SS #4 Brushed Finish Signage

Stainless steel has a number of different finish options, in this case, we did a #4 brushed finish signage for a CNCROi.com customer.

https://www.youtube.com/watch?v=ETZg8J0HeDo/

Having a #4 brushed finish on 304 stainless steel is probably the most popular finish we work with at CNCROi.com, it looks fantastic and is very easy to work with.

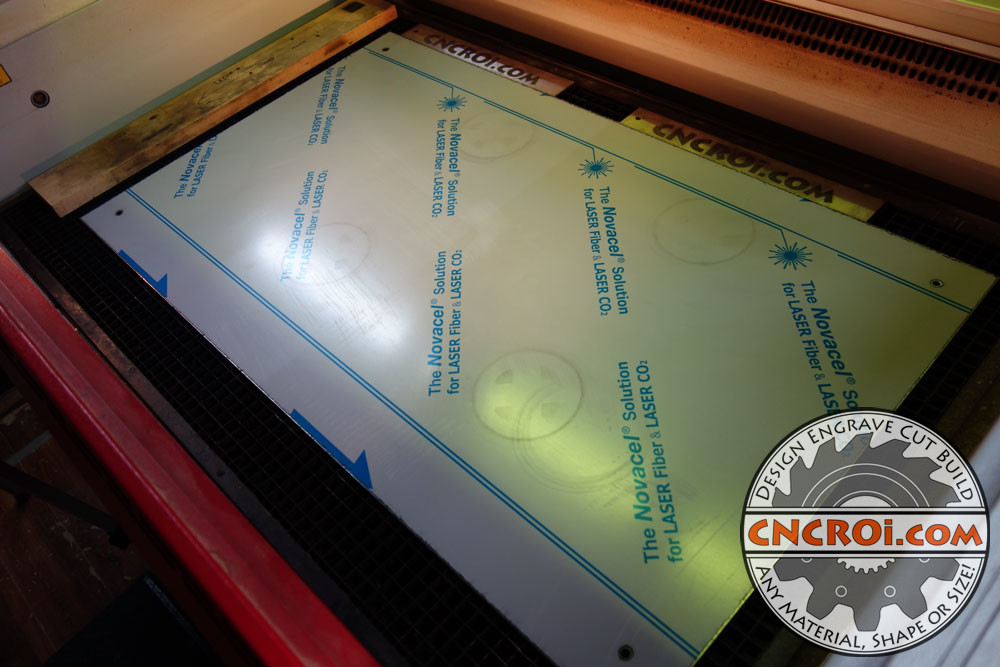

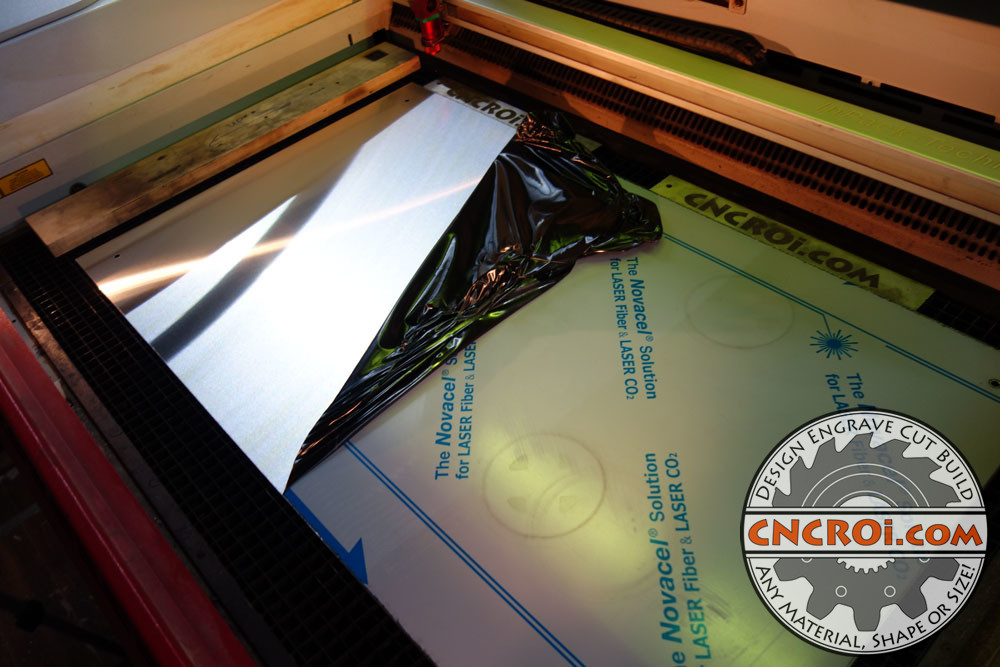

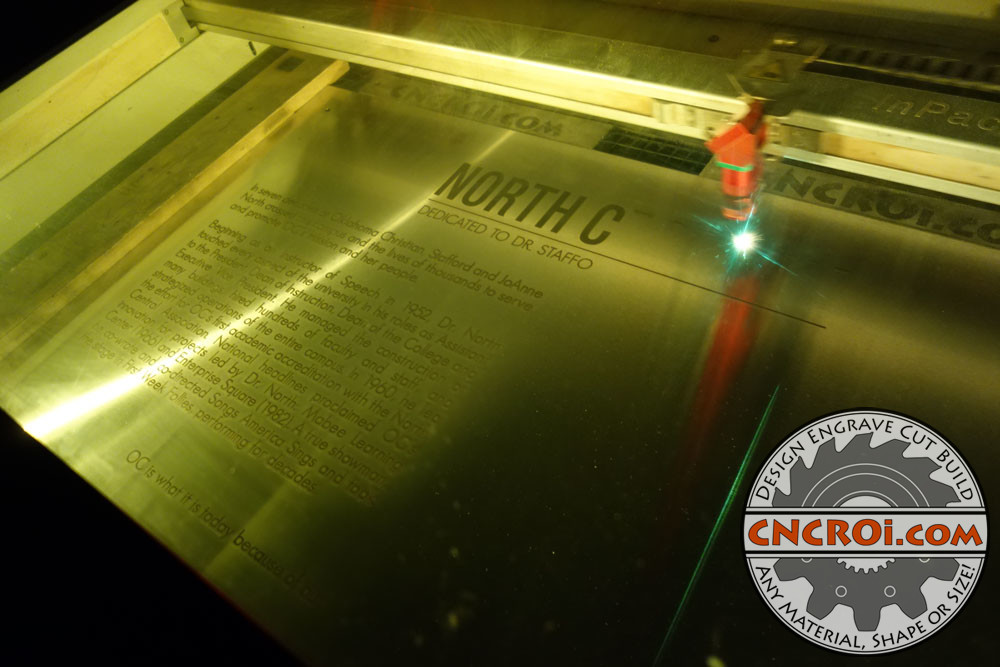

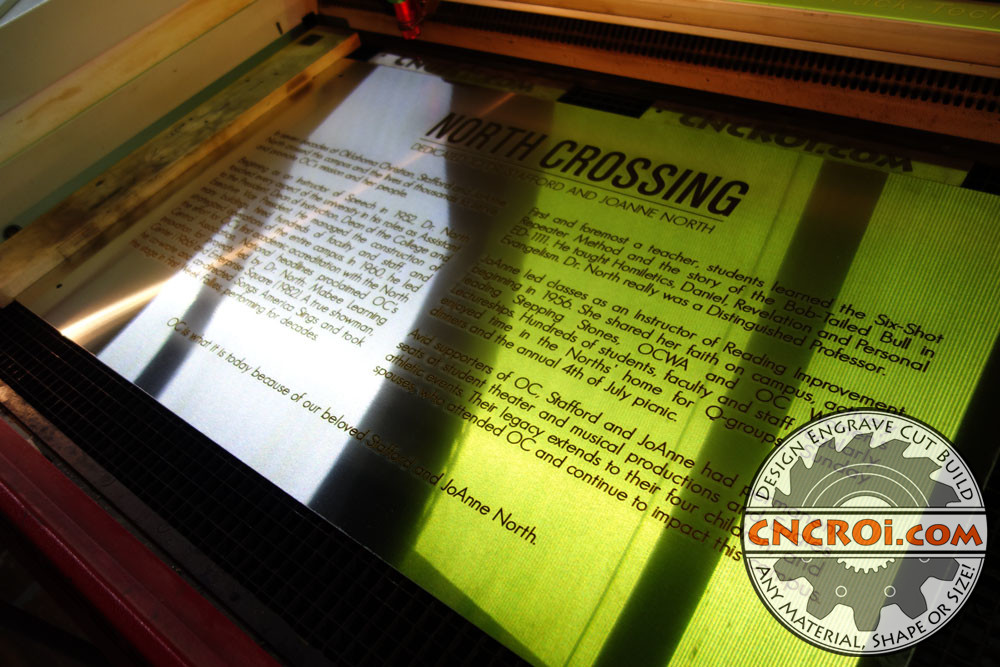

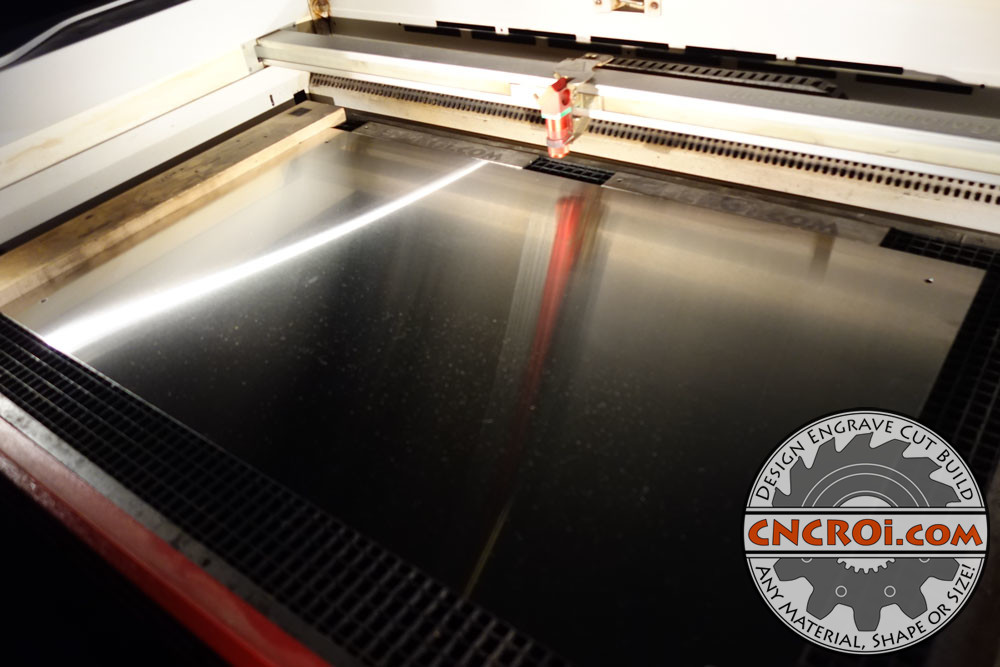

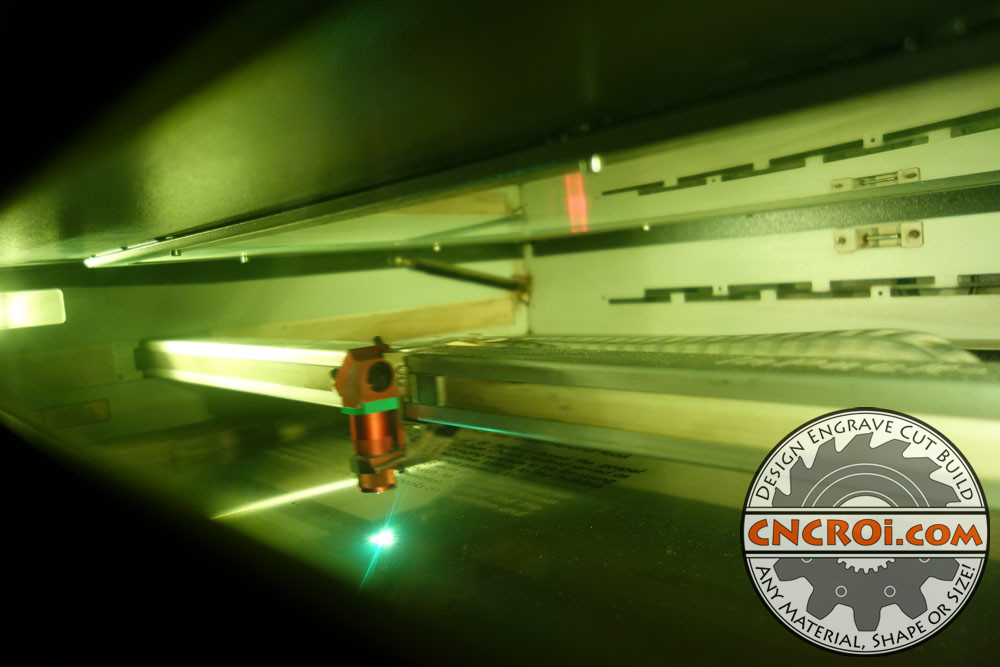

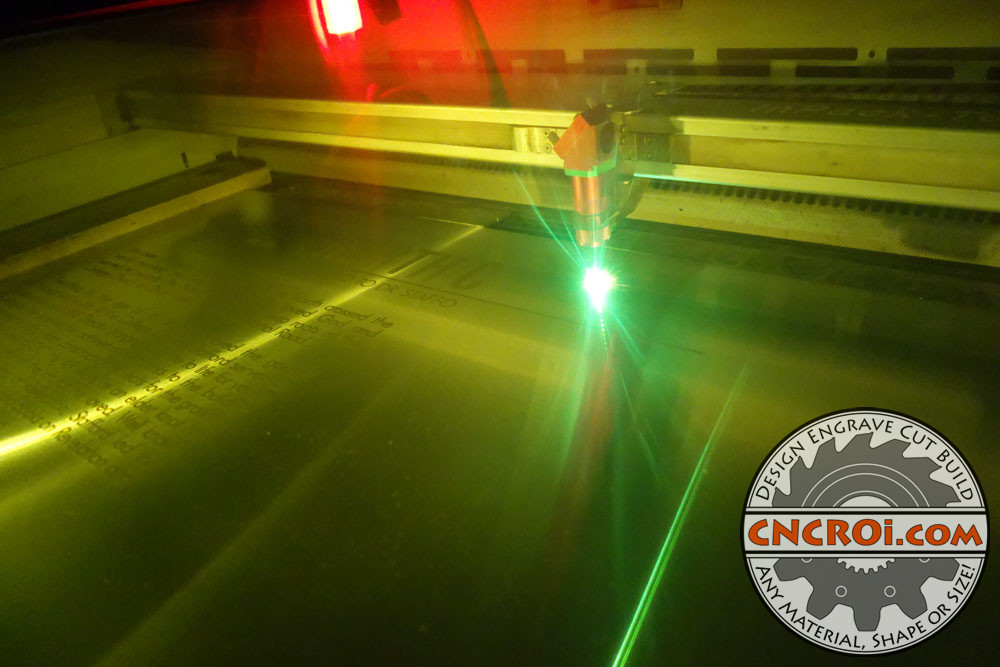

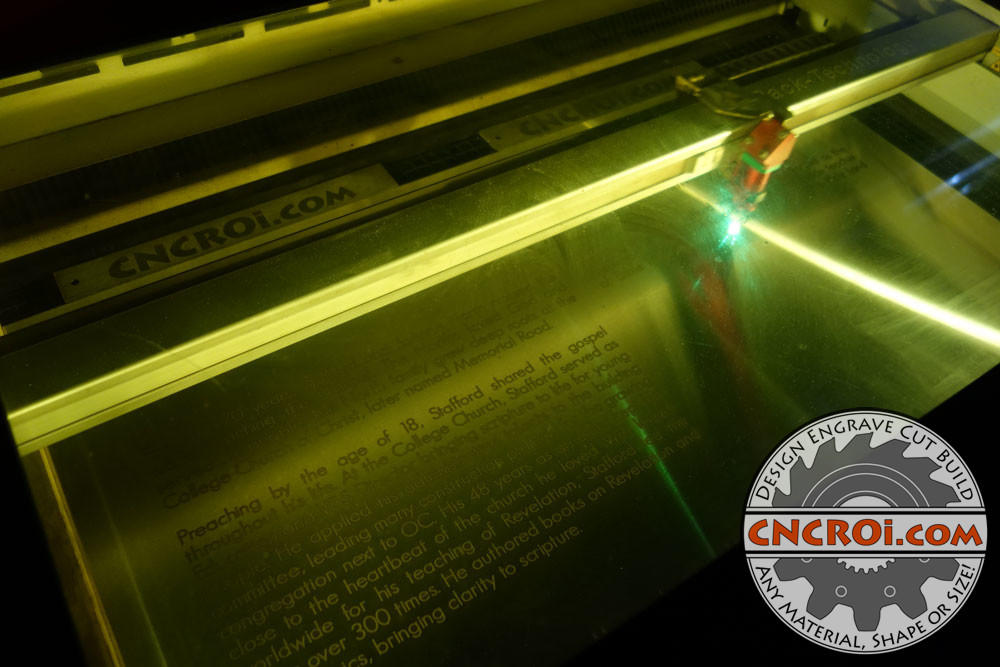

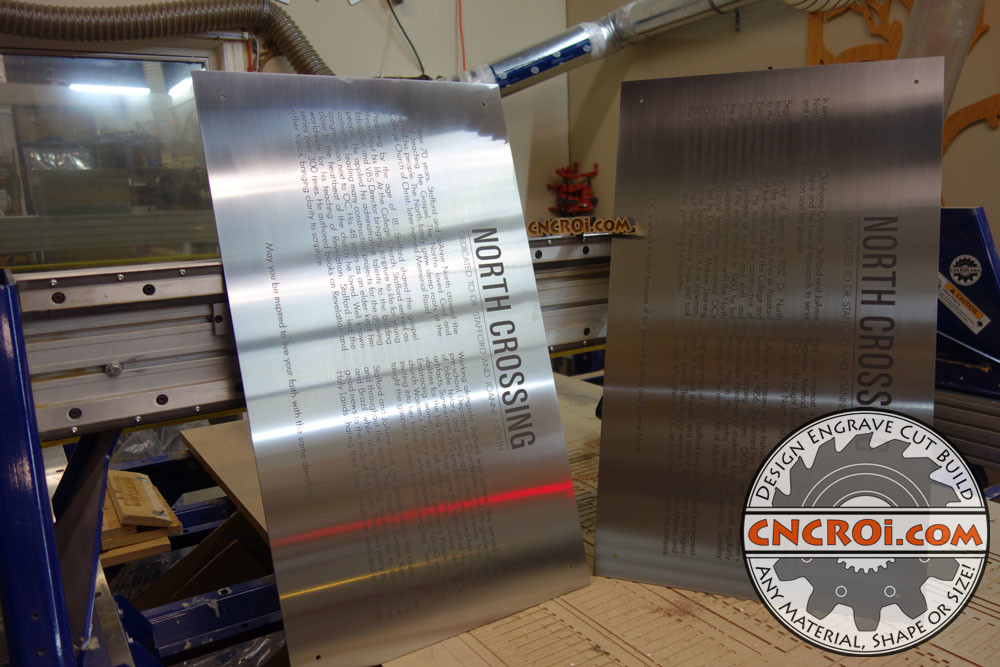

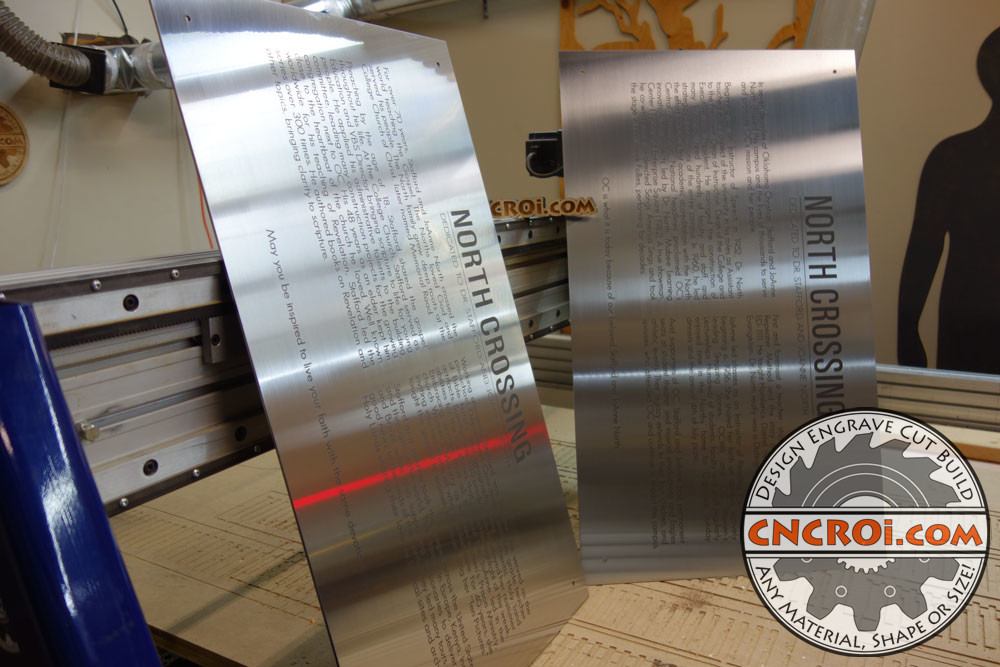

For this specific project, we used 10 ga 304 stainless steel with #4 finish, that’s why you see the coating on the stainless steel as it’s easy to scratch and very hard to fix if it should happen during the cutting process.

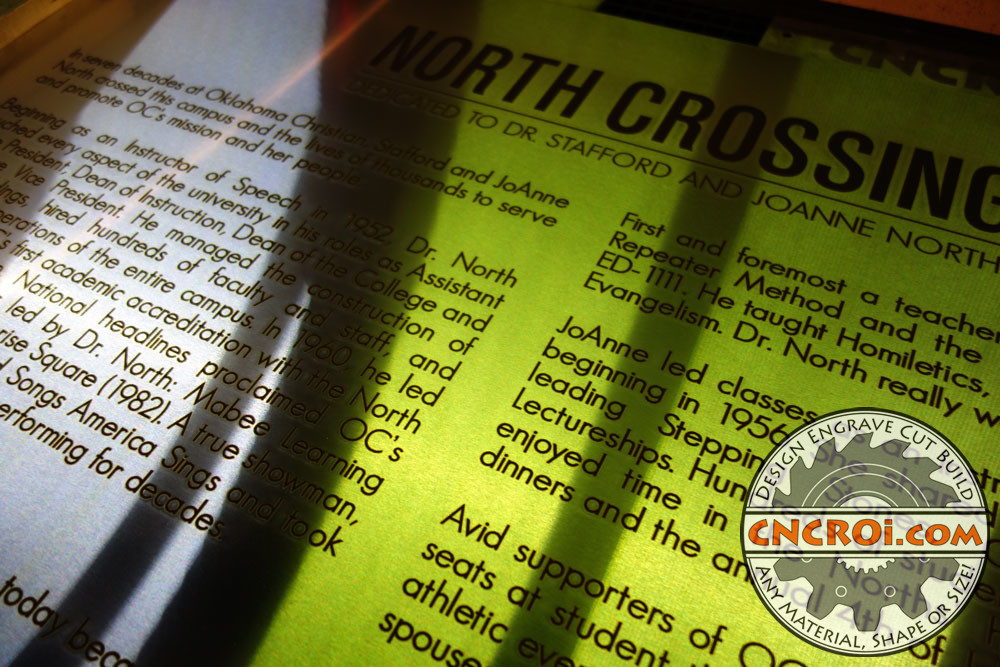

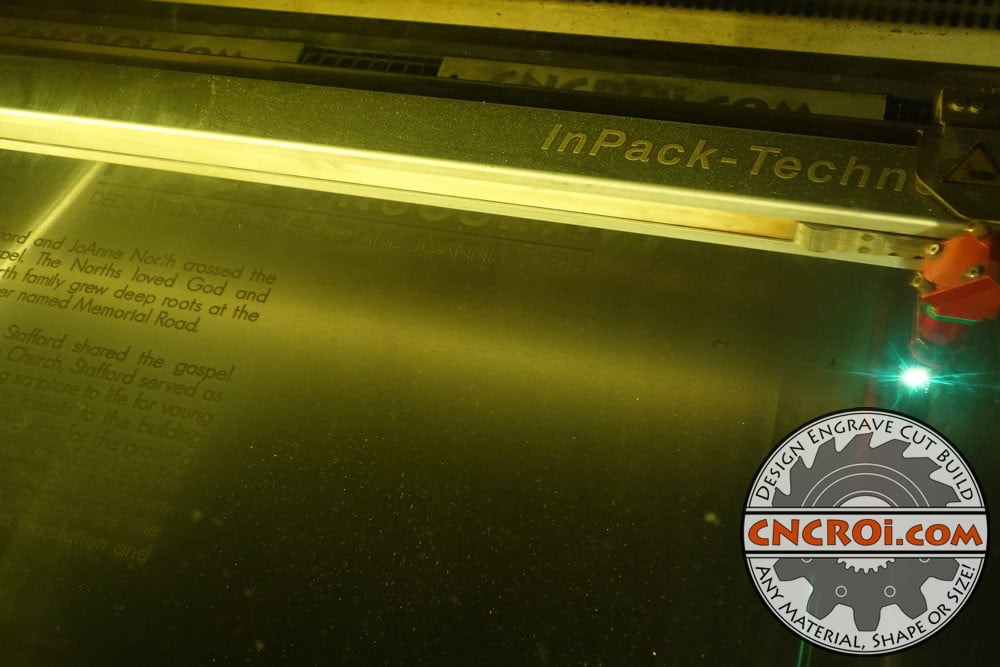

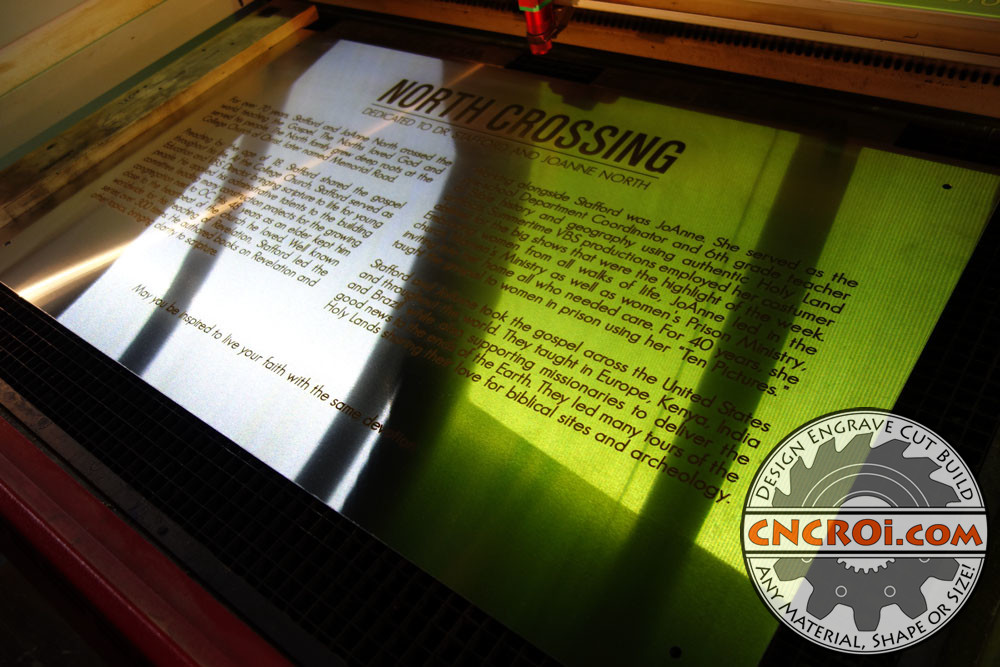

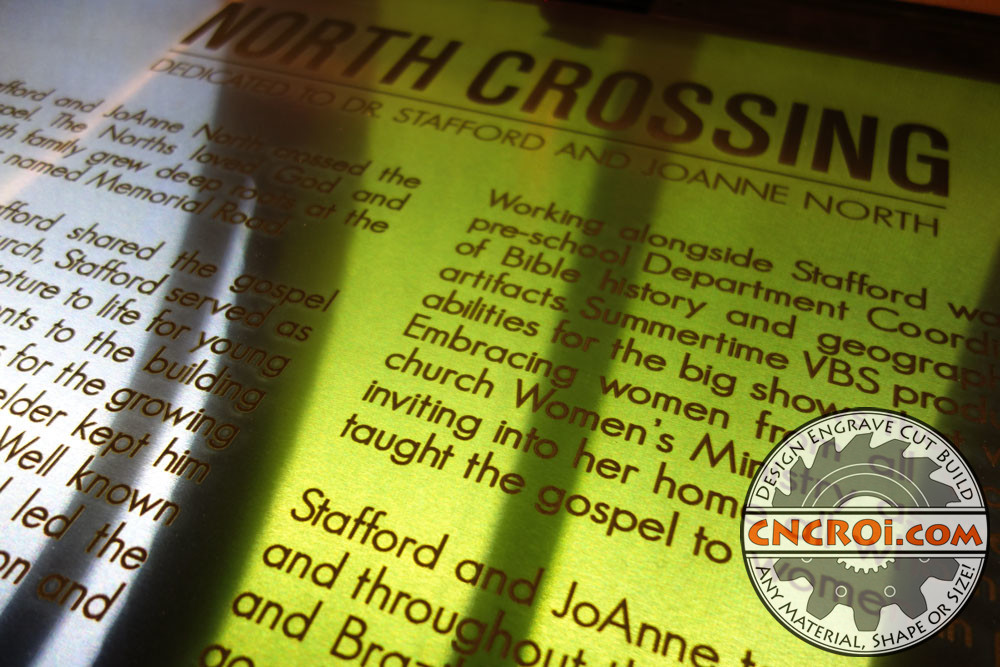

You can see how amazing this #4 brushed finish signage will look even before fiber etching the surface of it at CNCROi.com.

This is NOT a mirror finish by the way, if you look closely, you’ll see the “brush” marks close-up but from far away, you just have a nice dull reflection on the overall surface of the #4 brushed finish signage.

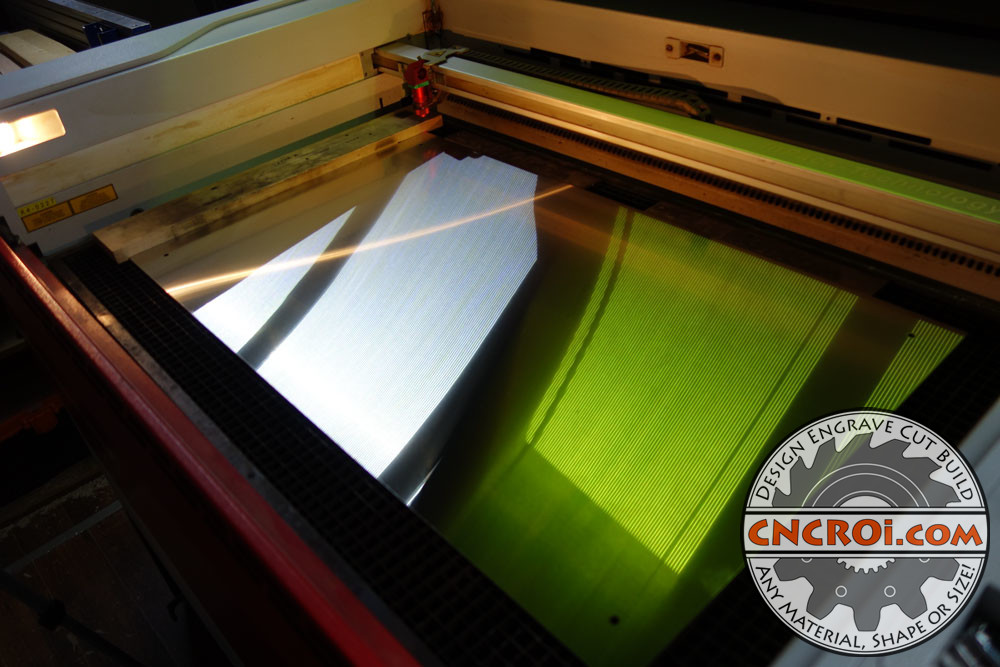

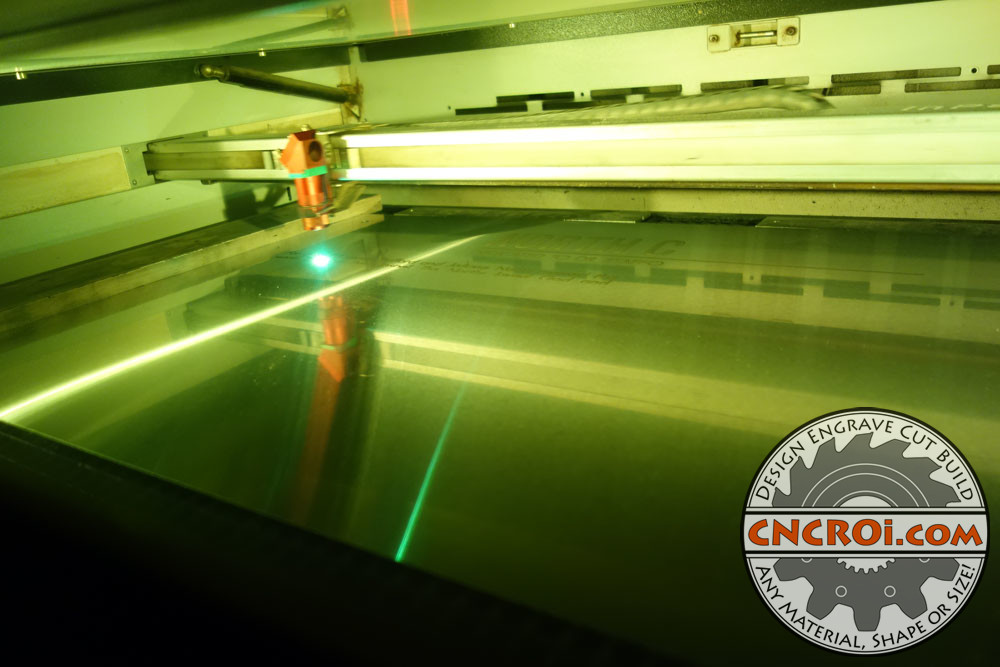

Fiber etching stainless steel is a task that we’ve done a tremendous amount of over the past years at CNCROi.com, we now have two fiber lasers in the shop and looking at acquiring the capabilities of a third unique platform to handle the unique tasks our customers keep coming-up with.

Why is fiber laser etching so popular? Unlike any other method of etching stainless steel, this will not fade, crack or peel over time, it’s so strong in fact that you need to use an angle grinder to remove it… and I’ve done it and it isn’t fun nor an easy process by any stretch.

If you need something cut that requires something very sharp in detail on stainless steel, waterjet cutting wins each and every time.

https://www.youtube.com/watch?v=mEDJyj24G_8/

If you look very closely, you can see the #4 brushed finish signage, it’s going horizontally across the sheet of #10 ga 304 stainless steel.

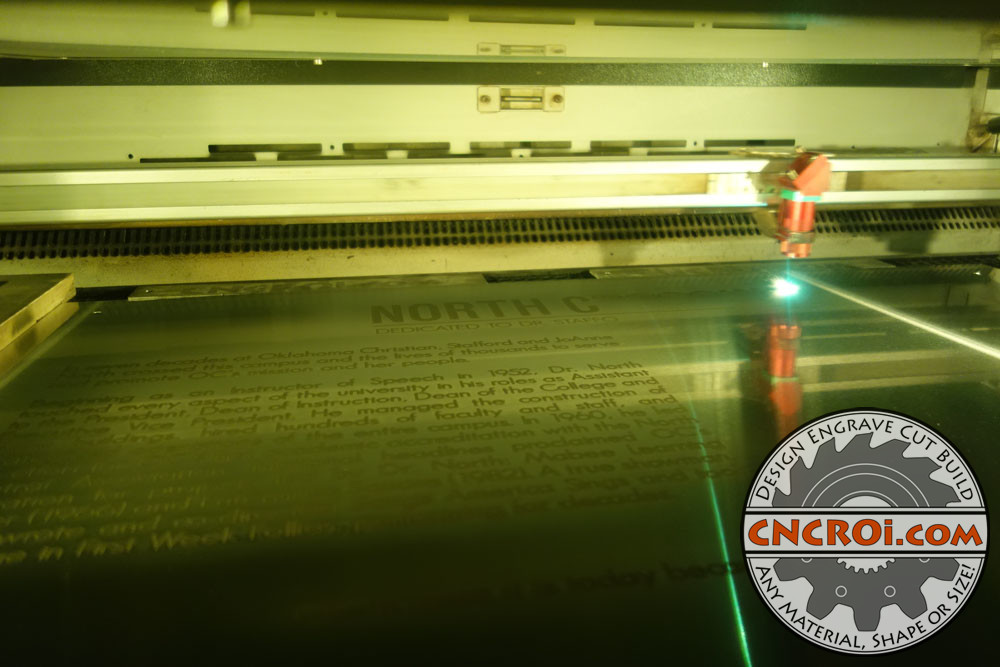

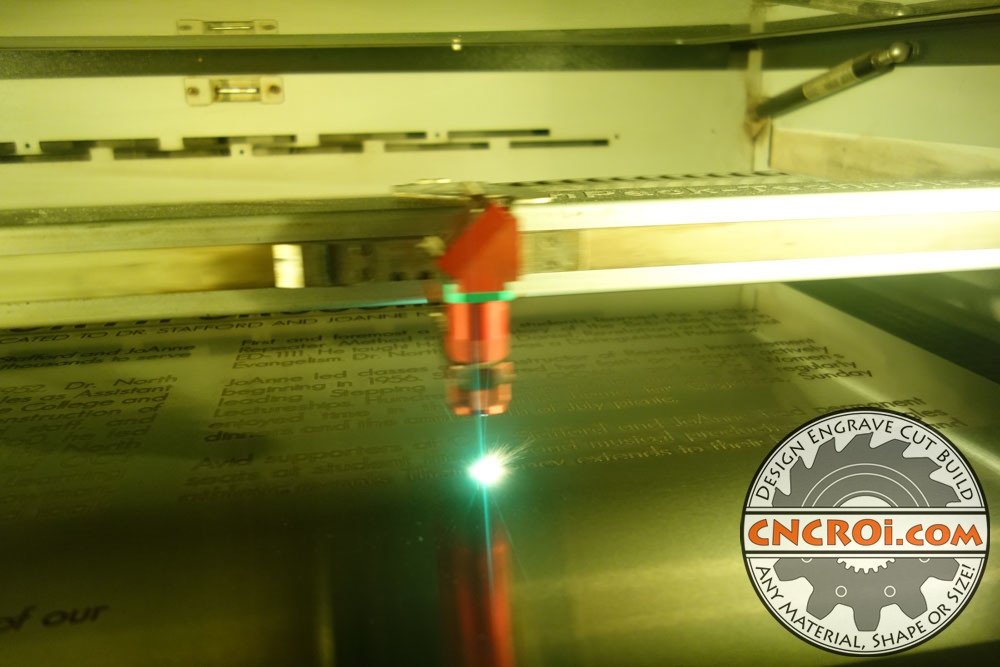

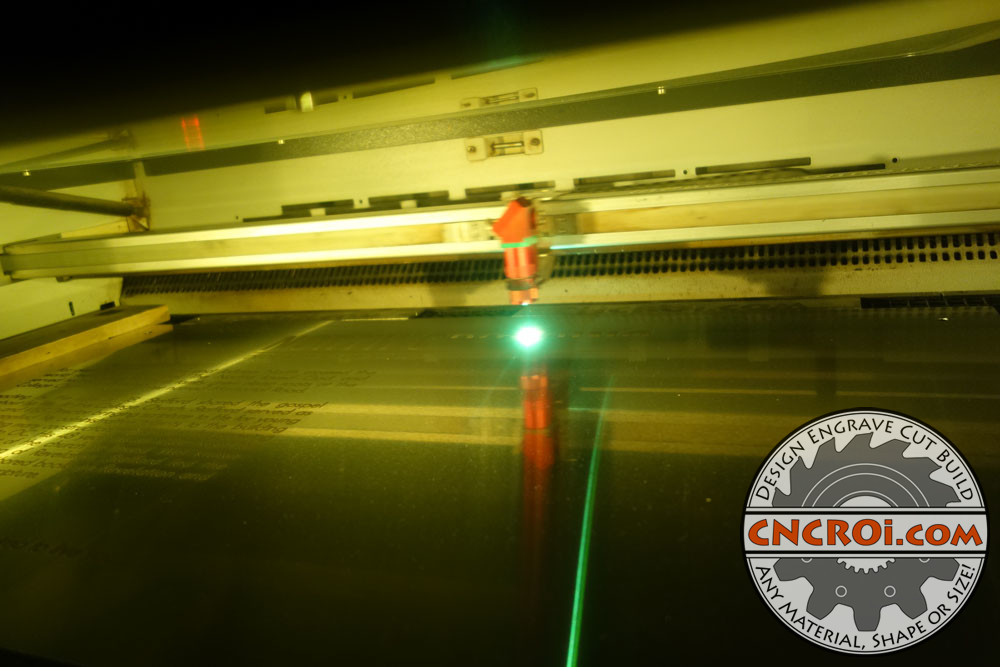

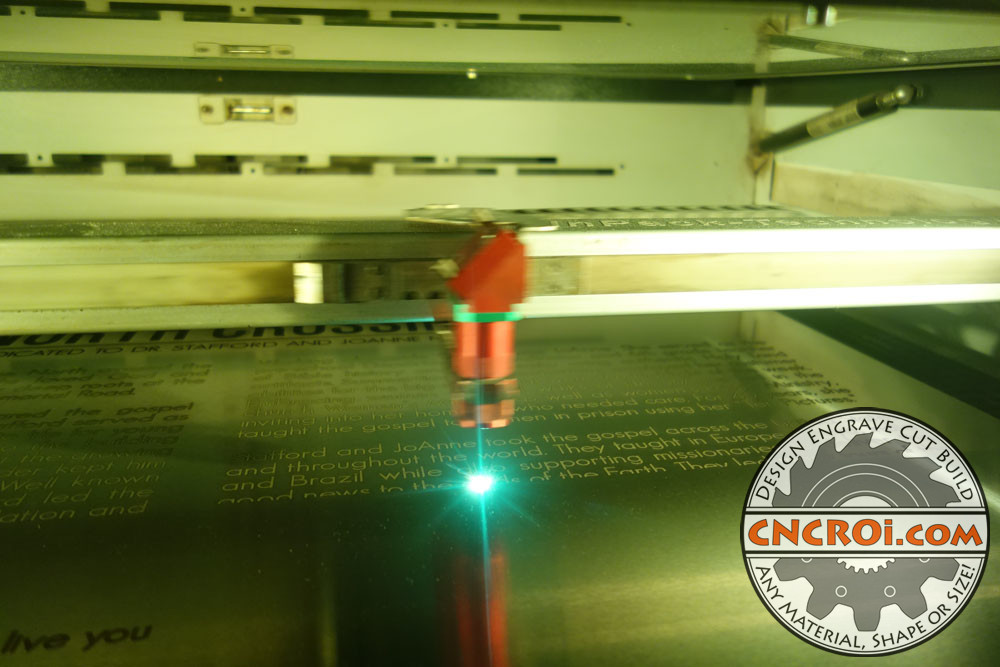

To save on production time and hence, customer money, we cut-up the fiber etching process into two parts, this is very specific to the design by the way, which is why you sometimes see CNCROi.com do this and sometimes not, if there is a savings, we do it, if not, then we don’t.

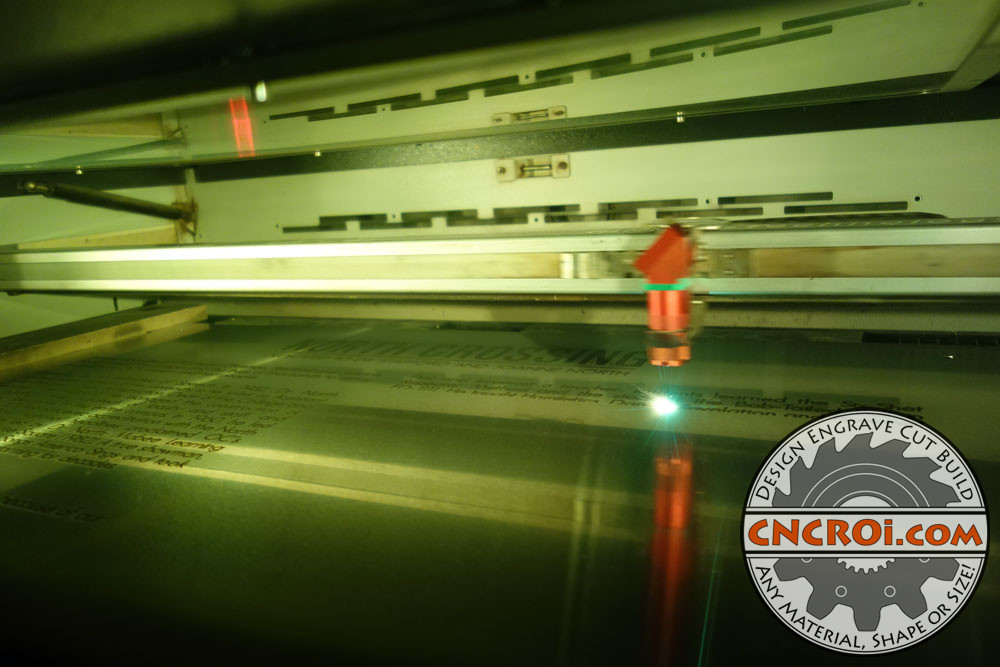

Fiber etching is a VERY slow process by the way, the entire process took a good long while across two days, one day a panel and yes, CNCROi.com can go faster, but the etching isn’t as deep or apparent… I don’t believe in cutting corners and my customers appreciate it!

Fiber etching both panels was performed without a hitch, the results look amazing and our customer was ecstatic when they received them in the mail, there is really nothing that matches the esthetic of #4 brushed finish signage.

Big projects or small ones, we handle them all using a variety of processes and equipment at our shop.

https://www.youtube.com/watch?v=BEIzFHDronM/

When it comes to your fiber etching options, they are endless, CNCROi.com can use any mix of fonts and vector black and white imagery to produce something amazing for a variety of applications, from custom coasters to prestigious stainless steel or titanium signage.

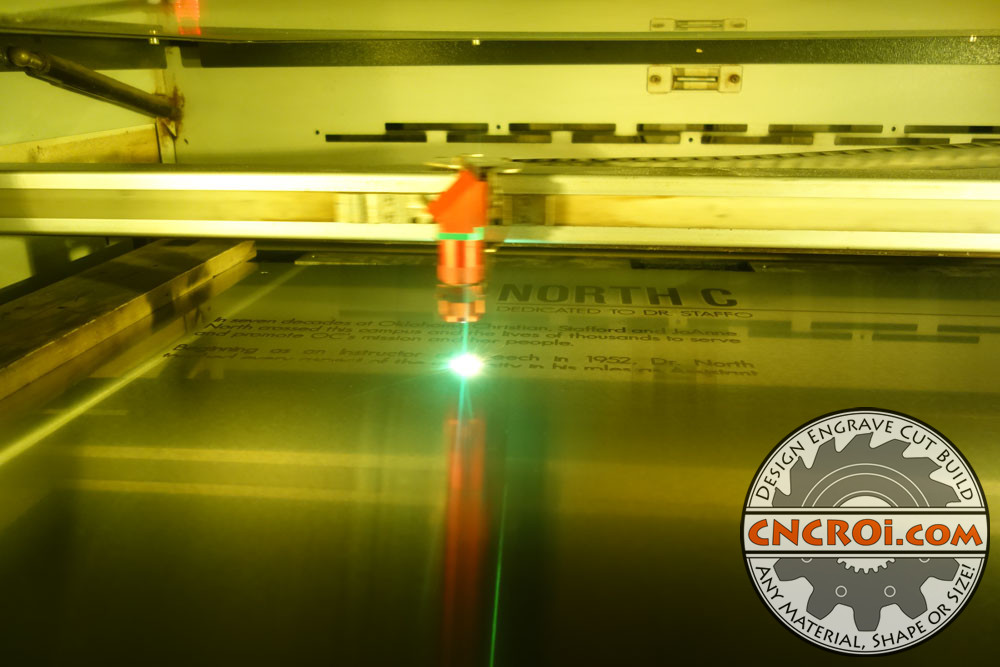

After this fiber laser etching was complete, you can more clearly see the results that CNCROi.com produced on behalf of our customer on this #4 brushed finish signage.

No other material really takes-on the environment that it’s found within, this is why stainless steel, #4 brushed finish or otherwise, can’t be matched, it’s just a wonderful reflective material that’s at home both indoor and out.

Again, looking at this #4 brushed finish signage from a few different angles, you can start to appreciate just how great this sign looks, nice think and heavy stainless steel mixed with a permanent etching across the entire surface.

Custom memorial plaques are another very popular item that CNCROi.com produces for our customers for the same reason as this signage, it’s durable and the etching won’t fade, crack or peel over time.

https://www.youtube.com/watch?v=B0463p1ovBw/

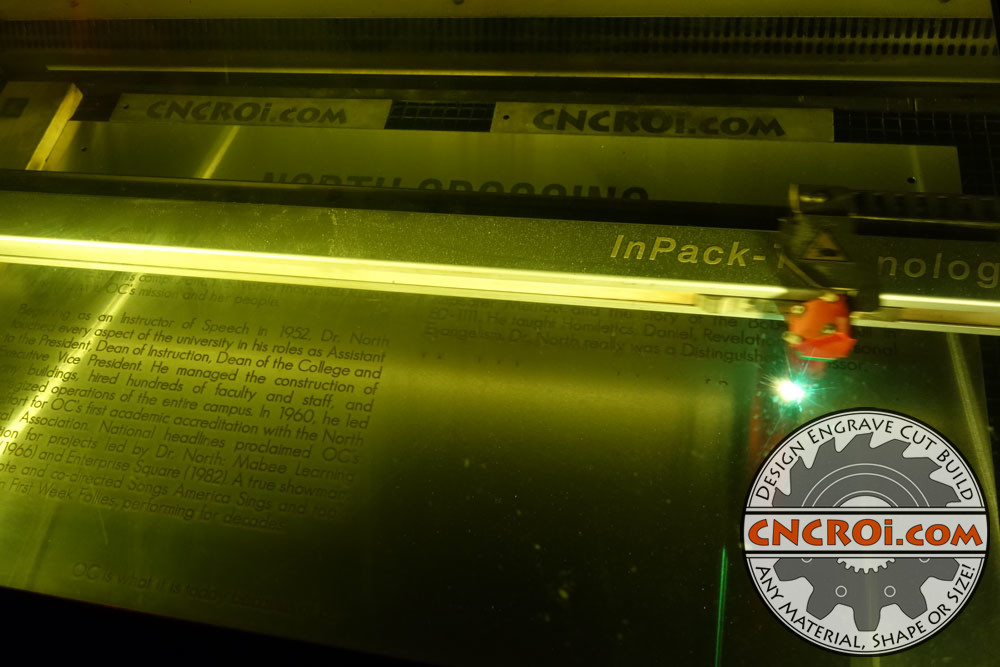

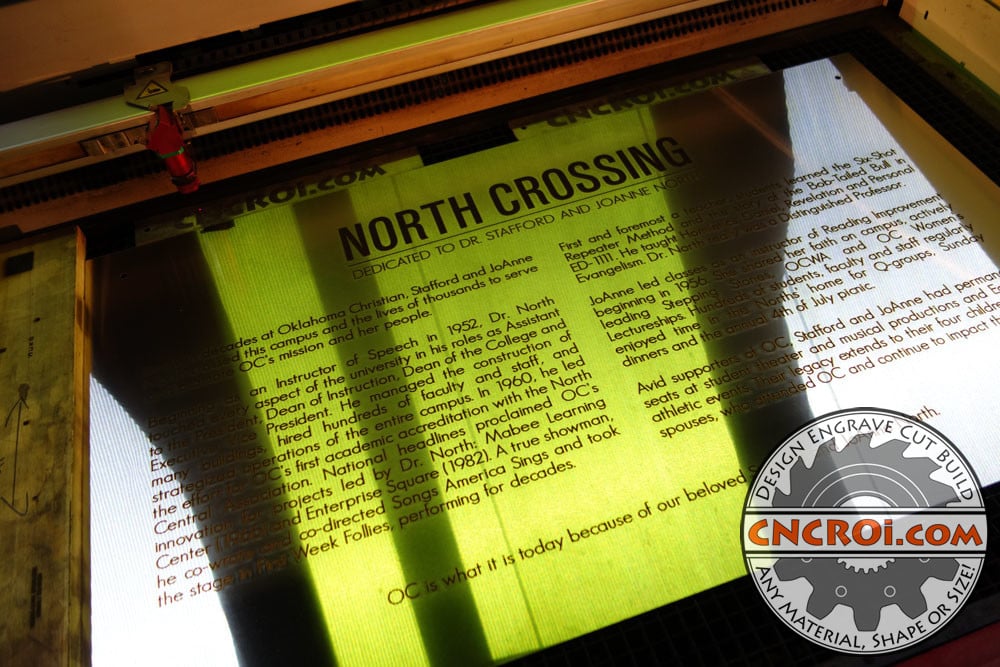

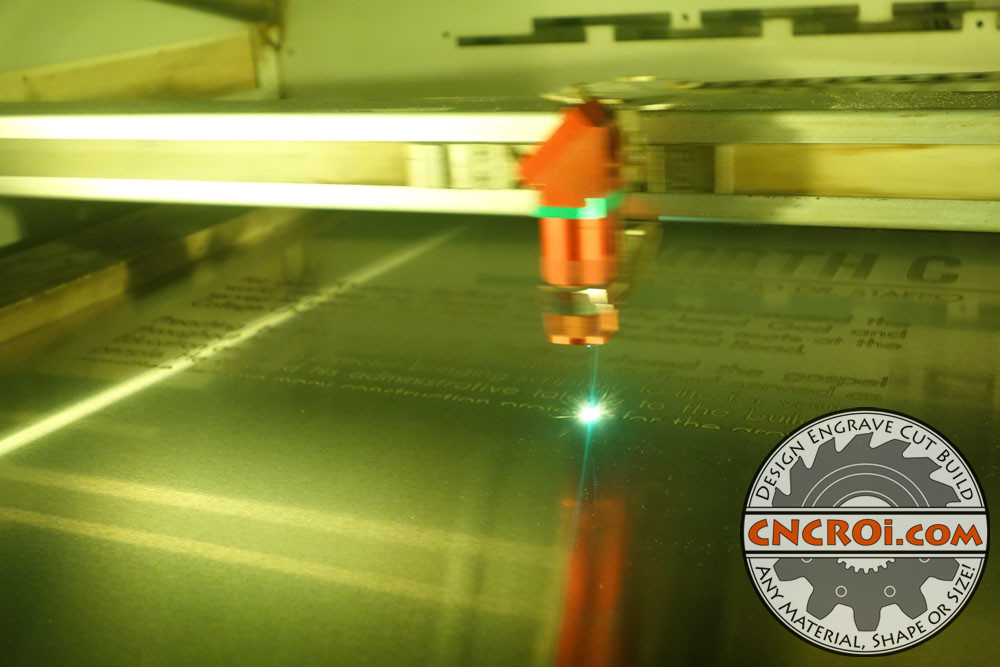

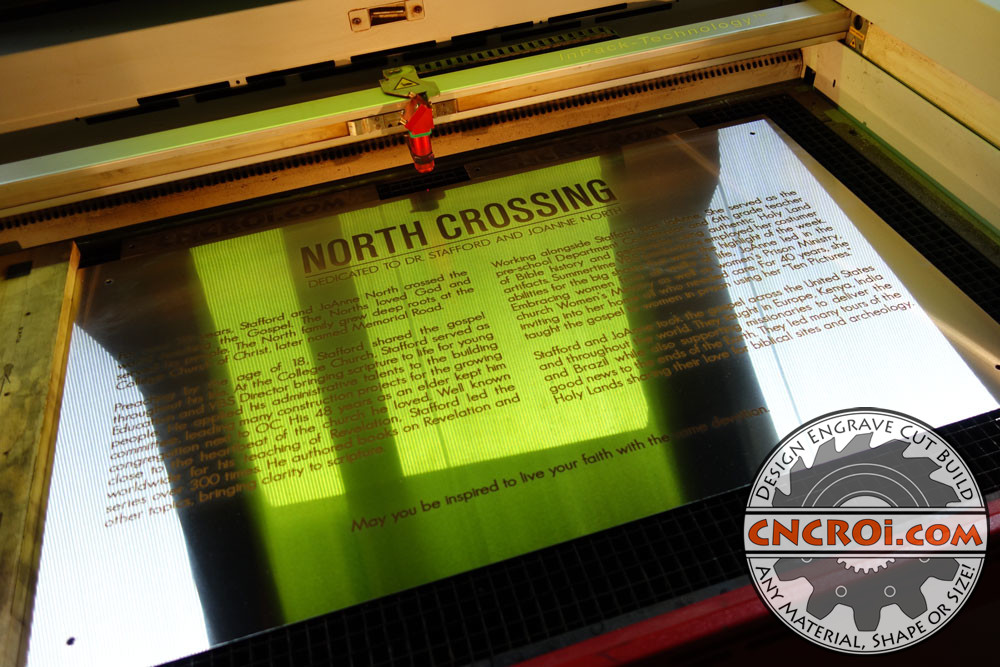

After the first of two #4 brushed finish signage was complete, it was time to load-up the next one onto our fiber laser bed and begin the process all over again, of course, this time around, it’s with different wording.

You can more clearly see in the image above the quarter inch holes that are 1.5″ offset from each corner X and Y, this will be mounted on a building and will easily outlast said building and then some.

Even if the information is different, the overall process of #4 brushed finish signage fabrication is the same for CNCROi.com.

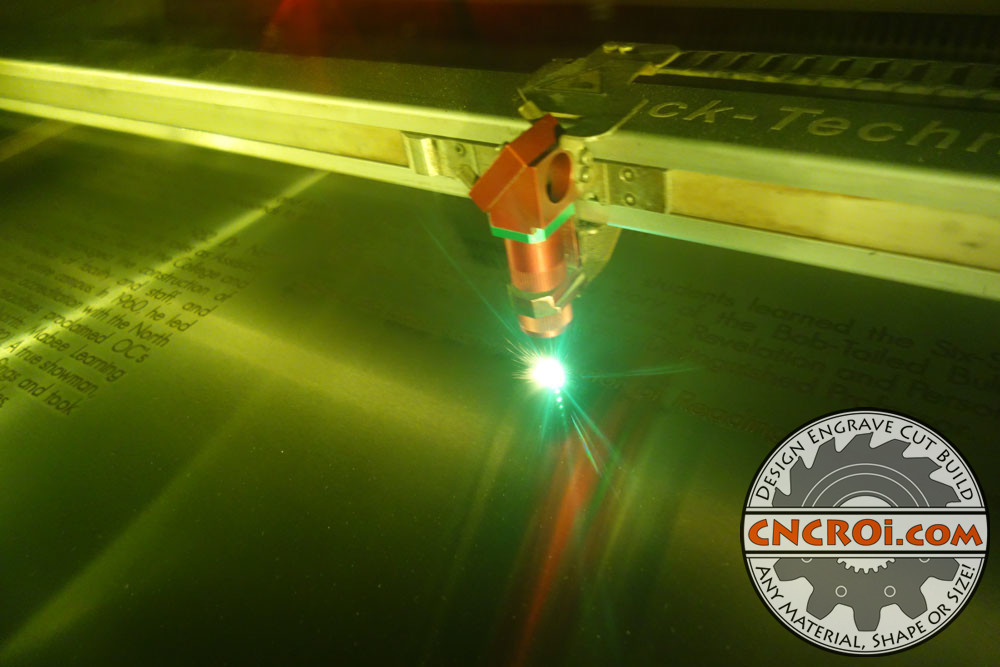

The sparks you see during the fiber laser etching process is the interaction of the light energy hitting into the stainless steel surface, scratching the surface and heating it as well in the spots that are “black” in the design file provided by the customer.

CNCROi.com makes a wide variety of custom projects using stainless steel, from wall art to crazy durable stencils made for military applications.

https://www.youtube.com/watch?v=ctfZ2tPTA1M/

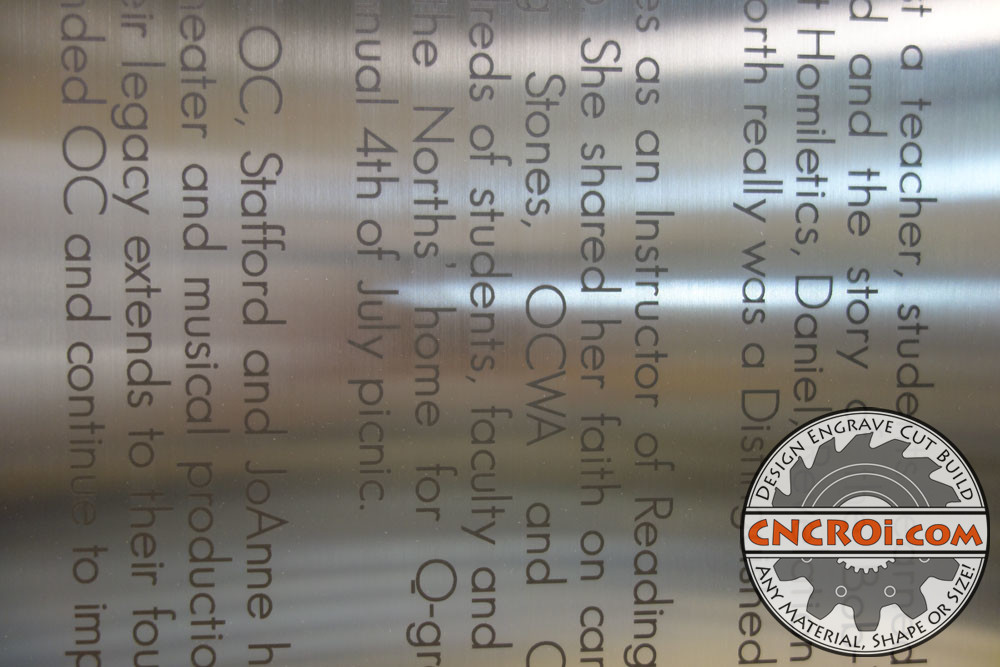

The resolution possible with CNCROi.com‘s is up to a thousand DPI which means even the smallest detail is recorded and etched into the #4 brushed finish signage.

Like the previous design file that CNCROi.com etched into this sheet of stainless steel, this is also done in a two step process, meaning the left part of the #4 brushed finish signage is done first followed by the right in order to speed up the already very slow production times of this project.

What I enjoy most about fiber laser etching stainless steel is the quality of the etching itself, unlike screen printing, you can actually feel the etching and you don’t need to worry about ever wearing it out.

Keep in mind that fiber laser etching #4 brushed finish signage is PERMANENT, meaning, you really want to triple check the words in the sign before we do the work as there is no way to fix it should there be a spelling error or formatting problem, we check things and send a digital proof of course before actual following-through with the production.

Our other fiber laser atCNCROi.com is a galvo system, perfect for much smaller applications with the same level of precision and repeatability as the big guy.

https://www.youtube.com/watch?v=rWeM9-VUOII/

As this #4 brushed finish signage project is coming to a close, you can start to appreciate the process behind making something this durable and beautiful, and the technology behind it that makes it all possible.

There is a lot of heat generated by the overall fiber etching process, larger plates like this spread it out a lot more than smaller jobs we do here at CNCROi.com but heat warping is still always an issue that has to be watched for during production.

Let’s look at the finished #4 brushed finish signage from a few different angles so you can see how well it takes-in the environment it’s found within.

Of course, there are other things that CNCROi.com can make using stainless steel, like custom BBQ grills!

https://www.youtube.com/watch?v=Ln9EXslzc04/

After cleaning-up the stainless steel #4 brushed finish signage, you can see how the dark brown becomes a back, it all really still depends on the angle of viewing, hence why you see the reflection and refraction differences across the sign.

Let’s take a close-up picture of this #4 brushed finish signage, you can see all the letters and vowels are clear, there is no jaggedness or bleeding of the fonts.

Need custom signage? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=n56CCFPCMbE/