Custom Negative Mold: MDF Routering

CNCROi.com is going to make a custom negative mold using our Thermwood CNC router, this is a scaled-down test or prototype before going full-scale.

Custom negative molds are essential tools used in the manufacturing process to create a wide range of products, they can literally be made out of anything, in this case, CNCROi.com made it using MDF as a test bed to see if the resin the customer wishes to use will work at a larger scale, meaning that once the resin cures, then the customer has a custom resin mold, throwing away the MDF as it has now served it’s purpose.

The reason for a custom negative mold in this specific case is because doing a positive mold using resin or aluminium is cost-prohibitive and wasteful as we’d be carving out a solid block of resin or aluminium and discarding most of it, this way, the customer can pour just enough resin to make the mold and the tooling is also dramatically less for MDF than hard cast resin.

The solid block of MDF here is glued together as MDF of this thickness isn’t available, and MDF glues very easily and bonds very well together once cured.

If you are wondering about the flexibility of design capable using our router, here’s an earlier prototype we made to verify a few things.

A custom negative mold is a tool used to create a part or product with a specific shape or design, by the way, it’s called a negative mold because it produces a part or product by creating a cavity in the shape of the desired object.

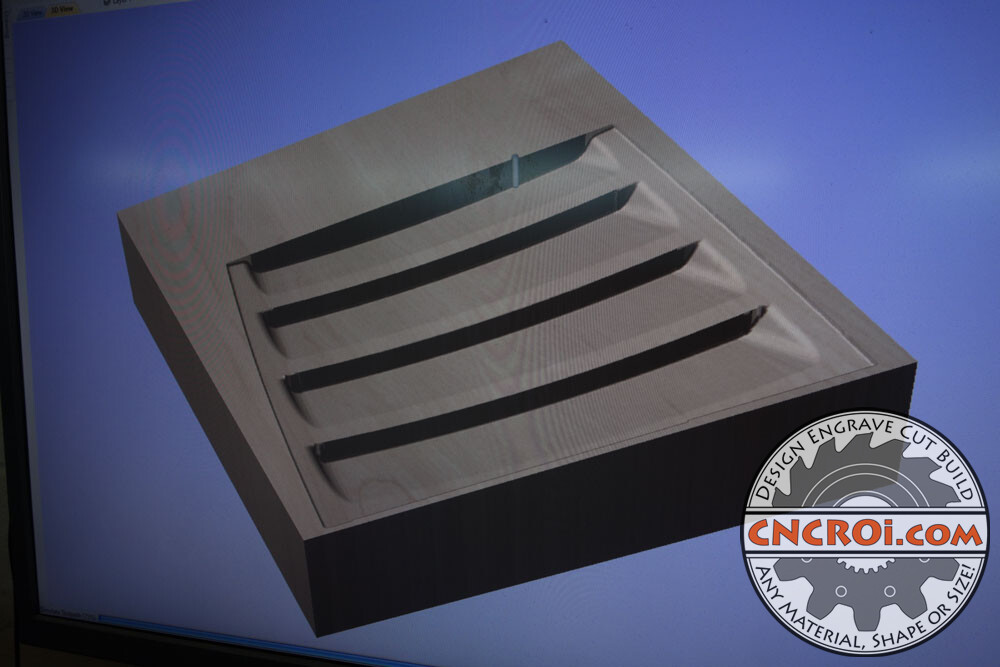

Before any dust is created at CNCROi.com, there is a virtual mold done, this gives us an idea of what the finished product will look like, the customer will be sanding this before pouring the resin so any roughness will be taken care of, which means there is less sanding on the resultant positive mold that this negative mold will produce.

The material that is used to create the final product is poured into the negative mold and allowed to cure, taking on the shape of the mold, so the cleaner the negative, the less work is required on the positive, which is then used to produce a wide range of products, including automotive parts, medical devices, consumer products, and more.

For smaller molds, CNCROi.com can also make them using our CNC laser, it all depends on the application you plan on using your mold for.

One of the main benefits of using custom negative molds is that they allow manufacturers to create complex parts and products with high precision and accuracy as the molds can be customized to fit the exact shape and design of the desired part, ensuring that the final product is of high quality and meets the specific requirements of the application.

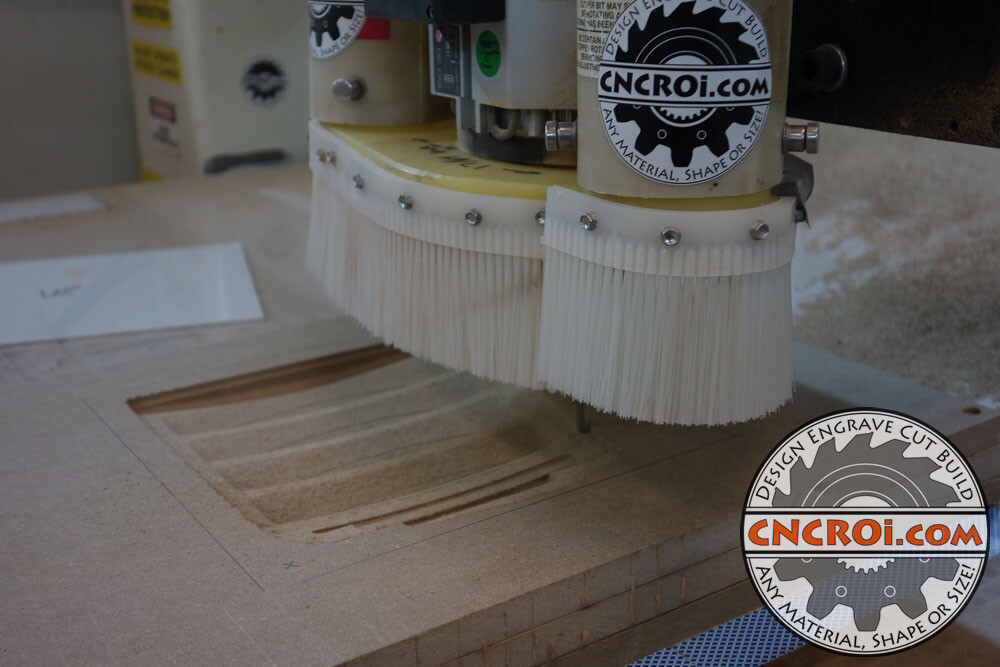

Currently there are two steps involved with carving out this custom negative mold though based on increasing experience, this will be augmented to have more for a quicker result, the first is a roughing bit which clears out most of the material that will become the mold, then a very fine finishing bit which will then produce a clean result for the CNCROi.com customer to then sand in preparation for their resin.

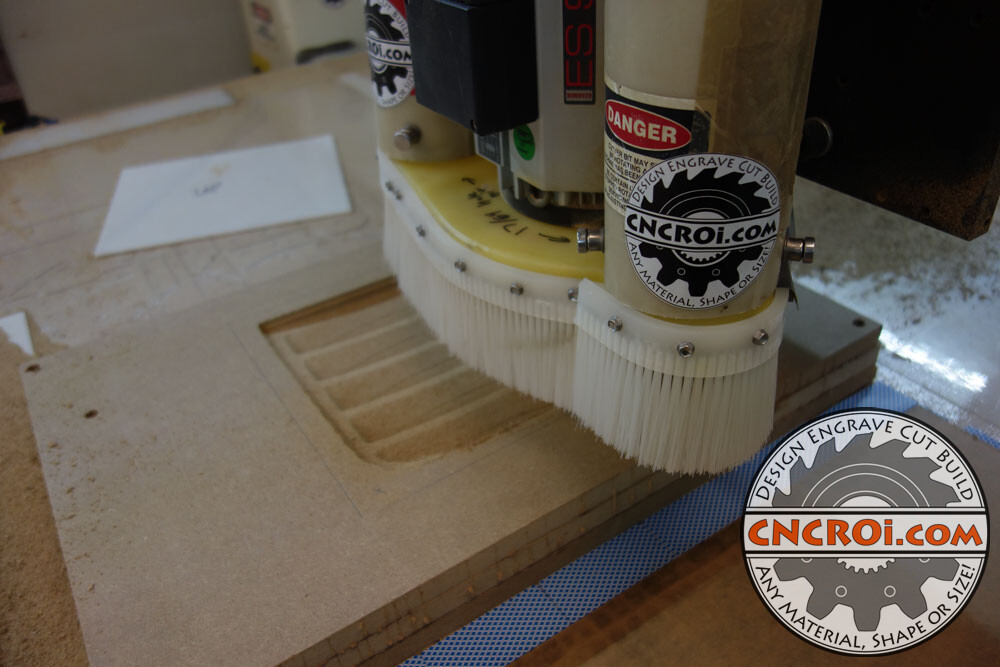

As this is a test or prototype, we aren’t too concerned about the look of this MDF, it has some sort of stain as you can see on the surface but this doesn’t matter, for the actual product, we’d use a fresh sheet and flatten it parallel at full size at CNCROi.com.

Another benefit of using custom negative molds is that they allow for the production of parts and products in large quantities at an increasing lower cost per unit price as once a custom negative mold has been created, it can be used to produce many identical parts or products quickly and efficiently.

If you are looking for molds to make using cement or concrete, CNCROi.com can also produce that for you using Corian.

The mass production capability of a custom negative mold is especially important for industries that require high-volume production, such as the automotive and consumer goods industries but in this case, we are dealing with not enough volumes that would require the investment in a custom aluminium mold, so this is why MDF and resin are being used as a substitute, if the product does well, then CNCROi.com can make the actual aluminium mold for them as the product has proven itself.

Custom negative molds also allow for greater flexibility in the manufacturing process, manufacturers can easily switch between different parts or products without the need to invest in new equipment, this flexibility is particularly useful for small or medium-sized businesses that need to adapt to changing market demands quickly.

You can now see CNCROi.com‘s CNC router is going back over the cleared areas and turning a rough carving into a very fine one, notice the dramatic decrease in chip size, we are essentially shaving the MDF left from the initial roughing bit in order to increase the resolution of the overall negative mold.

CNCROi.com also has a smaller CNC router which does a wonderful job making carvings, big or small, we can do it all.

Custom negative molds can help to reduce production costs since the molds are designed to fit the exact shape and design of the desired part, there is less material waste and fewer production defects leading to significant cost savings for manufacturers in terms of both time and money.

You’ll notice this custom negative mold is extremely small considering how big our Thermwood CNC router is, the machine we are using for this has a 5ft x 10 ft table, and unlike most routers, the gantry is static, which means vibrations are kept at an absolute minimum, producing very clean results for customers.

Having a solid machine with absolute positioning means that, worse comes to worse, we get a power failure or whatever, the machine always knows exactly where it is, so it can just continue from where it left-off rather than CNCROi.com throwing away the mold and starting all over again.

This custom negative mold is now finished, you can see a layer of glue after the carving that’s bowing, this is an optical illusion as it’s the mold carving that’s bowing and not the base MDF.

Mold can be made by CNCROi.com however complex or detailed you require, the only real limitations we (like any other manufacturer) have to content with is depth as the longer the bit, the more prone it is to breaking, producing backlash and vibrations.

As a result, when it comes to negative or positive molds, there really aren’t any limitations other than bit length, so sometimes CNCROi.com has to make multi-layered molds, which I’ll show in a future video, in order to compensate for bit lengths.

I’m very happy with how this mold came-out, it really shows in the final product just how powerful having a crazy solid 12 000 pound CNC router is when it comes to producing custom products for our customers without having to contend with vibrations or other issues that can cause defects in production.

Need a custom negative mold? Contact CNCROi.com right now!