Custom Steel Plaques: 12 ga 304SS

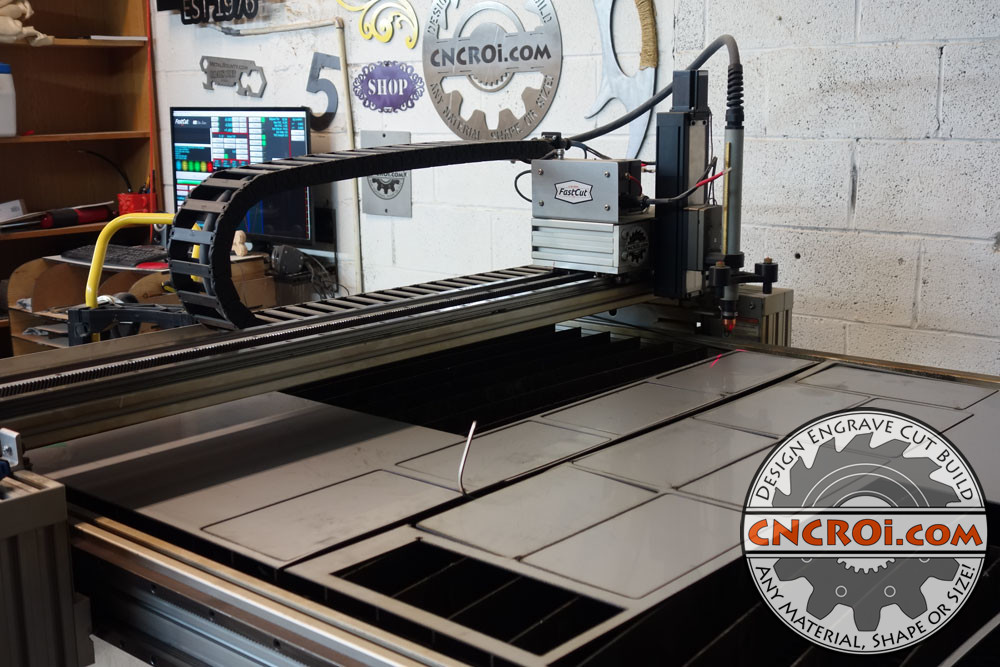

Making custom steel plaques has become a routine task at CNCROi.com, more often than not, they head right to one of our two fiber laser sources (galvo or gantry) for permanent branding but I thought I’d do a video just showing the first half of the process for a change.

https://www.youtube.com/watch?v=JTtxsW0XNbQ/

For this specific project, we are making the custom steel plaques using 12 ga (3 mm or 1/8″ thick) 304 stainless steel, after this run, we are doing another using 316 stainless steel at the same spec which will be shown in a future video.

I’m starting to develop a lot of very good scrap pieces so this was a fantastic run to use them up to send the rest of the metal to the metal recyclers down the street from the CNCROi.com shop.

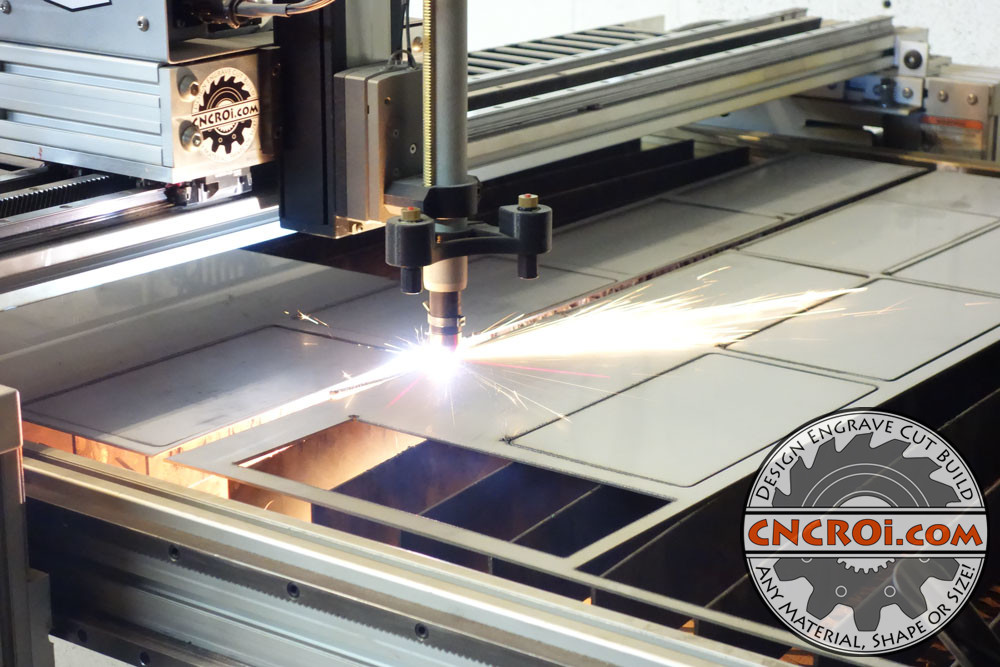

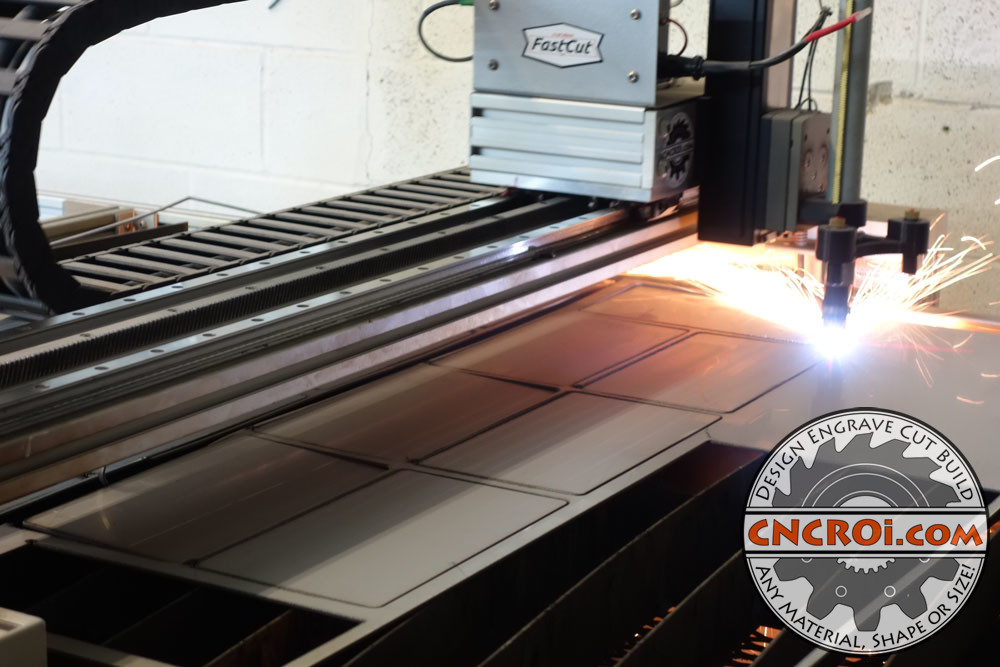

Bright lights, sparks, fire… what’s not to love about CNC plasma cutting these custom steel plaques out… I’d seriously do this kind of stuff all day, it’s just so much fun!

Ever since Simon came into the world, it’s been tough trying to keep to a tight schedule with these blogs, doing jobs is no problem, but having a one year old kid to take care of who loves hitting the keyboard and can’t come to the shop means I’m spending a lot more time with him and a lot less editing these posts out.

https://www.youtube.com/watch?v=6QrDGM8_G6U/

It’s quite a balance managing and making in a rapidly growing company while having other duties to attend to at the same time, lots of long nights!

These type of custom steel plaques are very straight forward with well established steps, it’s the video editing and photography that surprisingly adds a lot of time to a job, but I’m getting better all the time and in less than a year, another massive step forward for CNCROi.com will be occurring.

These custom steel plaques are part of a much bigger job that CNCROi.com was commissioned to do, the specs were basically a rectangle with rounded corners (for safety) and two holes, one each side, for easy fixation.

CNCROi.com can also mix and match materials however you like, here’s a wall clock I made for the shop.

https://www.youtube.com/watch?v=vqiPA6lVGN0/

Of course, if you wanted custom steel plaques using thicker material, a different material, different shape or hole size or position, that’s no problem for CNCROi.com.

What I really enjoy about plasma cutting is how similar the technology is to the other CNC machines I have in the shop, like the laser, there is never any contact between the head and the material during the cutting process.

Like the CNC router, I produce a diameter of roughly 1/8″ during the piercing process that initiates the arc which then allows for the cut through of these custom steel plaques.

There is no event that can’t require a little stainless steel love.

https://www.youtube.com/watch?v=3Tkn8fuTcCM/

I’ve done a lot of waterjet cutting, and to see just how fast and efficient plasma cutting is by comparison still blows my mind, of course, it isn’t a replacement for other technologies, each have their plus and minus in the grand scheme of things.

The sparks you see is the instant vaporization of the stainless steel that the plasma is able to achieve, this stuff gets and goes everywhere in the shop, from the furnace to fans to the floor.

For these custom steel plaques, a few steps are required before they are ready for the fiber laser etching using our gantry system, the first is what you see now, the plasma cutting from sheet to the design the customer requires for their project.

Custom wall ornaments is also a fantastically wonderful use of metal that CNCROi.com can cut for you!

https://www.youtube.com/watch?v=jaKn8PzDg1E/

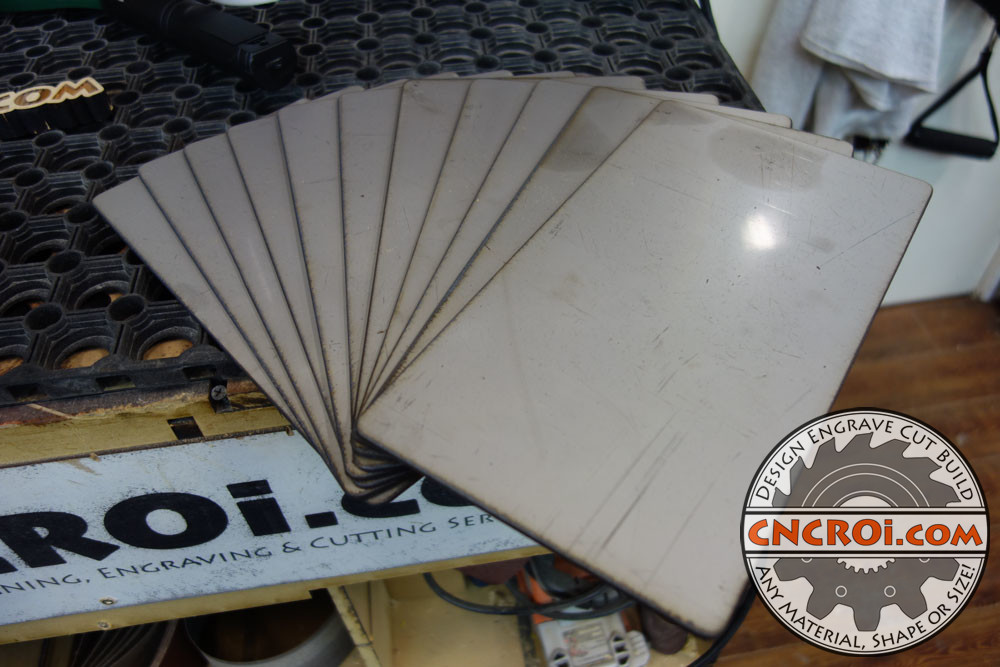

You’ll notice that the holes on these custom steel plaques aren’t produced by the plasma cutter for this specific job, that’s because they are too small, ever since I got my awesome drill press, making holes in metal is such a pleasure that I use any excuse I can to manually make holes if at all possible at CNCROi.com.

You can see in the image below that I had a great use of material in this small production run on scrap stainless steel I had in the shop laying around for a while.

Here’s what the finished custom steel plaques look like straight off the plasma cutter before any cleaning or hole production is done.

I’ve had the honor to make a lot of custom stainless steel memorials, nothing beats this material for this application!

https://www.youtube.com/watch?v=B0463p1ovBw/

As for holes, again, just so much fun – having the right equipment makes jobs that use to be frustrating to one that’s easy – this is coming from a guy who used a greatly underpowered and borderline junk drill press for years that would actually bend under the pressure of drilling holes in stainless steel.

My new drill press rarely goes over 10% load making holes in stainless steel, my old drill press would actually stop if I pressed too hard!

After holes are put into the custom steel plaques, the next step is angle grinding off the metal shards on the back and then sanding both sides with the orbital, you can see the dramatic change in the picture below.

Finally, the next step for these custom steel plaques is to fiber etch them, due to NDA, you won’t be seeing this being done for this specific job at CNCROi.com.

Need custom steel plaques? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=IUZfyH1IcYI/