304 Stainless Steel Donor Wall Text

This 304 stainless steel donor wall text is not only incredibly great looking but it’s generational in durability as well.

https://www.youtube.com/watch?v=kD10k1Es-VA/

The CNC plasma cutting process is seamless, the quality I’m getting is amazing – thanks to both my table and the clean cutting Hypertherm Powermax85 generating the plasma act.

This text was actually part of another job we recently finished, you can see what this wall had by watching this video.

https://www.youtube.com/watch?v=BEIzFHDronM/

As you can see in the video and text, CNCROi.com is making this custom 304 stainless steel donor wall text “on demand”, what this mean is any aspect of this project could be customized to your own liking.

For instance, you want a different text? No problem! You want a larger or smaller font? No problem! You want each letter to be individualized rather than in segments as you see in this 304 stainless steel donor wall text? No problem!

CNC plasma cutting produces a very nice finish with an aesthetically pleasing kerf along the edges, in other words, there is a slight chamfer or curving to the edge rather than a straight edge like you’d get with waterjet, router or laser cutting.

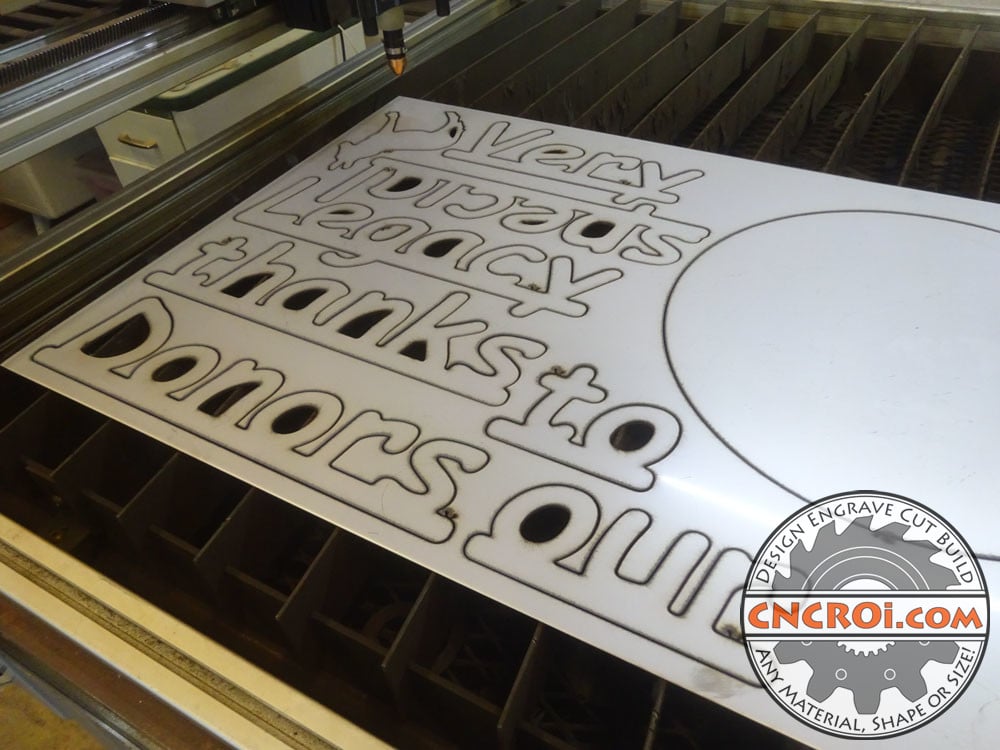

For CNCROi.com, the first step after designing and receiving approval from our customer for this 304 stainless steel donor wall text is to cut out all the inside parts, as we aren’t making a stencil, all the inner parts can fall out and as the words are segmented together to make screwing it on the wall far easier, a lot more design flexibility is possible.

Stainless steel is a very durable material, it can be fiber laser etched and can be surface coated to increase contrast of the result… it can also be bent to shape.

https://www.youtube.com/watch?v=6QrDGM8_G6U/

Just in case something moves, that’s why CNCROi.com is cutting out the inside parts before proceeding to the outside ones – this allows for incredible precision in the finished piece.

The bright light you see during the plasma cutting process is caused by the arc of plasma gas literally vaporizing through the stainless steel for this 304 stainless steel donor wall text, some dross melts away as it doesn’t get hot enough (too far from the arc) but most of it is instantly turned into smoke.

The sparks you see are basically the same you’d see during welding but they are a lot finer and not as sooty… and yes, they fly EVERYWHERE making a nice fine mist of dust in the air and on the ground around the CNC plasma.

CNCROi.com does have different technology available to cut stainless steel when the specs are outside of what’s possible using plasma.

https://www.youtube.com/watch?v=-idkUWEOXeI/

Cutting out letters and vowels for this 304 stainless steel donor wall text was a lot of fun, I’m always amazed at how smooth our plasma cutter dances across even the toughest of materials, for something so heavy and powerful, it’s incredibly elegant and efficient.

CNC plasma cutting can be done on other materials than stainless steel – though we do process a lot of it at CNCROi.com – aluminium though titanium can be cut with our machine but the most often cut materials in the shop is by far stainless steel followed by mild steel.

When it come to the power we have in our machine, rarely do we need to max it out, we have up to 85 amps on our machine but generally cut at 20 below that, although our system is set-up on 3-phase power, the quality we get at 65 amps and the speed of production is more than fine for our general purposes as the shop.

What I enjoy about plasma cutting jobs on-demand for our customers is the diversity of designs they allow us to cut for them, no two projects are the same.

https://www.youtube.com/watch?v=ygB1tfsdAzw/

Plasma cutting is a fun process that really never gets boring to watch and experience, I wished I got one of these years ago but this year was the year to get more into metal and this was a massive part of that push, and next year, CNCROi.com will do another big investment in that direction as well.

Generally we use stainless steel with our plasma cutting projects because it’s far more corrosive resistant than mild steel and because we also have a CNC fiber laser, we can etch the surface with a lot more visibility than what is possible using only mild steel.

How long does everything stay “hot” after production? A few minutes, right off the machine, this 304 stainless steel donor wall text is still too hot to touch by hand.

When it comes to plasma cutting, it’s a pretty safe machine as long as you aren’t dumb around it, a lot more can go wrong playing around with 3-phase but I’d consider this machine safer than a box cutter.

If you are wondering what mild steel plasma cutting looks like by comparison, here’s a video showing just that, very similar but a lot less sparks.

https://www.youtube.com/watch?v=vqiPA6lVGN0/

You can now see this 304 stainless steel donor wall text is almost done, the inside parts are all cut-out and the outlines are just finishing the last Donors wording.

When plasma cutting, I have my full welding gear on, helmet and all… otherwise, I’d get a nice tan where the UV generated by the arc hit my skin.

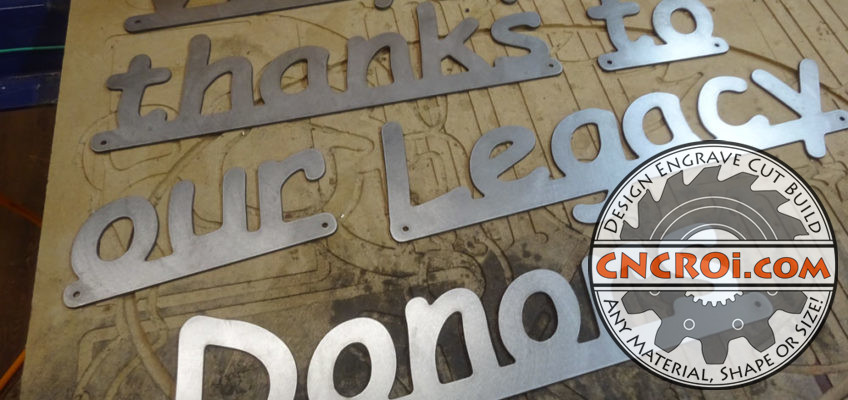

Now you can see the finished 304 stainless steel donor wall text, the next step is to clean it all up, it still has the mill scale from the steel mill which CNCROi.com will make all nice and dull-shiny.

That circle you see in the above picture was actually for another job, I just cut all this at the same time to save time.

https://www.youtube.com/watch?v=mOsxRyCauCU/

Here’s a close-up of the 304 stainless steel donor wall text, you can see there is very little dross on the edges, and what is there, literally falls off during sanding and angle grinding so it’s never a concern to worry about.

But first, we use our new drill press to make holes into the 304 stainless steel donor wall text so that the customer can easily screw this right into the wall at their facility.

I’ve drilled a lot of stainless steel holes in the past, my new drill makes this EASY by comparison, I have a DVR which means it EASILY drills through this with a nice sharp result.

Literally any shape or design can be plasma cut out of stainless steel… even custom stainless steel Christmas trees!

https://www.youtube.com/watch?v=3Tkn8fuTcCM/

After all the holes are drilled, the next step is to grind off the burr on the underside and then just sand everything to a nice polish.

Stainless steel is a lot of fun to work with when you have the right tooling, doing all of this with a jigsaw is nothing but headaches but a plasma, DVR drill and other tools make this a cinch.

I rally love the holes in the stainless steel, just awesome how beautiful they are – and I’ve drilled a lot of holes before using lesser equipment with far worse results.

Need a custom 304 stainless steel donor wall text? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=fRarSjTywmU/