Stainless Steel House Numbers: 304 Stainless Steel

Stainless steel house numbers, yep, CNCROi.com makes that too, out of any grade you want, 304 is the most effective but if you want a more corrosive resistant 316 stainless steel house numbers (or signage), no problem!

https://www.youtube.com/watch?v=37mNZz3GvUA/

The major advantage of stainless steel is that it doesn’t need to be sealed, as it’s a lot more corrosion resistant than mild steel, which will rust pretty quickly outside in the elements.

When it comes to custom house number signage, CNCROi.com can also make them out of wood, using a variety of different processes.

https://www.youtube.com/watch?v=2ECENTcf-eY/

I always tell CNCROi.com customers that if they plan on painting the steel house numbers we produce for them, go with mild steel, it’s more cost effective, no point paying a premium for a material that will be hidden under a layer of paint.

If you really like the shinny results of stainless steel, it can also be achieved using mild steel, but needs to be sealed, again, using stainless steel, it’s good as/is for your own custom stainless steel house number sign.

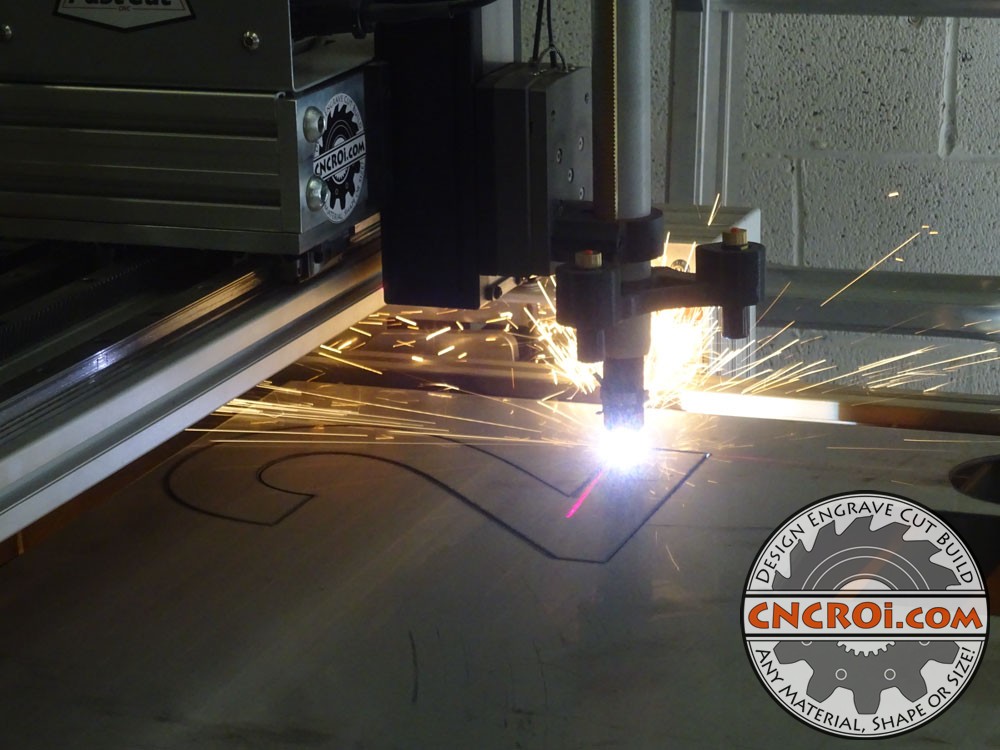

CNCROi.com has multiple ways of cutting metal, CNC waterjet through CNC plasma and CNC laser, each has their optimal production envelope where one machine and process is advantaged by the other.

Another material that you may wish to consider for custom house numbers is Corian, it’s a compressed plastic that’s easily paint filled.

https://www.youtube.com/watch?v=lzScZjA4v1I/

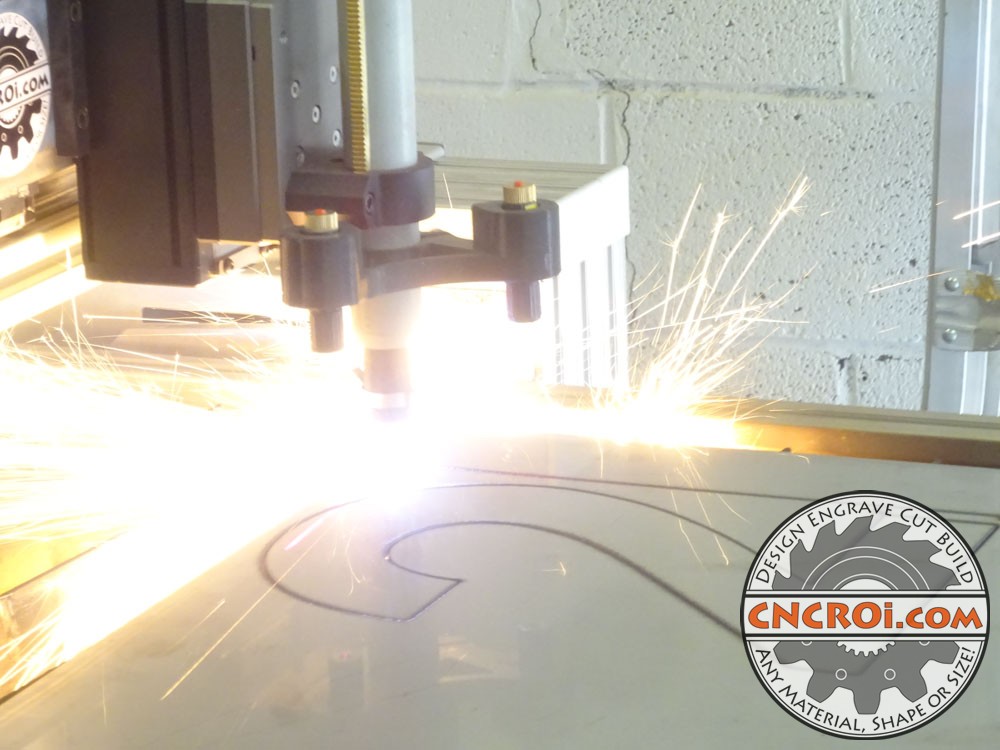

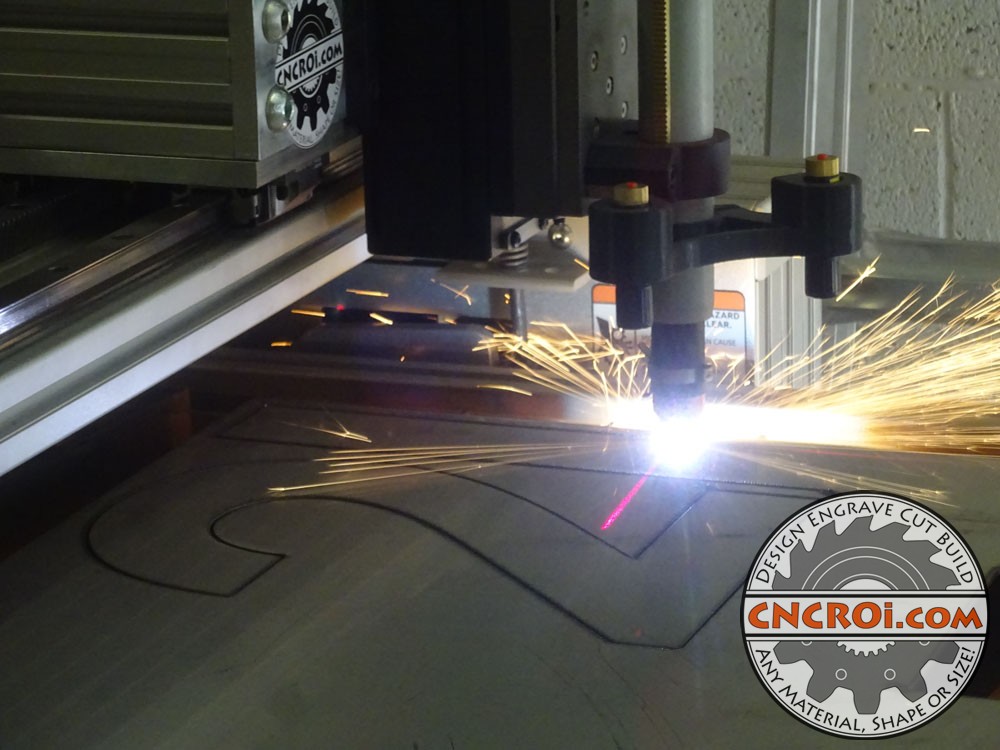

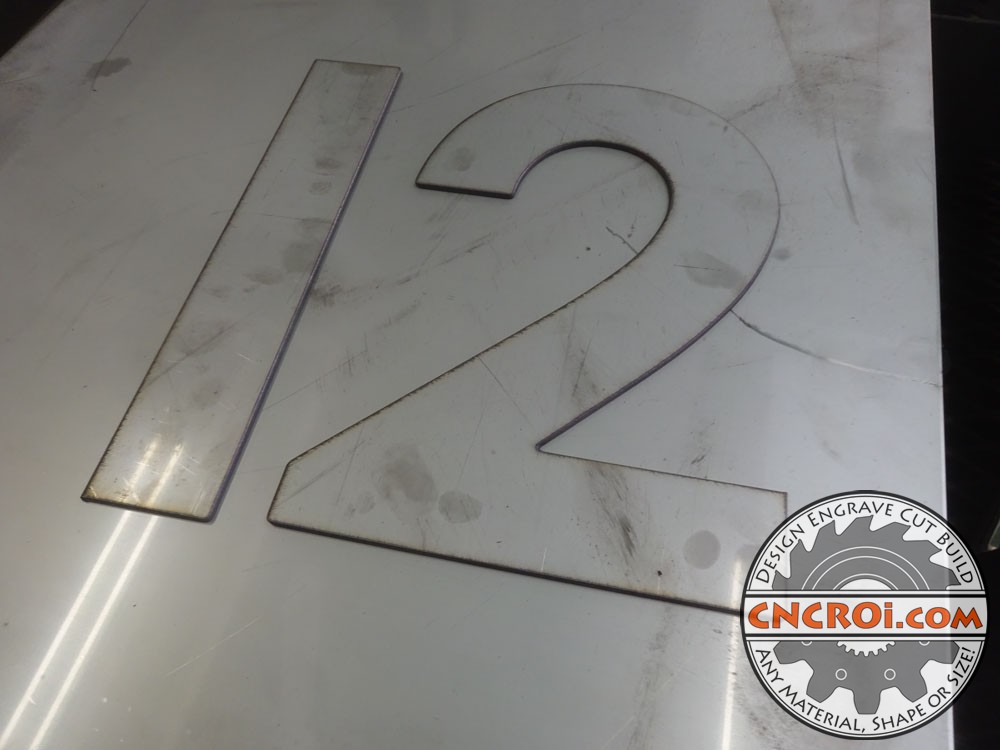

The nice thing about CNC plasma cutting custom stainless steel house numbers is that it’s FAST, unlike CNC waterjet cutting, but it does come at a design cost, inner sharp corners aren’t possible with a CNC plasma but for these two numbers, 1 and 2, this isn’t an issue so that’s the best way forward.

Scale also comes into play, meaning if you want something extremely small, the speed of the CNC plasma starts to diminish in favor for CNC waterjet or CNC laser, when it comes to thicker materials as well, CNC plasma wins over CNC waterjet and CNC laser.

You’ll notice the production method is quite different, though at the same accuracy, as the CNC waterjet.

https://www.youtube.com/watch?v=mEDJyj24G_8/

Anyways, I can easily write a book about why CNCROi.com goes with one machine over another, there are a lot of variables, but what’s important for YOU is that you don’t need to know any of this, just trust that we want to produce the best possible result without limitations regarding machine types.

Out of all the machines CNCROi.com has though, the CNC plasma is the most fun and “clean”, CNC waterjet is mucky and a pretty dirty machine, CNC laser is blazing fast but limited to material thickness and type and CNC plasma makes sparks and fire in all directions.

You’ll notice the sparks and fire are pretty much the same for making custom house number signs, of course, if you want a custom stainless steel house numbers also painted, that’s fine too.

https://www.youtube.com/watch?v=DxHyaObcZjs/

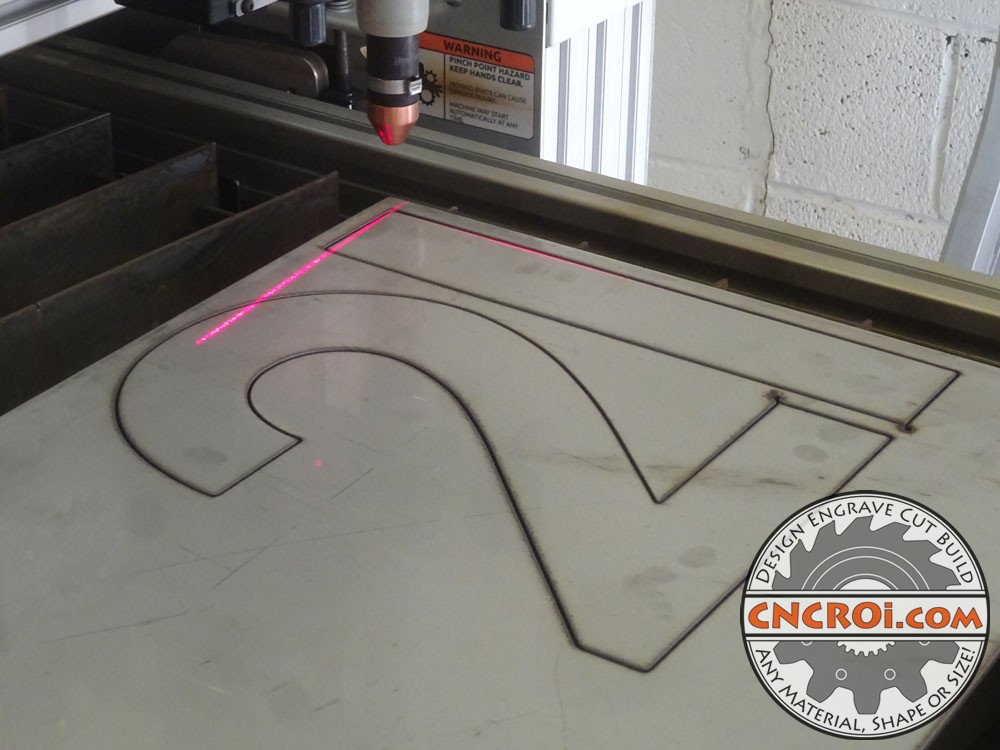

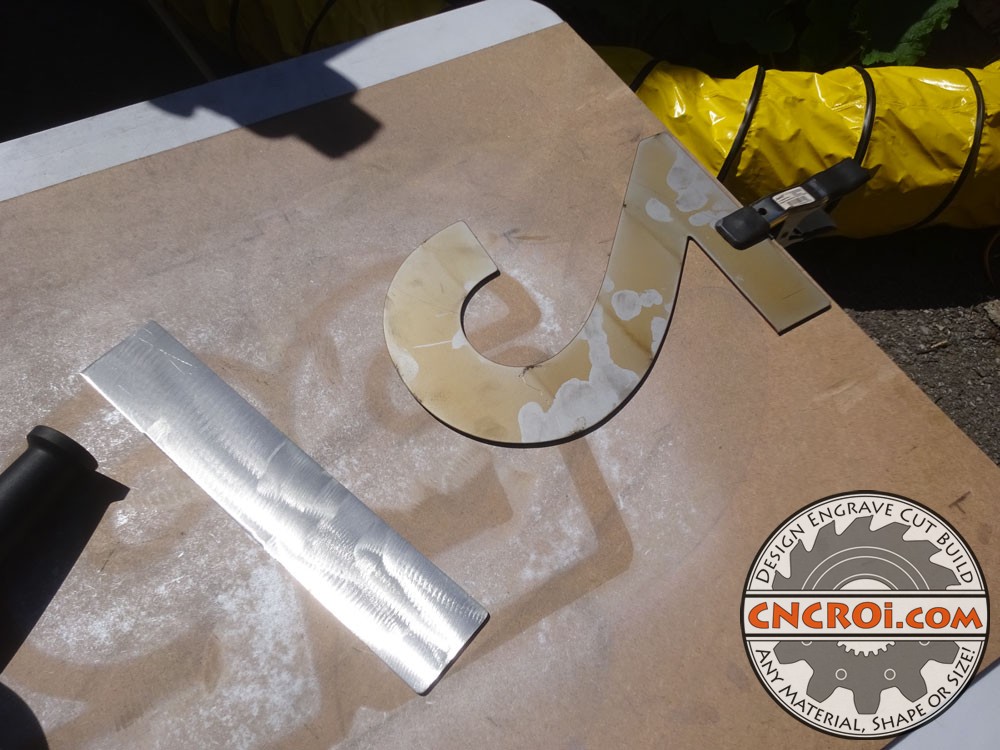

You can see how clean these two custom stainless steel house numbers are, the surface quality is great, but CNCROi.com will clean off the surface and give them a really nice polish to reveal the beauty hidden behind the it.

The precision of the cutting, regardless of machine CNCROi.com uses to produce them is the same though, it’s only the tolerances of the spec and material type that balance the production method towards one machine over another, regardless of the project, whether it’s these custom stainless steel house numbers or a stencil.

Removing the top coat on 304 stainless steel is a lot easier than mill scale off mild steel, it’s nowhere near as tough.

Unlike mild steel, stainless steel requires a lot less prep after production, the quality is the same though as far as cutting is involved.

https://www.youtube.com/watch?v=Ys8QC5vxIkM/

The really nice aspect of custom stainless steel house numbers is the shine, it stands-out in any light and is highly reflective.

For this project specifically, my traditional method of adhering the house number sign onto the brick won’t work, so I used a bolt and a cut washer to produce a tab that would fit with a screw and anchor system in the brick.

The idea behind this system is simple, just slot the custom stainless steel house numbers onto the anchors in the wall and let it hang using gravity.

Cutting it was a little rough, I think I’ll plasma cut some tabs in the near future to produce a nicer finish using mild steel, but this gives you a great idea of the concept that I came-up with.

Of course, CNCROi.com can make other items using steel.

https://www.youtube.com/watch?v=W1eJ0VT8wWM/

The process is pretty straight forward, the offset is made by the bolt, which is welded to the back of the stainless steel house numbers, only one is needed on the top of the number because gravity will take care of the rest.

Welding does require hold-down, so I used a piece of metal to hold it in place while I MIG welded the bolt to the back of the stainless steel.

It isn’t pretty, but after clean-up, it will work great, and it’s as solid as the original metal.

At another angle, only a slight offset is required, it was then coated so that it won’t be exposed to the elements.

Want a custom metal sign or house numbers? Contact CNCROi.com right now!

https://www.youtube.com/watch?v=6QrDGM8_G6U/