Custom Distilling Stencil: Waterjet Cut 304SS 2B Finish

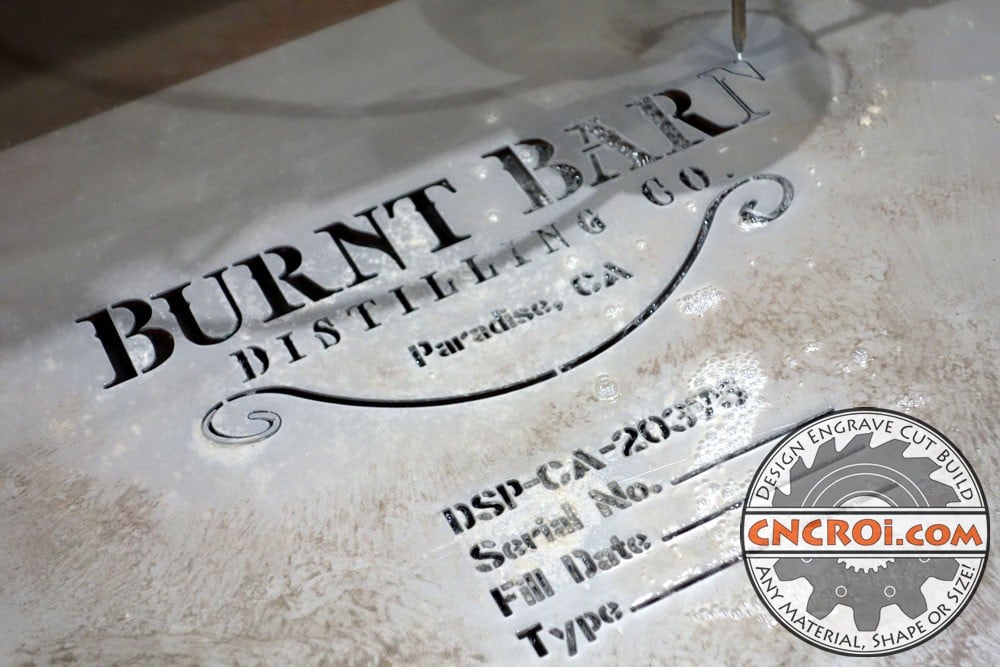

Need a custom distilling stencil? CNCROi.com makes those… this time we’ll use waterjet cutting through 304 stainless steel using 2B finish.

If you are wondering what a custom distilling stencil is, it’s something you (in this case), use a propane torch to brand your barrel heads with.

Although we could have lasered this custom distilling stencil out just as easily as waterjet cut it out, for this specific project, the numbers were more in the favor of waterjet than laser so that’s what CNCROi.com went with.

The very tight details in this custom distilling stencil meant that plasma cutting was out of the running, at least with the system we have at CNCROi.com, due to heat affected zones and the resolution of the plasma itself.

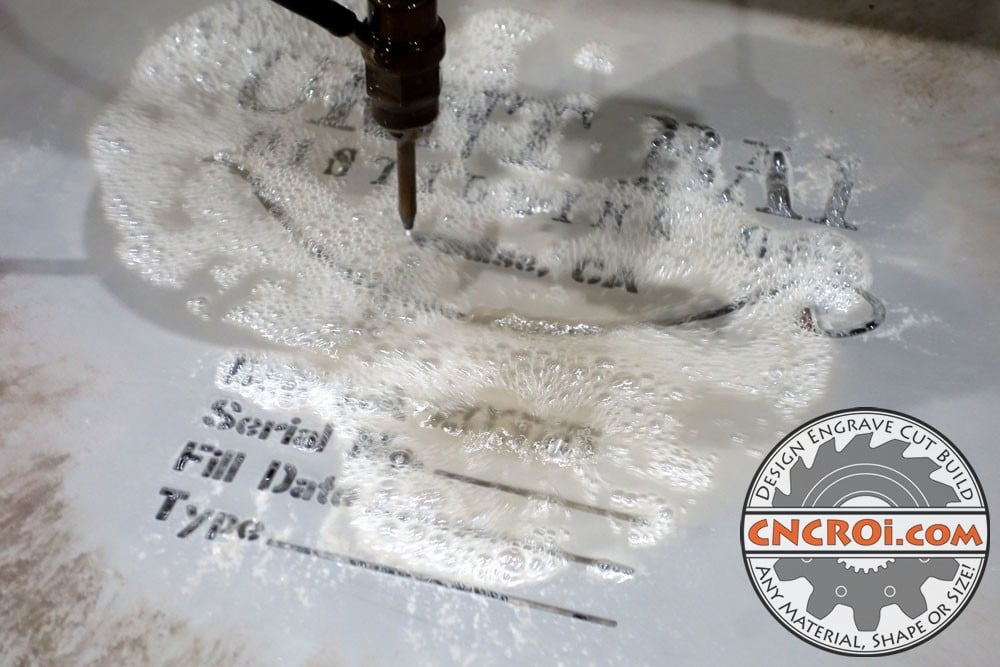

So what happens to all the stainless steel “bits” that seem to just magically disappear during the waterjet cutting process of this custom distilling stencil?

Most of it is abraded away, so it’s nothing but particles that sit in the waterjet vat until it’s emptied, but any bigger bits just float around or go down the bottom, unlike plasma or laser, where the metal is vaporized (becomes a gas) and the little bigger bits end-up at the bottom of the machine.

QR stencils are quite popular with CNCROi.com customers, they are easily made out of any material and are generally used for spray paint applications.

The major advantage of waterjet cutting stainless steel especially, as it tends to love holding onto heat, thus having larger heat affected zones, is that waterjet is a cold process, so there is never any fear of things warping due to heat even if a cut is done in very high density in any particular area of the sheet.

When it comes to laser cutting stainless steel, waterjet is just as precise as laser as router, the resolution is about the same across the board, what’s different is the edge finish and the tightness of the cut line itself.

It may seem obvious but unlike laser, there is a bit of clean-up required from the “wet” added during the cutting process, this is why generally, I’m agnostic at CNCROi.com regarding what process to cut stainless steel, such as this custom distilling stencil but tend to avoid waterjet for mild steel projects because of the flash rusting that happens from the moisture of the process.

Regardless of the CNC machine that CNCROi.com employs to cut metal (or any other material for that fact), it’s always a fun process to watch and the finished results are always spectacular after clean-up.

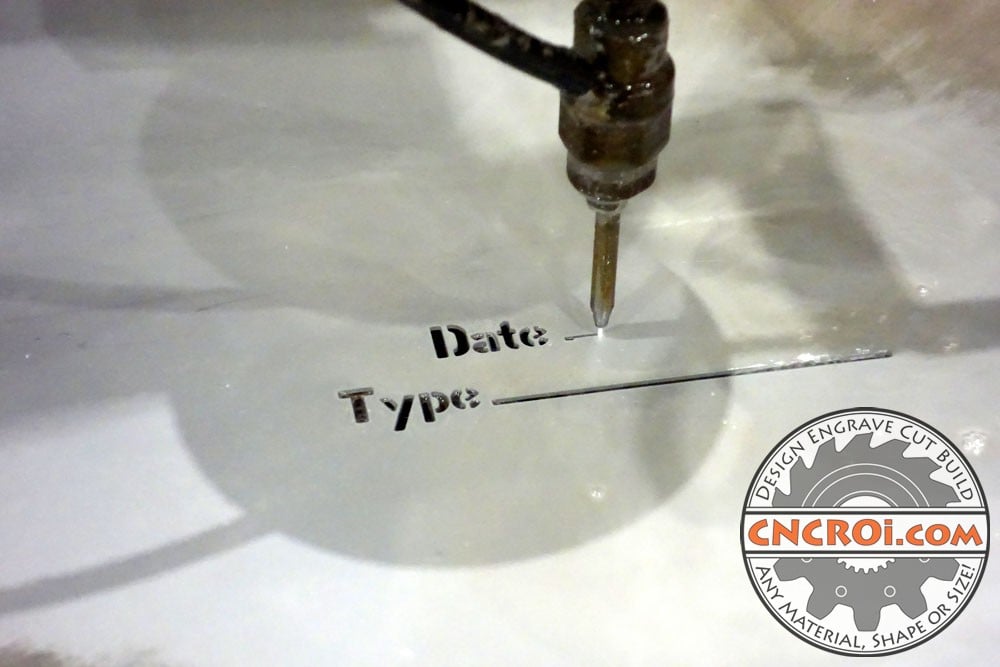

As with any other machine we employ at CNCROi.com, we always cut the inside parts before cutting out the final project because this makes sure that nothing moves during the production of said part or project, such as this custom distilling stencil.

We can do quite highly detailed work for our customers when it comes to custom stenciling, from names and signatures to ornamental fretwork, just about anything works for us if it works for you!

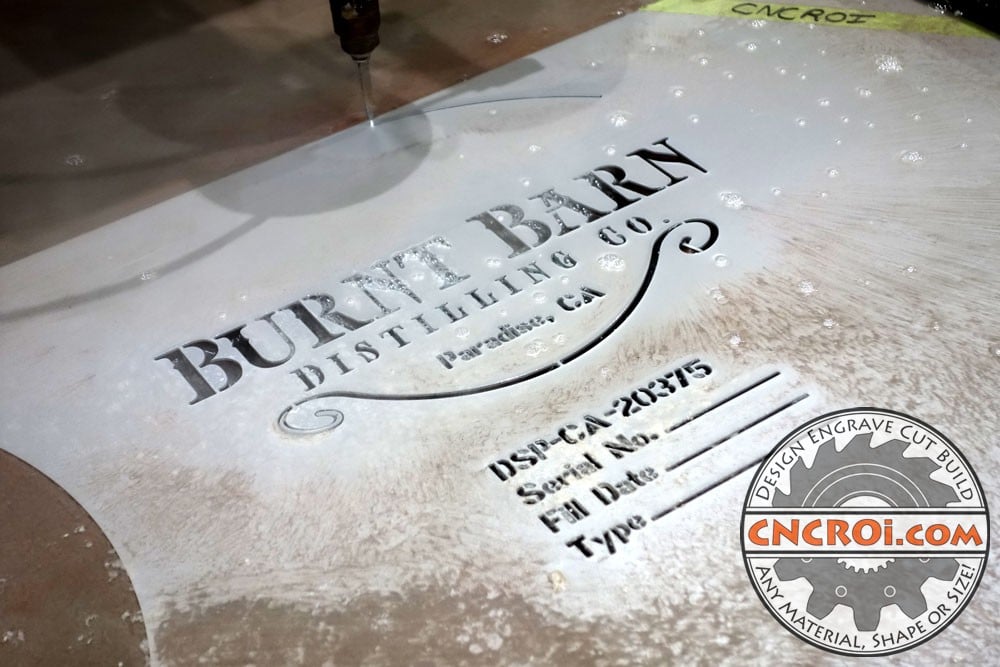

If you are wondering about how much material is abraded off the cut line, look at the image above, that spray of water and “sand” is the thickness of material that’s worn through as the head passes over the material, this is a bit thicker with plasma as the plasma has a wider area of melting and smaller with the laser as the beam is more focused.

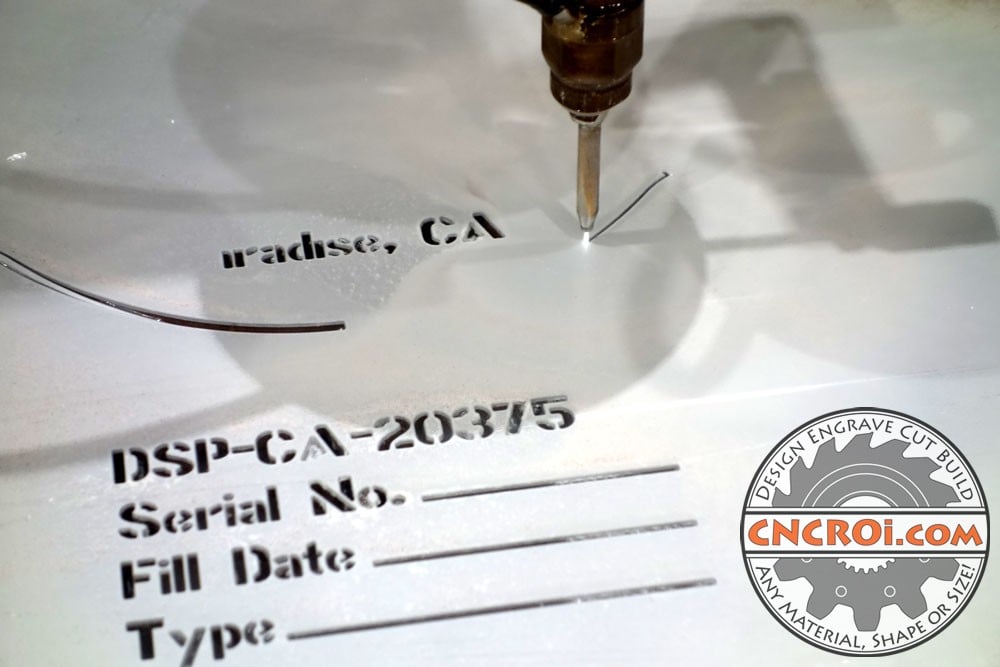

As this custom distilling stencil proceeds, you can see how the movement of the CNC is dead-on, this is the same regardless of platform, and this is where the true power of using CNC equipment comes to play at CNCROi.com.

We’ve done many jobs at CNCROi.com where we actually required the use of more than one CNC machine to complete a project, and in those cases, any mistakes along the chain of production would be irreversible… this has not happened ONCE over the past decade.

The nice thing about a stainless steel custom distilling stencil over polycarbonate or any other material for that matter is clean-up, just a pressure spray will easily remove the paint from the surface while having no affect on the underlying steel.

CNCROi.com doesn’t make many paper stencils but if that’s what you want, we can make those for you too.

Now that the waterjet is finished cutting the inside parts of the custom distilling stencil, it can now cut the perimeter of the finished stencil out so we can ship it to the customer after a little clean-up.

You have to keep in mind that there is some dross being formed on the underside during the cutting of this stencil, you get the same with the laser or plasma for that matter, just instead of a melting, it’s a pushing.

This is why I generally orbital sand both sides of stainless steel stencils, the dross is easily removed and it really does a great job cleaning-up all the surfaces of the custom distilling stencil.

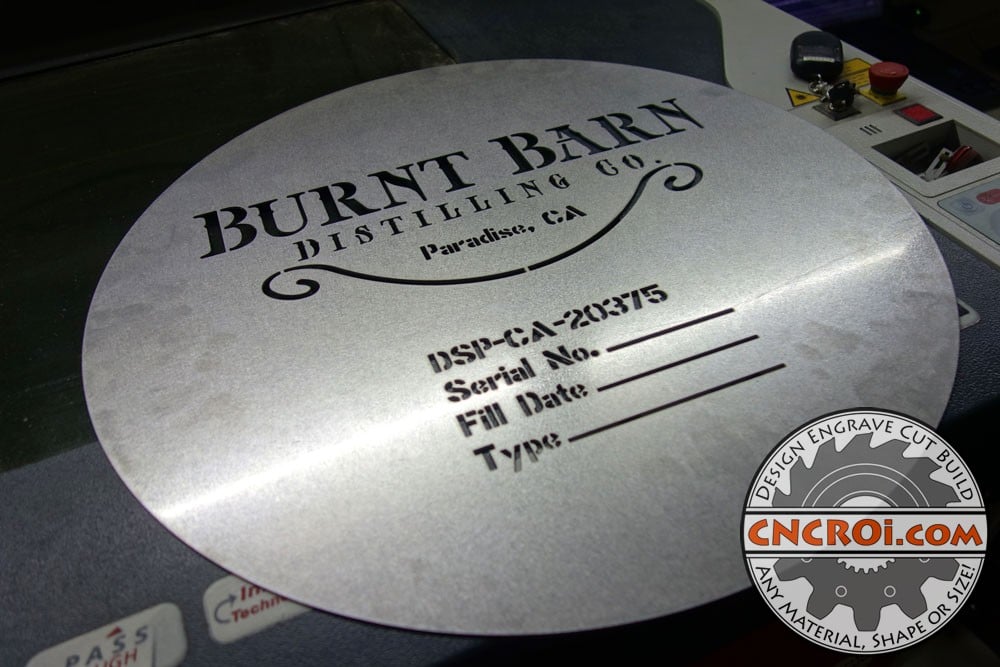

It’s quite a difference between the raw sheet of stainless steel above and the nicely sanded one below, I really like this texture for a whole bunch of reasons as scratches are easily removed if that is a concern and seeing them in the first place is a challenge as they don’t stand out.

The nice thing about plywood is that it’s easily spray painted, in this case, water painted, onto sidewalks with minimal fuss.

As it’s very difficult to properly photograph (much less videotape) stainless steel, here’s the finished custom distilling stencil at another angle at CNCROi.com.

If you need a custom distilling stencil, contact CNCROi.com right now!