycarbonate as well, it’s a permanent way of branding using lasers that won’t fade, crack or peel off over time, unlike traditional inks or dyes.

Something to keep in mind with custom polycarbonate parts made at CNCROi.com is that it comes in a variety of grades, each with its own properties and characteristics, for example, some grades of polycarbonate are better suited for applications where heat resistance is critical, while others are more suitable for applications where impact resistance is important.

These material characteristics follow-through with UV durability, some polycarbonate degrades relatively quickly, like lamacoids, to UV exposure while others are incredibly durable in the outside sunlight.

Small parts or big parts, CNCROi.com can make them all for our customers far and wide!

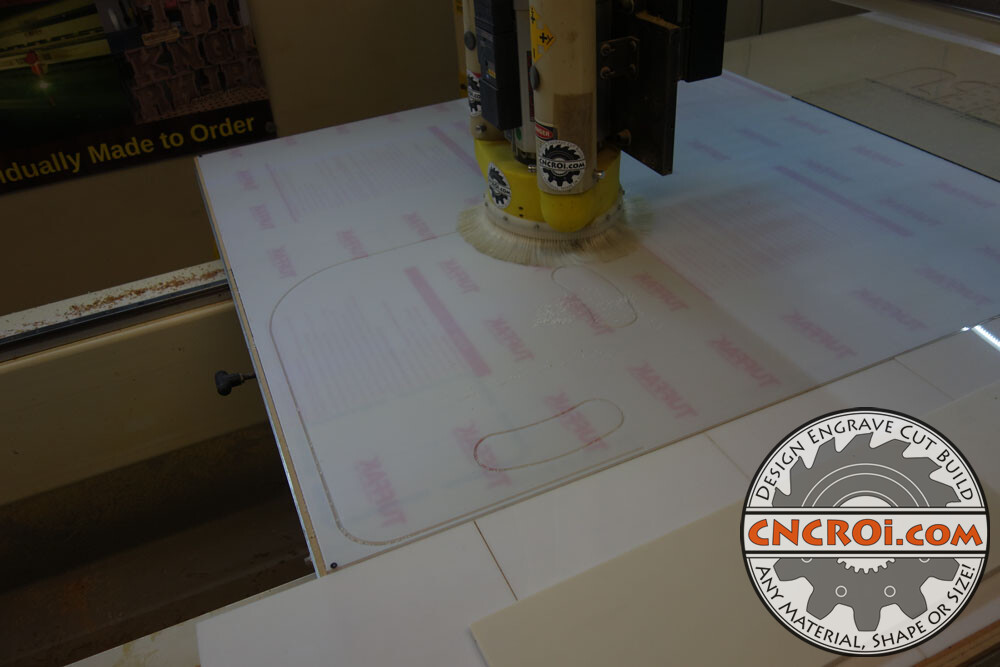

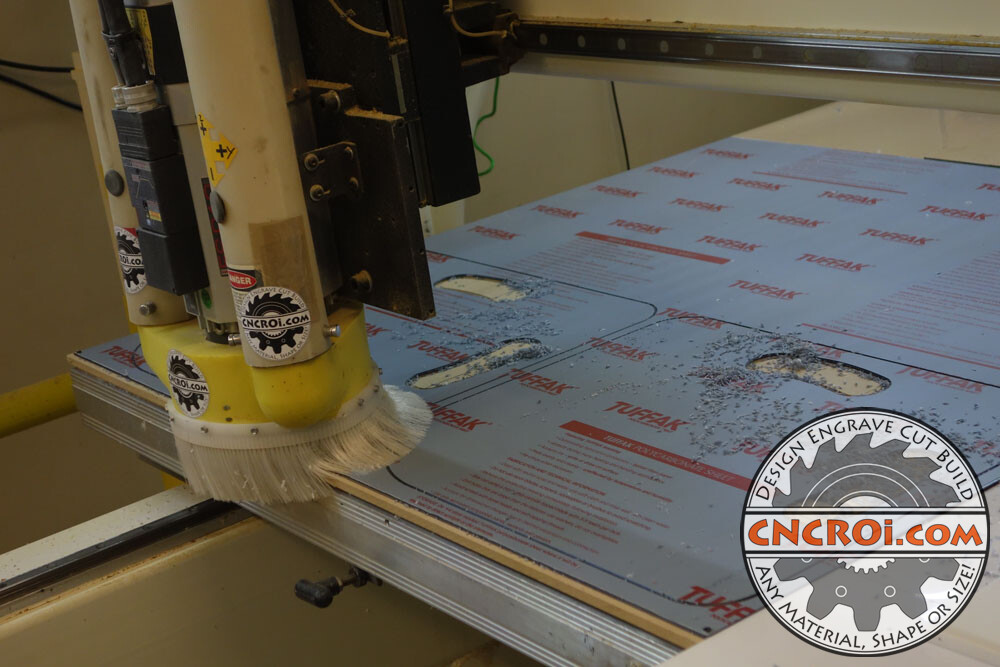

For these specific custom polycarbonate parts, CNCROi.com employed our CNC router, though we also have lasers that can cut through this as well, but the thickness of this polycarbonate lends itself better to router cutting than laser melting.

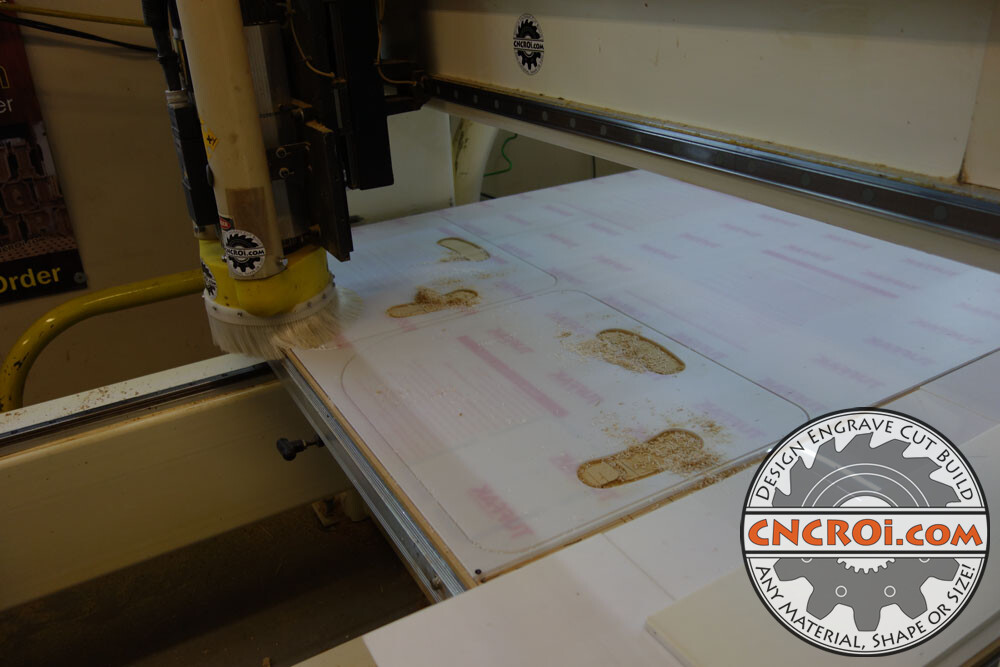

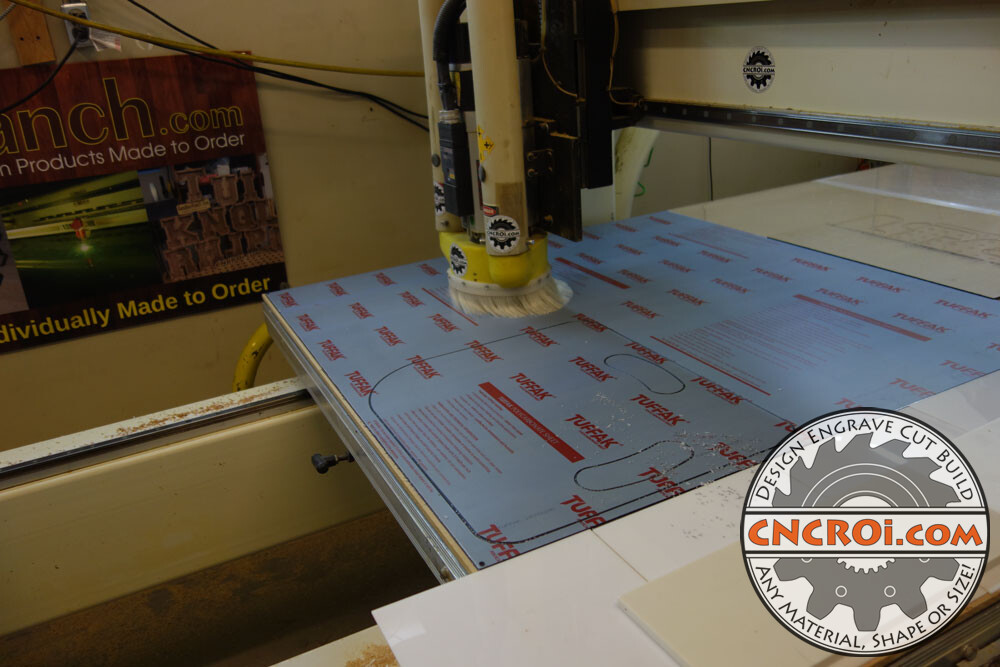

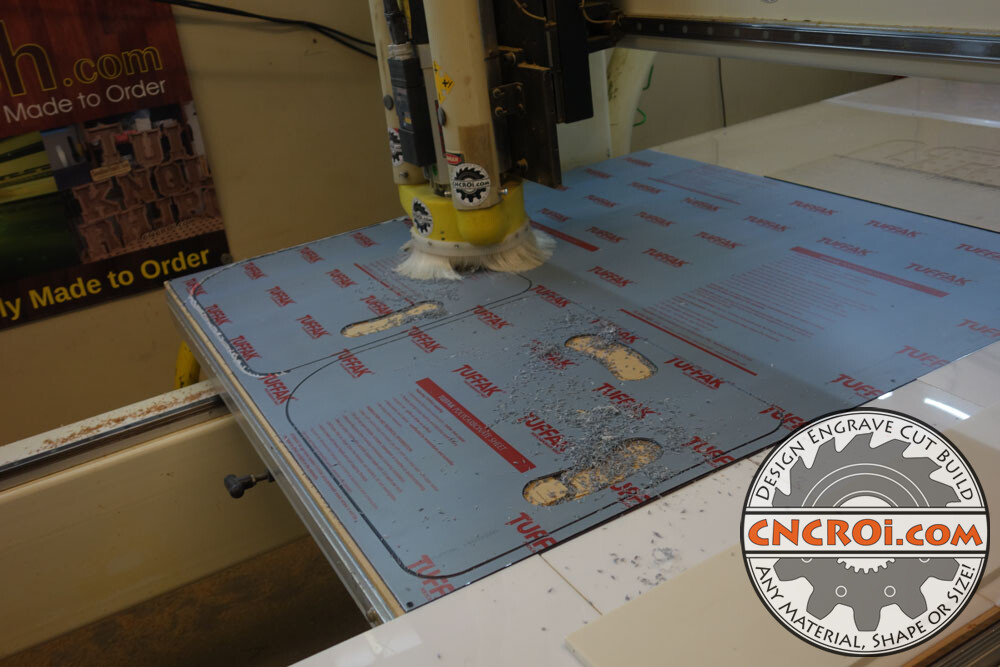

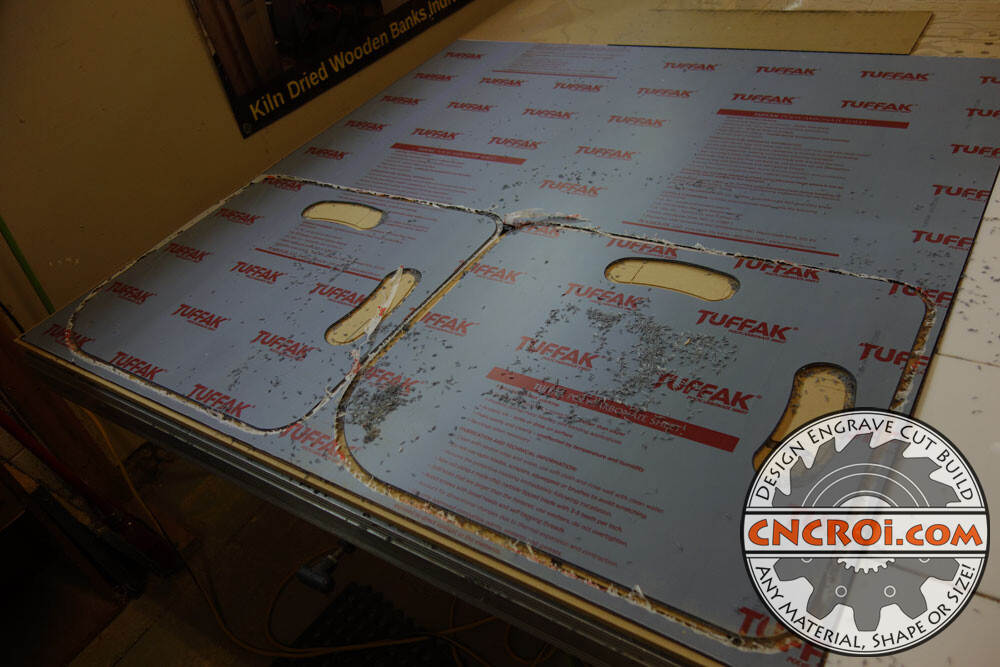

Now that the first two prototype parts are cut using clear polycarbonate, it’s time to do the same using jet black polycarbonate, sometimes you want to see through the bullet proof glass, sometimes you don’t!

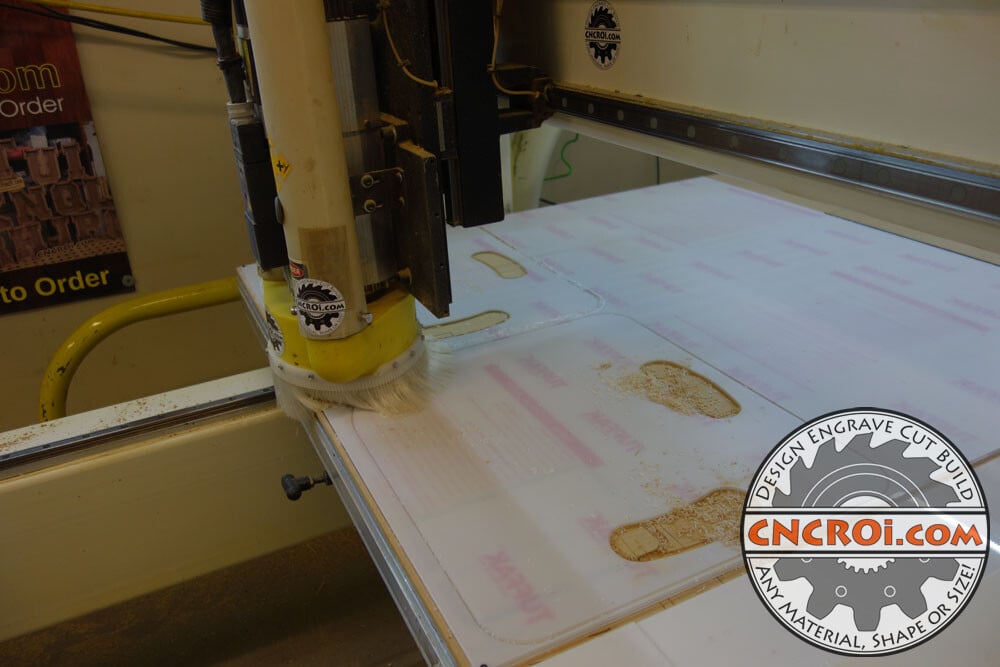

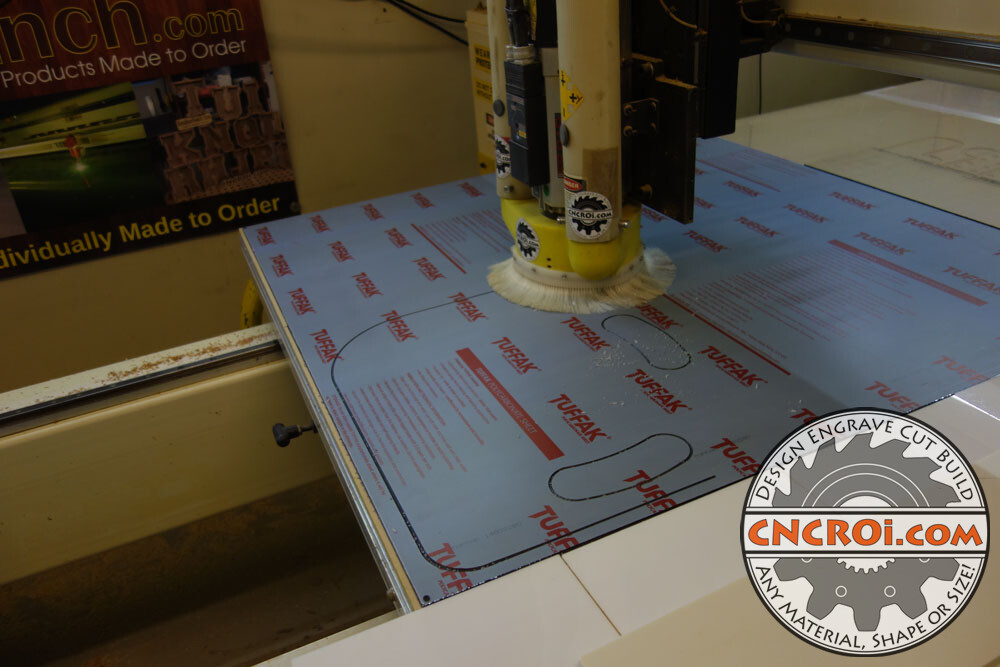

For both aspects of prototyping custom polycarbonate parts in this production run, there is a chamfer that’s performed before the actual cutting out of the parts, this type of production makes me realize how much it’s great to have a tool changer at CNCROi.com after so many years without one.

CNCROi.com is able to perform some very intricate polycarbonate work using our laser on thin stock that just isn’t possible using our router due to the hold-down troubles this material provides, of which there are none using our laser.

The process of making these custom polycarbonate parts is completely identical, clear or jet black, it makes no difference, the parts are identical in every way regardless for this prototyping.

CNC routers can create custom polycarbonate parts with high precision and accuracy, making it ideal for applications where tight tolerances are important, as unlike our laser, it’s chipping away at the material rather than melting its way through at CNCROi.com.

The laser does a wonderful job though cutting polycarbonate if the material is thin, thicker material lends itself better to routering as it holds onto heat, which is released in bigger chunks using a bit than a laser where it just builds-up and can warp as a result.

CNCROi.com does a lot of work involving “barrels” as a result, many of our polycarbonate stencils end-up looking like highly ornamental art!

Just to give you an idea of how big CNCROi.com‘s CNC router is, the table alone is 5ft x 10 ft and unlike most machines, the table moves rather than the gantry, which means an incredible level of rigidity is possible.

Even with the screws holding down the custom polycarbonate parts being made here, we still have the vacuum going full-force and even with that, the polycarbonate still wants to lift, so doing multiple light passes until the material is fully gone through is required as well.

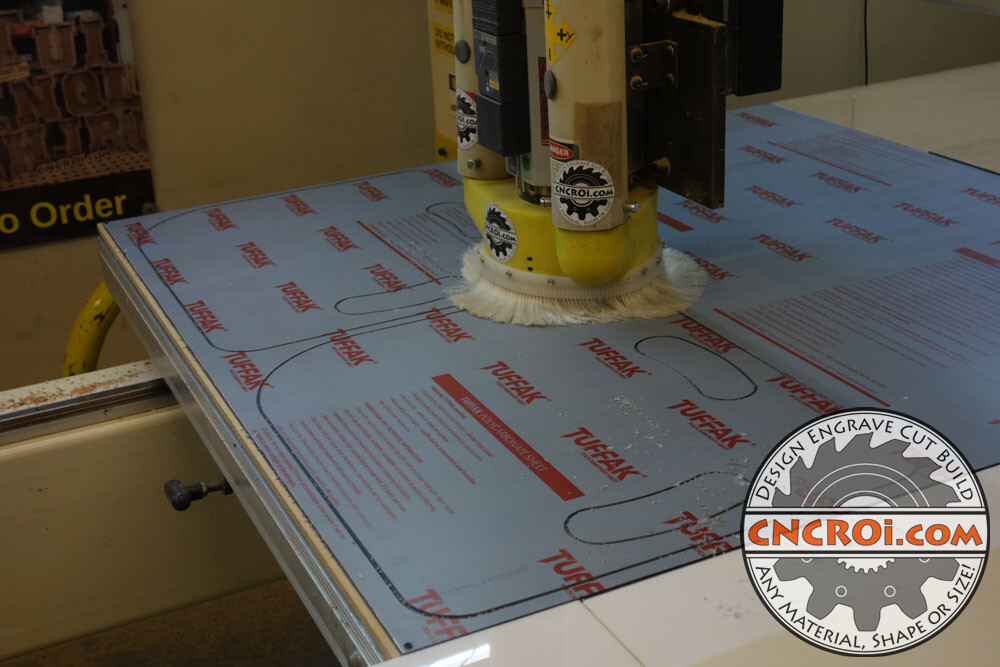

Because the edges of polycarbonate can be pretty sharp, many of our clients ask us to also chamfer one side just to save their fingers from band aids.

Polycarbonate is one of those materials that really doesn’t enjoy being cut no matter what technology you use, to cut it with, it has very narrow cutting tolerances that if you get out of range, it pays you with frustration and headaches.

These black prototyping custom polycarbonate parts are now complete, you can see just how precise the cut has been and how there hasn’t been any movement during production, polycarbonate loves to vibrate while being cut through which doesn’t help!

And here’s a side by side, identical parts, two different colors of polycarbonate, made at CNCROi.com using our CNC router.

Need custom polycarbonate parts? Contact CNCROi.com right now!