Custom Metal Tray: 12 ga Mild Steel

I’ve been wanting to make a custom metal tray ever since I got my CNC plasma cutter, it’s just one of those types of projects that are useful and have A TON OF LEARNING opportunities.

https://www.youtube.com/watch?v=fj5EAbLlHQI/

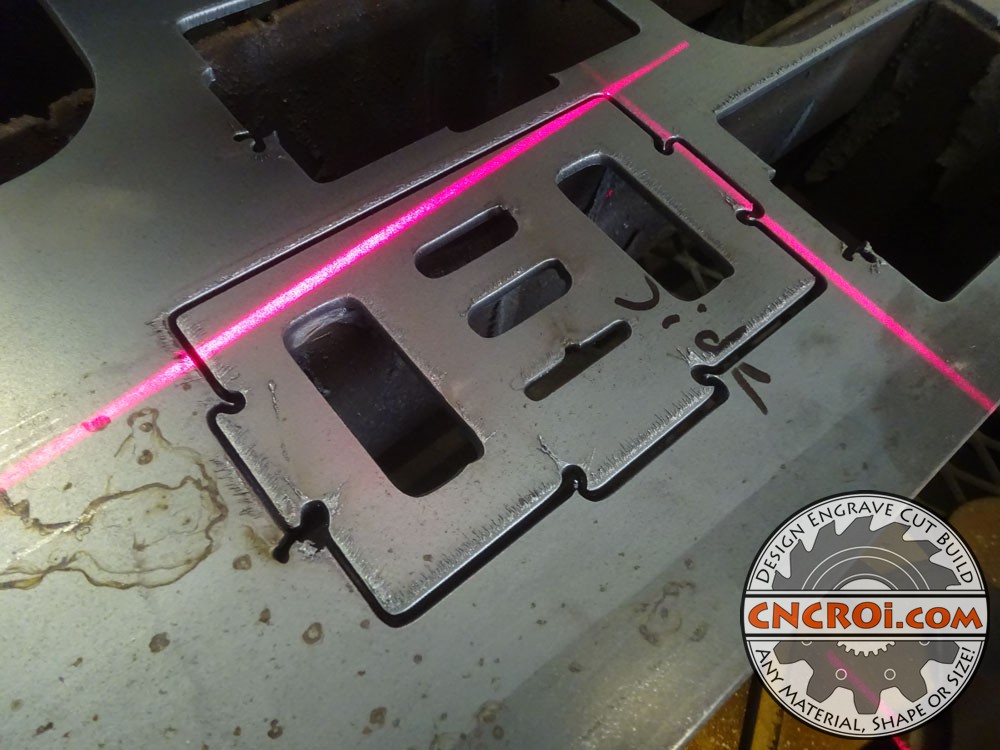

This custom metal tray was done in several steps, the first was prototyping my slot and tab approach towards design, last thing I wanted to do was make a tray that didn’t fit together because I assumed the tolerances I enjoy with wood are similar in metal.

Luckily, I did do just that because I found that I have zero give when it comes to metal tab and slot design approaches, always to a quick prototype before proceeding with the real thing!

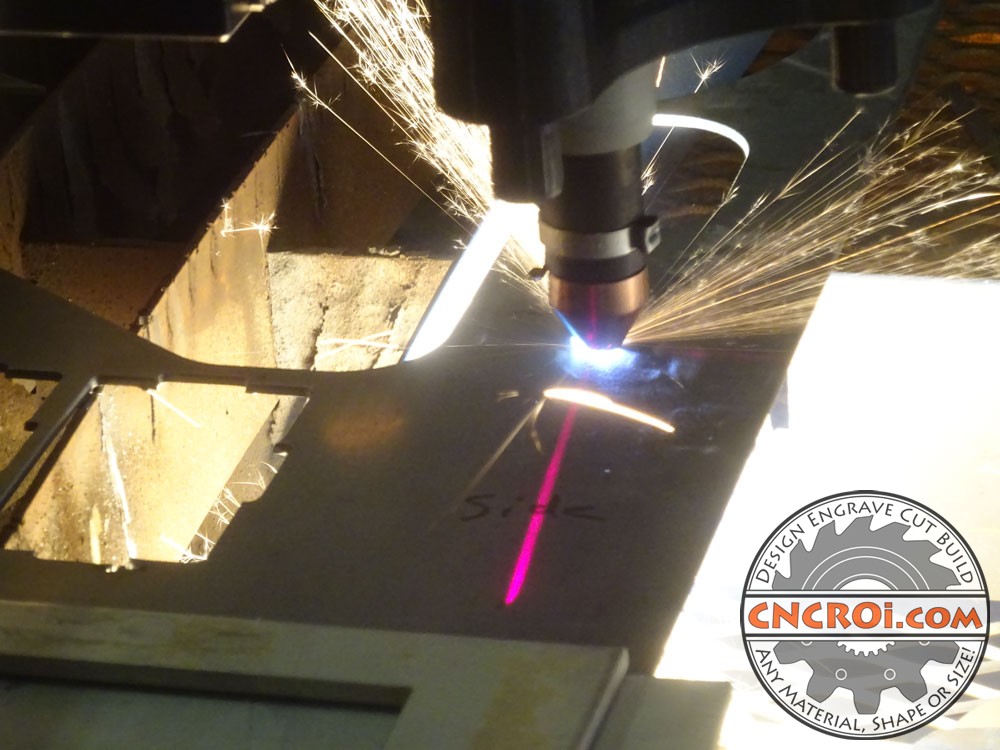

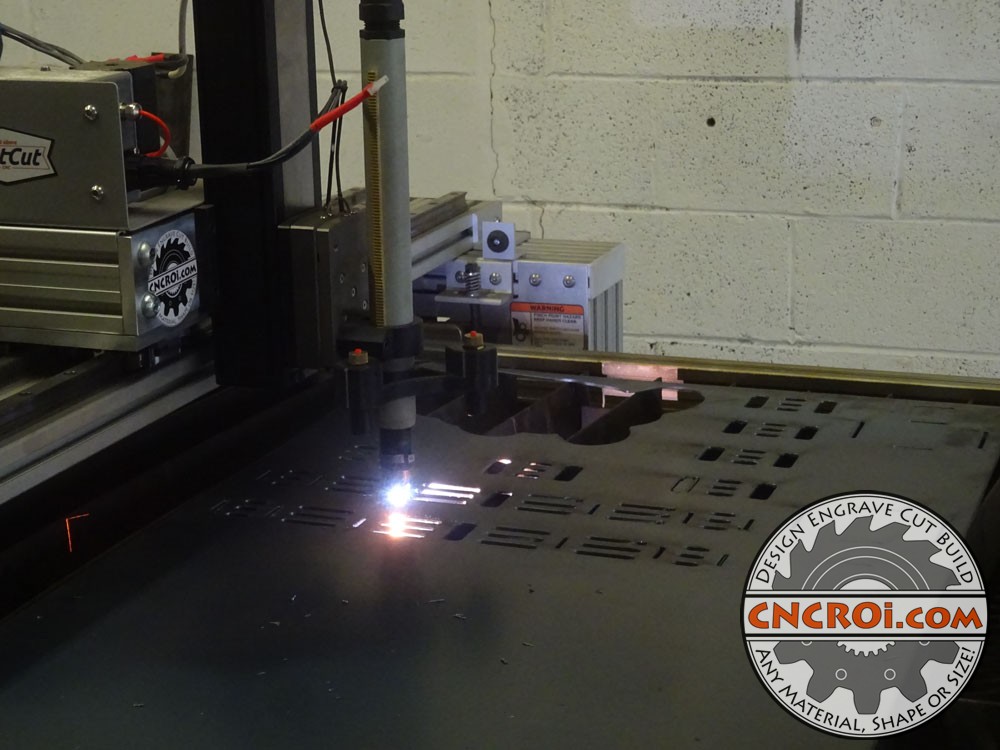

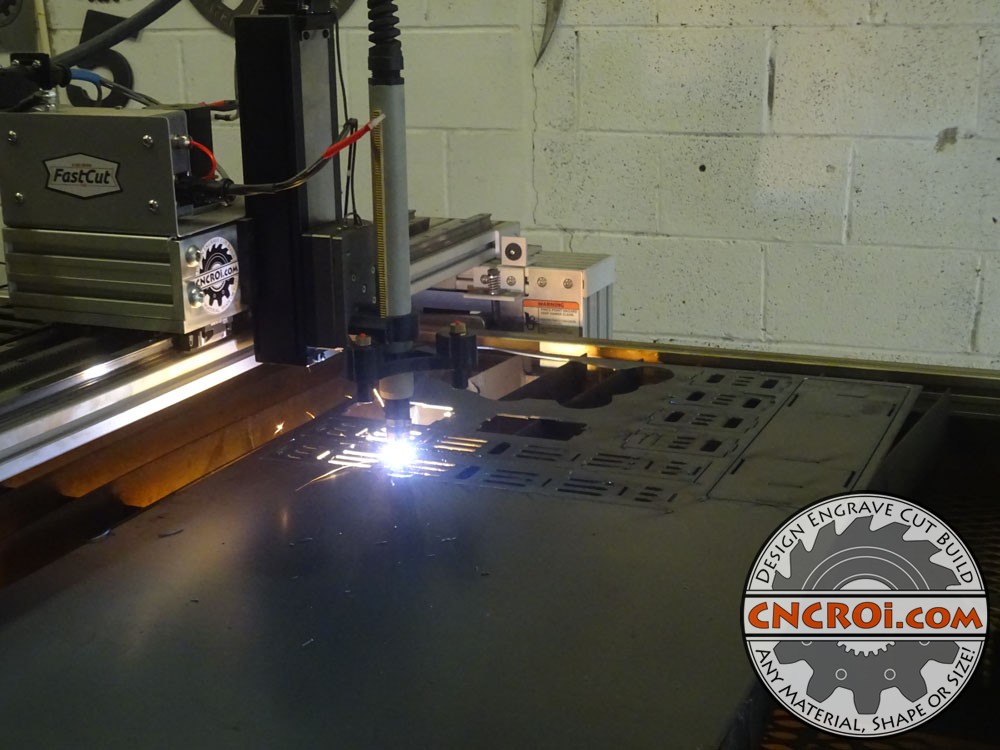

The prototyping was done using “scrap” bits of 12 ga mild steel I had in the shop, the laser pointer you see me employing makes sure when I’m cutting said pieces, I cut the whole thing, it doesn’t fall off to on an edge or something worse.

CNCROi.com has been producing custom welding tags for customers across North America for years.

https://www.youtube.com/watch?v=N4AQRyrI6CA/

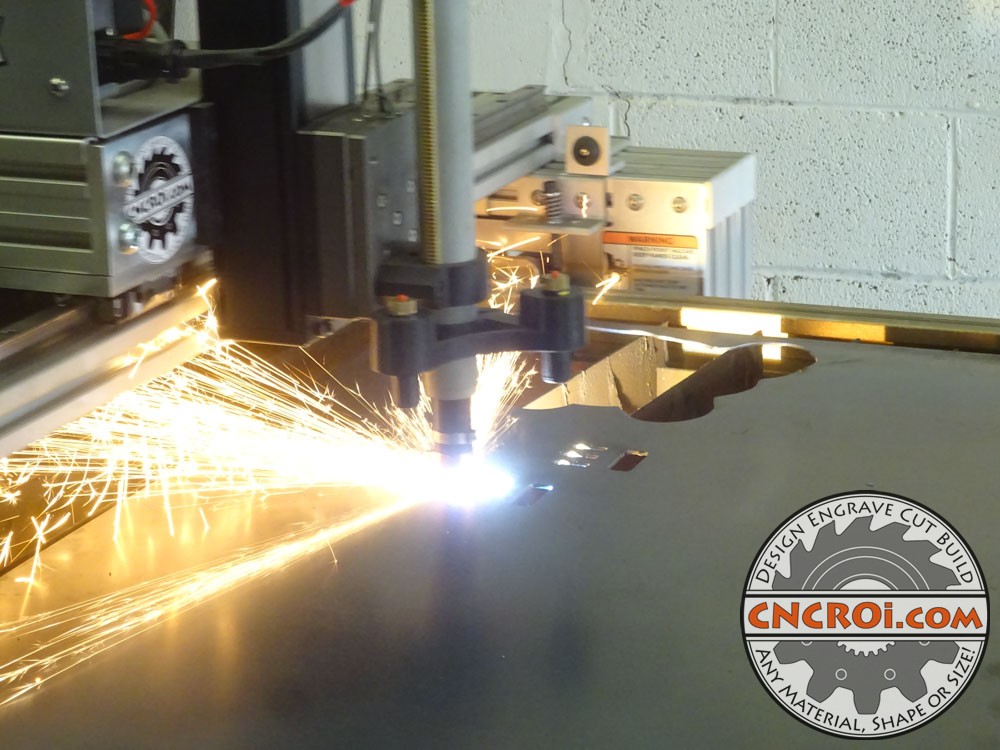

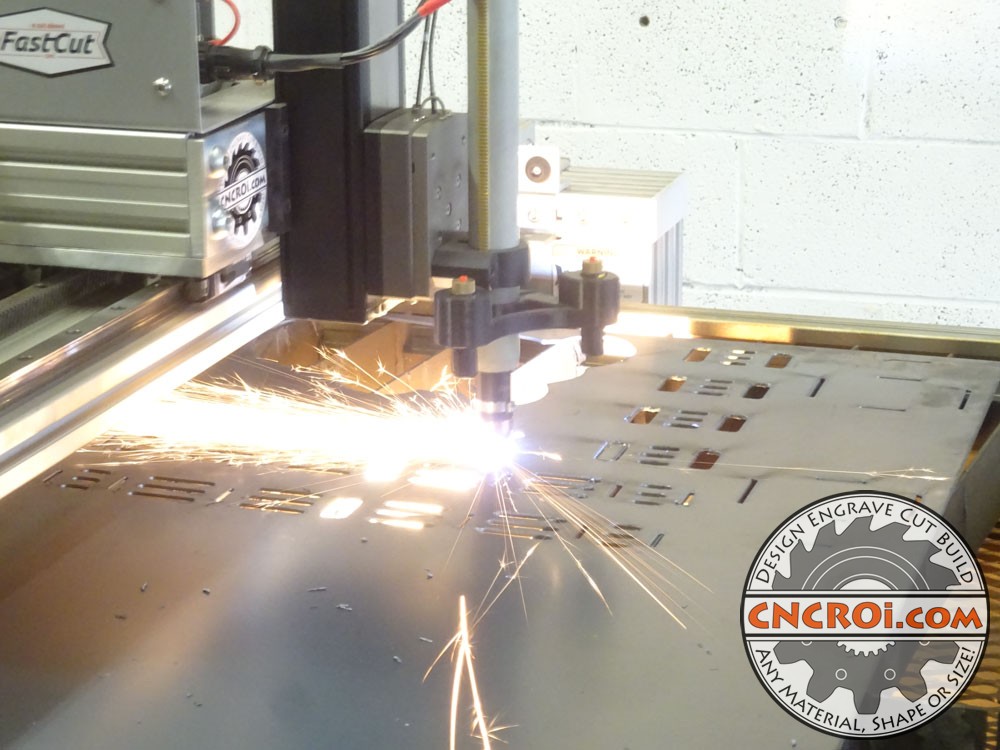

I just love CNC plasma cutting, the sparks, the smoke, the flames… it’s really an enjoyable process, it’s the same reason I got into welding and teaching myself how to do so, it’s just fun to cut and stick stuff together using electricity.

There is quite a contrast between CNC plasma cutting and CNC waterjet cutting, the plasma is way more fun and faster though you don’t get as high a resolution and it’s a wet vs a dry process.

https://www.youtube.com/watch?v=mSHumTfoLBU/

There is no perfect machine, just the optimal one given the material, budget and time constraints, even laser is fun but not as entertaining, especially for me as the operator of all these wonderful machines at CNCROi.com.

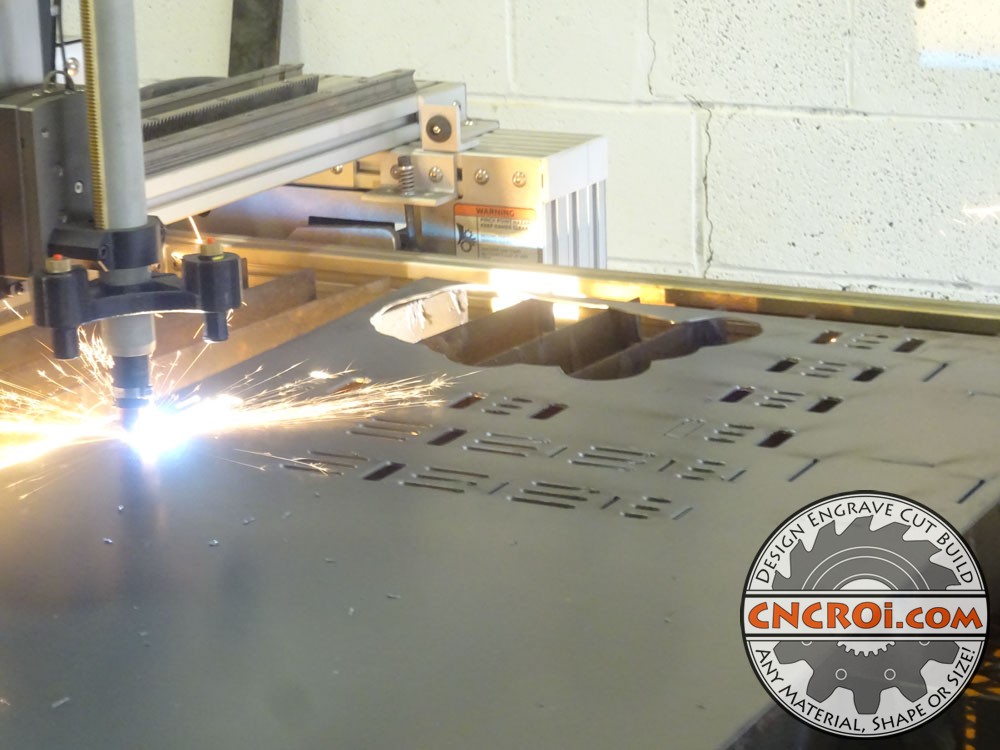

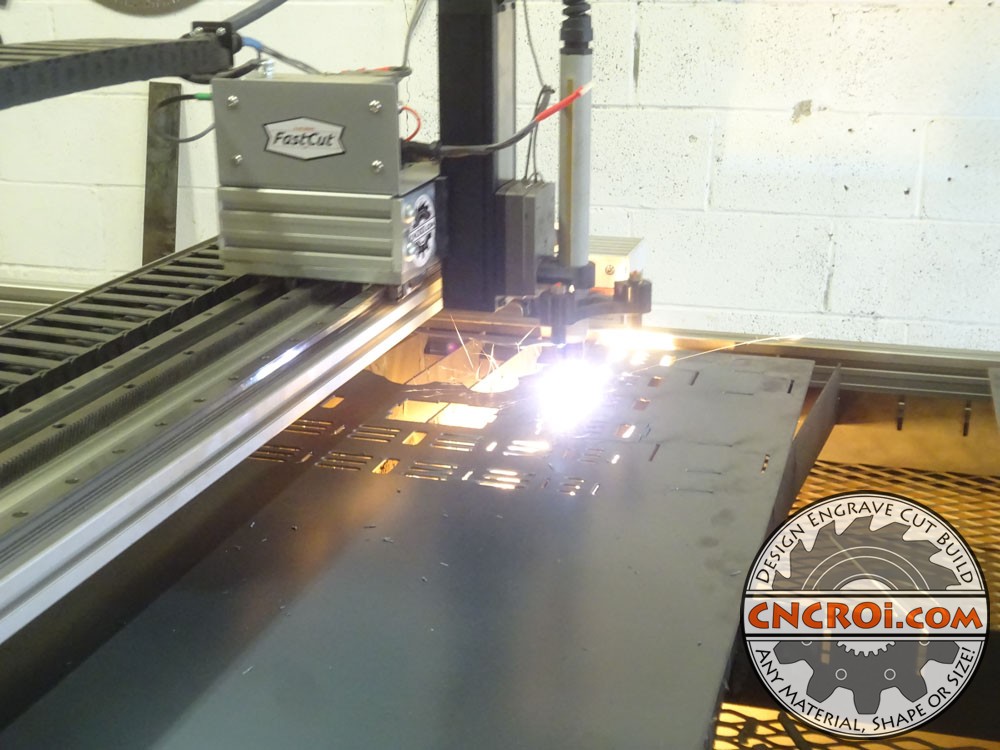

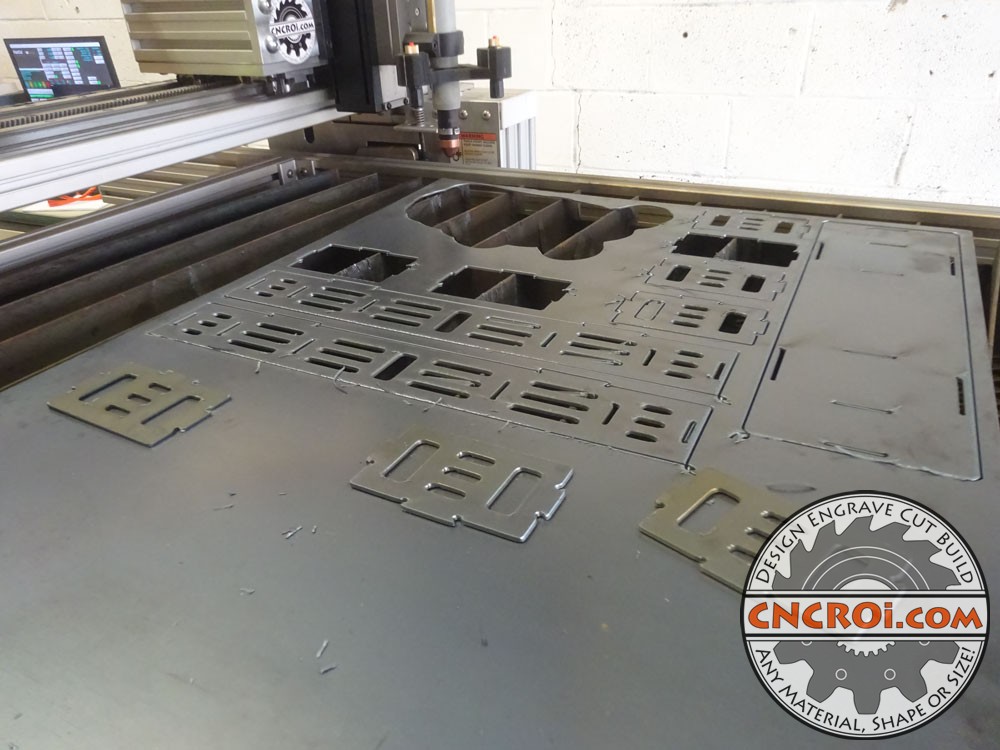

What I’m doing here for the custom metal tray is cutting out all the inside parts first, this produces a more accurate project than to do the outside then the inside, as it may move, or fall down into the CNC plasma tray.

I’m not happy with just making stuff, I like to test it out as well, here’s why CNCROi.com‘s custom welding tags are so popular, they don’t peel, crack or fade over time

https://www.youtube.com/watch?v=N4AQRyrI6CA/

CNC plasma cutting is a hot process, meaning a lot of heat is generated, you can actually see this happening when I’m cutting this sheet of 12 ga mild steel in the video, notice how the metal bends and warps slightly?

That’s the heat that’s going from hot zones (just cut) to cold zones, and thus creating slight material warping, this goes down dramatically the thicker the material I use at CNCROi.com.

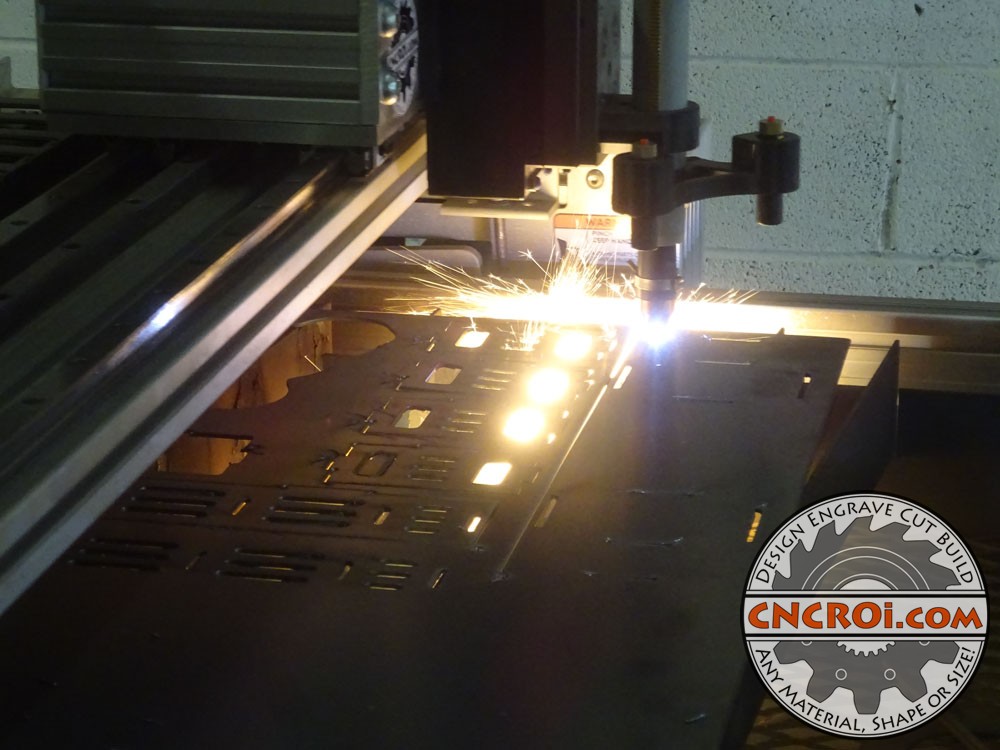

The plasma arc produced when plasma cutting metal jobs at CNCROi.com is impressive, just look at the “fire” generated and how bright it is even under the plasma cutting table – the amount of UV this also releases is insane, which is why I’m basically in welding gear when doing these types of jobs.

CNCROi.com processes a lot of metal, as a result, getting our industrial CNC plasma cutter was a no brainer, it doesn’t replace the waterjet, just augments our capabilities as we generally end-up using our laser to brand what we produce.

https://www.youtube.com/watch?v=a5JdXkAFz1M/

At CNCROi.com, I’ve designed trays using a wide variety of materials but this is the first I made using metal and planned on welding together, it’s fantastic practice for welding and a lot more fun than just sticking two random pieces together.

It doesn’t really matter the thickness when it comes to plasma cutting mild steel, the process is just as efficient cutting 1″ as it is 1/16″ material, the only real difference is when I’m cutting stainless steel, that’s a far harder material with it’s own tolerances.

The edge quality of CNCROi.com‘s CNC plama when it comes to mild steel rivals laser cutting, it’s a very consistent and smooth cut profile.

If you are wondering what the difference is between etching and annealing, we use both processes for our custom metal tags, watch the video below.

https://www.youtube.com/watch?v=EdEIRd9_c4w/

CNCROi.com generally uses 85 amps to cut 12 ga mild steel, higher amperage just means a faster cut though if needed for tighter tolerances, we can dial it down if needed.

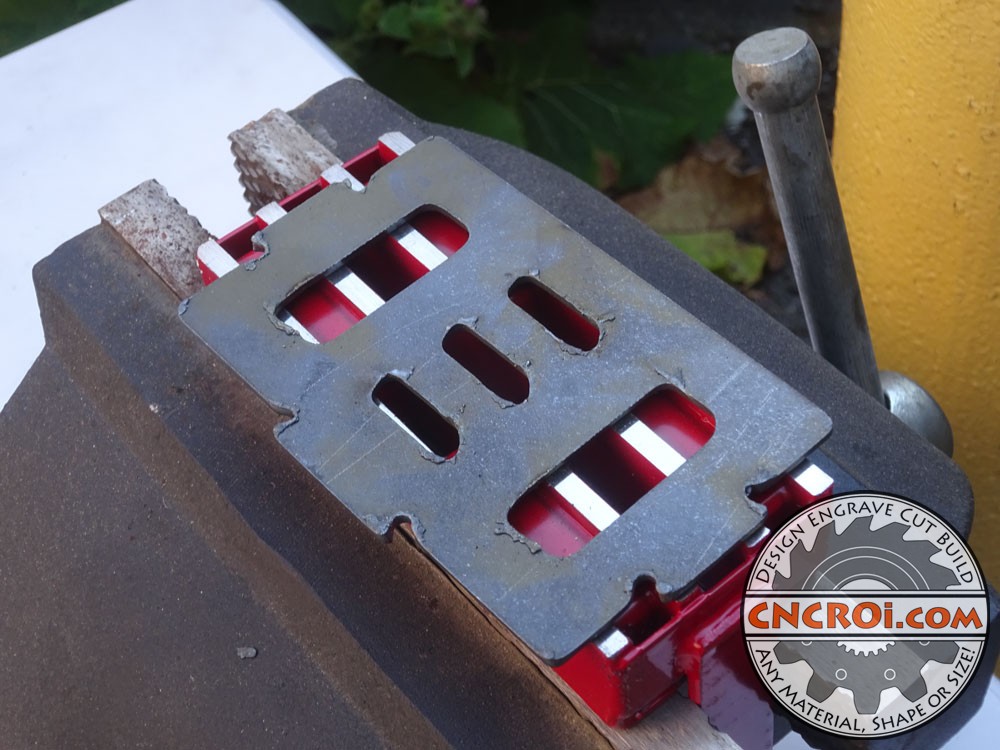

After all the CNC plasma cut parts that will make-up my custom metal tray are finished being plasma cut, it’s time to remove the minimal dross that forms along the cut surfaces, both above and below.

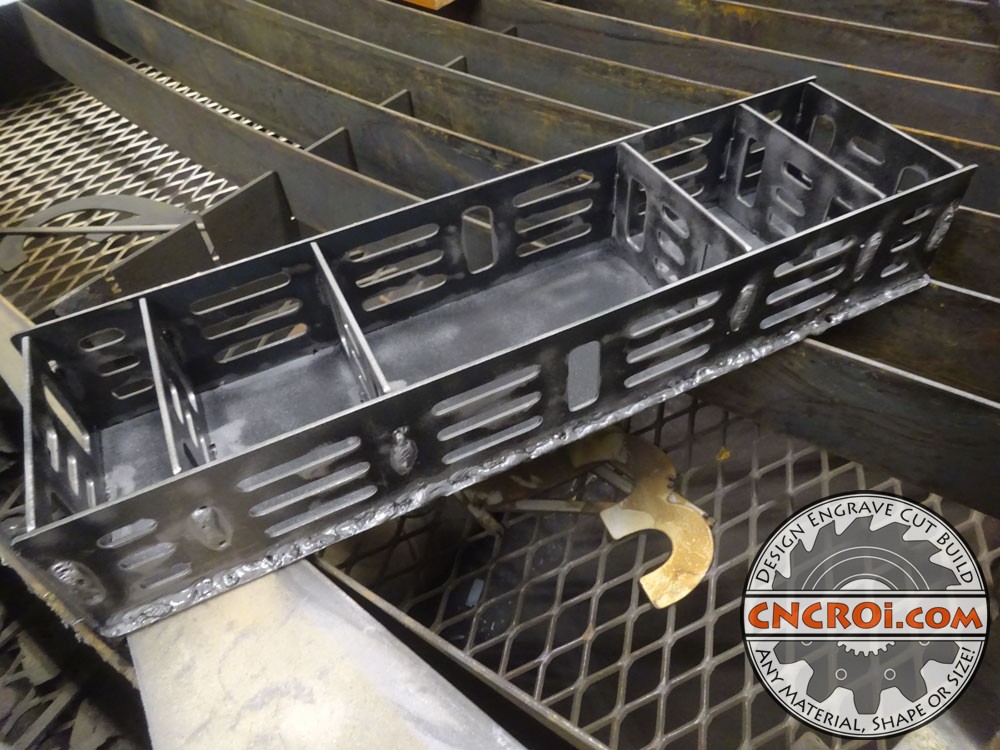

You can see the before and after of one of the small parts that make-up the dividing aspect of my custom metal tray, the holes were designed to give it a more airy look and it also cuts down dramatically on the weight.

Regardless of the process, there is always some clean-up required, waterjet pushes material while abrading it, and plasma makes it molten which pools at the bottom.

https://www.youtube.com/watch?v=ObgxYj3yoLM/

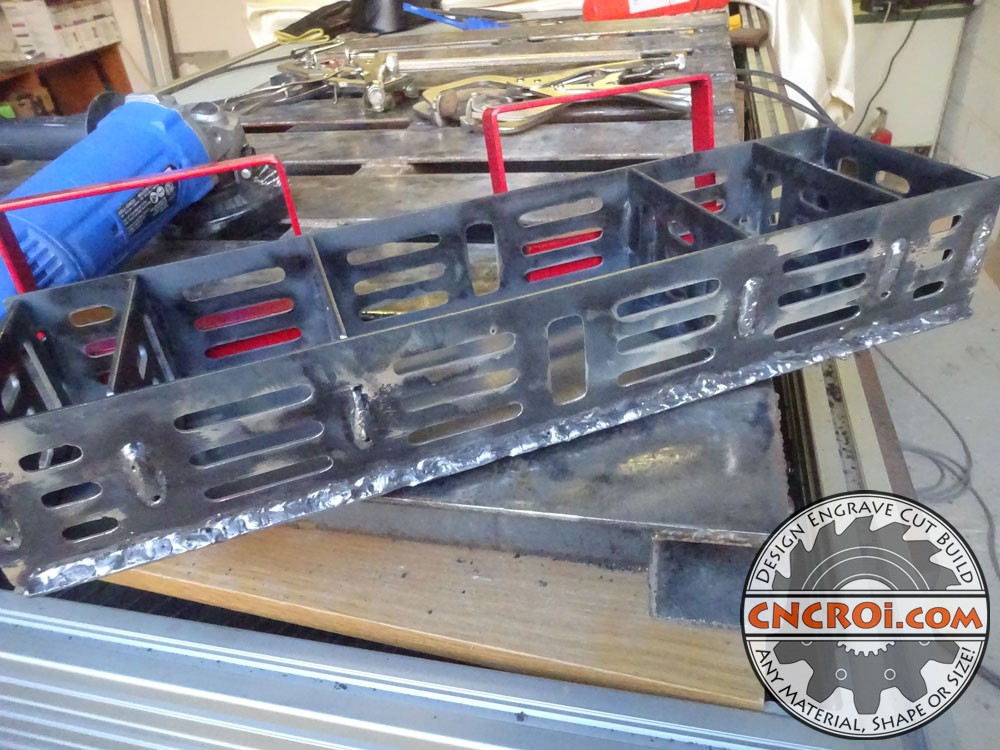

After all the parts are angle ground clean at CNCROi.com, again, the work is minimal, it’s time to take inventory of all the parts, it’s a simple build process, all the dividers are the same and the bottom holds the left and right side of the sides, which are also the same design.

Doing a dry fit, everything fits well together, I could technically leave this as/is and it would perform it’s function great but this is as much a tolerance practice job as a welding one, and that’s what I look forward to doing next for this custom metal tray.

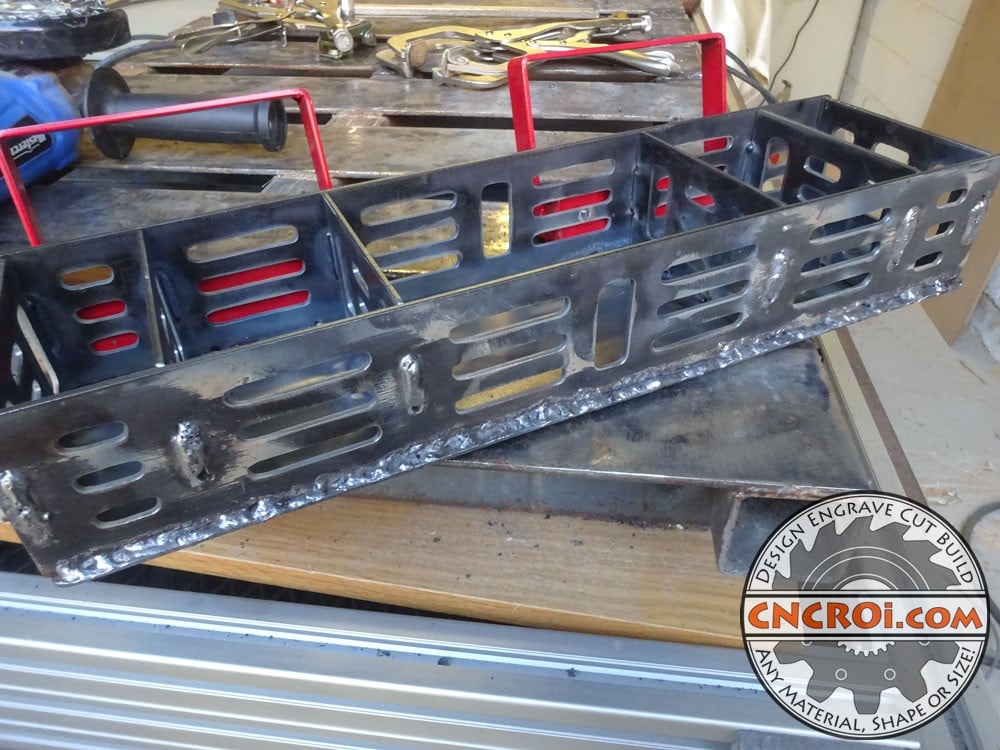

Just to hold it somewhat together while I do the stick welding on this custom metal tray using 7018AC, I MIG tack welded a few areas to make my job under the hood easier.

This included tack welding the dividers along the bottom, I think my welds were the best under hear because it was a flat surface and the tabs melted wonderfully with the surrounding material.

Probably one of my more fun jobs at CNCROi.com was etching a samurai on some 316 stainless steel, running a custom fabrication shop doesn’t need to be boring!

https://www.youtube.com/watch?v=QpmehwehCt4/

One thing I completely forgot to do was clean the MIG tack welds before doing the stick welding, thus there was some porosity and other issues with the finished look, these haven’t been cleaned-up but you can see the issues right there, I also don’t use gas with my MIG so that produced a lot more splatter and contamination.

I took my time on the underside stick welding all the elements together but when it came to stick welding the bottom plate to the sides, I was so scared of burning through the 12 ga material, I went way too fast.

The tabs all look alright to me, these might not be professional welds but I’m getting better at CNCROi.com with personal projects like these to hone my skills, again, the welds haven’t been cleaned-up yet.

CNCROi.com also produces custom valve tags and other metal accessories for our customers, if it’s metal, and if it needs to be cut and or branded, we can do it!

https://www.youtube.com/watch?v=uuzjVpAT-Oo/

Now for the sides of this custom metal tray I cut at CNCROi.com, way too fast, for some reason I forgot to also weld the sides to the bottom plate, which is the entire purpose of doing this welding to begin with, not sure what happened but just fear of going through it, which I’ve found was completely unfounded, made me not take my time with these welds and pull the puddle a lot faster than it needed to for proper fusion.

You can see the welding here is look very rough, no worries, I’m not doing structural work or pipeline jobs so although this will not fall apart anyways, nobody can be harmed if it does.

I like to make props and other fun little jobs in the shop to hone my skills, the most recent was my custom BBQ grill for my fire pit.

https://www.youtube.com/watch?v=StBesadXpkw/

and of course, no shop is complete without a Klingon Bat’leth!

https://www.youtube.com/watch?v=W1eJ0VT8wWM/

Again, same issue on the other side, moving way too fast – the important part of all this learning is LEARNING from the mistakes I did and not doing them again, so in my book, this has already been a fantastic course in practical welding for me at CNCROi.com.

I actually enrolled myself in a welding course a few months back, it had over 10 hours of welding a week for 3 months straight, of course, right when the theory was done and it was time to move to practical… the epidemic hit and I never got the opportunity to weld with a teacher’s supervision – so I’m pushing through myself.

Other uses around the house for metal fabrication include an extremely sturdy towel holder for my Son who was born June 2nd of this year.

https://www.youtube.com/watch?v=6QrDGM8_G6U/

After all that fun welding and cleaning-up my welds, I decided to have a bit more fun and booted-up the CNCROi.com industrial sand blaster to see what it would look like after this process.

I have to admit, the welds look way better after sand blasting them, it gets rid of the shine and removes some of the mill scale on my custom metal tray which causes everything to blend far nicer aesthetically.

You can see the finished CNC plasma cut custom metal tray I designed at CNCROi.com and will be using in my shop for eons to come, really fun job and a great reminder at how much more I need to learn!

I already have my next fun job lined-up to proceed with more welding practice, this is far more enjoyable a process than just putting practice welding plates together… need something custom cut? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=Ys8QC5vxIkM/